D.

SOUNDSTAGE

12

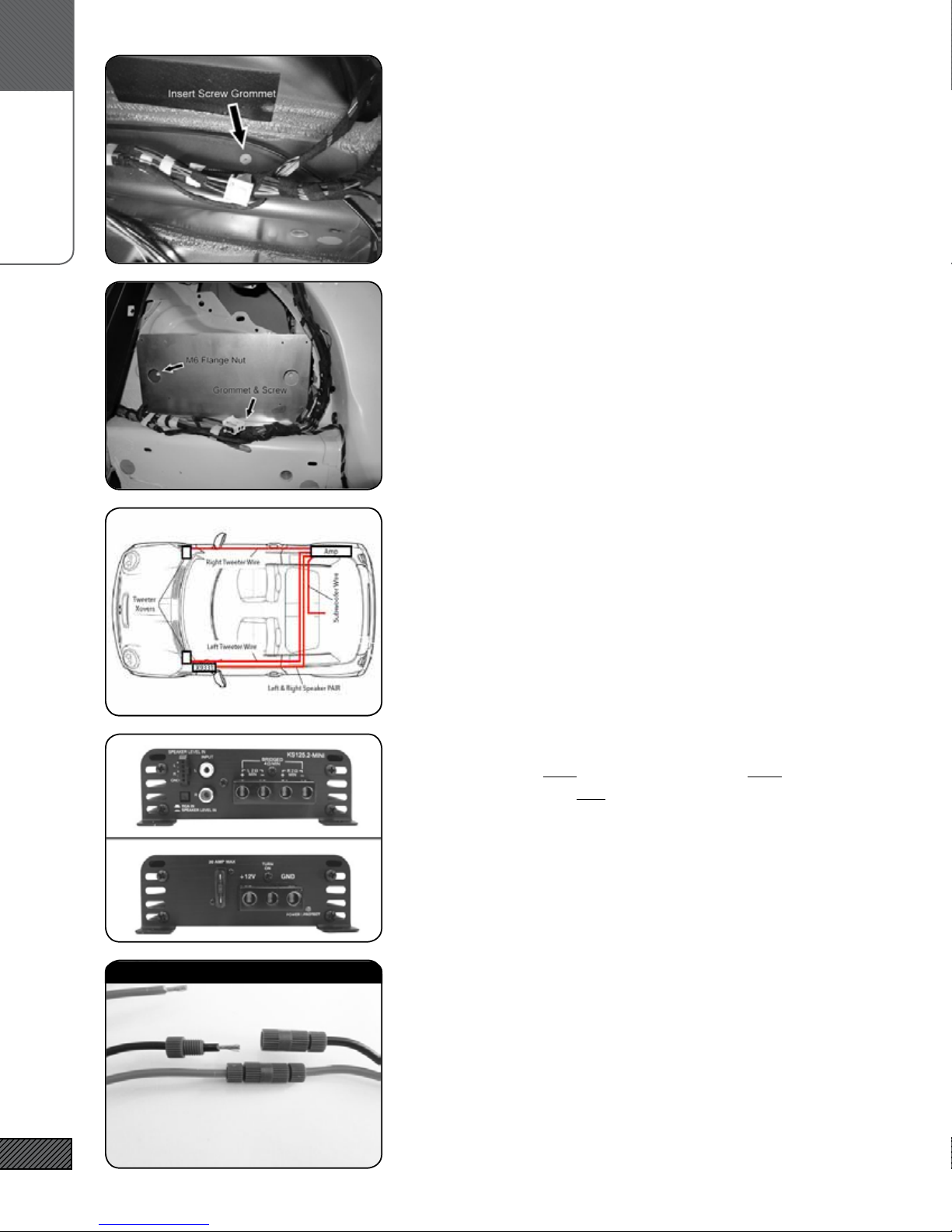

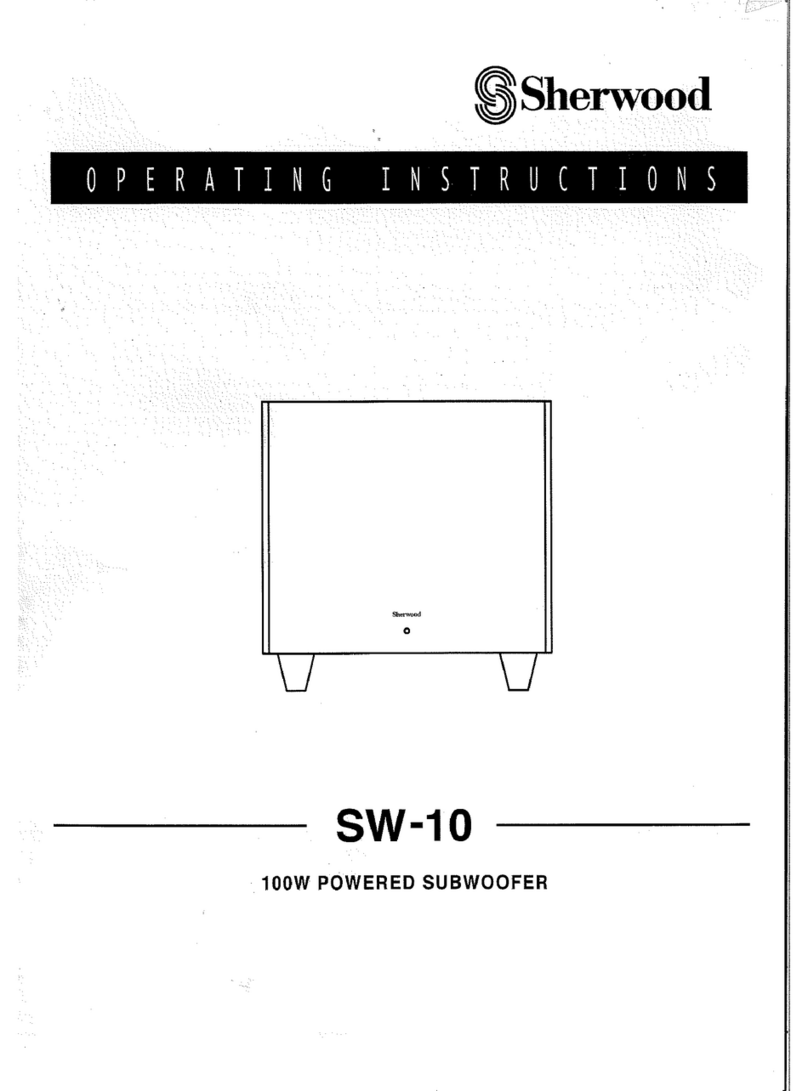

30. INSTALL THE AMPLIFIER BRACKET (PART 1)

Loosen the wire bundle running along the bottom of the right

rear wheel well area. Insert the Screw Grommet into the hole in

the horizontal section of sheet metal as shown. Place the bracket

with rear horizontal hole aligned with the screw grommet and

the forward hole over the threaded stud. You may need to bend

the bracket slightly to get it to t.

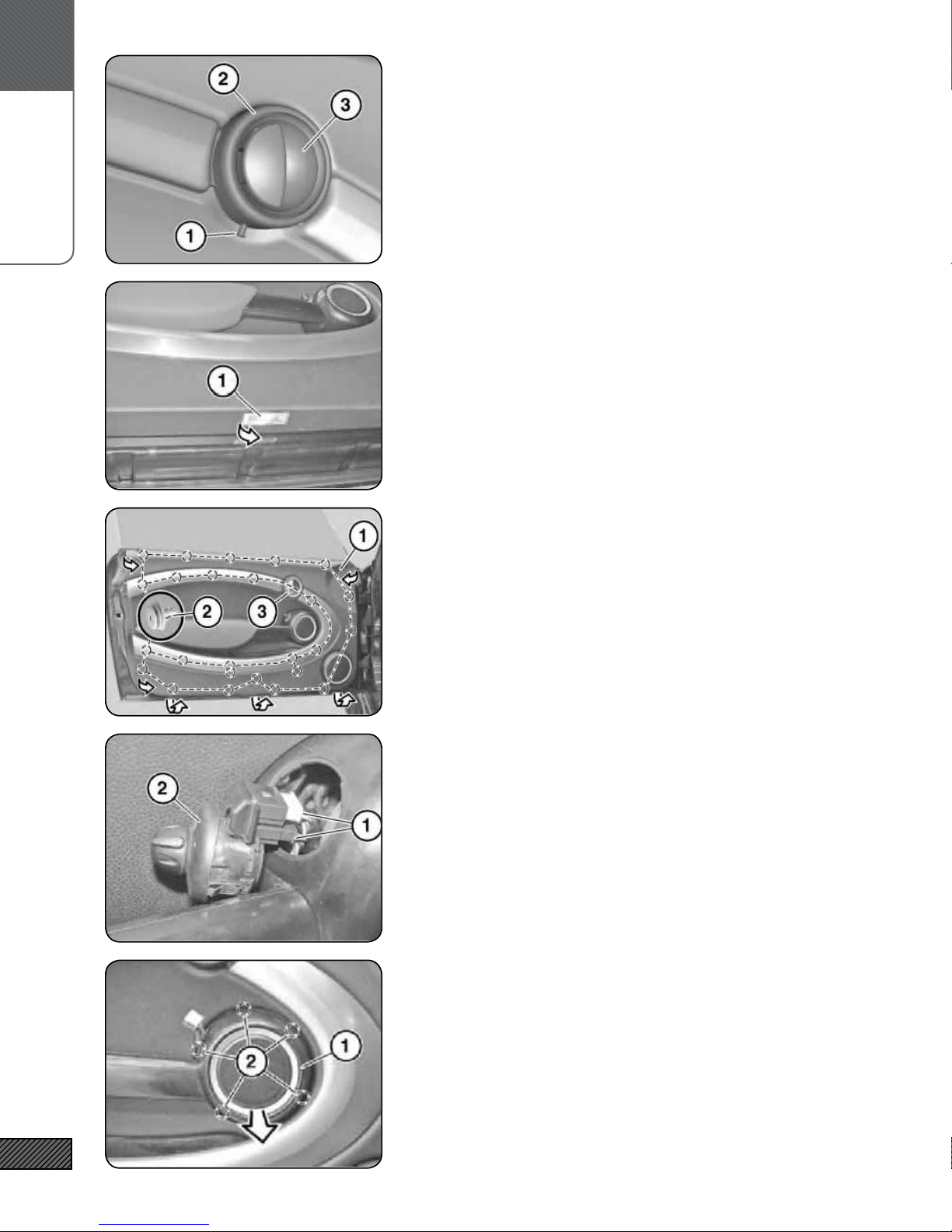

31. INSTALL THE AMPLIFIER BRACKET (PART 2)

Fasten the #8 X ½” Screw through the rear hole in the bracket and

into the Screw Grommet. If the Grommet turns, use a straight

pick or small screwdriver inserted into the split in the Grommet

to keep it from turning.

Attach the bracket to the threaded stud protruding through the

hole at the forward end (towards the front of the car) with the M6

nut. A deep socket is helpful for this step.

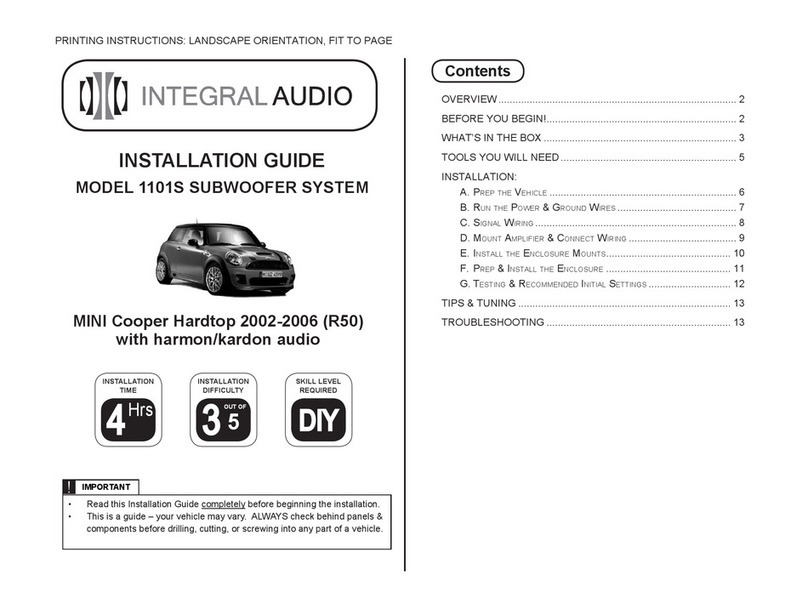

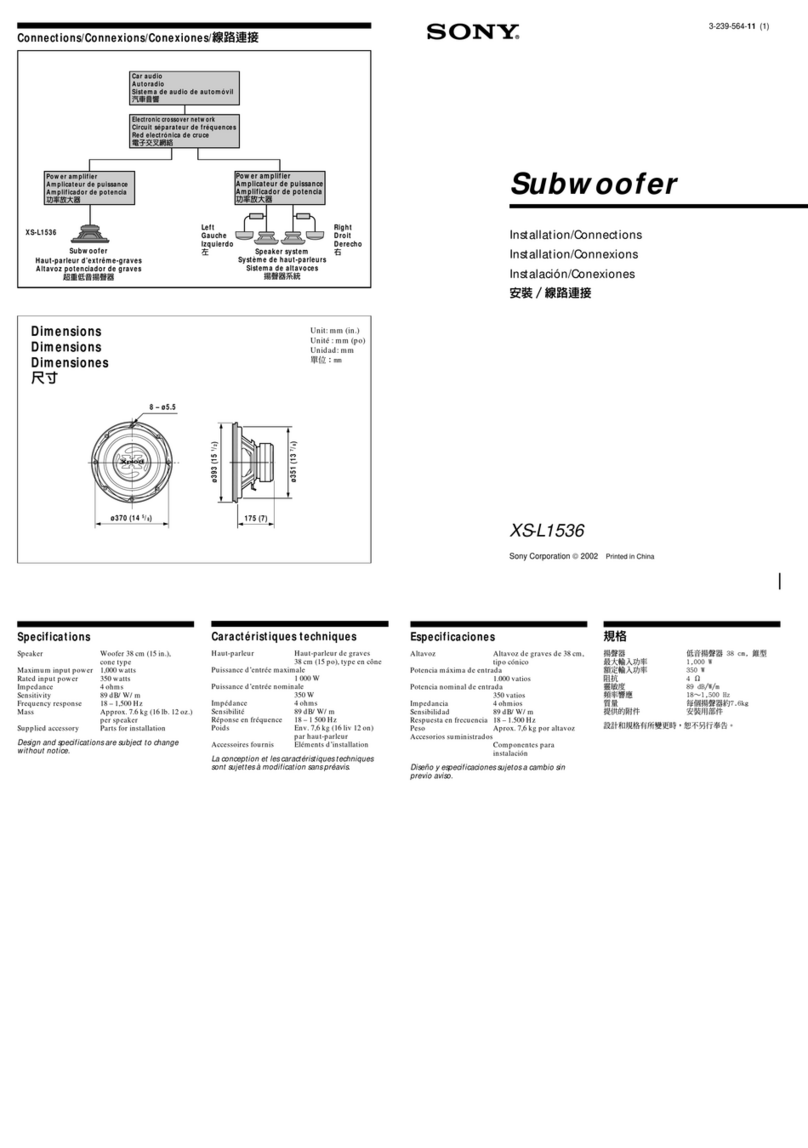

32. SPEAKER WIRING (OVERVIEW)

The front channels of the ARC amplier drive the front tweeter

and midrange/midwoofer in parallel. The rear channels drive

the subwoofer. The factory HU/Amp continues to drive the rear

ll speakers. In Standard 6 speaker vehicles, the signal wiring

harness feeds the door midrange and midwoofer via the X9331

T-harness. In HiFi/HK equipped vehicles, a separate connection is

made to the factory wiring downstream of the HiFi/HK amplier.

There are separate wires for the tweeters in all vehicles.

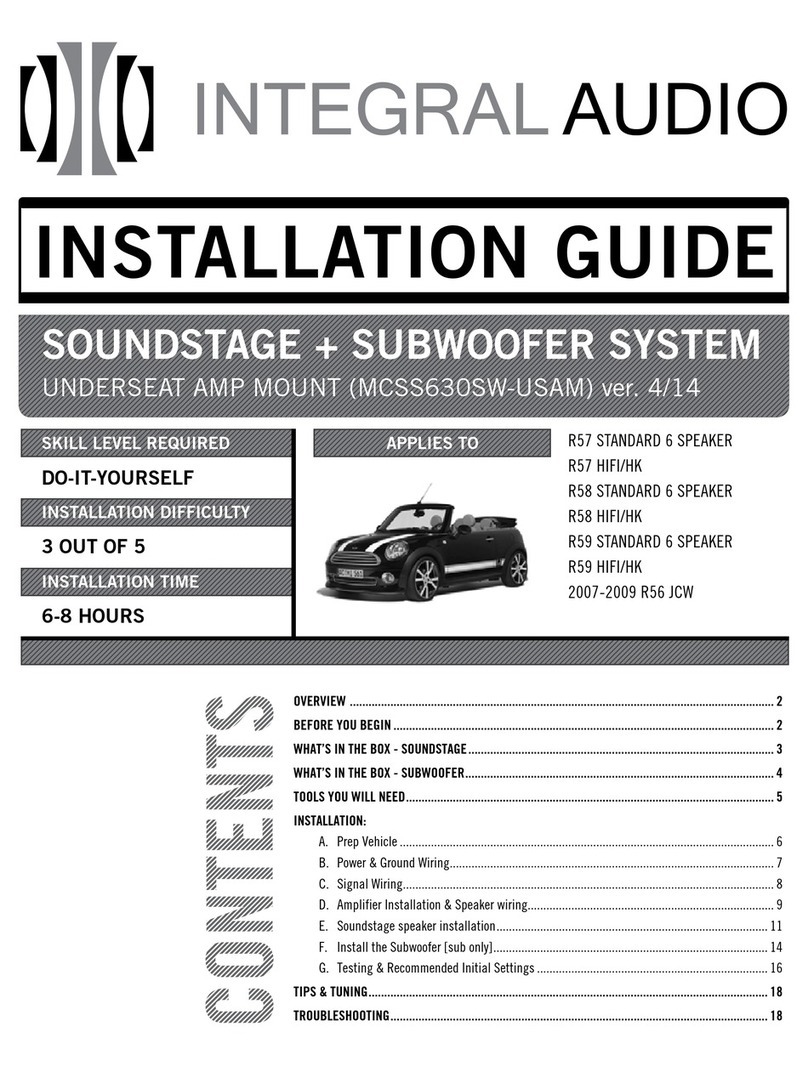

33. AMPLIFIER TO SPEAKER OUTPUT CONNECTIONS

Connect BOTH the Left Tweeter wire AND the Left Midrange/

Midwoofer wires to the Left channel of the ARC ampler. Repeat

for the right channel. YOU WILL HAVE TWO WIRES IN EACH OF

THE HOLES.

[SUB ONLY] Connect the Subwoofer wire to the rear channels in

the “bridged” conguration as shown on amp. YOU WILL HAVE

ONE WIRE IN EACH OF THE OUTER HOLES.

NOTE: 2ch amp shown. The 4ch has 2 rows of speaker outputs.

34. HOW TO CONNECT THREADLOCKS

[HIFI/HK ONLY] The Threadlocks will be used in the next steps

for HIFI/HK equipped vehicles. They work like this: Strip 3/8” of

insulation from the wire to be connected. Unscrew one end of

the Threadlock and insert the wire through the end, then tighten.

There should be no exposed wire and the wire should be secured

thightly in the connector. These form a mechanical connection

that is easily reversible and more reliable than a soldered connec-

tion.

[hifi/hk ONLY]