Integral Spray Paver User manual

08.20.2020 Rev G www.integraldx.com

Spray Paver

Operator’s Manual

Operation • Maintenance • Troubleshooting

©2020 Integral dx. All rights reserved.

3 |P a g e

Table of Contents

Introduction.........................................................................................7

Thank you!............................................................................................... 7

Limited warranty ..................................................................................... 8

Claim Administration Policy Procedures ............................................. 8

Indemnity........................................................................................... 10

Product Improvement Liability Disclaimer........................................ 10

Safety..................................................................................................... 11

Safety alerts....................................................................................... 11

Damage warning, notes and tips....................................................... 12

General safety rules........................................................................... 13

Safety decals...................................................................................... 15

General description............................................................................ 18

General specifications ........................................................................... 20

Components .......................................................................................... 21

Emulsion tank group.......................................................................... 22

Pump group ....................................................................................... 24

Emulsion spray group ........................................................................ 26

Hydraulic system ............................................................................... 41

Pneumatic system ............................................................................. 41

Emulsion tank heating system........................................................... 43

Control system................................................................................... 48

Installation......................................................................................... 58

System delivery and inspection............................................................. 58

Machine setup....................................................................................... 58

Operation .......................................................................................... 59

Pre-operating precautions .................................................................... 59

Operating precautions .......................................................................... 60

Fire and explosion precautions ............................................................. 61

Hydraulic system precautions ............................................................... 62

Using the display screen unit ................................................................ 63

Start screen........................................................................................ 60

Display navigation ............................................................................. 61

4 | P a g e

Sprayer selection screen ................................................................... 62

Pump function screen ....................................................................... 68

Spray bar vacuum screen .................................................................. 71

Totals screen...................................................................................... 72

Camera screens (1 and 2).................................................................. 70

Password screen................................................................................ 71

Service screen.................................................................................... 72

System Data Screen........................................................................... 73

Troubleshoot Sequence..................................................................... 74

Auto-Nozzle Option ........................................................................... 79

Alarms screen .................................................................................... 81

Spray paving steps................................................................................. 84

Loading emulsion in the tank(s) ........................................................ 88

Circulating the tank ........................................................................... 90

Circulating the spray bar ................................................................... 91

Spraying emulsion ............................................................................. 92

Vacuuming back emulsion................................................................. 94

Cleaning out and rinsing.................................................................... 95

Maintenance.................................................................................... 102

Recommended spare parts ................................................................. 102

Service interval.................................................................................... 103

Routine maintenance procedures....................................................... 100

Cleaning the spray wand ................................................................. 102

Cleaning the machine...................................................................... 102

Cleaning the strainer screen in the pumping station...................... 107

Checking the hydraulic oil level....................................................... 108

Inspecting hydraulic hoses and emulsion hoses ............................. 108

Checking the fluid level in the clean out tank................................. 108

Cleaning blockage from the emulsion tank overflow tubes ........... 108

Cleaning the hydraulic cylinder rods............................................... 109

Draining the air compressor tank and air filter............................... 109

Draining the emulsion tank sump ................................................... 110

Inspecting the packing gland on the emulsion pumps.................... 110

Inspecting the emulsion pump coupler........................................... 111

5 |P a g e

Lubricating the emulsion pump bearings........................................ 111

Inspecting the packing gland on the emulsion tank........................ 111

Checking the tightness of the tank tie-down hardware.................. 111

Checking spray nozzle alignment .................................................... 111

Checking the spray bar hardware.................................................... 111

Checking the condition of the hydraulic filter................................. 112

Removing debris in the emulsion tank sump.................................. 112

Checking oil in the compressed air oiler ......................................... 112

Changing the hydraulic oil and filter ............................................... 113

Changing the fluid in the clean out tank ......................................... 113

Replacing the engine air filter element........................................... 113

Calibrating the small asphalt pump................................................. 113

Storage ................................................................................................ 116

Startup after storage........................................................................... 117

Hydraulics system check.................................................................. 117

Cleaning agent check....................................................................... 117

Function check................................................................................. 118

Troubleshooting............................................................................... 121

Cleaning the emulsion tank................................................................. 125

Cleaning a stuck pump ........................................................................ 129

Setting the small emulsion pump bypass pressure............................. 132

Appendices ...................................................................................... 133

Appendix 1: Valve and emulsion pump configurations for the pump

functions.............................................................................................. 134

Appendix 2: Pump group flow paths................................................... 136

Tank load ......................................................................................... 136

Tank circulate .................................................................................. 137

Spray bar circulate........................................................................... 138

Spray auto........................................................................................ 139

Spray bar vacuum............................................................................ 140

Clean out.......................................................................................... 141

Bypass setting.................................................................................. 142

Appendix 2: Updating PLC and display software ................................ 143

Downloading and running the software ......................................... 143

6 | P a g e

Programming the display screen unit ............................................. 144

Programming the control unit......................................................... 147

Appendix 3: Maintenance record........................................................ 150

Appendix 4: Emulsion tank configuration........................................... 151

7 |P a g e

Introduction

Thank you!

Thank you for choosing the Integral dx spray paver.

The spray paver is an accessory for an asphalt paving machine that

applies emulsified asphalts (emulsion) to surfaces before paving. The spray

paver sprays emulsion uniformly, at specified application rates, and without

the paver wheels or tracks running over the applied emulsion.

The spray paver is designed and manufactured in the USA with quality

materials and workmanship. With proper use and care, it will provide you

many years of trouble-free service.

Keep this manual handy for frequent reference, and to pass onto new

operators or owners. Contact Integral dx if you need assistance, further

information or additional copies of the manuals.

The information in this operator’s manual is in effect at time of printing.

It is subject to change without notice. Configurations of specific models

may vary.

8 | P a g e

Limited Warranty

Integral dx warrants products of its manufacture, when used correctly

under normal operating conditions, to be free of defects in materials and

workmanship. Integral dx makes no other warranty expressed or implied.

This warranty shall be for a period of 6 months from the date the product

is put into service, provided Integral dx is supplied with the in-service

date. The warranty shall not apply to any products that have been

altered, changed, or repaired in any manner whatsoever, except by an

authorized Integral dx repair facility; nor to any product which has been

subject to misuse, negligence, or accident. The exclusive and sole remedy

for breach of contract shall be limited to repair, modification, or

replacement at the sole discretion of Integral dx. Integral dx shall not in

any event be liable for the cost of any special, direct or consequential

damages. Integral dx reserves the right to make changes or

improvements in the design or construction of any part without incurring

the obligation to install such changes on any previously delivered

products.

Claim Administration Policy Procedures

Integral dx must be contacted immediately for authorization to proceed

when a warranty problem is suspected. If parts need to be replaced,

please ask for a Return Goods Authorization (RGA) number at this time.

Hydraulic components (i.e. pumps, motors, planetary drives, and valves)

are not to be disassembled when performing possible warranty work.

Unauthorized disassembly of these components will void warranty.

A Returned Goods Authorization (RGA) number must be obtained and the

defective parts returned immediately with the RGA number marked on

the parts and the shipping containers before any warranty consideration

can be determined. Return these components prepaid via common

carrier or UPS ground to Integral dx for examination.

9 |P a g e

Warranty will not be allowed against failure due to the following:

Normal wear and tear

Abuse or accident

Modification of original equipment

Improper service or maintenance

Improper installation

Contamination

Labor will be credited at 75% of the authorized providers published labor

rate, travel time not included.

Travel to and from job sites will be covered at $0.50 per mile and not to

exceed a 100 mile round trip.

Before warranty claims will be paid, Integral dx will need to have on file

the In-Service Report.

Overnight or other special freight charges will not be covered under

warranty.

All claims must be submitted within 30 days of service on an Integral dx

claim form with the authorized providers work order attached.

All repair part orders will require a purchase order and will be billed at a

normal rate. Credit will be issued when warranty is approved.

Original Equipment Manufacturer (OEM) parts will be warranted

according to the OEM warranty upon shipment date of product.

10 | P a g e

Indemnity

Buyer agrees to indemnify and hold Integral dx harmless for all loss, cost

including but not limited to legal and other cost of proceedings, and

damages suffered by Buyer or claimed by third parties by or related to

Buyer’s use of Integral dx products.

Product Improvement Liability Disclaimer

Integral dx reserves the right to make any changes in or improvements to

its products without incurring any liability or obligation whatsoever and

without being required to make any corresponding changes or

improvements to products previously manufactured or sold.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES EXPRESSED OR

IMPLIED INCLUDING ANY IMPLIED WARRANTIES OF MERCHANTABILITY

OR FITNESS FOR A PARTICULAR PURPOSE, WHICH ARE HEREBY

DISCLAIMED AND OF ANY OTHER OBLIGATION OR LIABILITY OF INTEGRAL

DX. THE REMEDY SET FORTH ABOVE IS BUYER’S EXCLUSIVE REMEDY FOR

A BREACH OF THE WARRANTY.

UNDER NO CIRCUMSTANCES WILL INTEGRAL DX BE RESPONSIBLE FOR

INCIDENTAL, CONSEQUENTIAL, SPECIAL OR OTHER INDIRECT DAMAGE.

11 |P a g e

Safety

How you operate and maintain your equipment directly affects your

safety and the safety of others. Therefore, read and understand this

manual and any other safety information provided, including safety

decals on the equipment.

Integral dx cannot anticipate every possible circumstance that may

involve a potential hazard. The safety alerts in this manual are therefore

not all inclusive. If you use an operating procedure, installation or work

method not specifically recommended, you must be sure that it is safe for

you and for other persons. You must also ensure that the product will not

be damaged or made unsafe by the procedure that you use.

Safety alerts

Safety alert symbols in this manual or on the machine indicate important

messages regarding safety. When you see the safety alert symbol and the

signal word after, carefully read the message that follows and understand

there is a possibility of injury or death if you do not adhere to the

requirements of the safety message.

12 | P a g e

Danger: Indicates a hazardous situation that, if not avoided,

will likely result in death or serious injury.

Warning: Indicates a hazardous situation that, if not avoided,

could result in death or serious injury.

Caution: Indicates a hazardous situation that, if not followed,

could result in minor or moderate injury.

Damage warning, notes and tips

Avoid damage: Indicates a situation that could cause damage

to the spray paver or property damage.

Note: A note contains information that is important for

operating or maintaining the spray paver.

Tip: A tip contains useful information that can improve or

optimize use of the spray paver.

0

13 |P a g e

General safety rules

The general safety rules are included in this section of the manual.

Specific safety rules will appear throughout the manual.

Danger: Before operating or servicing this equipment,

complete proper training. Also read and fully understand the

operator's manual and the safety labels on the machine.

Danger: Do not smoke around the machine. Fuel, emulsion,

and fumes can explode when exposed to flames or heat from

smoking or other sources.

Warning: Have a first-aid kit available and know how to use it.

Warning: Keep a charged fire extinguisher within reach

whenever you work in an area where fire may occur.

Warning: Wear safe work clothing, which includes rough-

soled work shoes, safety glasses and any other protective gear that is

warranted by the work environment. Do not wear clothing that is

loose fitting or in poor repair when working on machinery. Do not

wear rings, wristwatches, or other jewelry while working on

machinery. They can catch moving parts and pull you into the

machinery, causing serious injury or death.

14 | P a g e

Warning: Stop operation and investigate anything that does

not look or feel right.

Danger: Asphalt emulsion is a water-base product. As such it

will boil at 212°F (100°C), causing steam inside pipes, which can result

in an explosion.

Warning: When hot emulsion touches your skin, flush the

affected area immediately with cold water. Do not apply ice directly

to the affected area. Do not attempt to remove emulsion with

products containing solvents or ammonia. Natural separation will

occur in about 48 to 72 hours. Get medical attention as soon as

possible.

15 |P a g e

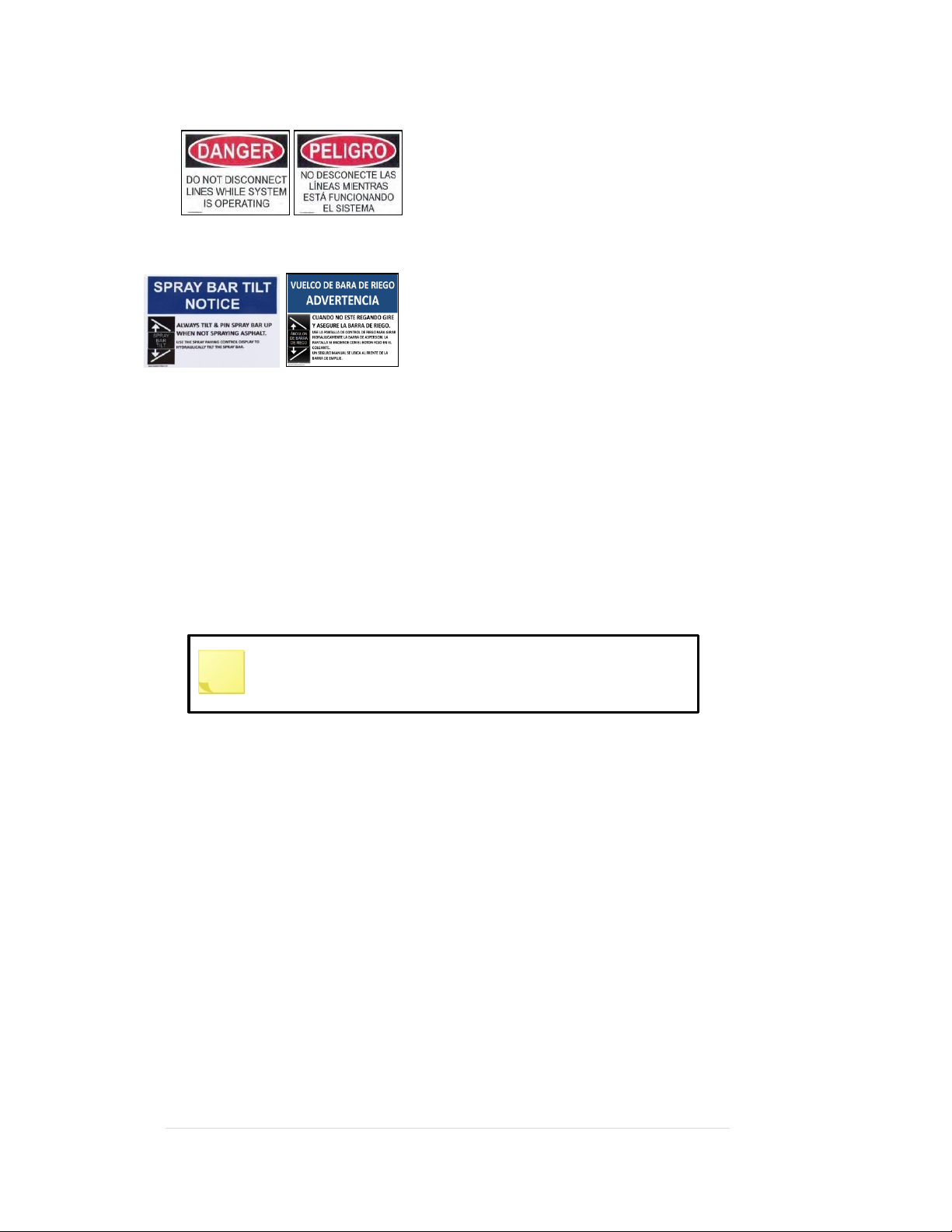

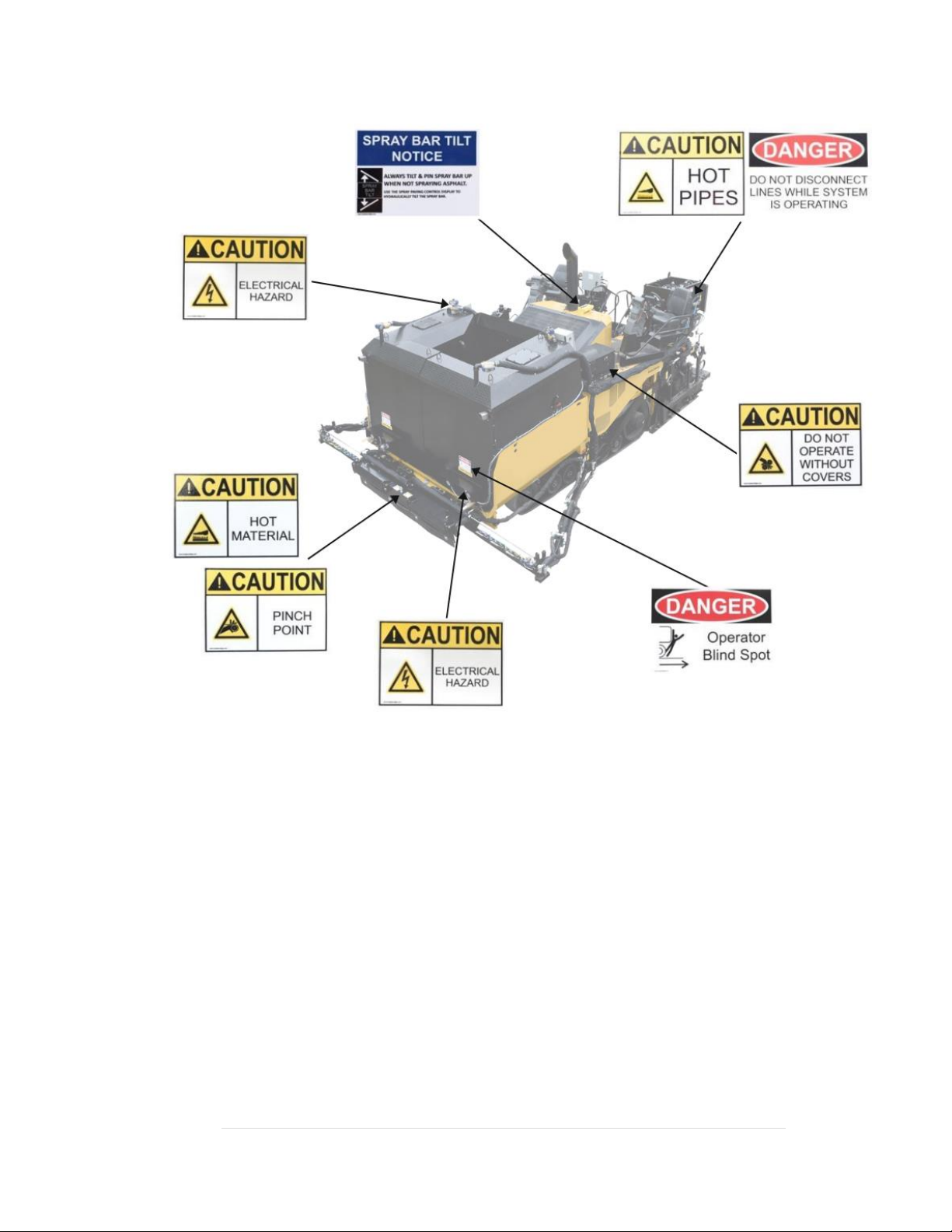

Safety decals

The Integral dx Spray Paver is equipped with a number of safety decals

indicating hazards to be avoided when operating the spray paver.

Understand the decals before using the spray paver:

Hot material is present. Take care to

avoid contact with it during spray

paver operations.

Moving parts could pinch a hand,

foot, etc. Take care to not get body

parts trapped between the parts.

An electrical hazard exists that could

potentially provide a serious shock.

Avoid the hazard during operation.

Hot pipes are present that could

provide serious burns to exposed

skin. Avoid contact with them.

Ensure covers are in place for safe

operation of the spray paver.

The operator cannot see this part of

the machine. Stay away during

operation.

16 | P a g e

Do not disconnect lines. Doing so

during spray paver operation will

cause death or serious injury.

Spray bars may be damaged by low

ground clearance. Always tilt and pin

the spray bar assembly up when not

spraying emulsion.

Safety decal location

Note the location of each of the safety decals on the Integral dx spray

paver (see Figure 1).

Note: Decal location will vary with machine configuration.

Safety decals must be present, in good condition, and in the specified

locations at all times.

If any decals are missing or damaged, replace them before

operating the spray paver.

When replacing parts that previously displayed a safety decal, be

sure to replace the decal as well.

Instructions for replacing worn or missing decals are provided

below.

17 |P a g e

Figure 1: Safety decal location (may vary depending upon model)

18 | P a g e

Safety decal replacement

Warning: Do not operate the spray paver until the safety

labels are in place.

Replace safety decals as follows:

1. Be sure that the installation area is clean and dry. Use hot soapy

water, then dry the application area thoroughly.

2. Decide on the exact decal position by taking measurements and

test fitting before you remove any of the backing paper.

3. Remove part of the adhesive backing.

4. Align the decal over the specified area, and carefully press the

exposed adhesive backing into place.

5. Slowly peel back the remaining adhesive backing, carefully

smoothing the remaining portion of the decal in place with a

cloth or sponge.

6. Check decal for air bubbles. If found, pierce small air pockets

with a pin, then carefully smooth them out.

7. When the decal is completely smoothed out, carefully remove

the top paper if present. Wipe the decal clean with a soft cloth

and warm soapy water.

19 |P a g e

General description

The Integral dx spray paver (Figure 2) applies emulsion volumetrically to

the road surface through a system of spray bars with nozzles.

Figure 2: Spray paver & major components independently:

The paver can pave with or without the spray paving system

operating.

The spray paver can operate with or without the paver operating.

20 | P a g e

The spray paver’s emulsion pump(s) are capable of handling products

ranging from light applications of emulsified asphalt to heavy asphalt

cements heated to spraying viscosity.

Avoid damage: Check with Integral dx before applying

anything other than emulsion products below 200° F.

Our spray paving system has an easy-to-use display screen unit. The

operator uses the display screen unit to set both application rate and

spray width. Using these inputs along with vehicle speed, the display

screen unit works with a control unit to automatically apply emulsion at

the set application rate.

Volumetric spraying is different from using a pressure system. With

volumetric spraying, each revolution of the emulsion pump achieves a

specified amount of flow in gallons; flow is directly related to the pump

RPM. By monitoring the pump RPM using a sensor in the hydraulic pump

drive motor, the control unit knows the exact amount of flow achieved. A

flow meter is not needed when using the volumetric emulsion pump(s).

The spray system is “ground oriented,” meaning it is linked to the paver

speed. The spray system monitors speed using the paver speed signal;

the control unit knows the exact paver speed during spraying.

As the paver speeds up or slows down, the pump also speeds up or slows

down to ensure the exact application rate, measured in gallons per

square yard (liters per square meter), is achieved.

The emulsion application maximum width depends upon the specific

model. Spray width can be adjusted incrementally.

Table of contents