Integral Audio 1101S User manual

IMPORTANT

!

• ReadthisInstallationGuidecompletelybeforebeginningtheinstallation.

• Thisisaguide–yourvehiclemayvary.ALWAYScheckbehindpanels&

componentsbeforedrilling,cutting,orscrewingintoanypartofavehicle.

Contents

INSTALLATION GUIDE

MINI COOPER

MODEL 1101S SUBWOOFER SYSTEM

DIY

SKILL LEVEL

REQUIRED

35

INSTALLATION

DIFFICULTY

OUT OF

4

INSTALLATION

TIME

Hrs

R57 Convertible (2009+)

R56 JCW Hardtop (2007-2009)

R58 Coupe (All Years)

R59 Roadster (All Years)

OVERVIEW.................................................................................... 2

BEFOREYOUBEGIN!................................................................... 2

WHAT’SINTHEBOX.................................................................... 3

TOOLSYOUWILLNEED.............................................................. 5

INSTALLATION:

A.PrePtheVehicle.................................................................. 6

B.runthePower&Groundwires.......................................... 7

c.siGnAlwirinG....................................................................... 8

d.MountAMPlifier&connectwirinG...................................... 9

e.instAlltheenclosureMounts............................................ 10

f. PreP&instAlltheenclosure............................................ 11

G.testinG&recoMMendedinitiAlsettinGs............................. 12

TIPS&TUNING........................................................................... 13

TROUBLESHOOTING................................................................. 13

2|IntegralAudio|InstallationInstructions Continuedonnextpage...

• reAdtheseinstructionscoMPletelyfroMstArttofinishBe-

foreGoinGneArthecAr!!

• instAllAtionVAriesdePendinGonVehicleModelAndequiPMent.

MAkesureyouhAVeProPerlyidentifiedyourVehicleAndnote

whichinstAllAtionstePsAPPly.stePslABeledAsfollows:

- [r5Xonly]APPlyonlytothesPecificModellisted.MAke

sureyouknowwhAtdesiGnAtionyourVehicleis.

- ifnoVehicledesiGnAtionislisted,theinstAllAtionsteP

APPliestoAllVehicles

• disconnecttheneGAtiVeBAtteryterMinAl

• GAtherAllrequiredtools

• lAyout&identifyAllcoMPonents&hArdwAre.MAkesureyou

hAVeAllthecoMPonentsrequiredforyourinstAllAtion.

• note:donotPutthekeyfoBintheiGnitioniftheelectricAl

connectortoeitherfrontseAtdisconnected!!youwillsetoff

thesrs/AirBAGliGhtAndwillhAVetohAVeitresetBythedeAler!

• note:eAchkitMAyAPPlytoMorethAnoneVehicleModelAnd

MAyincludeeXtrAiteMs.disreGArdAnyiteMsnotMentionedin

theinstructionsforyourVehicle.

• note:donotdeViAtefroMtheseinstructionsortheincluded

hArdwAre.eVerycoMPonentofthissysteMhAsBeencArefully

selectedByourenGineers.fAiluretofollowtheseinstruc-

tionsorcorrectlyidentifyAndusethesuPPliedhArdwAreMAy

resultinPoorPerforMAnceAndPossiBlesAfetyhAzArds.ifin

douBt,contActusAndwewillBehAPPytohelPyou.

Overview Before You Begin!

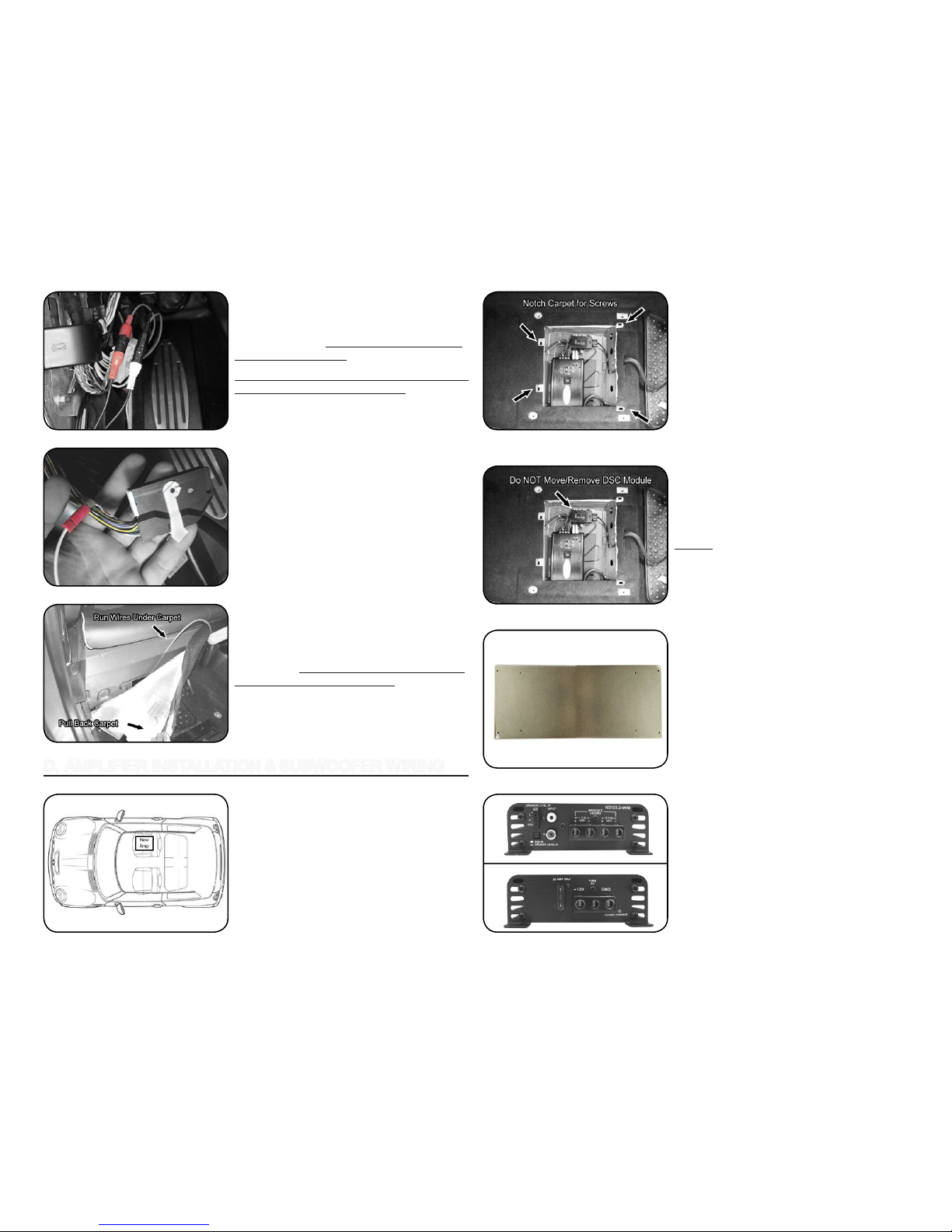

thisGuidecoVersinstAllAtionoftheModel1101ssuBwoofersysteMin

2009&uPMinicooPerr57conVertiBles,r58couPes,r59roAdsters,

Andr56hArdtoPsthAtdonothAVethesMAllstorAGecoMPArtMentonthe

riGhtsideoftheBoot.

thesuBwooferenclosureinstAllsintheflooroftheluGGAGecoMPArt-

Ment(AkAthe“Boot”).thesuBAMPlifierinstAllsunderthePAssenGer’s

seAt.AreMoteleVelcontrolinstAllsAtthedAshforon-the-flysuB-

wooferAdjustMent.

Power&GroundwiresAreconnectedtotheBAtteryAndAchAssis

GroundPointAndrundownthePAssenGersideoftheVehicleAndtotheAM-

Plifier.theAudiosiGnAlAndAMPlifierturn-onsiGnAlcoMefroMtheX9331

&X15connectorsintheleftfootwell.thesiGnAlwirinGisrunfroMthe

leftfootwelltothedAsh-MountedreMoteleVelcontrolAndthentothe

suBAMPlifier.

3|IntegralAudio|InstallationInstructions Continuedonnextpage...3|IntegralAudio|InstallationInstructions Continuedonnextpage...

What’s In The Box

2

24

28

26

25

11

98

10

3534

37273676543

15

14

13

*selectcoMPonentsforidentificAtion-notAllcoMPonentsshownBelow

iMAGesnottoscAle

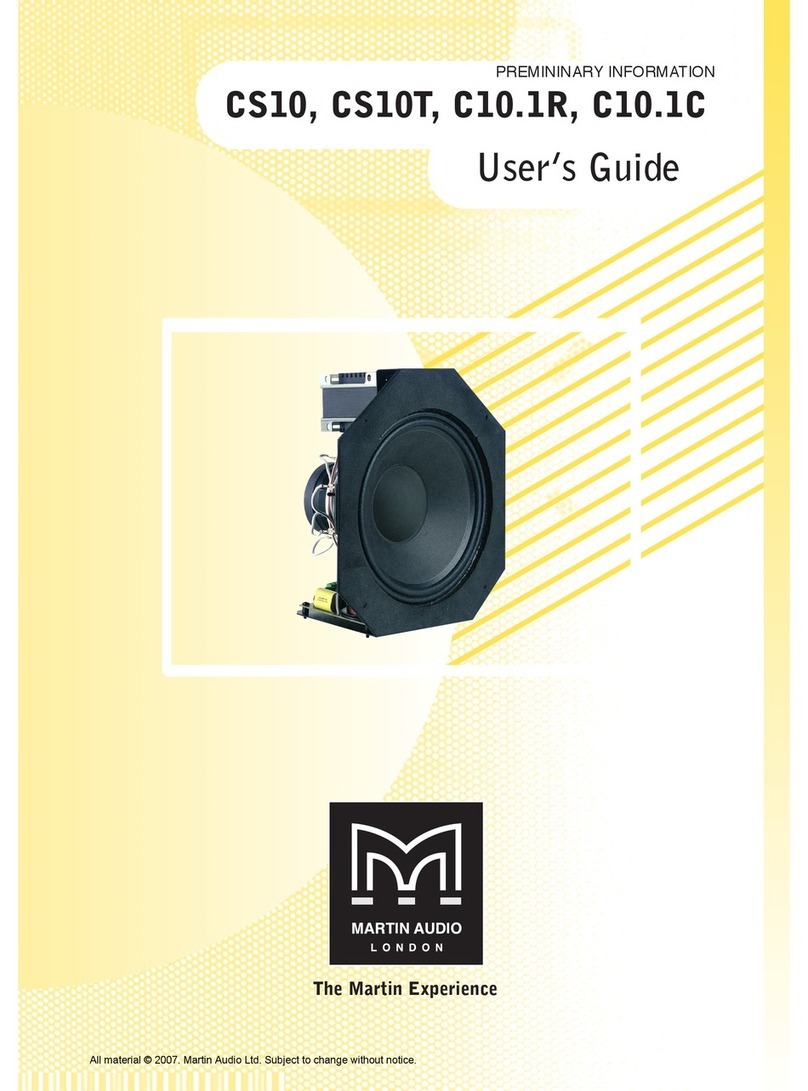

I. Model1101SSubwooferencloSure

II. SbAcouStIcS10”Subwoofer

III. ArcAudIoKS125.2MInIAMplIfIer

IV. fAlSefloorpAnel

V. SubwooferencloSureHArdwAreKIt

1. terMinAlcuPw/GoldBindinGPosts

2. #10X2.5”PAnheAdscrew(3)

3. #10X1.5”PAnheAdscrew(6)

4. ¼”X1”heXheAdBolt

5. #10X1”BlAckPAnheAdscrew(8)

6. #10X¾”PAnheAdscrew(8)

7. #6X¾”BlAckPAnheAdscrew(4)

8. threAdedinsert(3)

9. threAdedinsertinstAllAtiontool

10. cuPwAsher(6)

11. ruBBerstAnd-off(9)

12. suBwooferwirinGhArness

13. suBwooferMountinGBrAcket(2)

14. rosettethuMBscrew(2)

VI. AMplIfIerInStAllAtIon&wIrIngKIt

15. X9331wirinGhArness

16. PAclc1reMoteleVelcontrol

17. PreMiuMrcAinterconnects

18. cABleties(5)

19. AlcoholPrePwiPe(3)

20. 3MdouBle-sidedfoAMtAPe

21. 3MelectricAltAPe

22. BAnAnAPluGs–1PAir[red&BlAck]

23. wAterProofAGufuseholder

24. 30AMPAGufuse(2)

25. #6X½”heXwAsherscrew,stAinless(3)

26. 5/16”GoldrinGterMinAl–1PAir[red&BlAck]

27. 8AwGredultrAfleXPowerwire(15feet)

28. 8AwGBlAckultrAfleXGroundwire(7feet)

29. 18AwGwhitereMoteturn-onwire(15feet)

30. 16AwGred/BlAcksPeAkerwire(8+2feet)

31. under-seAtAMPlifierMountinGPlAte

32. under-seAtMulti-fuctionBoXcoVer

4|IntegralAudio|InstallationInstructions Continuedonnextpage...4|IntegralAudio|InstallationInstructions Continuedonnextpage...

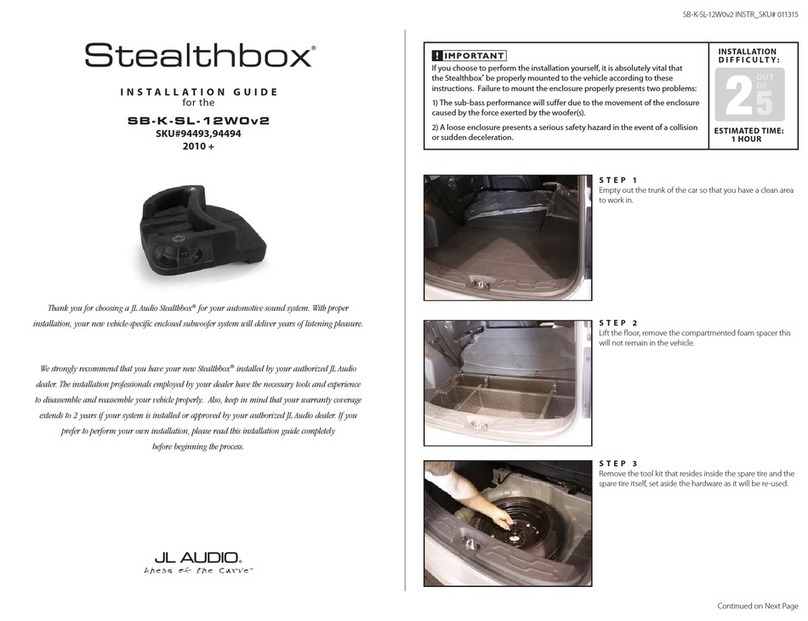

Tools You Will Need

A. wIreStrIpper/crIMper

b. torxbItS:

• t50

c. electrIcdrIll

d. drIllbItS:

• 1/8”

• 7/16”

e. wrencHeSorSocKetS:

• 7/16”

• 8MM

• 10MM

• 19MM

f. 3MMAllenwrencH

g. electrIcIAn’SwIrefISH

H. ScISSorS

I. lIgHterorSMAlltorcH

J. utIlItyKnIfe

K. pencIlorfIne-tIpMArKer

l. plIerS

M. pAnelreMoVAltoolS

n. pIcK&HooKSet

o. centerpuncH

p. MAgnetIcpArtStrAy

P

C

G

H

L

A

I

M

E

N

K

O

D

J

B

F

iMAGesnottoscAle

5|IntegralAudio|InstallationInstructions Continuedonnextpage...

1. reMoVepASSengerSeAt

Slide the seat forward. Using a Torx T-40, remove the

two screws holding the rear of the seat (1). Slide the

seat backward and repeat for the two front screws.

A. PREPVEHICLE

7. reMoVeleftdoorSIlltrIM(pArt3)

[Seat shown removed for clarity]

Remove the door seal over the entire length of the

right door sill by lifting it up and off. Pull up/loosen

the rubber door seal gasket along the length of the

door. Pull Door Sill Panel (2) inward, releasing clips

(3). This requires a rm pull at each of the clip loca-

tions. Remove the small trim piece (1) by pulling it

toward the rear of the vehicle, releasing spring clip.

5. reMoVeleftdoorSIlltrIM(pArt1)

Using a Torx T-50 bit, remove the seat belt screw (1)

where it passes through the rear of the door sill trim.

3. reMoVepASSengerSeAt(pArt3)

If present, remove the plastic panel under the seat.

2. reMoVepASSengerSeAt(pArt2)

Tilt the seat back. Disconnect the airbag wiring under

the seat by pulling the black slide catch on the side

of the yellow plug. Disconnect the seat heater wiring

if equipped. DO NOT put the key FOB in the ignition

while this plug is disconnected. Remove the seat

from the vehicle.

6. reMoVeleftdoorSIlltrIM(pArt2)

Remove metal seat belt bushing (1) if not removed

in the previous step. Pull Rear Side Trim Panel (4)

in, releasing clip (3) and freeing tab of Door Sill (2)

located behind Side Panel (4).

4. reMoVedrIVerSeAt

[R57 with HIFI/HK ONLY]

Repeat the previous steps to remove the Driver seat.

SeePrevious

Images

8. reMoVetHerIgHtdoorSIlltrIM

Repeat the previous three steps for the Right Side of

the vehicle.

SeePrevious

Images

6|IntegralAudio|InstallationInstructions Continuedonnextpage...

9. releASefrontoftHereArSeAtbottoM

[R55 & R56 ONLY]

Pull up rmly on the front of the edge of the rear

seat bottom to release. This will allow you access to

under the carpet in later steps.

15. feedpowerwIreIntocAbIn

Cut the end off the spare wiring nipple at the wiring

bushing adjacent to the batter. Feed the 8AWG Red

Power Wire through the spare wiring nipple and into

the cabin. From inside the vehicle, locate the wire

coming in. Feed the wire around the fuse box and

along the Right Door Sill.

16. groundwIre

Locate the Common Ground point under the Right

Door Sill. Remove the nut with a 10mm socket. Strip

the end of the Ground wire, crimp the black 5/16”

Gold Ring Terminal to the end, and attach to the

Common Ground point.

NOTE: On some vehicles the common ground is

located a bit further forward. Enough ground wire is

included to reach either location.

14. InStAllfuSeHolder(pArt2)

Mount the Fuse Holder to the plastic bulkhead next

to the battery using 2 of the #6 x ½” Stainless Hex

Washer Head Self-tapping screws. Use a Center

Punch to form a starting hole or pre-drill the holes

with a 1/8” bit.

Remove the auxiliary nut on the battery post with a

19mm socket and attach the Ring Terminal of the 18”

length. Do not install the fuse into the holder yet.

13. InStAllfuSeHolder(pArt1)

Cut approx 18” from the Power Wire to run from the

fuse holder to the battery. Strip the end of the Power

Wire and both ends of the 18” length. Crimp the red

5/16” Gold Ring Terminal to one end of the 18” length.

Remove one end cap of the fuse holder and insert

the other end of the 18” length, then secure the gold

terminal end of the fuse holder onto the wire with a

3mm Allen wrench. Repeat the process to attach the

other section of wire.

12. reMoVetHru-wAllcoVer

OPTIONAL: The next few steps are easier if you

remove the battery.

Locate the thru-wall bushing behind the battery. Us-

ing a at screwdriver, release the indicated retain-

ing tabs then remove the plastic thru-wall cover to

expose the thru-wall opening.

B. POWER&GROUNDWIRING

10. power&groundwIrIng(oVerVIew)

The 12V+ wire runs directly from the battery to the

new amplier that installs under the passenger seat.

An inline fuse is installed at the battery.

The Ground wire runs from the amplier to one of the

factory-installed common ground points along the

door sill

11. reMoVerIgHtcowlpAnel

Open the Bonnet (aka the hood!). Remove the black

plastic Cowl covering the battery by releasing nuts (2)

and (3) with a 10mm socket. Loosen & remove cowl.

NOTE: When replacing the cowl, be sure the seal (1)

is seated properly and that the secondary tab of the

cowl (4) is inserted into the plastic channel (5) that

attaches to the bottom of the windshield.

7|IntegralAudio|InstallationInstructions Continuedonnextpage...

17. SIgnAlwIrIng(oVerVIew)

The factory audio signal is pulled from the X9331

connector in the driver-side footwell, described below.

The included custom T-harness plugs into each side

of the factory connector. RCA interconnects are run

to the to the remote-level control for the subwoofer (if

equipped) and to the amplier. The power-on signal

for the amplier is obtained from pin 1 of the X15

connector.

22. reMoVefootwellpAnel

Remove the panel next to gas pedal by releasing

the Torx T-25 screws and pulling the panel out and

towards the rear of the vehicle.

21. MountreMoteleVelcontrol

Mount the Remote Level Control below the toggle

switches. Wipe the surface with the Alcohol Prep Pad

before applying.

Do a dry-run to check the placement and be sure

you know exactly where you’d like the control. You

will nd that you can place it more toward the front of

the recess for easier access, or toward the rear for a

more hidden look.

20. reMoteleVelcontrol

[SUB ONLY]

Attach the 3M VHB double-sided adhesive (this is

the green 3in length) to the top of the Remote Level

Control. Trim extra length from the VHB, if neces-

sary. Wipe the surface with one of the Alcohol Prep

Pad before applying.

19. connectx9331t-HArneSS

Unplug the X9331 connector and connect the T-

Harness. The RCA Jacks are the OUTPUT from the

factory stereo - in later steps they will be connected

to the INPUT on the remote level control [sub only]

and the amplier. Red = Right Channel, White = Left

Channel. Both reds and both whites carry the same

signal and are interchangable. The stripped wire

ends are SPEAKER INPUT and will be connected to

the amplier OUTPUT. The left channel is labeled.

18. AcceSSx9331&x15connectorS

Locate these connectors in the left footwell. The

X9331 is behind and attached to the larger X15.

Remove both by twisting counter-clockwise ¼ turn

and pulling outwards. Separate the X9331 from the

X15 by releasing the locking tabs on the connector

joining them.

23. connectreMoteleVelcontrol

Feed the Remote Level Control leads under the bot-

tom edge of the center stack and around to the are

under the panel you just removed.

Connect the 3FT RCAs to the “IN” leads on the Re-

mote Level Control, and one of the 17FT RCAs to the

“OUT” leads. Wrap the exposed metal of the RCAs

with electrical tape!

24. routercAInterconnectS

[SUB ONLY]

Pull rmly on the top of the plastic panel under the

steering wheel to release the top edge of the panel.

Feed the RCAs along and under the knee bolster

and secure with cable ties. Be sure the wires are

clear of any moving parts or pinch points.

C.SIGNALWIRING

8|IntegralAudio|InstallationInstructions Continuedonnextpage...

25. x9331SIgnAlconnectIonS

Connect the 3FT RCA from the “IN” on the Remote

Level Control to one red/white pair of RCA jacks on

the X9331 harness. Wrap the exposed metal of the

RCAs with electrical tape!

All exposed metal of RCA and/or wire ends MUST be

taped off and isolated from each other!!

31. AttAcHAMplIfIerMountIngplAte

Attach the amplier to the mounting plate using the

#6 x 3/8” screws. Cut strips of the 3M Double-Sided

Foam Mounting tape and afx one side to the back

of the amp mounting plate and any original equip-

ment from the underseat compartment. Arrange all

components so that they t. Clean all components

and the sheet metal with an Alcohol Prep Pad prior to

attaching the Foam Mounting Tape.

32. AMplIfIerpower&SIgnAlconnectIonS

Strip and connect the Power, Ground, and Remote

Turn-on Lead wires to the amplier.

Connect the RCA Interconnects. Set the Signal input

selector on the amp to “RCA”. Refer to the Amp

manual if needed. Do not mount or cover the amp

yet - you will want it uncovered for settings adjust-

ments.

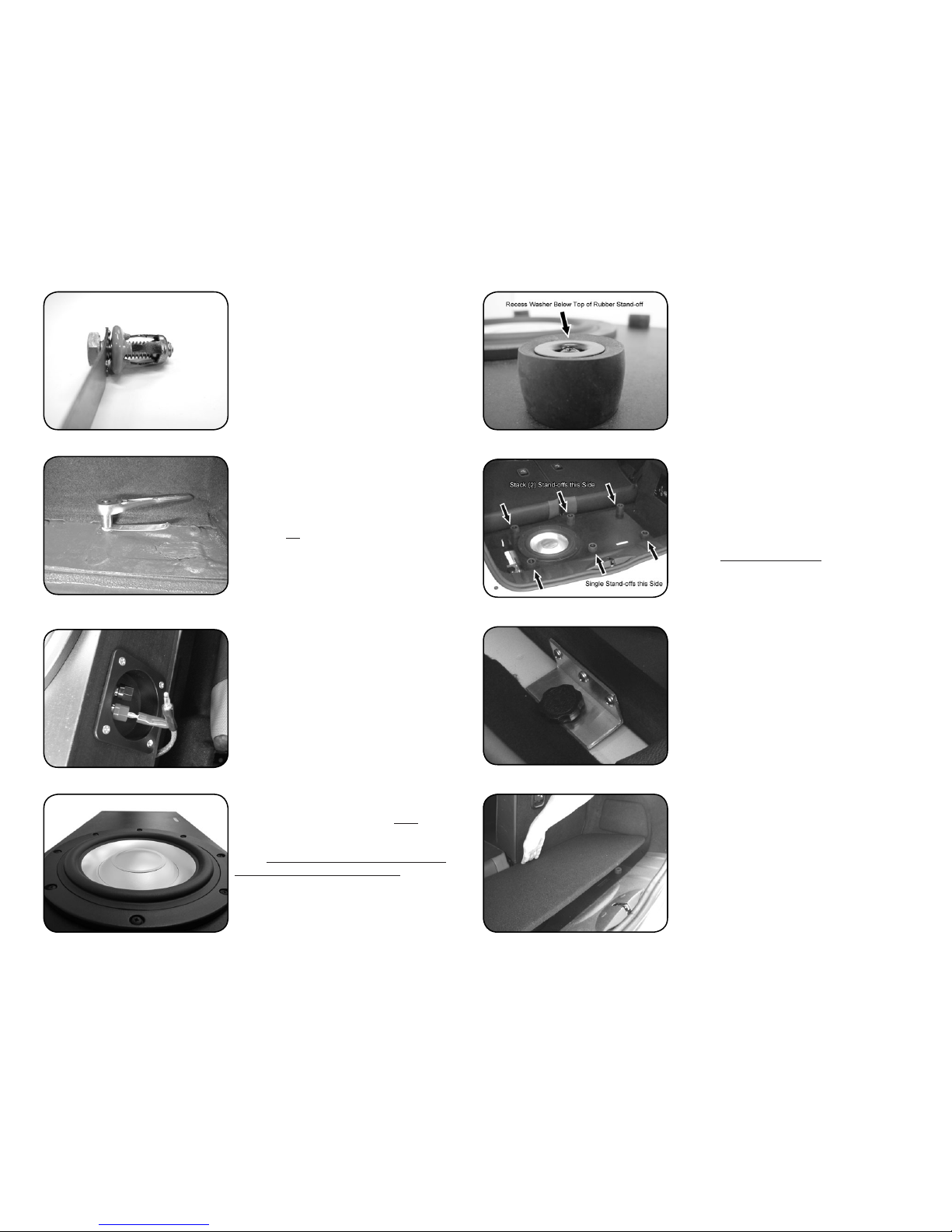

30. reMoVetHeplAStIctub

[FOR VEHICLES WITH EXISTING COVER]

Remove the plastic tub liner from the compartment.

Detach any equipment mounted to it.

DO NOT remove or remount the DSC module (see

image)

29. trIMcArpetforcoMpArtMentcoVer

[FOR VEHICLES WITH CARPET UNDER SEAT]

Lay the Amplier Compartment Cover on the area

underseat. Note where the carpet needs to be cut

and mark with tape. Cut the carpet and foam backing

with a utility knife. Cut CAREFULLY - there are wires

running along the front edge of the compartment.

The carpet should be cut SMALLER than the cover or

there will be exposed area. Use the driver’s side as a

guide. Notch the carpet in the mounting screw areas.

28. AMplIfIerMountIng(oVerVIew)

The amplier mounts in the compartment under the

passenger seat. If your vehicle does not have a com-

partment with cover under the seat, one has been

included in your kit. You will cut the carpet, remove

the foam block inside, and then mount the amp.

27. runSIgnAlwIrIngtoAMp

Beginning in the left (driver’s) side footwell, run the

RCAs and remote turn-on along the door sill, and

under the carpet in the rear seat footwell area.power/

ground wires. Be sure the wiring is clear of all pinch

points, including the Seat Belt screw.

AVOID PLACING SIGNAL WIRING DIRECTLY

ADJACENT TO OR TOUCHING OTHER WIRING

BUNDLES!

26. reMoteturn-onwIre

Identify the solid black wire coming out of pin 1 of the

X15 connector (see step 21). Strip 3/8” of insulation

from one end of the 18AWG White Turn-on Lead wire.

Unscrew both ends of the Posi-tap (the Posi-tap has

a hole in only one end, the Posi-lock used later has a

hole in each end. Slip the “U”-shaped bottom around

the signal wire to be tapped. Carefully thread the

body of the Posi-tap onto this and tighten rmly. Be

sure not to cross-thread the Posi-tap.

D.AMPLIFIERINSTALLATION&SUBWOOFERWIRING

9|IntegralAudio|InstallationInstructions Continuedonnextpage...

39. tHreAdedInSertS(oVerVIew)

Self-Sealing Threaded Inserts are used to secure

the enclosure to the vehicle. It is important that you

follow these installation steps carefully and com-

pletely. An extra Insert is provided in case you run

into trouble.

40. InStAlltHreAdedInSertS(pArt1)

Using a 7/16” bit (NOT a ½” bit!), drill holes in the 2

positions marked on the boot oor. Do not let the drill

bit penetrate more than ¼” through the sheet metal.

You may nd it helpful to use a cut-to-length wood

block as a stop for the drill. It is important to drill the

holes EXACTLY where they were marked.

Remove any metal burrs - the hole must have clean

edges.

38. AttAcHtHeMountIngbrAcKetS

Remove the enclosure. Align the brackets with the

lines marked in the previous step. Place the bottom

of the bracket approx 1/4” above the bottom edge

of the enclosure. Attach the bracket with the #10 x

¾” Pan Head Screws. Replace the enclosure and

conrm hole locations are correctly market. Remove

the enclosure.

37. MArKforbrAcKetAndtHreAdedInSert

Center the enclosure in the boot. Place a Mounting

Bracket on each side with the single-hole centered

over the raised area of the boot oor. Keep the hole

at least 3/8” away from the edges of the raised area

of the sheet metal. Cut a notch in the carpet edge if

necessary. Mark the center with a marker or center

punch. Mark the location of the vertical sides of the

bracket against the enclosure with a pencil.

36. SubwooferbAnAnAplugS

Split and strip the end of the Subwoofer Speaker

wire. Attach the Banana Plugs to the other end by

loosening the 3mm Allen screw, inserting the wire,

and tightening the screw.

34. runSubwooferwIre

[R58 & R59 ONLY]

Loosen the edge of the panel by removing the three

friction clips (1).

35. runSubwooferwIre(pArt2)

[R58 & R59 ONLY]

Lift up the rear quarter panel interior trim exposing

the area underneath. Using the electrician’s wire sh,

sh the subwoofer wire through the area indicated.

Run the wire under the trim covering the cross-beam

and exit it at the center.

33. runSubwooferwIre

[R57 & R56 JCW ONLY]

Run the speaker wire for the subwoofer to the boot.

Begin at the amp, run the wire along the rear side

panel (tucking it underneath the panel), and then

under the trim covering the cross-beam at the front

of the boot area. Exit the wire at the center of the

cross-beam.

E. INSTALLTHESUBWOOFER

10|IntegralAudio|InstallationInstructions Continuedonnextpage...

41. InStAlltHreAdedInSertS(pArt2)

Using a utility knife, carefully trim the PVC jacket out

of the center of the Self-Sealing Threaded Inserts as

shown. Insert the 1” Hex Bolt through the Installation

Tool. Then thread the 1” Hex Bolt into the Threaded

Insert. Be sure the “nubs” on the Installation Tool

face the top of the Threaded Insert. These “nubs” are

what grip the Insert and prevent it from turning during

installation.

47. InStAlltHeencloSure

Place the enclosure back into the boot. Connect

the Banana Plugs to the Terminal Cup. Insert the

Rosette Thumbscrews through the Mounting Brackets

and screw into the Threaded Inserts. If you made a

mistake drilling the holes and the Thumbscrews do

not line up, drill larger holes in the mounting brackets.

NOTE: We recommend coating the threads of the

Rosette Thumbscrews with grease to keep them

operating smoothly and avoid corrosion.

48. HowtoreMoVetHefAlSefloor

[R57 & R56 JCW ONLY]

The False Floor Panel slides through the hatch

opening and rests on the oor supports. To remove,

simply push down on the edge near the rear seat

backs, lift, and remove – clean, simple, easy!

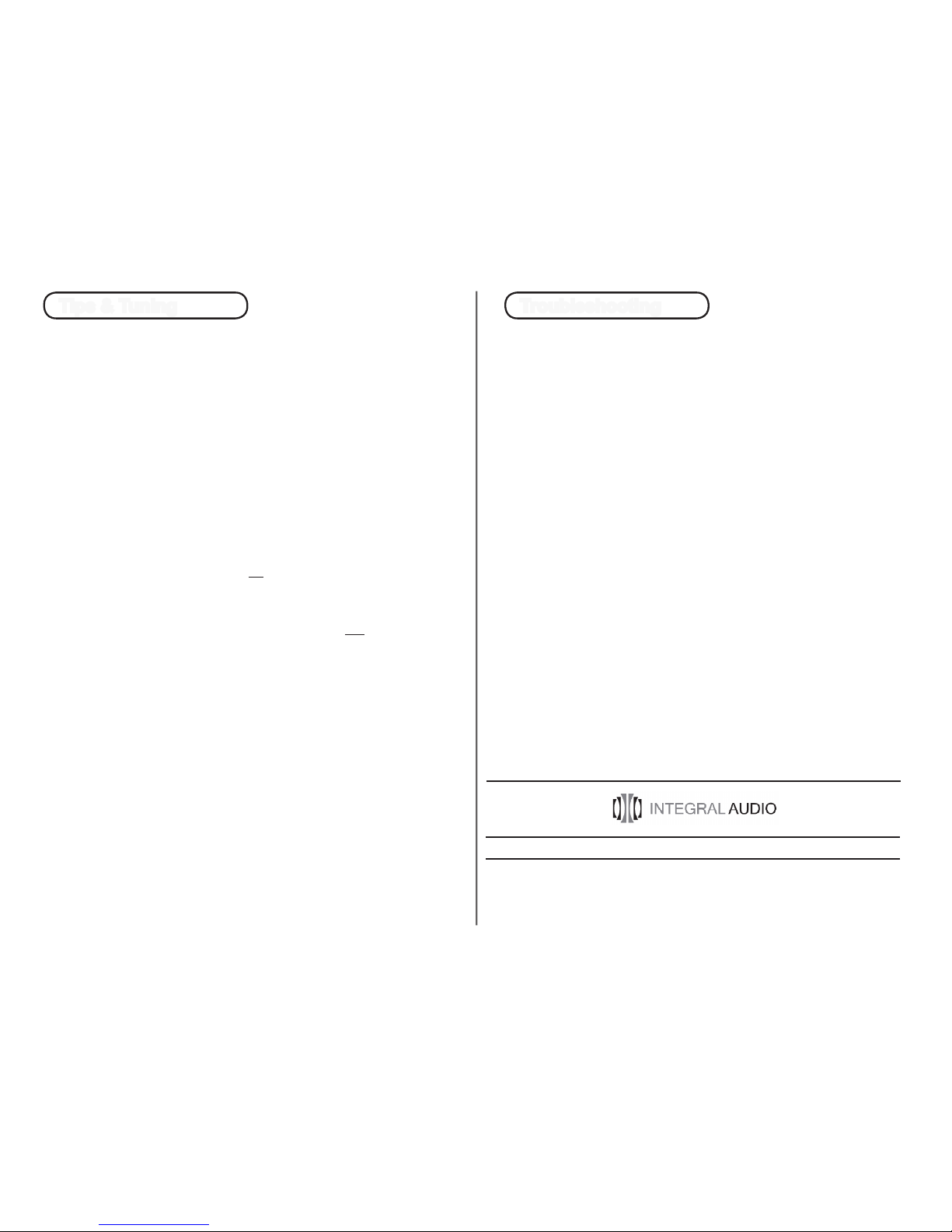

46. MounttHefloorSupportS(pArt2)

Mount the Stand-offs centered approx 2” in from

the edges of the enclosure. Mark and drill 1/8” pilot

holes. Attach the supports with the Screws and Cup

Washers.

IMPORTANT: Tighten the screws until the metal

Washer is recessed below the top of the Rubber

Stand-off, providing a soft surface for the False Floor.

If this is not done, the oor will rattle on the washer/

screw-head.

45. MounttHefloorSupportS(pArt1)

The 3 front supports are assembled with one Rubber

Stand-off, one Cup Washer, and one #10 x 1.5” Pan

Head Screw. The rear supports are twice as tall and

are assembled with two Stand-offs (stacked), one

Cup Washer, and one 2.5” Pan Head Screw.

NOTE: The Stand-offs may have warped in transit.

To get them to stack cleanly, wrap a few turns of

electrical tape around them at the seam. Remove

after installation.

44. MounttHeSpeAKer

Mount the speaker with the #10 x 1” Black Pan Head

Screws. The speaker is a snug t - tap it in with a

rubber mallet until the gasket ange contacts the

bafe. Tighten the screws in a “star” pattern, go

slowly and take care not to strip them. Make sure the

speaker ange is ush against the enclosure – the

gasket on the back of the speaker ange MUST make

an airtight seal.

43. wIrIng&terMInAlcup

Connect the subwoofer to the terminal cup using the

subwoofer connection harness. The .25” terminals

connect to the subwoofer, the .205” terminals connect

to the terminal cup.

Mount the Terminal Cup using the (4) #6 x ¾” Black

Pan Head Screws.

42. InStAlltHreAdedInSertS(pArt3)

Insert the Threaded Inserts into the holes drilled

in the previous step. Keep the Insert vertical and

keep the head of the Insert ush against the sheet

metal and carefully tighten the bolt by hand with a

wrench (do not use a powered tool of any kind) until

you begin to feel resistance and the insert is secure.

Take your time - do not over-tighten. Remove the 1”

Hex bolt. If you have trouble with an Insert, you can

remove it by partially unthreading the 1” Hex bolt and

tapping it with a hammer.

11|IntegralAudio|InstallationInstructions Continuedonnextpage...

49. HowtoreMoVetHeencloSure

To remove the enclosure, simply disconnect the

speaker wire, unscrew the Rosette Thumbscrews,

and remove.

WARNING: Try not to allow the Banana Plug connec-

tors to short (touch each other) while the system is

energized. The amp has short circuit protection and

will temporarily shut down if shorted.

54. AMplIfIerSettIngS(HIfI-equIppedVeHIcleS)

Gain: 75% (see ARC manual)

Output: LOW (low-pass crossover)

Crossover: 60 Hz

Bass Boost: 0 [THIS MUST BE ZERO!!]

Input: RCA In (button should be OUT)

Factory Radio Bass Level: -2

53. recoMMendedInItIAlSettIngS

The following steps list initial recommended settings.

Use these settings as a starting point and adjust from

there.

IMPORTANT: Depending on the source input/

material the head unit is capable of delivering volt-

ages that can drive the amp to clipping and damage

the speakers and/or subwoofer - excercise caution

and listen for signs of distortion or distress at high

volumes, especially with overly synthsized or bass-

intensive music.

F. TESTING&RECOMMENDEDINITIALSETTINGS

55. AMplIfIerSettIngS(H/K-equIppedVeHIcleS)

Gain: 90% (see ARC manual)

Output: LOW (low-pass crossover)

Crossover: 60 Hz

Bass Boost: 0 [THIS MUST BE ZERO!!]

Input: RCA In (button should be OUT)

Factory Radio Bass Level: -2

51. reconnecttHebAttery&InStAllfuSe

Reconnect the Battery Negative Terminal and Install

one of the 30 amp AGU fuses in the fuse block. A

spare fuse is included.

56. AMplIfIerSettIngS(Std6SpKrStereo)

Gain: 60% (see ARC manual)

Output: LOW (low-pass crossover)

Crossover: 80 Hz

Bass Boost: 0 [THIS MUST BE ZERO!!]

Input: RCA In (button should be OUT)

Factory Radio Bass Level: -3

52. teStforcorrectoperAtIon

Turn on the system and check for correct operation.

Once you have conrmed that everything is operating

correctly, proceed with settings and tuning described

below.

test!

50. reconnectfrontSeAtAIrbAgwIrIng!!

IMPORTANT! IMPORTANT!

Place the front seats back in the vehicle and recon-

nect the yellow plug housing before placing the key

FOB in the ignition or turning on the system. Failure

to do this will result in setting off the Airbag light which

will have to be reset by the dealer.

Leave the passenger seat all the way forward to allow

access to the amplier for settings adjustments in the

next steps.

wArninG!

wArninG!

12|IntegralAudio|InstallationInstructions Continuedonnextpage...

57. AuxInputVoluMe

58. The volume setting for the AUX input on the head-

unit can be accessed by pressing and holding the

right side of the 4th button from the right. The factory

default is 2. We recommend a starting setting of 4.

Please refer to the MINI Manual for setting the Aux

level on NAV and MINI Connect equipped vehicles.

59. InStAllpreStolcAgeSforAMpcoVer

Once you have nished the amp adjustments, you

can install the amplier cover. The mounting screws

for the amp cover thread into the Prestol Cages. In-

sert a Prestol Cage into each of the four square holes

at the corners of the under seat area. Use a hammer

to tap the Prestol Cages ush.

60. InStAllAMplIfIercoVer

Install the amplier cover with the either the removed

factory screws or the included #10 x 1” black oxide

screws.

61. replAceAllpAnelS&trIM

All parts, panels, and trim install in the opposite man-

ner and order that they were removed.

refertoAll

PreViousiMAGes!

13|IntegralAudio|InstallationInstructions Continuedonnextpage...

• TUNING & PERFORMANCE: The factory audio system is “tuned” to provide

exaggerated bass at around 60Hz, giving the temporary illusion of better bass

performance. Unfortunately the factory speakers aren’t capable of producing

this exaggerated level of bass without creating distortion that affects the other

frequencies the speaker is asked to produce. The Integral Audio subwoofer sys-

tem allows the correction of this factory “tuning”. Because the subwoofer system

has an independent volume control, the “Bass” EQ setting on the headunit can

be lowered. This reduces the exaggerated bass level being sent to the factory

speakers and eliminates the greatest source of distortion in the system, improving

the transient response of the factory speakers. The recommended initial settings

listed earlier will give nearly at frequency response in the sub-bass region.

• SIGNAL SOURCE QUALITY: A poor quality signal will always sound poor no

matter how good an audio system is. If you are using MP3s or home-burned CDs

it is critical that you understand the limitations and impacts of digital compression

methods. MP3s at less than 256kbps will have noticeable loss of quality. Satel-

lite radio is also compressed and will have similar quality issues. Non-commer-

cially obtained music (especially downloaded via P2P le-sharing) recordings are

often re-mixed by third parties and will have been compressed in an unknown and

uncontrolled manner. If you want good quality sound, use only commercial CDs

or MP3s compressed at 256kbps or 320kbps.

• FACTORY RADIO SETTINGS: Please note that the settings (Bass, Treble, Fade,

Balance, AUX input level, etc.) are stored on the Key FOB & are specic to the

Source (Radio, CD, AUX). You will need to edit and save the settings for each

source and each FOB to have consistent sound.

Allspecicationsaresubjecttochangewithoutnotice.IntegralAudio®andtheIntegralAudiologo,areregisteredtrademarksof

IntegralAudio.Formoredetailedinformationpleasevisitusonlineatwww.integralaudio.com.

www.integralaudio.com

Having Trouble? The best thing to do is contact us at support@integra-

laudio.com or via the phone number listed on the receipt that was emailed

to you. We’ll get you xed up!

Tips & Tuning Troubleshooting

Other manuals for 1101S

2

Table of contents

Other Integral Audio Subwoofer manuals

Integral Audio

Integral Audio 81S User manual

Integral Audio

Integral Audio 1100S User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio MCSS630SW-RAM User manual

Integral Audio

Integral Audio SoundStage + Subwoofer System User manual

Integral Audio

Integral Audio PHANTOM User manual

Integral Audio

Integral Audio 1101S User manual

Integral Audio

Integral Audio PHANTOM User manual