- 6 -

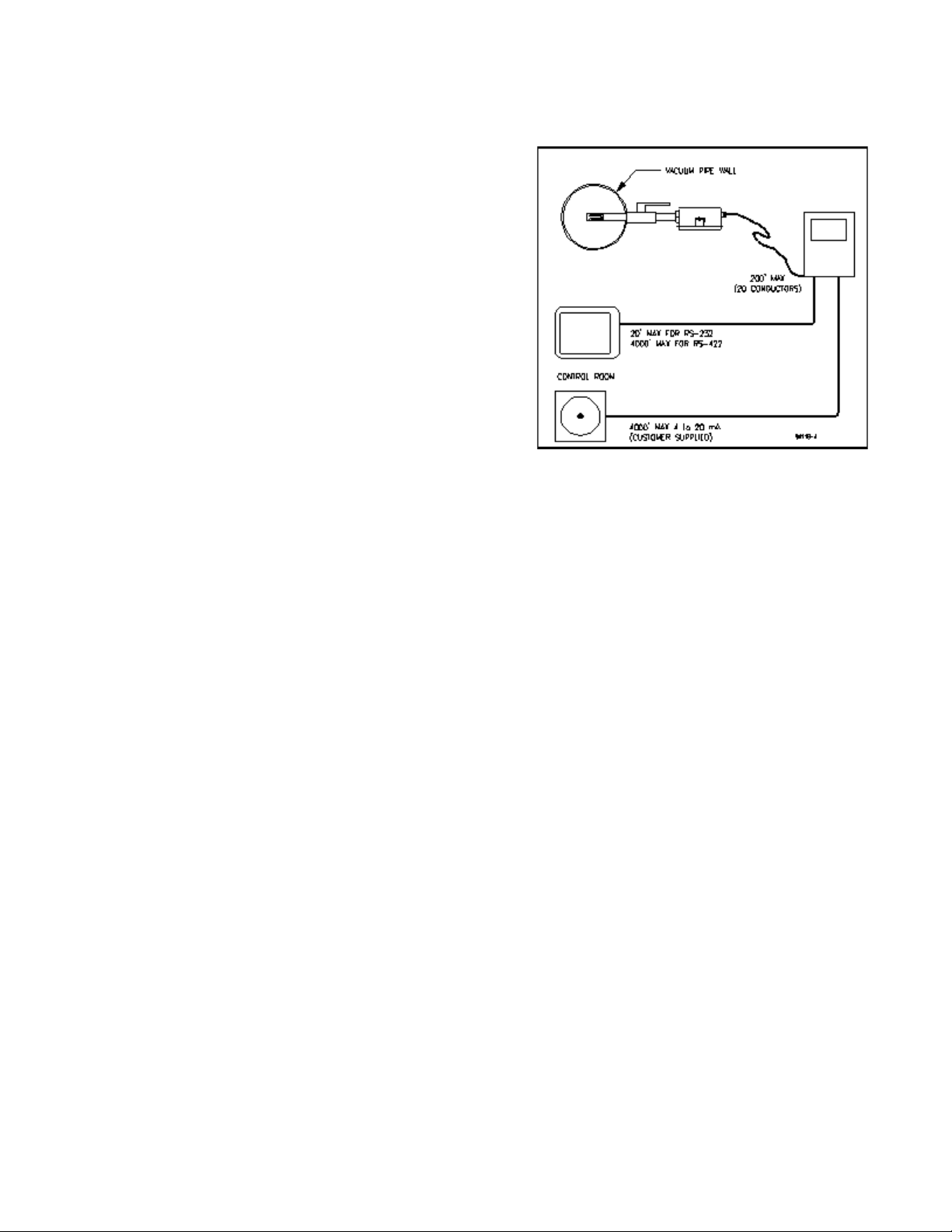

Figure 4 Maximum Cable Lengths

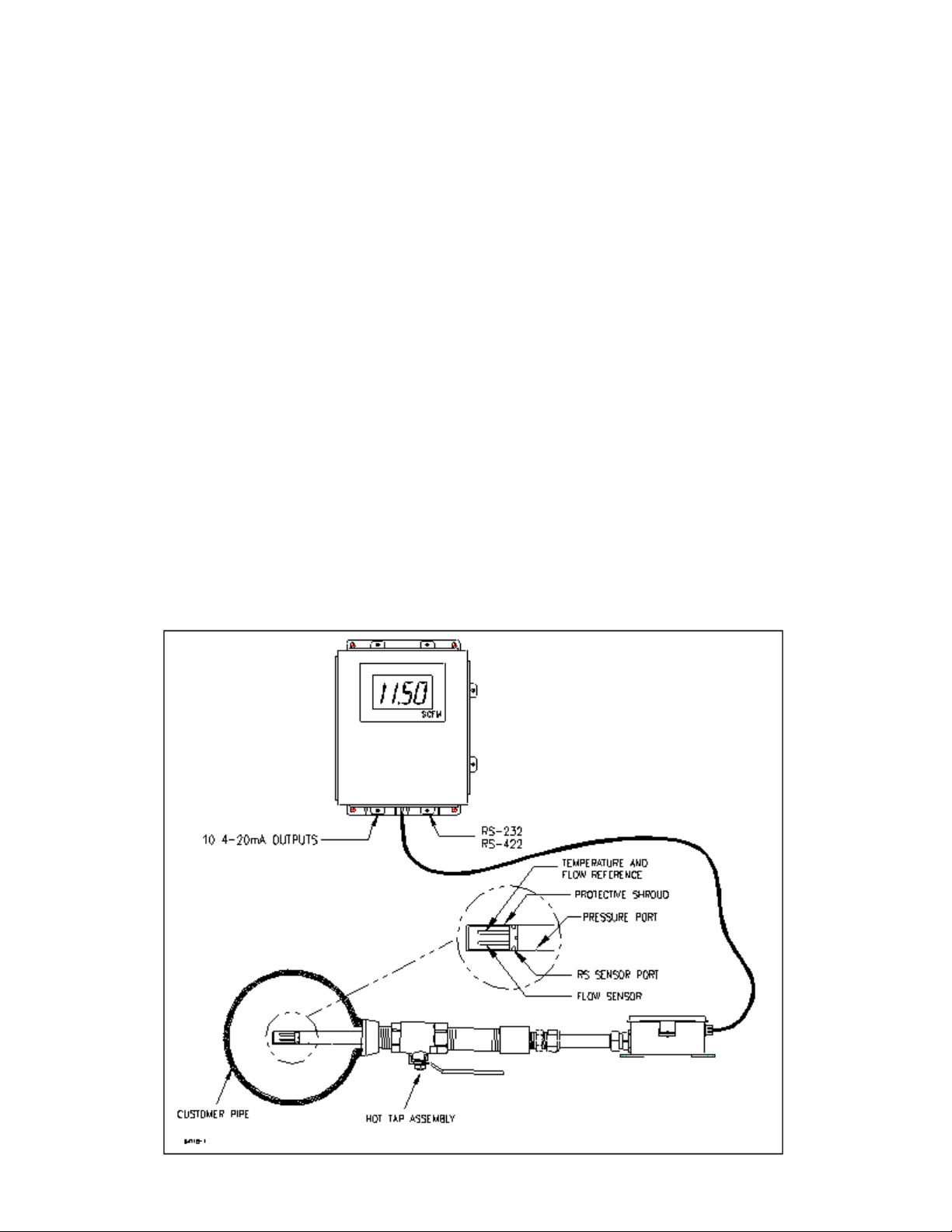

2.3 MOUNTING HA RDWARE INSTALLATION

ÎCheck hardware. Verify that the probe slides

through the hot tap assembly.

ÏCheck installation configuration. Make sure

the probe is parallel to the floor. (see Figure3).

ÐCheck installation clearance. Verifythere is a

probe insertion clearance of 4 feet from the

pipe wall.

ÑInstall the mounting hardware. Drill a 1½”

through hole and weld the thread-o-let onto

the condenser vacuum pipe (See Figure 3).

Thread the hot-tap assembly into the thread-

o-let. Use thread tape or pipe dope to seal the

connection.

ÒIt should be convenient to apply a force of

about 23 lb to remove or replace the probe

under plant operating conditions.

2.4 TRANSDUCER INSTALLATION

ÎCheck proper installation direction. The transducer has a directional arrow on the tag and/or

etched into a metal part. Before installing the unit, note proper flow direction. This is

important to instrument operation.

ÏCheck serial number. If more than one RheoVac unit has been purchased, make sure the

completeserial number of the transducer matches the complete serial numberof the separate

electronics unit. The transducer and electronics are a matched set. Mismatched components

will result in erroneous readings.

ÐVerify stop clamp location (see Figure 6). A stop clamp is attached to the probe as an

indication of its insertion depth. It is important this stay in place so the sensors are in the

correct location and ensure the probes do not contact the opposite pipe wall. The clamp’s

location was determined based on your pipe diameter, as shown in SECTION 6.2, and is

marked with a groove on the probe’s shaft. Refer to this mark if the stop clamp is

inadvertently moved.

ÑInspect the transducer probe tips. Be sure wetted surfaces are clean before installing.If

cleaning is needed, use a damp cloth wetted with alcohol and wipe dry using a soft, lint-free

cloth. Do not immerse probe in liquid alcohol or any other liquids.

ÒInstall the transducer.The instrument should be mounted through the pipewallusing thehot-

tap assembly. The transducer installs so that the two probes are side-by-side across the gas

stream. The transducer has a flow directional arrow on the transducer tag and/or marked into

the fitting. When installing under vacuum, do not allow the clamp to "slam" against the seal

nut upon opening the valve. Grasp the transducer shaft firmlybefore opening the ball valve.

Allow the transducer to slide through the valve by controlling the amount of grip on its shaft.

Special installation instructions, if any, will be noted in SECTION 6.