Integral Audio 1100S User manual

IMPORTANT

!

• ReadthisInstallationGuideCarefullyandCompletelybeforeproceeding.

• DisconnectNegativeBatteryTerminalbeforebeginningwork.

• Thisisaguide–yourvehiclemayvary.ALWAYScheckbehindpanels,

etc.beforedrillingorscrewingintoanypartofavehicle.

• Youareresponsibleforyourownvehicle–useyourbrainandbecareful!

35

INSTALLATION

DIFFICULTY

OUT OF

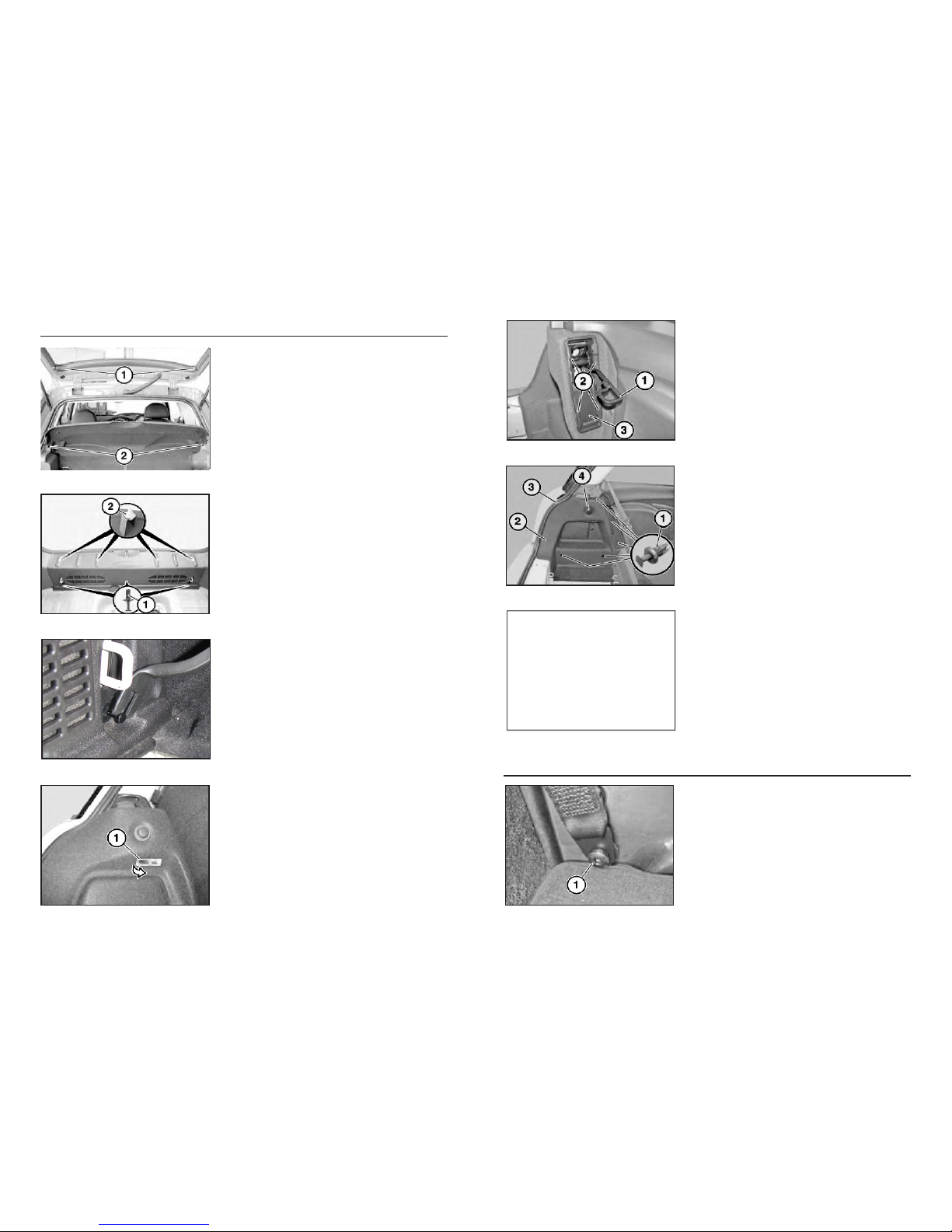

INSTALLATION GUIDE

MINI Cooper Hardtop 2007+ (R56)

Model 1100S Subwoofer System

TheMC1100SSubwooferenclosureinstallsinthe

flooroftheluggagecompartment(boot).Theampli-

fierinstallsbehindthetrimpanelontherightsideof

theboot.

VehiclesequippedwiththeDigitalTuneroptionwill

needtoinstalltheamplifierunderthefrontseat(con-

tactusformoreinfo).

Contents

WHAT’SINCLUDED&WHATYOUWILLNEED...................................2

INSTALLATION:

A.PREPTHEVEHICLE....................................................................3

B.RUNTHEPOWER&GROUNDWIRES.......................................3

C.SIGNALWIRING(BASESTEREO)..............................................5

D.SIGNALWIRING(HIFI).................................................................6

E.AMPLIFIERMOUNTING&CONNECTIONS................................6

F. INSTALLENCLOSUREMOUNTS................................................7

G.INSTALLENCLOSURE................................................................7

H.TESTING&RECOMMENDEDSETTINGS..................................8

TIPS&TUNING.......................................................................................9

TROUBLESHOOTING............................................................................9

1. Integral Audio Model 1100S Subwoofer Enclosure

2. Integral Audio IASW26-4 10” Subwoofer

3. ARC Audio KS125.2 MINI Amplier

4. R56 False Floor Panel

5. Subwoofer Installation Kit

• AluminumMountingBracket(2)

• ThreadedInsert(2)

• ThreadedInsertInstallationWrench

• ¼”x1”HexHeadBolt

• #10x¾”PanHeadScrew(8)

• KnurledKnob(2)

• RubberStand-off(9)

• #10x1.5”PanHeadScrew(6)

• #10x2.5”PanHeadScrew(3)

• CupWasher(6)

• TerminalCupw/GoldBindingPosts

• #6x¾”BlackPanHeadScrew(4)

• #10x1”BlackPanHeadScrew(8)

• ¼”FemaleQuickDisconnect(4)

6. Amplier Installation & Wiring Kit

• ¼”MaleQuickDisconnectTerminal[Blue](5)

• 3MWireTaps[Red](5)

• RollofElectricalTape

• HeatShrinkButtConnectors[Yellow](5)

• BananaPlugs–1pair[Red&Black]

• WaterproofAGUFuseHolder

• 30AmpAGUFuse(2)

• #6x½”HexWasherScrew,Stainless(3)

• ¼”GoldRingTerminal–1pair[Red&Black]

• 8AWGRedUltraexPowerWire(15feet)

• 8AWGBlackUltraexGroundWire(7feet)

• 18AWGWhiteRemoteTurn-onWire(15feet)

• 4-conductorShieldedSignalCable(15feet)

• HeavyDuty3MSelf-AdhesiveVelcro(18inches)

• 16AWGRed/BlackSpeakerWire(8feet)

• Self-AdhesivePadding(16inches)

• ExtraRingTerminal(OptionalforAlternateAmpGrounding)

WHAT’S INCLUDED:

• WireStripper/Crimper

• TorxT50

• FlatScrewdriver

• SmallPhillipsScrewdriver

• ElectricDrill

• Drillbits:1/8”,7/16”

• WrenchesorSockets:7/16”,10mm,19mm

• 4mmAllenwrench

• Pliers

• Electrician’sWireFishTape

• Scissors

• Utilityknife

• LighterorSmallTorch

• PickSetorSetofPlasticPanelRemovaltools

• PencilorFine-tipBlackMarker

• ContainertoholdremovedScrews,Clips,etc.(You’llthankuslater!)

2|IntegralAudio|InstallationInstructions Continuedonnextpage...

WHAT YOU WILL NEED:

A. PREPTHEVEHICLE

Detach straps (1) and slide the parcel shelf out of

guides (2).

1. REMOVE REAR PARCEL SHELF

Remove the luggage compartment oor panel. Locate

the three expansion rivets (1) at the lower edge of the

sill. Hidden friction clips (2) shown for next step.

2. REMOVE REAR SILL (PART 1)

Remove the center-pin of each expansion rivet with a

at screwdriver or panel removal tool. Pry out the base

of the expansion rivet. Pull the bottom of the rear sill

toward the front of the vehicle to clear the luggage “D”

rings, then pull the whole panel up, popping free the

friction clips (2) shown above.

3. REMOVE REAR SILL (PART 2)

Remove the luggage compartment light (1) by prying

the rear edge down and forward. Unplug the light.

CAUTION: the light may be hot!

4. REMOVE LEFT WHEEL ARCH TRIM (PART 1)

B. RUNTHEPOWER&GROUNDWIRES

Lift the seat catch (1) up halfway. Using a 90 degree

pick or an appropriate panel tool, pry the retaining clips

(2) inward and forward to release them. Remove the

trim piece (3).

5. REMOVE LEFT WHEEL ARCH TRIM (PART 2)

Remove the ve expansion rivets (1). Feed out the

Wheel Arch Trim panel (2). Disconnect the 12V plug

(4).

NOTE: When re-installing the panel, make sure to feed

the seal (3) over the top of the edge of the trim panel

(2).

6. REMOVE LEFT WHEEL ARCH TRIM (PART 3)

Repeat Steps 5 & 6 for the right side.

7. REMOVE THE RIGHT WHEEL ARCH TRIM

Using a Torx T-50 bit, remove the seat belt screw (1)

where it passes through the rear of the door sill trim.

NOTE: Left (Driver’s) side shown, but the procedure is

the same for left & right sides.

8. REMOVE RIGHT DOOR SILL TRIM (PART 1)

3|IntegralAudio|InstallationInstructions Continuedonnextpage...

SeeSteps5&6

4|IntegralAudio|InstallationInstructions Continuedonnextpage...

Remove metal seat belt bushing (1) . Pull Rear Side

Trim Panel (4) in, releasing clip (3) and freeing tab of

Door Sill (2) located behind Side Panel (4).

NOTE: Left (Driver’s) side shown, but the procedure is

the same for left & right sides.

9. REMOVE RIGHT DOOR SILL TRIM (PART 2)

[Seat shown removed for clarity] Pull Door Sill Panel (2)

directly in, releasing clips (3). This requires rm pres-

sure. Remove small trim piece (1) by pulling toward the

rear of the vehicle, releasing a spring clip.

NOTE: Left (Driver’s) side shown, but the procedure is

the same for left & right sides.

10.REMOVE RIGHT DOOR SILL TRIM (PART 2)

Open the Bonnet (hood). Remove the black plastic

Cowl (4) covering the battery by releasing nuts (2) and

(3) with an 10mm socket. Feed the Cowl out.

NOTE: When replacing the cowl, be sure the seal (1)

is seated properly and that the panel is properly seated

against the windshield (5).

11. REMOVE RIGHT COWL PANEL

Using a at screwdriver, release the indicated retaining

tabs then remove the plastic thru-wall cover to expose

the thru-wall opening.

12. REMOVE THRU-WALL COVER

Cut the end off the spare wiring nipple.

NOTE: Before re-installing the Thru-wall cover, seal the

nipple and power wire with the included electrical tape.

13. CUT SPARE NIPPLE

Cut approx 18” of wire to run from the fuse holder to the

battery. Strip the jacket from the ends of the 8AWG Red

Power Wire. Remove one end cap of the fuse holder

and insert the wire, then secure the gold terminal end

onto the wire with a 4mm Allen wrench. Repeat above

for the other side of the fuse holder using the 18” length

of wire.

14. INSTALL FUSE HOLDER

Mount the fuse holder as shown using 2 of the #6 x ½”

Hex Washer Head screws. Crimp the red ¼” Gold Ring

Terminal to the remaining end of the 18” length of Power

Wire from the previous step. Remove the auxiliary nut

on the battery post with a 19mm socket and attach the

Power Wire.

15. MOUNT FUSE HOLDER

Feed the 8AWG Red Power Wire through the spare wir-

ing nipple and along the Door Sill. Insert your sh tape

from the passenger’s side of the luggage compartment

behind the Rear Right Side Panel and up to the Door

Sill, then use it to pull the Power Wire to the luggage

compartment area.

NOTE: Leave enough slack in the wire to be able to

reinstall the Thru-wall cover.

16. FISH POWER WIRE FROM AMP TO BATTERY

5|IntegralAudio|InstallationInstructions Continuedonnextpage...

Release the 2 expansion rivets at each side of the

carpet trim covering the raised cross-member at the

front of the luggage compartment. Run the 8AWG

Black Ground Wire from the passenger-side of the lug-

gage compartment to the driver’s side, routing the wire

underneath the carpet.

17. GROUND WIRE (PART 1)

On HiFi-equipped vehicles, it is helpful to temporarily

remove the HiFi amplier to ease access to the wiring.

Release the 10mm nut (1) at the top of the amplier

(2). Remove the amplier by sliding it up and out.

Disconnect the plug by releasing and sliding forward the

locking lever.

18. REMOVE THE AMPLIFIER [HIFI ONLY]

Locate the Common Ground point on the left side of the

vehicle. Remove the nut with a 10mm socket. Strip the

end of the Ground wire, crimp the black ¼” Gold Ring

Terminal to the end, and attach to the Common Ground

point.

19. GROUND WIRE (PART 2)

Repeat Steps 8-10 for the left side of the vehicle.

20. REMOVE DRIVER’S SIDE DOOR SILL

C. SIGNALWIRING(BASESTEREOONLY)

Beginning in the left (driver’s) side footwell, run the

4-Conductor Shielded Signal Wire along the door sill,

behind the Left Rear Side Panel (using the shtape),

under the carpet trim covering the cross member (see

Step 17), ending at the right side of the luggage com-

partment. (see previous images)

21. RUN SIGNAL WIRE

At each end of the Signal Wire, remove 4-6 inches of

the outer jacket and shielding, exposing the 2 twisted

pairs of signal wire. Strip both ends of the 4 signal

wires. At the footwell end, carefully crimp a ¼” Insu-

lated Male Disconnect (these are blue, with a at blade

shaped connector inside) on each wire, 4 total. You

may solder the connections if you aren’t condent in

your crimping tool or ability.

22. PREP SIGNAL WIRE

Locate the X9331 connector in the left footwell. The

X9331 is behind and attached to the larger X15.

Remove both by twisting counter-clockwise ¼ turn and

pulling out. Separate the X9331 from the X15.

23. ACCESS X9331 CONNECTOR

Cut the wrapping and unbundle about 8” of the wiring.

Install the 3M T-taps to each of the wires indicated in

the chart below. Use pliers to make it easier to lock the

tap onto the wire. Double-check that you are selecting

the correct wires by verifying the Pin location. Attach

the correct Signal Wire to each T-tap.

24. MAKE SIGNAL CONNECTIONS

SeeSteps8-10

SeeStep17

X9331

Connector

E. AMPLIFIERMOUNTING&CONNECTIONS

6|IntegralAudio|InstallationInstructions Continuedonnextpage...

Locate the two small gauge solid black wires in the

wiring bundle running up the right edge of the rear

hatch opening. Install a 3M T-tap on either of these

(both carry the same signal). Cut the 18AWG White

Turn-on Lead wire to length, strip both ends, crimp a ¼”

Insulated Male Disconnect on one end, and attach to

the T-tap. Proceed to Step 29.

25. REMOTE TURN-ON WIRE

Run the 4-Conductor Shielded Signal Wire and the

18AWG White Remote Turn-on Lead from the right side

to the left side of the luggage compartment, routing the

wires under the carpet trim covering the cross member

(see Step 17). Cut the wires to length, leaving about

18” excess on each end. (see Step 17 Image)

26. RUN SIGNAL WIRE

At each end of the Signal Wire, remove 4-6 inches of

the outer jacket and shielding, exposing the 2 twisted

pairs of signal wire. Strip both ends of the 4 signal

wires and the remote wire. At the end near the factory

amplier, carefully crimp a ¼” Insulated Male Quick

Disconnect on each wire, 5 total. Solder the connec-

tions if desired.

27. PREP SIGNAL WIRE

D. SIGNALWIRING(HIFIONLY)

Cut the wrapping and unbundle about 8” of the wiring.

Install the 3M T-taps on each of the wires indicated in

the chart below. Use pliers to make it easier to lock the

tap onto the wire. Double-check that you are selecting

the correct wires by verifying the Pin location. Attach

the correct Signal Wire to each T-tap.

NOTE: After making the signal connections, replace the

HiFi amplier removed in Step 18.

28. SIGNAL CONNECTIONS

The amplier mounts against the side of the right rear

wheel well. Cut the Self-Adhesive Foam Padding to

length, remove the backing, and afx to the top of

the horizontal section of sheet metal (the side of the

amplifer will rest on top of this padding). Cut the Velcro

into 3 equal length pieces and afx to the vertical sec-

tion of sheet metal. Attach the other half of the Velcro to

the back of the amplier. Make sure both sides align.

29. MOUNT AMPLIFIER

Cut the 2 feet from the length of 16AWG Speaker

Cable. Split and strip the ends of the remaining 6 feet

of Speaker Wire. Connect one end to the amplier

(bridged). Attach the Banana Plugs to the other end.

(no image)

30. SPEAKER WIRE & BANANA PLUGS

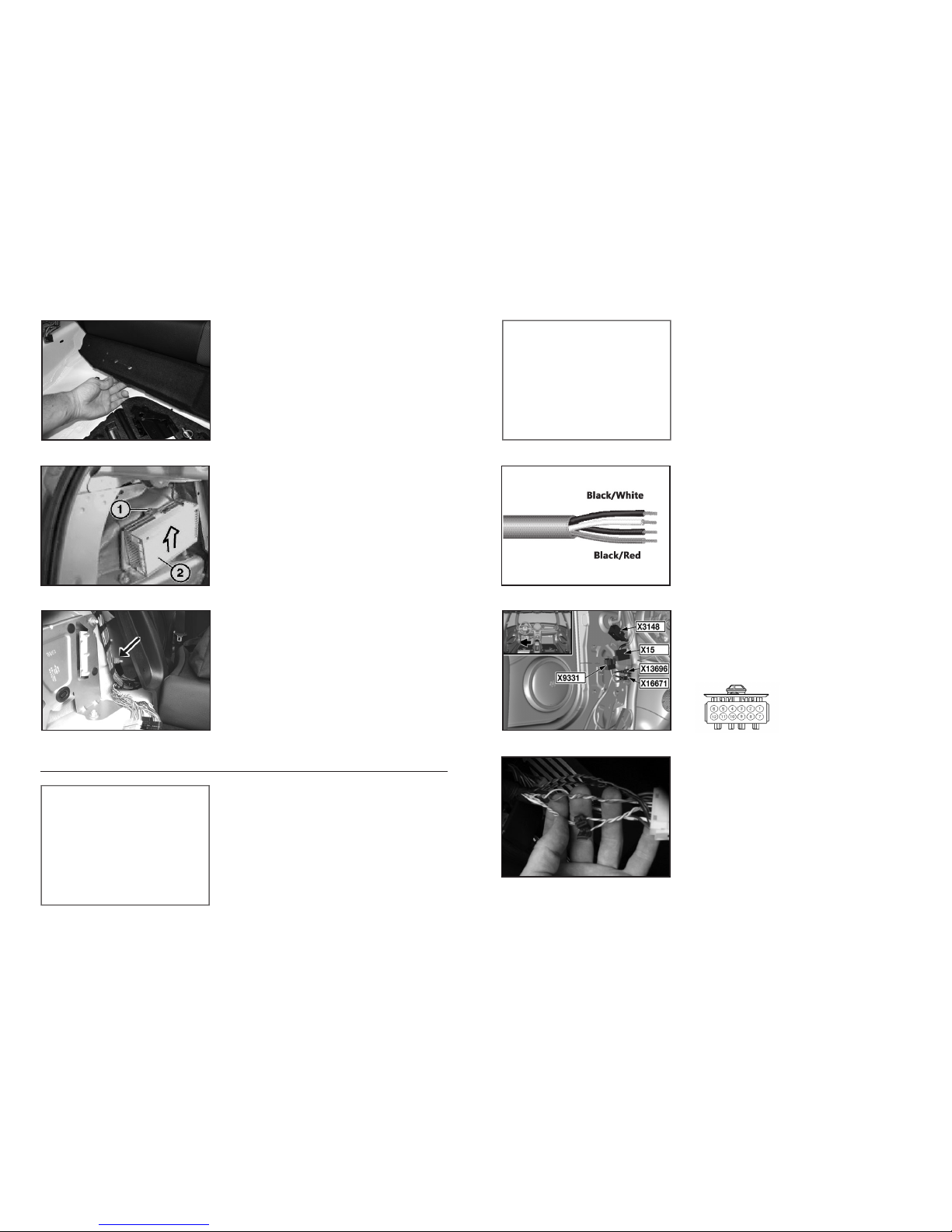

Footwell Connector (X9331) - R56 Base Stereo

Signal : Wire Color: Pin: Connect To Signal Wire:

FrontLeft++ Blackw/RedStripe 5 Red

FrontLeft-- Blackw/VioletStripe 6 Black(fromBlk/RedPair)

FrontRight++ Yelloww/BrownStripe 3 White

FrontRight-- Yelloww/BlackStripe 4 Black(fromBlk/WhtPair)

HiFi Amplier Connector (X10266) - R56 HiFi

Signal : Wire Color: Pin: Connect To Signal Wire:

RearLeft++ Bluew/BrownStripe 37 Red

RearLeft-- Bluew/BlackStripe 29 Black(fromBlk/RedPair)

RearRight++ Brownw/OrangeStripe 8 White

RearRight-- Yelloww/RedStripe 16 Black(fromBlk/WhtPair)

RemoteTurn-on SolidBlack 10 ToAmpRemoteTurn-on

SeeStep17

7|IntegralAudio|InstallationInstructions Continuedonnextpage...

Connect the Power, Ground, and Remote Turn-on Lead

wires. Using the Heat-Shrink Butt connectors, connect

the Signal Wire to the ARC Audio Amplier Pigtail Con-

nector as noted at left. After crimping, gently heat the

butt connectors with a lighter or torch to shrink and seal.

Do not burn the wire!

If not already connected, connect the Remote Turn-on

Wire to the amplier.

31. AMPLIFIER CONNECTIONS

Temporarily replace the Wheel Arch Trim Panels.

Place the subwoofer enclosure in the boot and center

it. Place one Mounting Bracket on either side with the

single large hole centered over the indicated raised area

of the boot oor. Mark the center of all ve holes of the

bracket.

32. MARK FOR BRACKET PLACEMENT

Remove the enclosure. Using the #10 x ¾” Pan Head

Screws, attach the mounting brackets in the spots

marked in Step 32. Replace the enclosure and conrm

hole locations are correctly market. Remove the

enclosure.

33. ATTACH THE MOUNTING BRACKETS

Using a 7/16” bit, drill holes in the 2 positions marked

on the boot oor. Do not let the drill bit penetrate more

than ¼” through the sheet metal. You may nd it helpful

to use a cut-to-length wood block with a hole in the

center as a stop for the drill.

34. INSTALL THREADED INSERTS (PART 1)

F. INSTALLENCLOSUREMOUNTS

Clean up all metal shavings from the previous step. Us-

ing a utility knife, trim the PVC jacket out of the center

of the -Sealing Threaded Inserts as shown. Insert the

Self-Sealing Threaded Inserts into the holes drilled in

the previous step.

35. INSTALL THREADED INSERTS (PART 2)

Insert the 1” Hex Bolt through the Threaded Insert

Installation Tool and thread the bolt into the Threaded

Insert. Keep the insert ush against the boot oor and

tighten the bolt until the insert is secure but do not over-

tighten. Remove the bolt and repeat for the other side.

36. INSTALL THREADED INSERTS (PART 3)

Split and strip the ends of the remaining 2 feet of

16AWG Speaker Cable. Crimp (and solder if desired)

the 4 female ¼” Quick Disconnects to the wire and

connect to the Terminal Cup. Mount the Terminal Cup

using the #6 x ¾” Black Pan Head Screws.

37. WIRING & TERMINAL CUP

Connect the speaker wiring, observing correct polarity.

Mount the speaker with the #10 x 1” Black Pan Head

Screws. The speaker is a snug t! Tighten the screws

in a “star” pattern, go slowly and take care not to strip

them. Make sure the speaker is mounted ush - the

gasket on the back of the speaker ange should seal.

38. MOUNT THE SPEAKER

G. INSTALLTHEENCLOSURE

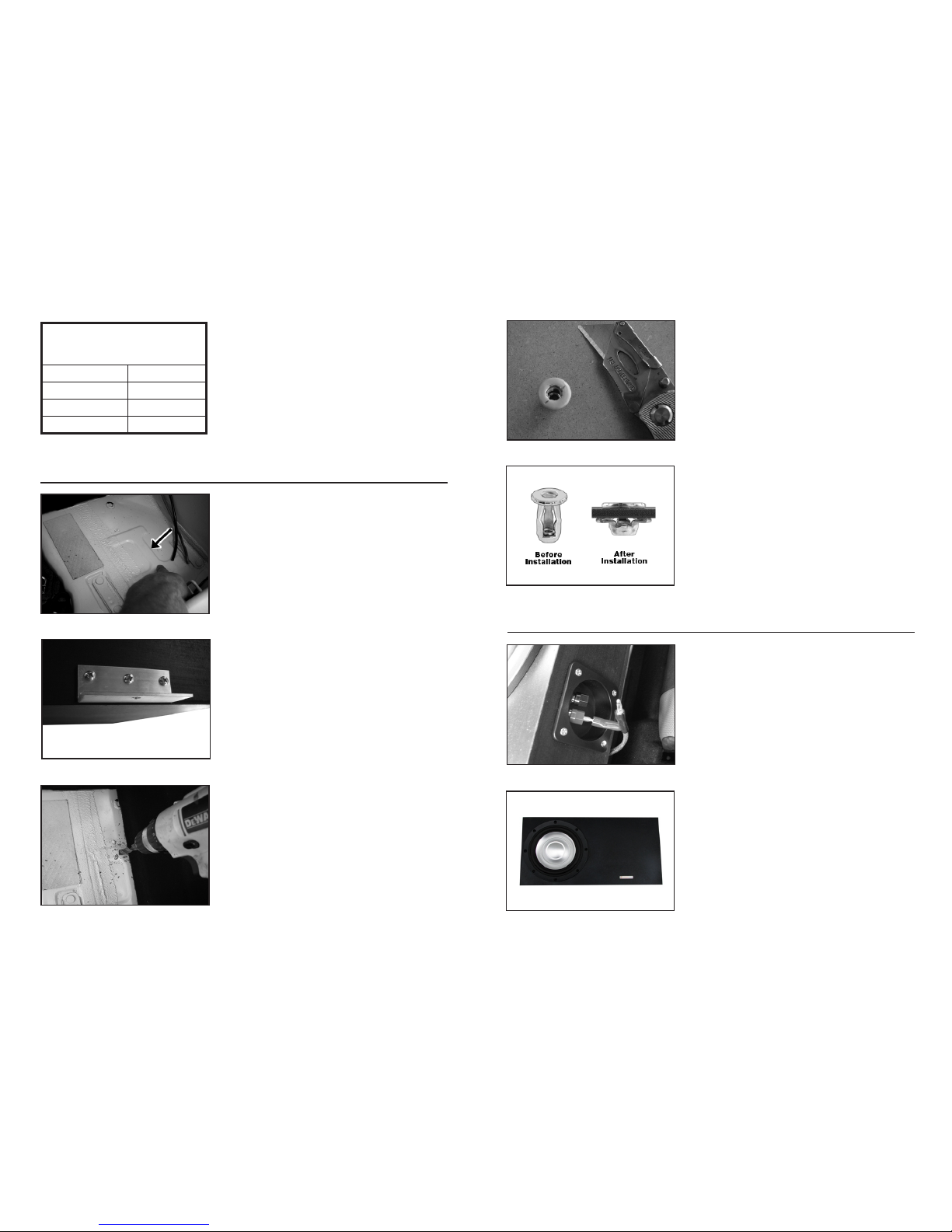

Signal Wire to ARC MINI Connections

Signal Wire: Connect to Pigtail:

Red White

Black (from Black/Red pair) White w/Black

White Gray

Black (from Black/Wht pair) Gray w/Black

8|IntegralAudio|InstallationInstructions Continuedonnextpage...

Replace the enclosure in the boot. Connect Banana

Plugs to Terminal Cup. Secure the enclosure with the

Knurled Knobs.

WARNING: Do not allow the Banana Plug connectors

to short (touch each other) when unplugged and the

ignition is on.

39. INSTALL ENCLOSURE

Each of the 3 front supports are assembled with one

Rubber Stand-off, one Cup Washer, and one #10 x 1.5”

Pan Head Screw. The rear supports are twice as high

and are assembled with two Stand-offs (stacked), one

Cup Washer, and one 2.5” Pan Head Screw.

40. MOUNT THE FLOOR SUPPORTS (PART 1)

Place the Floor Supports as shown. Mark and drill a

1/8” Pilot hole. Attach the Supports with the screws.

NOTE: The Rubber Stand-offs may have warped

slightly in transit. To get the rears to stack perfectly,

wrap a few turns of electrical tape around them at the

seam. Remove the tape after they are screwed down.

41. MOUNT THE FLOOR SUPPORTS (PART 2)

The False Floor Panel slides through the hatch opening

and rests on the oor supports. To remove, simply

push down on the edge near the rear seat backs, lift,

and remove - Clean, Simple, Easy!

42. HOW TO REMOVE FALSE FLOOR

H. TESTING&RECOMMENDEDSETTINGS

Reconnect the Battery Negative Terminal and Install

one of the 30 amp AGU fuses in the fuse block. A spare

fuse is included.

43. RECONNECT THE BATTERY & INSTALL FUSE

Once you have conrmed that everything is operating

correctly, reinstall all panels and trim removed during

the installation. Use the provided electrical tape to wrap

and secure all wiring bundles and harnesses, especially

the signal connections at the 3M T-taps.

44. TEST OPERATION

For HiFi-equipped vehicles, recommended amplier set-

tings are listed. Your preferences may vary. Contact us

if you are having difculty or something doesn’t sound

right.

45. AMPLIFIER SETTINGS (HIFI ONLY)

For Base Stereo-equipped vehicles, recommended am-

plier settings are listed. Your preferences may vary.

Contact us if you are having difculty or something

doesn’t sound right.

46. AMPLIFIER SETTINGS (BASE STEREO ONLY)

• Gain: 40% (see ARC manual)

• Output: LOW (low-pass crossover)

• Crossover: 90 Hz

• Bass Boost: 0

• Input: Speaker Level In (button IN)

• Factory Radio Bass Level: -1

• Factory Radio Fade: Front +3

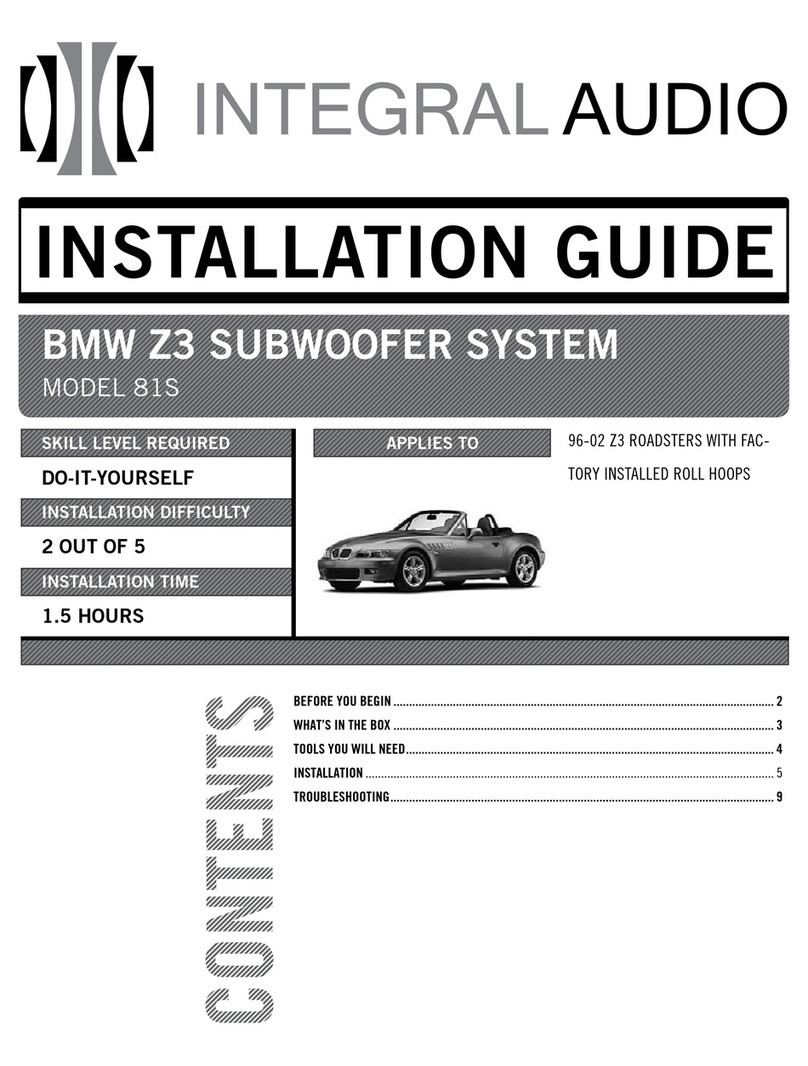

ARC KS125.2 Settings - HIFI

• Gain: 60% (see ARC manual)

• Output: LOW (low-pass crossover)

• Crossover: 80 Hz

• Bass Boost: 0

• Input: Speaker Level In (button IN)

• Factory Radio Bass Level: -1

• Factory Radio Fade: Front +5

ARC KS125.2 Settings - Base

TEST!

• BASS LEVEL CONTROL: HiFi-equipped vehicles can adjust the bass level on-the-y by fading

to the front (decrease bass level) or to the rear (increase bass level). Base Stereo-equipped

vehicles can adjust the bass on-the-y if they perform the front-to-rear channel swap (contact us

for more info). Otherwise, Base Stereo-equipped vehicles adjust the bass level with the Amplier

Gain.

• SIGNAL SOURCE QUALITY: No matter how good the stereo system, a poor quality signal will

always sound poor. If you are using MP3s or home-burned CDs it is critical that you understand

the limitations and impacts of whatever digital compression method you are using. MP3s at less

than 256kbps WILL have noticable loss of quality. Non-commercially obtained music (especially

downloaded via P2P le-sharing) recordings are often re-mixed by third parties and will have

been compressed in an unknown and uncontrolled manner. If you want good quality sound, use

ONLY commercial CDs or MP3s that you have ripped yourself at 256kbps or 320kbps.

• FACTORY RADIO SETTINGS: Remember that settings (Bass, Treble, Fade, Balance, AUX

input level, etc.) are stored on the Key FOB & are specic to the Source (Radio, CD, AUX). You

will need to edit and save the settings for each source and each FOB to have consistent sound.

Allspecicationsaresubjecttochangewithoutnotice.IntegralAudio®andtheIntegralAudiologo,areregisteredtrademarksof

IntegralAudio.Formoredetailedinformationpleasevisitusonlineatwww.integralaudio.com.

www.integralaudio.com

9|IntegralAudio|InstallationInstructions

TROUBLESHOOTING

TIPS & TUNING

Having Trouble? The best thing to do is contact us at [email protected] or via the

phone number listed on the receipt that was emailed to you. We’ll get you xed up!

Table of contents

Other Integral Audio Subwoofer manuals

Integral Audio

Integral Audio 81S User manual

Integral Audio

Integral Audio PHANTOM User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio SoundStage + Subwoofer System User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio MCSS630SW-RAM User manual

Integral Audio

Integral Audio PHANTOM User manual