Integral 1502 LT Setup guide

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ JJ

B Sep 6, 2019 UPDATED BODY CAP TORQUE VALUES JZ RS

Integral Flow Equipment

#100-310 Burnt Park Way

Red Deer County, Alberta T4S 2L4

403.348.8958

www.integralflowinc.com

3’’ 1502 LT Plug Valve Repair Instructions

2

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

Table of Contents

1.0 Exploded View _______________________________________________________________________ 3

2.0 Parts List ___________________________________________________________________________ 4

3.0 Disassembly Instructions ______________________________________________________________ 5

4.0 Assembly Instructions ________________________________________________________________ 5

4.1 Valve Body Assembly......................................................................................................................... 5

4.2 Wingnut Assembly .............................................................................................................................. 7

4.3 Gear Op Assembly ............................................................................................................................. 7

4.4 Greasing Procedure ........................................................................................................................... 7

3

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

1.0 Exploded View

4

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

2.0 Parts List

ITEM

NO.

PART NUMBER DESCRIPTION QTY.

1 03-PVL-33061-01 3’’ 1502 PLUG VALVE, LT, VALVE BODY, SG 1

2 03-PVL-33090-02 3’’ 1502 PLUG VALVE, LT, CAP/ ADJ. NUT 1

3 03-PVL-33000-25 3’’ 1502 PLUG VALVE, LT, PLUG, REG PORT, SG 1

4 03-PVL-33001-20 3’’ 1502 PLUG VALVE, LT, SEAT INSERT, REG

PORT, SG

2

5 10-ROR-11236 O-RING, SEAT INSERT 2

6 10-PVS-02601 PLUG SEAL, LT 2

7 10-ROR-11257 O-RING, CAP/ ADJ. NUT 1

8 10-FLW-01202 WASHER, FLAT, OVERSIZED 1

9 10-FLW-01201 WASHER, FLAT 1

10 10-HCS-00401 HEX CAP SCREW 1

11 10-SRP-01700 SPIRAL HD ROLL PIN 2

12 10-GRZ-02101 BUTTON HEAD GREASE FITTING W/ RELIEF

GROOVE

1

13 09-SEG-33000 SEGMENT SET, WINGNUT, 3’’ 1502 1

14 09-WND-33001 WING NUT, 3’’ 1502, SG, DETACH 1

15 10-SRE-10450 SNAP RING, 3’’ 1502 SEGMENTS 1

16 09-USR-33101 3’’ 602/1502 SEAL RING HSN 1

17 10-CTR-00501 THREADED ROD 8

18 10-HFN-00801 NUT, HEX FLANGE 8

19 10-SHC-00306 SOCKET HEAD CAP SCREW 4

20 03-PVL-33000-03 3’’ 1502 PLUG VALVE, LT, GEAR OP MOUNT 1

21 03-PVL-33000-04 3’’ PLUG VALVE, LT, GEAR OP STEM ADAPTOR 1

22 03-PVL-30000-06 GEAR OP 1

23 03-PVL-30000-05 3’’ PLUG VALVE, HANDWHEEL 1

5

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

3.0 Disassembly Instructions

1. Remove the gear op (22) and gear op mount (20). Turn valve over so that the

body cap (2) is facing up. Leaving the bottom plug bolt (10) in place, screw out

(turning counter-clockwise) the body cap (2). This will allow the entire internal

assembly to be removed from the valve cavity at once.

2. Remove the plug bolt (10) that attaches the plug (3) to the body cap (2).

3. Remove the plug (3) and seat inserts (4).

4. Remove the seat insert O-rings (5), cap O-ring (7) and plug seals (6).

5. Clean all the old lubricant and debris from the parts and valve body cavity.

4.0 Assembly Instructions

4.1 Valve Body Assembly

1. Clean any grease, rust, debris etc. from the bore of the valve body (1) so that bare

metal is exposed.

2. Check surfaces around the valve bore (1) and inside the valve pocket for sharp

edges that could cause damage to O-rings or the seat inserts.

3. Check the threads of the valve cap (2) for any damage or burrs.

4. After inspection, grease the sealing groove of the cap (2) and install the cap O-

Ring (7) in the groove. Make sure the O-Ring is seated properly into the groove.

5. Check the roll pins (11) in the valve body by gently sliding a seat inserts (4) into the

valve. The seat (4) should move freely up and down the length of the roll pin slots

without interference.

6. Apply a thin film of lubricant to the recess in the valve body (1) and install the plug

seal (6) with the metal back towards the recess, facing away from the pressure.

7. Apply a thin film of lubricant to the recess in the body cap (2) and install the plug

seal (6) with the metal back towards the recess, facing away from the pressure.

6

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

8. Check the plug (3) outside diameter for surface defects such as scratches, dings,

nicks, or sharp edges that could affect the sealing area. Repair any defects.

9. Check the surface finish of the seat inserts (4) making sure they do not have any

scratches, dings, nicks or sharp edges that could also affect the sealing area.

Repair any defects.

10. Pack the cap plug seal (6) with valve grease.

11. Install the bottom end of the plug (3) (opposite the hex) into the cap (2). Push

down on the plug until it shoulders against the cap.

12. Apply a thin film of valve grease to the entire O.D. of the plug (3).

13. Place the seat inserts (4) around the plug (3), making sure the bottom shoulder of

the carrier fits with the groove of the cap (2).

14. Place the seat insert O-rings (5) in to the grooves on the seats (4). Pack with valve

grease to retain the rings and thoroughly grease the sealing surfaces.

15. Secure the plug (3) to the cap (2) with the plug bolt (10) and two washers (8 & 9).

Do not tighten the bolt past “finger tight”. This allows the valve cap (2) to rotate

freely during installation.

16. Lubricate the valve pocket with valve grease.

17. Apply anti-seize to the cap threads.

18. Support the valve body so that the plug (3) hex can pass through unobstructed.

19. Install the plug (3), carrier (4) and cap (2) assembly into the valve body.

20. Screw the body cap assembly into the valve body (1) until snug. With a wrench,

tighten the cap down until it is bottomed out or cannot be tightened anymore. At

this point, back the cap off ¼ turn. With a torque wrench, re-tighten the cap to 125

ft*lbs.

21. Apply anti-seize to the threads of the double check grease fitting (12). Do NOT use

Teflon tape on the grease fitting.

22. Install double check grease fitting (12). Torque to 125 ft*lbs.

7

REV#

DATE

REVISION DESCRIPTION

PREPA

RED BY

APPROVED BY

A Dec 9, 2018 CREATION OF DOCUMENT JZ RS

B Jun 19, 2019 UPDATED PART NUMBERS JZ RS

4.2 Wingnut Assembly

23. Place the 3’’ 1502 segment snap ring (15) onto the male end of the valve body (1).

24. Place wing nut (14) on male end and install the segment set (13).

25. Secure the segments (13) with the snap ring (15).

4.3 Gear Op Assembly

26. Install the threaded rods (17) into the top of the valve body (1). Thread until

bottomed out.

27. Place the gear op mount (20) onto the valve body (1) and threaded rods (17).

Secure the mount with the flanged locknuts (18).

28. Place the stem adaptor (21) onto the hex of the plug (3). Check that the stem

adaptor is properly indexed.

29. With a 7/16’’ by 7/16’’ key stock, install the gear op (22) to the stem adaptor (21).

Secure gear op (22) to the mount (20) with 4 cap screws (19).

4.4 Greasing Procedure

30. With the valve in the open position, grease to 4,000 psi.

31. Cycle the valve to the closed position and then back to the open position. Repeat

greasing the valve to 4,000 psi. Complete this cycle a total of 4 times. This ensures

that no air is trapped in the cavity of the valve.

Table of contents

Popular Control Unit manuals by other brands

Johnson Controls

Johnson Controls M300CJ quick start guide

Grundfos

Grundfos CIM 200 Functional profile and user manual

Bosch

Bosch rexroth Automax 100 operating instructions

Acromag

Acromag IP236A Series user manual

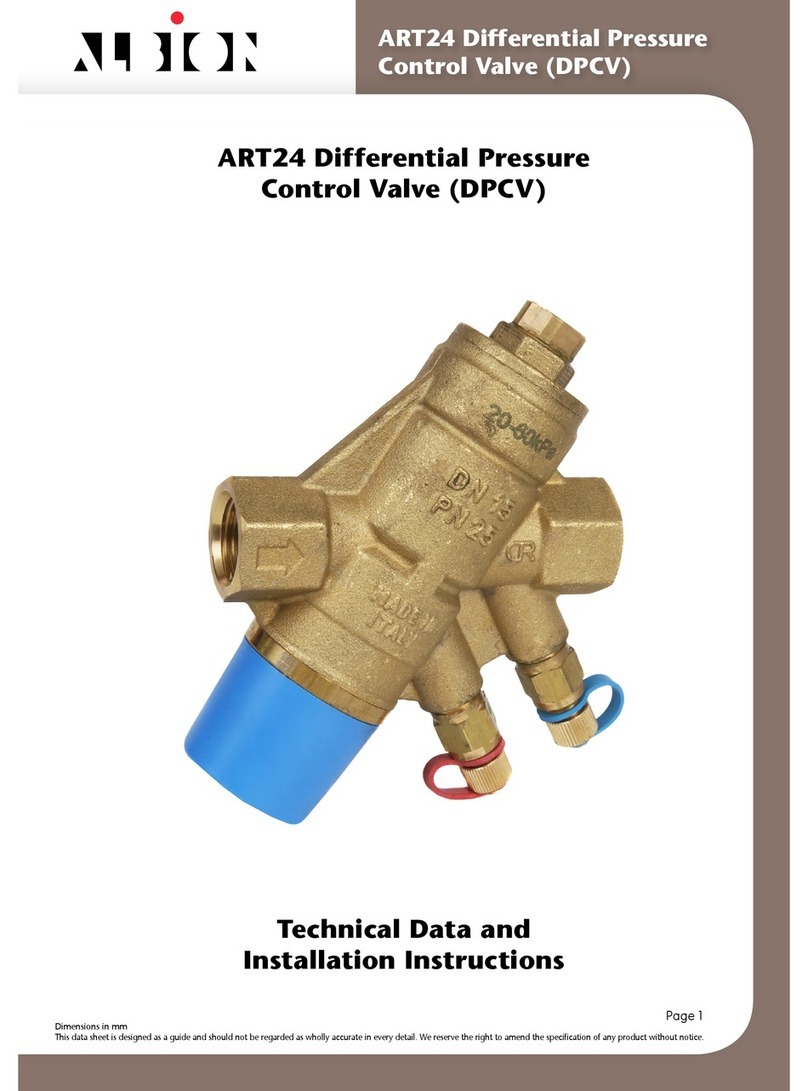

Albion

Albion ART24 Technical Data and Installation Instructions

Glyn

Glyn ACLAVIS TX-LVDS manual