Integral Audio 1101S User manual

MINI Cooper Hardtop 2002-2006 (R50)

with harmon/kardon audio

IMPORTANT

!

• ReadthisInstallationGuidecompletelybeforebeginningtheinstallation.

• Thisisaguide–yourvehiclemayvary.ALWAYScheckbehindpanels&

componentsbeforedrilling,cutting,orscrewingintoanypartofavehicle.

Contents

INSTALLATION GUIDE

MODEL 1101S SUBWOOFER SYSTEM

DIY

SKILL LEVEL

REQUIRED

35

INSTALLATION

DIFFICULTY

OUT OF

4

INSTALLATION

TIME

Hrs

PRINTING INSTRUCTIONS: LANDSCAPE ORIENTATION, FIT TO PAGE

OVERVIEW.................................................................................... 2

BEFOREYOUBEGIN!................................................................... 2

WHAT’SINTHEBOX.................................................................... 3

TOOLSYOUWILLNEED.............................................................. 5

INSTALLATION:

A. PREP ThE VEhICLE .................................................................. 6

B. RUN ThE POwER & GROUND wIRES .......................................... 7

C. SIGNAL wIRING ....................................................................... 8

D. MOUNT AMPLIFIER & CONNECT wIRING ...................................... 9

E. INSTALL ThE ENCLOSURE MOUNTS ............................................ 10

F. PREP & INSTALL ThE ENCLOSURE ............................................ 11

G. TESTING & RECOMMENDED INITIAL SETTINGS ............................. 12

TIPS&TUNING........................................................................... 13

TROUBLESHOOTING................................................................. 13

2|IntegralAudio|InstallationInstructions Continuedonnextpage...

• READ ThESE INSTRUCTIONS COMPLETELy

• DISCONNECT ThE NEGATIVE BATTERy TERMINAL

• GAThER ALL REqUIRED TOOLS

• LAyOUT & IDENTIFy ALL COMPONENTS & hARDwARE. USE ExTRA

CARE TO BE CERTAIN yOU hAVE PROPERLy IDENTIFIED EACh SCREw.

• NOTE: EACh kIT MAy APPLy TO MORE ThAN ONE VEhICLE MODEL AND

MAy INCLUDE ExTRA ITEMS. DISREGARD ANy ITEMS NOT MENTIONED IN

ThE INSTRUCTIONS FOR yOUR VEhICLE.

• NOTE: DO NOT DEVIATE FROM ThESE INSTRUCTIONS OR ThE INCLUDED

hARDwARE. EVERy COMPONENT OF ThIS SySTEM hAS BEEN CAREFULLy

SELECTED By OUR ENGINEERS. FAILURE TO FOLLOw ThESE INSTRUC-

TIONS OR CORRECTLy IDENTIFy AND USE ThE SUPPLIED hARDwARE MAy

RESULT IN POOR PERFORMANCE AND POSSIBLE SAFETy hAzARDS.

Overview Before You Begin!

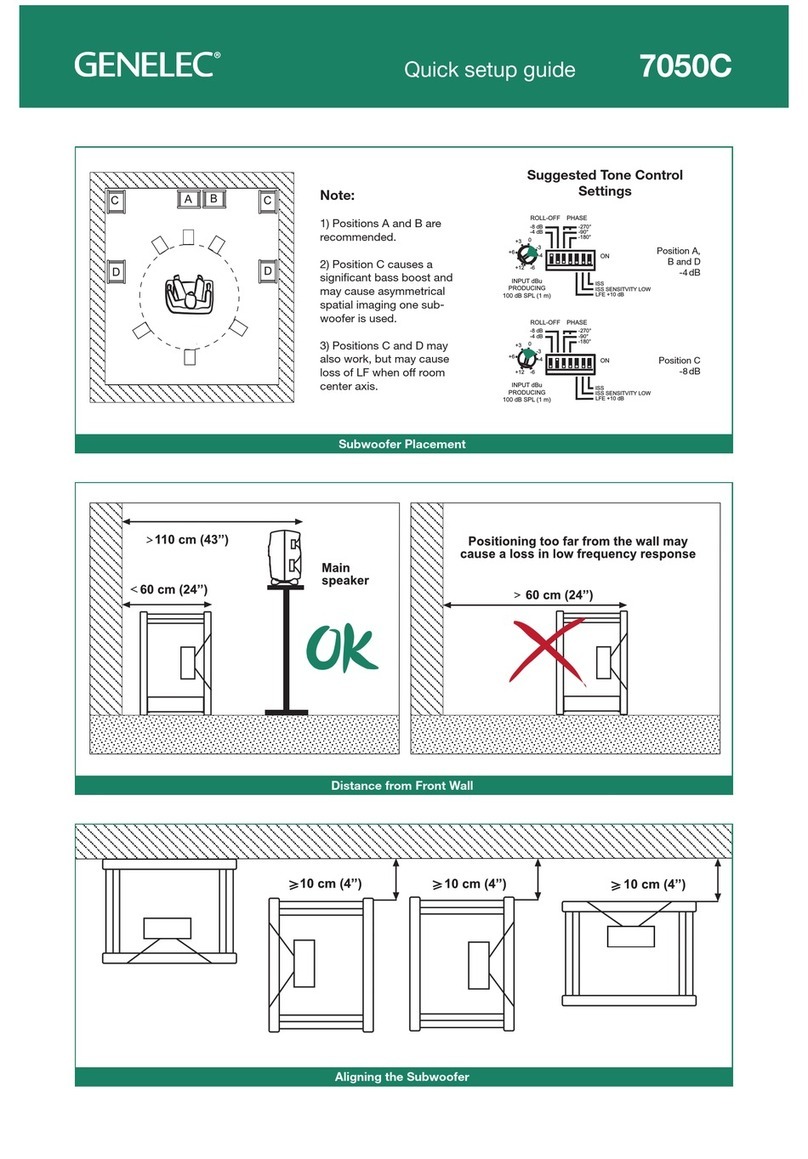

ThIS GUIDE COVERS INSTALLATION OF ThE MINI COOPER MODEL 1101S

SUBwOOFER SySTEM IN 2002-2006 MINI COOPER hARDTOPS (R50) wITh ThE

hARMON kARDON 8 SPEAkER STEREO.

ThE SUBwOOFER ENCLOSURE INSTALLS IN ThE FLOOR OF ThE LUGGAGE COMPART-

MENT (AkA ThE “BOOT”). ThE SUB AMPLIFIER INSTALLS IN ThE SMALL COMPART-

MENT ON ThE DRIVER’S SIDE OF ThE BOOT AND MOUNTS TO AN INCLUDED ALUMINUM

BRACkET. A REMOTE LEVEL CONTROL INSTALLS AT ThE DASh FOR ON-ThE-FLy

SUBwOOFER ADjUSTMENT.

POwER & GROUND wIRES ARE CONNECTED TO ThE BATTERy AND A ChASSIS

GROUND POINT AND RUN DOwN ThE LEFT SIDE OF ThE VEhICLE. ThE AUDIO SIGNAL

AND TURN-ON SIGNAL ARE TAPPED AT ThE BACk OF ThE RADIO (OR AT ThE AMP FOR

hk-EqUIPPED VEhICLES. ThE SIGNAL wIRING IS RUN TO ThE DASh-MOUNTED REMOTE

LEVEL CONTROL AND ThEN BACk TO ThE SUB AMPLIFIER.

3|IntegralAudio|InstallationInstructions Continuedonnextpage...3|IntegralAudio|InstallationInstructions Continuedonnextpage...

What’s In The Box

I. Model1101SSubwooferencloSure

II. IntegralaudIoIaSw26-410”Subwoofer

III. arcaudIoKS125.2MInIaMplIfIer

IV. falSefloorpanel

V. SubwooferencloSureHardwareKIt

1. TERMINAL CUP w/ GOLD BINDING POSTS

2. #10 x 2.5” PAN hEAD SCREw (3)

3. #10 x 1.5” PAN hEAD SCREw (6)

4. ¼” x 1” hEx hEAD BOLT

5. #10 x 1” BLACk PAN hEAD SCREw (8)

6. #10 x ¾” PAN hEAD SCREw (8)

7. #6 x ¾” BLACk PAN hEAD SCREw (4)

8. ThREADED INSERT (3)

9. ThREADED INSERT INSTALLATION wRENCh

10. CUP wAShER (6)

11. RUBBER STAND-OFF (9)

12. ¼” FEMALE qUICk DISCONNECT (4)

13. SUBwOOFER MOUNTING BRACkET (2)

14. ROSETTE ThUMBSCREw (2)

VI. aMplIfIerInStallatIon&wIrIngKIt

15. PAC LC1 REMOTE LEVEL CONTROL

16. PREMIUM RCA INTERCONNECTS

17. POSITAP wIRE TAP CONNECTORS (5)

18. RCA-TO-STRIPPED wIRE PIGTAILS (2)

19. hEAT ShRINk TUBING

20. CABLE TIES (5)

21. ALCOhOL PREP wIPE (3)

22. 3M DUAL-LOCk (2”)

23. 3M ELECTRICAL TAPE

24. BANANA PLUGS – 1 PAIR [RED & BLACk]

25. wATERPROOF AGU FUSE hOLDER

26. 30 AMP AGU FUSE (2)

27. #6 x ½” hEx wAShER SCREw, STAINLESS (3)

28. 5/16” GOLD RING TERMINAL – 1 PAIR [RED & BLACk]

29. 8 AwG RED ULTRAFLEx POwER wIRE

30. 8 AwG BLACk ULTRAFLEx GROUND wIRE

31. 18 AwG whITE REMOTE TURN-ON wIRE

32. 16 AwG RED/BLACk SPEAkER wIRE

VII. aMplIfIerMountIngKIt(rearMount)

33. AMPLIFIER MOUNTING BRACkET

34. M6 FLANGE NUT (1) & wAShERS (2)

35. SCREw GROMMET

36. #8 x ½” TRUSS hEAD SCREw (1)

37. #6 x 3/8” PAN hEAD SCREw (4)

2

24

28

26

25

11

98

10

17

3534

37273676543

18

33

14

22

13

12

*SELECT COMPONENTS FOR IDENTIFICATION - NOT ALL COMPONENTS ShOwN BELOw

IMAGES NOT TO SCALE

4|IntegralAudio|InstallationInstructions Continuedonnextpage...4|IntegralAudio|InstallationInstructions Continuedonnextpage...

Tools You Will Need

a. wIreStrIpper/crIMper

b. torxbItS:

• T50

c. electrIcdrIll

d. drIllbItS:

• 1/8”

• 7/16”

e. wrencHeSorSocKetS:

• 7/16”

• 8MM

• 10MM

• 19MM

f. 3MMallenwrencH

g. electrIcIan’SwIrefISH

H. ScISSorS

I. lIgHterorSMalltorcH

J. utIlItyKnIfe

K. pencIlorfIne-tIpMarKer

l. plIerS

M. panelreMoValtoolS

n. pIcK&HooKSet

o. centerpuncH

p. MagnetIcpartStray

P

C

G

H

L

A

I

M

E

N

K

O

D

J

B

F

IMAGES NOT TO SCALE

5|IntegralAudio|InstallationInstructions Continuedonnextpage...

1. reMoVerearparcelSHelf&floorpanel

Detach straps (1) and slide the parcel shelf out of

guides (2).

Remove the luggage compartment oor panel. The

oor panel will not be placed back into the vehicle

and can be stored.

A. PREPTHEVEHICLE

7. detacHrIgHt&leftSIderearpanel

Depress latches (1) and remove cover.

Remove screws (2) and (3).

Repeat this step for the LEFT side. The left side

does not need to be removed (see next step), it just

needs to be loosened to facilitate access for mounting

the amplier.

8. reMoVerIgHtSIderearpanel

Detach the rear seat belt at the bottom with a Torx

T-50. Pull the panel towards the interior of the

vehicle releasing the friction clips (2). Then lift up

on the panel, freeing it from the metal retaining clips

attached along the top of the panel (1).

Reinstallation is the reverse of the above. Guide the

panel onto the retaining clips (1) rst. You may nd it

easier to bend the clips open slightly.

5. reMoVerearSeat(part2)

The outside of each seat back has a pin that sits in

a “T” shaped keyway. Rotate each seat back up to

about 45 degrees and pull toward the center of the

vehicle to release.

4. reMoVerearSeat(part1)

Fold down the rear seat backs. Remove the 10mm

bolt at the base of the center attachment of the rear

seat backs. Pry the catch up. Lift up on the seat

back to release.

3. reMoVerearSIll

Locate the three expansion rivets (1) at the lower

edge of the rear sill. Pry out the center-pin of each

expansion rivet with a at screwdriver or panel

removal tool. Pry out the base of the expansion rivet.

Pull the bottom of the rear sill toward the front of the

vehicle to clear the metal “D” rings. Pull the whole

panel upwards, releasing the friction clips (2). Keep

the center-pins with the expansion rivets to avoid

confusion with similar pins removed in later steps.

2. reMoVefloorpanel

Pry the center pin (1) out of the two retaining clips.

Remove the oor panel (2).

6. reMoVerearSeatbottoM

Pull up rmly on the front of the edge of the rear seat

bottom to release. The back of the seat is attached

by wire rod loops hooked into down-ward facing tabs.

Press down on the back edge of the seat bottom and

pull forward to release .

6|IntegralAudio|InstallationInstructions Continuedonnextpage...

9. detacHdrIVerSSeatbelt

Remove the Torx T-50 bolt. Remove the metal rod

that secures the bottom of the seat belt.

15. fISHpowerwIretHrougHfIrewall

Locate the wire pass-thru grommet in the upper left

of the area behind the knee bolster (just above and

left of the top of the clutch pedal, if present). Feed

your electrician’s sh tape through this grommet and

into the engine compartment. Locate the sh tape

(see item (1) from the next step). Tape the end of the

power wire to the sh tape and pull it into the cabin.

16. InStallfuSeHolder(part1)

Mount the fuse holder to a suitable location on the

wall of the compartment area (1) using two #6 x ½”

Stainless Hex Washer Head Self-tapping screws.

Remove the battery cover (2). Determine the routing

of the power wire to the battery. You may need to drill

a small hole in the plastic bulkhead.

14. pulldowntHeKneebolSter

Pull in and down rmly on the top of the Knee Bolster

(the panel under the steering wheel) to release the

top. Lift each outer edge to release the hinges.

Remove and set aside.

12. reMoVeleftdoorSIlltrIM(part3)

[Seat shown removed for clarity]

Remove the door seal over the entire length of the

right door sill by lifting it up and off. Pull Door Sill

Panel (2) inward, releasing clips (3). This requires

a rm pull at each of the clip locations. Remove the

small trim piece (1) by pulling it toward the rear of the

vehicle, releasing spring clip.

11. reMoVeleftdoorSIlltrIM(part2)

Remove the expansion rivet (1) from the front of the

Door Sill (in the footwell area). Pull rmly inward all

along the

B. RUNTHEPOWER&GROUNDWIRES

10. reMoVeleftdoorSIlltrIM(part1)

The top of the Left Rear Interior Panel locks over the

Left Door Sill Trim and must be released to remove

the Door Sill. Pull inward rmly on the bottom of the

front of the Left Rear Panel, releasing the friction clips

(1) for just this portion. It is not necessary

13. reMoVetHerIgHtdoorSIlltrIM

Repeat the previous three steps for the Right Side of

the vehicle.

SeePrevious

Images

7|IntegralAudio|InstallationInstructions Continuedonnextpage...

17. InStallfuSeHolder(part2)

Cut a length of Power Wire to run from the fuse

holder to the battery. Strip the length of the Power

Wire and both ends. Crimp the red 5/16” Gold Ring

Terminal to one end.

Insert the other end through one end cap of the fuse

holder and secure the gold terminal end onto the wire

with a 3mm Allen wrench. Repeat the process to

attach the other section of wire.

22. MountreMoteleVelcontrol

Mount the PAC LC1 Remote Level Control in the

location of your choice with the self-adhesive 3M

Dual-lock or the screws provided with the Level Con-

trol. Our preference is under the bottom of the center

console as shown.

NOTE: If using the 3M Dual-lock, wipe both surfaces

with one of the Alcohol Prep Pads before applying.

21. InputSIgnalwIrIngoVerVIew

The input signal connection is made by tapping into

the signal at the h/k amplier located on the right-

hand side of the luggage compartment area. From

here the signal runs up the right side of the vehicle to

the dash/console, where the remote volume control

will be mounted, and then back to the ARC subwoofer

amplier. The connection for the remote turn on lead

for the ARC amplier is also made at the h/k amp,

and runs directly to the ARC amp.

20. attacHgroundwIre

Locate the Common Ground point shown. Remove

the nut with a 10mm socket. Strip the end of the

Ground wire, crimp the black 5/16” Gold Ring Ter-

minal to the end. Feed the other end of the Ground

Wire back to the boot area along with the Power

Wire.

19. runpowerwIretoboot

Run the Power Wire to the boot, routing it along the

drivers side door sill area, behind the right side rear

interior panel, and to the area behind the small cover

panel removed in Step 7.

Make sure the wire is run clear of any obstructions

or sharp edges, and that it lays at and does not

obstruct any panels that need to be reattached.

18. attacHbatterylead

Remove the auxiliary nut on the battery post and

attach the power wire. Do not install the fuse into the

holder yet.

Secure any loose sections of wire with wire ties. Pull

any remaining slack wire into the cabin.

C.SIGNALWIRING

23. routeSIgnalwIreS

Connect the RCA-to-Stripped Wire Pigtails to the

“IN” leads on the Remote Level Control and RCA

Interconnects to the “OUT”. Route these wires up

around the console, under and behind the glove box,

along the passenger side door sill, and behind the

right rear interior panel to the h/k amplier area.

24. IdentIfySIgnalwIreS

Unplug the X10266 connector of the h/k ampler

(A18). Locate the wires identied in the chart below.

Each set of ++ and -- wires should be a twisted pair.

Conrm the wire by checking the pin number, which

can be observed by removing the gray and black

sections from the housing by lifting/releasing the

retaining notch at the open end of the housing. If

you are not sure you have identied the correct wires

contact us before proceeding!

8|IntegralAudio|InstallationInstructions Continuedonnextpage...

25. tapSIgnalwIreS

Unscrew both ends of the Posi-tap. Slip the “U”-

shaped bottom around the signal wire to be tapped.

Carefully thread the body of the Posi-tap onto this

and tighten rmly. Be sure not to cross-thread the

Posi-tap.

31. aMplIfIerbracKet(oVerVIew)

The amplier bracket mounts against the side of the

left rear wheel well, with the ange on the long side of

the bracket facing down. The large hole in the upper

right (towards the front of the vehicle) slides over the

threaded stud for the common ground point at the

front of the wheel well. The rear hole in the bottom

ange aligns with the hole in the sheet metal below.

Begin by removing the toolkit and nut on the common

ground point.

32. InStalltHeaMplIfIerbracKet(part1)

Insert the Screw Grommet into the hole in the

horizontal section of sheet metal as shown. Place

the bracket with rear horizontal hole aligned with the

screw grommet and the forward hole aligned over the

threaded stud. You may need to bend the bracket

slightly to get it to t.

30. reMoteturn-onwIre

Strip one end of the 18AWG White Turn-on Lead

wire. Use the remaining Posi-tap connector to attach

the turn-on wire to the Solid White wire at pin 10 of

the connector.

28. HeatSHrInKconnectIon

29. Slide the heatshrink tubing over the ends of the

Posi-taps. Using a small torch or lighter, gently

and evenly apply heat to the heatshrink tubing until

it shrinks securely over the Posi-tap connections.

There should be no exposed bare wire! Use Cable

Ties to secure the signal wiring as necessary.

27. connectpIgtaIlS(part2)

Cut the 4” length of Heatshrink tubing in half and in-

sert one Pigtail (both stripped wires) through one half.

Insert the stripped ends through the top cap of the

Posi-tap and then into the body. Keep the stripped

wire in contact with the body and thread the upper

portion on and tighten rmly.

26. connectpIgtaIlS(part1)

Feed the stripped ends of the RCA-to-Stripped Wire

Pigtails to the Posi-taps at the X9331 connector from

the last step. Measure about 8” of excess “working”

wire length and cut the remainder of the Pigtail. Slit

the outer jacket of the Pigtails lengthwise, taking care

not to cut the outer grounding wire. Strip approx 3/8”

of the jacket from the center (positive) conductor.

(You may nd it easier to disconnect the Pigtails and

remove them from the vehicle for slitting/stripping).

D.MOUNTAMPLIFIER&CONNECTWIRING

Amplier Signal Connections

Signal : HK Amp Wire Color: Pin: Connect To:

RearLeft++ Bluew/RedStripe 4 Pigtail1White

RearLeft-- Bluew/BrownStripe 3 Pigtail1Ground

RearRight++ Blue 2 Pigtail2White

RearRight-- Brown 1 Pigtail2Ground

RemoteTurnOn SolidWhite 10 18AWGWhite

9|IntegralAudio|InstallationInstructions Continuedonnextpage...

33. InStalltHeaMplIfIerbracKet(part2)

Leaving the Common Ground connection in place,

put the two 6mm washers over the Common Ground

threaded stud, then the bracket, and nally the 6mm

nut. Tighten the nut using a deep 10mm socket.

Fasten the #8 X ½” Screw through the rear hole in

the bracket and into the Screw Grommet. Prevent

the Grommet from turning with a straight pick or small

screwdriver inserted into the split in the side.

39. tHreadedInSertS(oVerVIew)

Self-Sealing Threaded Inserts are used to secure

the enclosure to the vehicle. It is important that you

follow these installation steps carefully and com-

pletely. An extra Insert is provided in case you run

into trouble.

40. InStalltHreadedInSertS(part1)

Using a 7/16” bit (NOT a ½” bit!), drill holes in the 2

positions marked on the boot oor. Do not let the drill

bit penetrate more than ¼” through the sheet metal.

You may nd it helpful to use a cut-to-length wood

block as a stop for the drill. It is important to drill the

holes EXACTLY where they were marked.

Remove any metal burrs - the hole must have clean

edges.

38. attacHtHeMountIngbracKetS

Remove the enclosure. Align the brackets with the

lines marked in the previous step. Place the bottom

of the bracket approx 1/4” above the bottom edge

of the enclosure. Attach the bracket with the #10 x

¾” Pan Head Screws. Replace the enclosure and

conrm hole locations are correctly market. Remove

the enclosure.

37. MarKforbracKetplaceMent

Temporarily replace the Rear Sill. Center the

subwoofer enclosure in the boot. Place a Mount-

ing Bracket on either side with the single-hole side

centered over the indicated raised area of the boot

oor. Keep the hole at least 3/8” away from the

edges of the raised area of the sheet metal. Cut a

notch the carpet edge if necessary. Mark the center

with a marker or center punch. Mark the location of

the vertical sides of the bracket against the enclosure

with a pencil.

36. MountaMplIfIer

Mount the Amplier to the bracket using the (4) #6 x

3/8” screws. Use the pre-drilled hole locations. Place

the wire bundle (that was loosened earlier) in the gap

between the amp and the sheet metal.

35. aMplIfIerconnectIonS

Connect the Power, Ground, and Remote Turn-on

Lead wires to the amplier. Connect the RCA Inter-

connects. Set the Signal input selector on the amp to

“RCA”. Connect the Speaker Wire to the Amp using

the “bridged” connection locations. Refer to the Amp

manual if needed.

34. SpeaKerwIre

Cut 2 feet from the length of 16AWG Speaker Cable

and set aside. Split and strip the ends of the remain-

ing 6 feet. Attach the positive wire to the L+ connec-

tor on the amp, negative to R-. Attach the Banana

Plugs to the other end by loosening the 3mm Allen

screw, inserting the wire, and tightening the screw.

Run the Speaker Wire from the amp area to the cen-

ter of the vehicle, routing it along & under the carpet

trim at the front of the boot area.

E. INSTALLTHEENCLOSUREMOUNTS

10|IntegralAudio|InstallationInstructions Continuedonnextpage...

41. InStalltHreadedInSertS(part2)

Using a utility knife, carefully trim the PVC jacket out

of the center of the Self-Sealing Threaded Inserts as

shown. Insert the 1” Hex Bolt through the Installation

Tool. Then thread the 1” Hex Bolt into the Threaded

Insert. Be sure the “nubs” on the Installation Tool

face the top of the Threaded Insert. These “nubs” are

what grip the Insert and prevent it from turning during

installation.

47. InStalltHeencloSure

Place the enclosure back into the boot. Connect

the Banana Plugs to the Terminal Cup. Insert the

Rosette Thumbscrews through the Mounting Brackets

and screw into the Threaded Inserts. If you made a

mistake drilling the holes and the Thumbscrews do

not line up, drill larger holes in the mounting brackets.

NOTE: We recommend coating the threads of the

Rosette Thumbscrews with grease to keep them

operating smoothly and avoid corrosion.

48. HowtoreMoVetHefalSefloor

The False Floor Panel slides through the hatch

opening and rests on the oor supports. To remove,

simply push down on the edge near the rear seat

backs, lift, and remove – clean, simple, easy!

46. MounttHefloorSupportS(part2)

Mount the Stand-offs centered approx 2” in from

the edges of the enclosure. Mark and drill 1/8” pilot

holes. Attach the supports with the Screws and Cup

Washers.

IMPORTANT: Tighten the screws until the metal

Washer is recessed below the top of the Rubber

Stand-off, providing a soft surface for the False Floor.

If this is not done, the oor will rattle on the washer/

screw-head.

45. MounttHefloorSupportS(part1)

The oor supports are assembled with one Rubber

Stand-off, one Cup Washer, and one #10 x 1.5” Pan

Head Screw.

NOTE: The Stand-offs may have warped in transit.

To get them to stack cleanly, wrap a few turns of

electrical tape around them at the seam. Remove

after installation.

44. MounttHeSpeaKer

Mount the speaker with the #10 x 1” Black Pan Head

Screws. The speaker is snug t! Tighten the screws

in a “star” pattern, go slowly and take care not to strip

them. Make sure the speaker ange is ush against

the enclosure – the gasket on the back of the speaker

ange MUST make an airtight seal.

43. wIrIng&terMInalcup

Split and strip the ends of the remaining 2 feet of

16AWG Speaker Cable. Crimp the (4) female ¼”

Quick Disconnects to the wire and connect one

pair the Terminal Cup and the other to the speaker,

observing correct polarity. If possible, we strongly

encourage soldering these connections instead of the

(4) disconnects. Mount the Terminal Cup using the

(4) #6 x ¾” Black Pan Head Screws.

42. InStalltHreadedInSertS(part3)

Insert the Threaded Inserts into the holes drilled

in the previous step. Keep the Insert vertical and

keep the head of the Insert ush against the sheet

metal and carefully tighten the bolt by hand with a

wrench (do not use a powered tool of any kind) until

you begin to feel resistance and the insert is secure.

Take your time - do not over-tighten. Remove the 1”

Hex bolt. If you have trouble with an Insert, you can

remove it by partially unthreading the 1” Hex bolt and

tapping it with a hammer.

F. PREP&INSTALLTHEENCLOSURE

11|IntegralAudio|InstallationInstructions Continuedonnextpage...

49. HowtoreMoVetHeencloSure

To remove the enclosure, simply disconnect the

speaker wire, unscrew the Rosette Thumbscrews,

and remove.

WARNING: Do not allow the Banana Plug connec-

tors to short (touch each other) while the system is

energized.

52. recoMMendedInItIalaMplIfIerSettIngS

Gain: 20% (see ARC manual)

Output: LOW (low-pass crossover)

Crossover: 80 Hz

Bass Boost: 0

Input: RCA In (button should be OUT)

Factory Radio Bass Level: -2

50. reconnecttHebattery&InStallfuSe

Reconnect the Battery Negative Terminal and Install

one of the 30 amp AGU fuses in the fuse block. A

spare fuse is included.

G.TESTING&RECOMMENDEDINITIALSETTINGS

51. teStforcorrectoperatIon

Turn on the system and check for correct operation.

Once you have conrmed that everything is operating

correctly, reinstall all panels and trim removed during

the installation. Use the provided electrical tape and

cable ties to wrap and secure wiring bundles and har-

nesses as necessary.

TEST!

12|IntegralAudio|InstallationInstructions

• TUNING & PERFORMANCE: The factory audio system is “tuned” to provide

exaggerated bass at around 60Hz, giving the temporary illusion of better bass

performance. Unfortunately the factory speakers aren’t capable of producing

this exaggerated level of bass without creating distortion that affects the other

frequencies the speaker is asked to produce. The Integral Audio subwoofer sys-

tem allows the correction of this factory “tuning”. Because the subwoofer system

has an independent volume control, the “Bass” EQ setting on the headunit can

be lowered. This reduces the exaggerated bass level being sent to the factory

speakers and eliminates the greatest source of distortion in the system, improving

the transient response of the factory speakers. The recommended initial settings

listed earlier will give nearly at frequency response in the sub-bass region.

• SIGNAL SOURCE QUALITY: A poor quality signal will always sound poor no

matter how good an audio system is. If you are using MP3s or home-burned CDs

it is critical that you understand the limitations and impacts of digital compression

methods. MP3s at less than 256kbps will have noticeable loss of quality. Satel-

lite radio is also compressed and will have similar quality issues. Non-commer-

cially obtained music (especially downloaded via P2P le-sharing) recordings are

often re-mixed by third parties and will have been compressed in an unknown and

uncontrolled manner. If you want good quality sound, use only commercial CDs

or MP3s compressed at 256kbps or 320kbps.

• FACTORY RADIO SETTINGS: Please note that the settings (Bass, Treble, Fade,

Balance, AUX input level, etc.) are stored on the Key FOB & are specic to the

Source (Radio, CD, AUX). You will need to edit and save the settings for each

source and each FOB to have consistent sound.

Allspecicationsaresubjecttochangewithoutnotice.IntegralAudio®andtheIntegralAudiologo,areregisteredtrademarksof

IntegralAudio.Formoredetailedinformationpleasevisitusonlineatwww.integralaudio.com.

www.integralaudio.com

Having Trouble? The best thing to do is contact us at support@integra-

laudio.com or via the phone number listed on the receipt that was emailed

to you. We’ll get you xed up!

Tips & Tuning Troubleshooting

Other manuals for 1101S

2

Table of contents

Other Integral Audio Subwoofer manuals

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio 81S User manual

Integral Audio

Integral Audio 1100S User manual

Integral Audio

Integral Audio MCSS630SW-RAM User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio PHANTOM User manual

Integral Audio

Integral Audio SoundStage + Subwoofer System User manual

Integral Audio

Integral Audio PHANTOM User manual