Intelligent Actuator RCON User manual

Catalog No. CE0264-1A (0619)

IAI Industrieroboter GmbH

Ober der Röth 4, D-65824 Schwalbach am Taunus, Germany

IAI (Shanghai) Co., Ltd.

Shanghai Jiahua Business Center A8-303, 808,

Hongqiao Rd., Shanghai 200030, China

IAI Robot (Thailand) Co., Ltd.

825 Phairojkijja Tower 7th Floor, Debaratana Rd.,

Bangna Nuea, Bangna, Bangkok 10260, Thailand

www.intelligentactuator.com

The information contained in this product brochure

may change without prior notice due to product improvements.

Please contact IAI for the latest information.

IAI America, Inc.

110 E. State Pkwy, Schaumburg, IL 60173 (800) 944-0333

1220 Kennestone Circle, Suite 108, Marietta, GA 30066 (888) 354-9470

US Headquarters: 2690 W. 237th Street, Torrance, CA 90505 (800) 736-1712

RCON

www.intelligentactuator.com

Gateway unit

PLC

Terminal unit

Actuator

Actuator Connectable

2-

axis

RCON is recommended for customers

who plan on using 2 axes or more.

Driver unit

22mm

is recommended for actuators with two axes or more.

Saves space inside

the control panel

Up to 2 axes of actuators can be connected to one RCON driver unit with 22mm width,

making it ideal for saving space in the control panel.

*3

*3 Minimum distance required for natural heat dissipation of the controller

PCON-CB x 16units

x 16-axis connection specication

1,010mm

223.4mm

30mm

179mm

115mm

Saves space by

85%

Up to 16 axes of actuators can be connected.

*1

16

axesmax.

8 driver units x 2 axes =

Driver unit x 16

*2 IAI product comparison

Saves up to 85% of control panel space.

*2

Select just as many

axes as necessary

*1 Actuator models

The maximum number of connectable axes diers

depending on (motor capacity / eld network

operation mode).

There will be no wasted space as driver units can be added in just the amount necessary.

Up to about 85% of control panel space can be saved, compared with models that connect a 1-axis actuator to a

single driver unit.

1

Gateway unit

PLC

Terminal unit

Actuator

Actuator Connectable

2-

axis

RCON is recommended for customers

who plan on using 2 axes or more.

Driver unit

22mm

is recommended for actuators with two axes or more.

Saves space inside

the control panel

Up to 2 axes of actuators can be connected to one RCON driver unit with 22mm width,

making it ideal for saving space in the control panel.

*3

*3 Minimum distance required for natural heat dissipation of the controller

PCON-CB x 16units

x 16-axis connection specication

1,010mm

223.4mm

30mm

179mm

115mm

Saves space by

85%

Up to 16 axes of actuators can be connected.

*1

16

axesmax.

8 driver units x 2 axes =

Driver unit x 16

*2 IAI product comparison

Saves up to 85% of control panel space.

*2

Select just as many

axes as necessary

*1 Actuator models

The maximum number of connectable axes diers

depending on (motor capacity / eld network

operation mode).

There will be no wasted space as driver units can be added in just the amount necessary.

Up to about 85% of control panel space can be saved, compared with models that connect a 1-axis actuator to a

single driver unit.

Gateway unit

PLC

Terminal unit

Actuator

Actuator Connectable

2-

axis

RCON is recommended for customers

who plan on using 2 axes or more.

Driver unit

22mm

is recommended for actuators with two axes or more.

Saves space inside

the control panel

Up to 2 axes of actuators can be connected to one RCON driver unit with 22mm width,

making it ideal for saving space in the control panel.

*3

*3 Minimum distance required for natural heat dissipation of the controller

PCON-CB x 16units

x 16-axis connection specication

1,010mm

223.4mm

30mm

179mm

115mm

Saves space by

85%

Up to 16 axes of actuators can be connected.

*1

16

axesmax.

8 driver units x 2 axes =

Driver unit x 16

*2 IAI product comparison

Saves up to 85% of control panel space.

*2

Select just as many

axes as necessary

*1 Actuator models

The maximum number of connectable axes diers

depending on (motor capacity / eld network

operation mode).

There will be no wasted space as driver units can be added in just the amount necessary.

Up to about 85% of control panel space can be saved, compared with models that connect a 1-axis actuator to a

single driver unit.

2

PCON-CB CC-Link specication x 16 units

PLC

PLC

Now, just one gateway is required.

Comparison example

For RCON

60% cost reduction

*4 IAI product comparison

*4

Reduces costs

by as much as 60% .

The conventional type ([Comparison example] below) requires network options installed to match the number of

controllers.

RCON can control driver units for up to 16 axes of actuators with a single gateway, allowing cost reductions up to

60% or so. It is especially recommended when using multiple axes.

A network option is required

for each controller.

CC-Link specication

high-output stepper

motor 16 axes

3

Can be connected to various eld networks.

PLC

Maintenance period reminders

Board replacement

period reminders

Rotation speed has dropped to 70%.

Fan unit

Driver unit

Actuator

Board replacement

period reminders

Fan replacement period reminders

Gateway unit

Capacitor capacitance has

dropped by 20%.

Capacitor life

sensor equipped

Capacitor life

sensor equipped

Patent

pending

Patent

pending

Capacitor capacitance has

dropped to 50%.

Motor temperature has exceeded

the set value due to motor overload,

grease depletion, wear on parts, etc.

Seven high-performance

functions that only IAI is

capable of delivering

High function

2

High function

1

Compatibility: No.1 in the industry with

seven eld network types supported

Predictive maintenance/preventative maintenance function

The RCON has a preventative maintenance function for the capacitor and a predictive maintenance function for the fan

unit and actuator.

Stop breakdowns

in advance!

PCON-CB CC-Link specication x 16 units

PLC

PLC

Now, just one gateway is required.

Comparison example

For RCON

60% cost reduction

*4 IAI product comparison

*4

Reduces costs

by as much as 60% .

The conventional type ([Comparison example] below) requires network options installed to match the number of

controllers.

RCON can control driver units for up to 16 axes of actuators with a single gateway, allowing cost reductions up to

60% or so. It is especially recommended when using multiple axes.

A network option is required

for each controller.

CC-Link specication

high-output stepper

motor 16 axes

4

Gateway unit

Fan unit

[RCON-FU]

Driver unit

Terminal unit

Connected axes

Controller interior

communication time

1~4-axis 1ms cycle

120

100

80

60

40

20

0

0 10 20 30 40 50 60

Operating temperature (°C)

With fan

Without fan

Install the optional fan unit to enable use in environments of 0 to 55°C without lowering actuator operating duty.

(one fan unit can be mounted across a driver unit and a terminal unit)

Controller interior communication time is 4ms even when 16 actuators are connected.

Controller interior communication time is 4ms cycle

PLC

5~9-axis 2ms cycle

10~14-axis 3ms cycle

15~16-axis 4ms cycle

Can also be easily

removed without

a tool.

(Retrotting is also

possible.)

High function

3

High function

4

Supports controller installation environment

temperatures of 0 to 55°C

Operating duty (%)

Field network

communication

5

Compatible with RCP2/3/4/5/6, RCA/2, RCD, RCL Series

Compatible with RCS2/3/4, IS(D)B, SSPA, LSA, NS, DDA Series

Large-capacity motor equipped actuator

RCON connection specication

SCON-CB/CGB

*

Expansion unit

(RCON-EXT)

Supports actuators equipped with a Battery-less absolute encoder as well as those with simple absolute and

incremental encoders.

When the SCON's RCON connection specication option (-RC) is selected, it can be connected to the RCON

expansion unit (RCON-EXT) to operate an actuator equipped with a large-capacity motor.

One RCON-EXT can connect to multiple SCON-CB controllers.

* IAI General Catalog product series / type model

Note that servo press actuator models, LSA-W21H, EC Series, SCARA robots,

TTA, ZR units and Wrist Units are not supported.

* As of December 2018

High function

5

No. 1 in the industry for number of supported actuators

(332 IAI actuator models ).

Connection cable CB-RE-CTL002

*Max. length 3m (CB-RE-CTLO30), total length

10m or less

Gateway unit

Fan unit

[RCON-FU]

Driver unit

Terminal unit

Connected axes

Controller interior

communication time

1~4-axis 1ms cycle

120

100

80

60

40

20

0

0 10 20 30 40 50 60

Operating temperature (°C)

With fan

Without fan

Install the optional fan unit to enable use in environments of 0 to 55°C without lowering actuator operating duty.

(one fan unit can be mounted across a driver unit and a terminal unit)

Controller interior communication time is 4ms even when 16 actuators are connected.

Controller interior communication time is 4ms cycle

PLC

5~9-axis 2ms cycle

10~14-axis 3ms cycle

15~16-axis 4ms cycle

Can also be easily

removed without

a tool.

(Retrotting is also

possible.)

High function

3

High function

4

Supports controller installation environment

temperatures of 0 to 55°C

Operating duty (%)

Field network

communication

6

All-axis motor power port

Single-axis motor power cuto

The following IAI 24V power supply (PSA-24) monitoring can be output to a PLC via RCON.

24V power supply (PSA-24)

*The graph is a reference image.

Output voltage Output current Power load factor Total energizing time

Internal temperature Low fan speed warning

Visualize power consumption

800

918[W]

[W]

600

400

200

0

0.5

Power supply peak power

Power supply rated power

Average power

1.0 1.5

[sec]

2.0 2.5

12[W]

0

Motor power cuto method can be selected.

Helps visualize equipment with 24V power monitor

PLC

Actuator single-axis

motor power cuto

Actuator all-axis

motor power cuto

Equipped with

communication

function to RCON

High function

6

High function

7

In accordance with customer safety function applications, the motor power (drive source) cuto method

at emergency stop can be selected through the RCON wiring method.

7

Each axis JOG (+/-) switch

USB port

Backward

Backward

Forward

Forward

Actuator

Home

(Coordinate: 0 mm)

Stroke end

Each axis brake release switch

Movable part

Actuator

Even without a teaching pendant or PC teaching software, each axis can be moved forward/backward.

Equipped with a brake release switch for each axis,

the movable parts can be moved by hand during

maintenance.

JOG switch enabled in manual mode, with PC software/

teaching pendant manual operation windows closed.

Connection to a PC is possible using

a commercial USB cable.

Dedicated cables are not required.

*Compatible with miniUSB (mini-B).

Forced brake

release

Enables easy start-up

and maintenance.

Movable

part

All-axis motor power port

Single-axis motor power cuto

The following IAI 24V power supply (PSA-24) monitoring can be output to a PLC via RCON.

24V power supply (PSA-24)

*The graph is a reference image.

Output voltage Output current Power load factor Total energizing time

Internal temperature Low fan speed warning

Visualize power consumption

800

918[W]

[W]

600

400

200

0

0.5

Power supply peak power

Power supply rated power

Average power

1.0 1.5

[sec]

2.0 2.5

12[W]

0

Motor power cuto method can be selected.

Helps visualize equipment with 24V power monitor

PLC

Actuator single-axis

motor power cuto

Actuator all-axis

motor power cuto

Equipped with

communication

function to RCON

High function

6

High function

7

In accordance with customer safety function applications, the motor power (drive source) cuto method

at emergency stop can be selected through the RCON wiring method.

8

<Selection example>

<Selection example>

SCON-CB

RCD RCP4 RCP2 RCA2 RCA2 RCP6

Controller Actuator

RCP2/3/4/5/6, RCA/2, RCD, RCL Series (24VDC)

<Selection example>

<24VDC>

<100/200VAC> ISB ISB

*Note that servo press actuator models, LSA-W21H, EC Series, SCARA robots, TTA, ZR units and Wrist Units cannot be connected.

Actuator selection

Selection Method

Step 1

Gateway unit selection

Select the gateway unit model from the network type.

Step 2

The actuator series are classied into two categories according to the table below.

<Selection example>

Gateway unit model

RCON-GW/GWG-DV

RCON-GW/GWG-CC

RCON-GW/GWG-CIE

RCON-GW/GWG-PR

RCON-GW/GWG-EC

RCON-GW/GWG-EP

RCON-GW/GWG-PRT

Network type

Select 1

Gateway unit

Gateway unit

16 axes of actuators can be connected to one gateway unit.

Gateway unit

+

×

Caution

RCD Series RCP4 Series RCP2 Series RCA2 Series RCA2 Series RCP6 Series ISB Series ISB Series

RCS2/3/4, IS(D)B, SSPA, LSA,

NS, DDA Series (100/200VAC)

Two

categories

Only one gateway unit can be connected per system.

When using two units or more, divide it into two.

One gateway

per system

* GW: Gateway unit of standard specications

GWG: Gateway unit of safety category type.

Contact IAI for additional safety category items (teaching pendant/TP adapter/

dummy plug/cable, etc.)

9

RCP4 RCP2

Actuator

External view Model Classication

Driver unit <Selection example>

RCON-PC-2

RCON-PC-1

RCON-PCF-1

RCON-AC-2

RCON-AC-1

RCON-DC-2

RCON-DC-1

1

1

-

1

-

-

1

2-axis specication

1-axis specication

1-axis specication

2-axis specication

1-axis specication

2-axis specication

1-axis specication

Stepper motor

RCP2

RCP3

RCP4

RCP5

RCP6

RCA

RCA2

RCL

2

5

10

20, 20S

30

RCD 3D

20P, 28P

35P, 42P

56P

56SP, 60P

86P

High thrust motor

Motor typeSeries

AC servo motor

DC brush-less motor

RCP6

RCA2 RCA2

RCD

2

*Connect to the RCON controller using a cable (CB-ADPC-MPA005).

The cable is supplied with the simple absolute unit.

Note: The ambient operating temperature of the simple absolute unit is within the range of 0~40°C.

* One simple absolute unit required per axis.

RCON-ABU-A RCON-ABU-P

Simple absolute unit selection

This is an example in which a 2-axis RCA2 Series actuator is selected for simple absolute specication.

<Selection example>

Driver unit Simple absolute unit

RCON-DC-1 RCON-PC-2 RCON-PC-1 RCON-AC-2 RCON-ABU-A x 2

Select 3

Driver unit selection

Step 3

Step 4

Select

2

Select

2

Select

2

Select

For actuators with simple absolute specication, select simple

absolute units (RCON-ABU-A/P) for the required number of axes.

Actuators to be made

compatible with

simple absolute

RCD

Series

RCP4

Series

RCP2

Series

RCP6

Series

RCA2

Series

RCA2

Series

Select the driver unit model number and required number of units according to the series name and motor type of the

actuator(s) to be connected to the RCON.

Number of axes

connected to actuator

Required

units

Simple absolute

battery

<Selection example>

<Selection example>

SCON-CB

RCD RCP4 RCP2 RCA2 RCA2 RCP6

Controller Actuator

RCP2/3/4/5/6, RCA/2, RCD, RCL Series (24VDC)

<Selection example>

<24VDC>

<100/200VAC> ISB ISB

*Note that servo press actuator models, LSA-W21H, EC Series, SCARA robots, TTA, ZR units and Wrist Units cannot be connected.

Actuator selection

Selection Method

Step 1

Gateway unit selection

Select the gateway unit model from the network type.

Step 2

The actuator series are classied into two categories according to the table below.

<Selection example>

Gateway unit model

RCON-GW/GWG-DV

RCON-GW/GWG-CC

RCON-GW/GWG-CIE

RCON-GW/GWG-PR

RCON-GW/GWG-EC

RCON-GW/GWG-EP

RCON-GW/GWG-PRT

Network type

Select 1

Gateway unit

Gateway unit

16 axes of actuators can be connected to one gateway unit.

Gateway unit

+

×

Caution

RCD Series RCP4 Series RCP2 Series RCA2 Series RCA2 Series RCP6 Series ISB Series ISB Series

RCS2/3/4, IS(D)B, SSPA, LSA,

NS, DDA Series (100/200VAC)

Two

categories

Only one gateway unit can be connected per system.

When using two units or more, divide it into two.

One gateway

per system

* GW: Gateway unit of standard specications

GWG: Gateway unit of safety category type.

Contact IAI for additional safety category items (teaching pendant/TP adapter/

dummy plug/cable, etc.)

10

For actuators to be connected to SCON-CB, select (1) to (3) below.

<Selection example>

x 1 unit

(1) Expansion unit (Model: RCON-EXT)

RCON expansion unit

RCON-EXT

max length 3m (030)

SCON-CB RC SCON-CB RC

<Selection example> I/O type

x 2 units

x Required number of units

Model: SCON- * - * * * - RC -*

Model: CB-RE-CTL

Total cable length may not exceed 10m

* 16 axes max.

* 100/200 VAC power supply for each SCON-CB RC

*

See P. 37

One cable (CB-ER-CTL002) is supplied as standard with SCON-CB for RCON connection.

(2) RCON connection specication SCON-CB

(3) RCON expansion unit to SCON-CB connection cable

Expansion unit selection

Step 5

4

Select

5

Select

RCON connection

specication

selected

Required for the number

of actuator axes to be

connected to SCON .

Must be separately

purchased only when

20 cm is too short.

When connecting SCON-CB and

RCON, one expansion unit is

required. One unit can connect to

multiple SCON-CB RC controllers.

Standard

accessory: 20 cm

Standard

accessory: 20 cm

SCON standard

accessory

SCON standard

accessory

11

Add up while checking the "Control Power Capacity List"below.

<Selection example>

<Selection example>

How to check

Gateway unit

Driver unit Simple absolute unitExpansion unit

RCON-DC-1 RCON-PC-2RCON-GW-CC RCON-EXT RCON-PC-1 RCON-AC-2 RCON-ABU-A x 2

RCD

SCON RCP4 RCP2 RCA2 RCA2RCP6

Without brake Without brake Without brakeWith brake

0.8A +0.1A + 0.2A + 0.2A + 0.4A + 0.2A +(0.2A x 2 axes)=2.3A < 9.0A

(Conrmed to be less than 9.0A. If larger than 9.0A, another gateway unit is required.)

Item Specications

Power supply voltage 24VDC±10%

Gateway unit (includes terminal unit) 0.8A

0.2A

0.4A

0.6A

0.1A

0.2A

Expansion unit

Simple absolute unit (common to all types)

Brake: No

Brake: Yes (1-axis specication)

Brake: Yes (2-axis specication)

x 1unit

x 1unit

x 1unit

x 2axes

Control power (CP)

( )

Control Power Capacity List

Calculating various unit control power capacities (CP)

Step 6

OK

Make sure that the total control power capacity of the

various units selected so far is within 9.0A.

Per driver unit

Gateway unit

Simple

absolute

specication

for 2 axes

Control power (CP)

9.0A or less

Control power

capacity (CP)

Driver unit

(common for

all types)

Current limit value

9.0A or less

For actuators to be connected to SCON-CB, select (1) to (3) below.

<Selection example>

x 1 unit

(1) Expansion unit (Model: RCON-EXT)

RCON expansion unit

RCON-EXT

max length 3m (030)

SCON-CB RC SCON-CB RC

<Selection example> I/O type

x 2 units

x Required number of units

Model: SCON- * - * * * - RC -*

Model: CB-RE-CTL

Total cable length may not exceed 10m

* 16 axes max.

* 100/200 VAC power supply for each SCON-CB RC

*

See P. 37

One cable (CB-ER-CTL002) is supplied as standard with SCON-CB for RCON connection.

(2) RCON connection specication SCON-CB

(3) RCON expansion unit to SCON-CB connection cable

Expansion unit selection

Step 5

4

Select

5

Select

RCON connection

specication

selected

Required for the number

of actuator axes to be

connected to SCON .

Must be separately

purchased only when

20 cm is too short.

When connecting SCON-CB and

RCON, one expansion unit is

required. One unit can connect to

multiple SCON-CB RC controllers.

Standard

accessory: 20 cm

Standard

accessory: 20 cm

SCON standard

accessory

SCON standard

accessory

12

Motor Power Capacity List

Actuator/driver unit

Item Motor typeSeries

Max. current

-

-

-

3.9A

-

3.3A

4.4A

4.4A

5.1A

4.0A

4.6A

6.4A

6.4A

1.5A

-

-

-

-

0.8A

1.9A

1.9A

2.3A

With PowerCON

20P/20SP/28P

56SP/60P/

86P

RCP2

RCP4

RCP5

RCP6

28P*

5W

10W

20W

20W(20S)

30W

2W

5W

10W

RCA

RCA2

RCL

RCD 3W

x 2axes

x 2axes

x 1axis

x 1axis

<Selection example>

Driver unitGateway unit

RCON-DC-1 RCON-PC-2RCON-GW-CC RCON-PC-1 RCON-AC-2

RCD

3W

Actuator

Series

Motor type

RCP4

28P

RCP2

20P

RCA2

20W

RCA2

20W

RCP6

35P

1.5A + 3.9A +0.8A + 3.9A +4.4A + 4.4A =

18.9A < 37.5A

(Conrmed to be less than 37.5A. If larger than 37.5A, another gateway unit is required.)

Stepper motor

RCON-PC

Stepper motor

RCON-PCF

AC servo motor

RCON-AC

DC brush-less motor

RCON-DC Standard

( )

How to check

28P/35P/42P/

42SP/56P

RCP4

RCP5

RCP6

5.7A

-

2.5A

2.5A

3.4A

2.2A

-

-

-

-

1.0A

1.3A

1.3A

1.7A

1.3A

0.8A

1.0A

1.3A

0.7A

-

* Applicable models: RCP2-RA3, RCP2-RGD3

Calculating various unit motor power capacities (MP)

Step 7 Gateway unit

OK

Make sure that the total motor power capacity of the driver units

selected so far is within 37.5A.

Add up while checking the "Motor Power Capacity List"below. If the

maximum current is listed, add the maximum current. If not, add the

rated current.

* Do not include the 100/200 VAC power supply to SCON-CB RC.

Rated

current

Motor power

capacity (MP)

Per 1-axis

actuator Standard / High

accel/decel /

Energy saving

Standard /

Hi-accel./decel.

Without

PowerCON

Without

PowerCON

Motor power (MP)

Current limit value

37.5 A or less

Motor power (MP)

37.5 A or less

<Selection

example>

When energy-

saving is set

Standard /

Hi-accel./decel.

RCP2

RCP3

Without

PowerCON

13

<Selection example>

<Selection example>

4 driver units ÷ 2 = 2 units Fan unit [RCON-FU]

1 6

Order using the model name for each unit.

Gateway unit (2 fan units included)

[RCON-GW-CC-FU2]

Expansion unit [RCON-EXT]

Driver unit [RCON-DC-1]

Driver unit [RCON-PC-2]

Driver unit [RCON-PC-1]

Driver unit [RCON-AC-2]

Simple absolute unit [RCON-ABU-A] x 2

RCON connection specication SCON

[SCON-*-***-RC] x 2

4

2

2

2

2

3

5

Fan unit selection

Step 8

Step 9 Unit models to be ordered

5 5

6 6

222241 1

3 3

6

Select

If the controller installation environment may exceed 40°C, a fan unit will be required. (Up to 55°C)

The number of fan units is the total number of driver units divided by 2.

If the total number of driver units is an odd number, add 1 to the total number and divide it by 2 (The last fan will connect to

the last driver card and the terminal unit).

When ordering, be sure to specify the gateway unit model.

Note: The ambient operating temperature of the simple absolute unit is

within the range of 0~40°C even when a fan unit is installed.

See pages 33 to 34 for applicable cables for each actuator.

Motor Power Capacity List

Actuator/driver unit

Item Motor typeSeries

Max. current

-

-

-

3.9A

-

3.3A

4.4A

4.4A

5.1A

4.0A

4.6A

6.4A

6.4A

1.5A

-

-

-

-

0.8A

1.9A

1.9A

2.3A

With PowerCON

20P/20SP/28P

56SP/60P/

86P

RCP2

RCP4

RCP5

RCP6

28P*

5W

10W

20W

20W(20S)

30W

2W

5W

10W

RCA

RCA2

RCL

RCD 3W

x 2axes

x 2axes

x 1axis

x 1axis

<Selection example>

Driver unitGateway unit

RCON-DC-1 RCON-PC-2RCON-GW-CC RCON-PC-1 RCON-AC-2

RCD

3W

Actuator

Series

Motor type

RCP4

28P

RCP2

20P

RCA2

20W

RCA2

20W

RCP6

35P

1.5A + 3.9A +0.8A + 3.9A +4.4A + 4.4A =

18.9A < 37.5A

(Conrmed to be less than 37.5A. If larger than 37.5A, another gateway unit is required.)

Stepper motor

RCON-PC

Stepper motor

RCON-PCF

AC servo motor

RCON-AC

DC brush-less motor

RCON-DC Standard

( )

How to check

28P/35P/42P/

42SP/56P

RCP4

RCP5

RCP6

5.7A

-

2.5A

2.5A

3.4A

2.2A

-

-

-

-

1.0A

1.3A

1.3A

1.7A

1.3A

0.8A

1.0A

1.3A

0.7A

-

* Applicable models: RCP2-RA3, RCP2-RGD3

Calculating various unit motor power capacities (MP)

Step 7 Gateway unit

OK

Make sure that the total motor power capacity of the driver units

selected so far is within 37.5A.

Add up while checking the "Motor Power Capacity List"below. If the

maximum current is listed, add the maximum current. If not, add the

rated current.

* Do not include the 100/200 VAC power supply to SCON-CB RC.

Rated

current

Motor power

capacity (MP)

Per 1-axis

actuator Standard / High

accel/decel /

Energy saving

Standard /

Hi-accel./decel.

Without

PowerCON

Without

PowerCON

Motor power (MP)

Current limit value

37.5 A or less

Motor power (MP)

37.5 A or less

<Selection

example>

When energy-

saving is set

Standard /

Hi-accel./decel.

RCP2

RCP3

Without

PowerCON

14

Model Specication Items

EXT ABU

RCON

SCON

RCON

RCON RCON

Type

Type

Type

Expansion Absolute Unit

RC 0

I/O Type

Motor Type Power Supply

Voltage

Number of

Axes

Type

Options

Encoder Type Options I/O Type I/O Cable Length

Series

Series

Series Series

GW Standard type

GWG Safety category spec type

PStepper motor

AAC servo motor

CC-Link connection specication

CC

CIE CC-Link IE Field connection specication

DV DeviceNet connection specication

EP EtherNet/IP connection specication

EC EtherCAT connection specication

PR PROFIBUS-DP connection specication

PRT PROFINET IO connection specication

1-axis specication

1

2-axis specication2

PC Stepper motor

PCF High thrust stepper motor

AC AC servo motor

DC DC brush-less motor

(1) Gateway unit

(5) SCON controller (RCON connection specication)

(2) Driver unit

(3) Expansion unit (4) Simple absolute unit

Type: PC

1.2A motor

1-axis

2-axis

20P

20SP

28P

35P

42P

42SP

56P

20stepper motor

20stepper motor (For RA2AC/RA2BC)

28stepper motor

35stepper motor

42stepper motor

42stepper motor (For RCP4-RA5C)

56stepper motor

Type: PCF

4A motor

1-axis

56SP

60P

86P

56high thrust stepper motor

60high thrust stepper motor

86high thrust stepper motor

Type: AC

2-30W motor

1-axis

2-axis

2

5

10

20

20S

30

2W servo motor

5W servo motor

10W servo motor

20W servo motor

20W servo motor (For RCA2-SA4/RCA-RA3)

30W servo motor

Type: DC

3D motor

1-axis

2-axis

3D 2.5W DC brush-less motor

(1)

(3) (4)

(2)

*Type: Only 1-axis can be selected for PCF

Fan unit mounting (: Specify the number of units, 1 ~ 8)FU

TRN Without terminal unit

* A terminal unit is required during operation.

* “-FU” can be deleted if fan unit is ordered separately.

Ex. RCON-GW-EP-FU2 is equal to RCON-GW-EP and RCON-FU (2 qty).

Contact IAI for model selection items

Only SCON-C RC option can be connected to RCON-EXT.

15

System Conguration

Field network

DeviceNet, CC-Link,

CC-Link IE Field, EtherCAT,

EtherNet/IP,

PROFIBUS-DP, PROFINET IO

RCON connection

specication

SCON controller

[I/O type: RC]

(Please contact IAI for

more details)

PC teaching software

(See P. 30)

<Model: IA-OS>

<Model: RCM-101-MW/USB>

Options

24 V power supply

(See P. 31)

<Model: PSA-24(L)>

Options

Connection cable

(See P. 37)

<Model: CB-RE-CTL002>

Supplied with SCON-CB (RC specication)

Drive source shuto connector

(See P. 32)

<Model: DFMC1.5/2-STF-3.5>

Supplied with driver unit

System I/O connector

(See P. 32)

<Model: DFMC1.5/

5-ST-3.5>

Included with gateway

unit

Connection cable

(See P. 35)

<Model:

CB-ADPC-MPA005>

Supplied with simple absolute unit

Terminal connector

(See P. 31)

<Model: RCON-EXT-TR>

Supplied with expansion unit

Options

Touch panel teaching

pendant

(See P. 30)

Options

Fan unit

(See P. 32)

<Model: RCON-FU>

Options

Simple absolute unit

(See P. 25)

<Model: RCON-ABU-P

(For stepper motor)>

<Model: RCON-ABU-A

(For AC servo motor)>

Motor/encoder cable*

RCS2/3/4

Series

Connectable actuators

100/200VAC 24VDC

RCP2/3/4/5/6 Series RCA/2 Series RCD SeriesDDA Series

LSA Series

IS(D)B Series

SSPA Series

* Refer to page 25 for actuators that

cannot be connected.

*The 100/200 VAC motor/encoder cable is supplied with the actuator.

The motor/encoder cables are dierent according to the actuator type to be connected.

Refer to page 33 if conversion cables need to be prepared.

Supplied with GWG specication

Dummy plug

(See P. 32)

<Model: DP-5>

For IA-OS: USB cable

For RCM-101:

Supplied with PC teaching

software

<Model: TB-02><Model: TB-03>

16

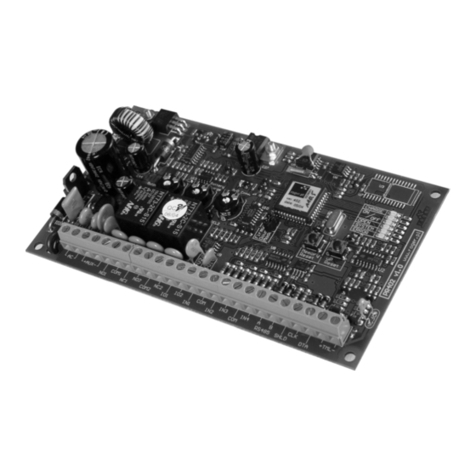

System CongurationUnit Conguration

The RCON has a modular conguration. Connect each unit under the following conditions.

Gateway unit Driver unit Terminal unitExpansion unit

Unit name Number of connected units Location

Gateway unit 1 Placed at far left

Expansion unit 1 Placed to right of gateway unit

Driver unit 16 axes max.*Placed to left of terminal unit

Terminal unit 1 Placed at far right

Product name Model Reference page

Gateway unit

(GWG: Safety category type)

DeviceNet connection specication RCON-GW/GWG-DV P. 20

CC-Link connection specication RCON-GW/GWG-CC P. 20

CC-Link IE Field connection specication RCON-GW/GWG-CIE P. 21

PROFIBUS-DP connection specication RCON-GW/GWG-PR P. 21

EtherCAT connection specication RCON-GW/GWG-EC P. 22

EtherNet/IP connection specication RCON-GW/GWG-EP P. 22

PROFINET IO connection specication RCON-GW/GWG-PRT P. 23

Expansion unit

For SCON-CB connection RCON-EXT P. 25

Terminal connector (for SCON-CB) RCON-EXT-TR P. 32

Driver unit

Stepper motor 1-axis specication RCON-PC-1

P. 24

Stepper motor 2-axis specication RCON-PC-2

High thrust stepper motor 1-axis specication RCON-PCF-1

AC servo motor 1-axis specication RCON-AC-1

AC servo motor 2-axis specication RCON-AC-2

DC brush-less motor 1-axis specication RCON-DC-1

DC brush-less motor 2-axis specication RCON-DC-2

Terminal unit Included with gateway unit RCON-GW-TR P. 25

Simple absolute unit

(1-axis specication)

For RCON-PC RCON-ABU-P

P. 25

For RCON-AC RCON-ABU-A

Fan unit One for every two driver units RCON-FU P. 32

* · Driver units can be rearranged.

· The maximum number of connectable axes varies depending on the operation mode.

For details, refer to “Maximum number of connectable axes (page 26)”.

Unit name and single product model number list

17

General Specications

Item Specications Details page

Power supply voltage 24VDC ±10% -

Power supply current Differs with system conguration P. 19

Number of axes controlled 1 to 16 axes *For maximum axes, refer to “Maximum number of connectable axes” P. 26

Encoder resolution

[pulse/r]

Stepper motor

Incremental 800

-

Battery-less Absolute

RCP4/RCP5 800

RCP6 8192

AC servo motor

Incremental

RCA

800

Battery-less Absolute 16384

Incremental

RCA2-***N/NA 1048

Excluding RCA2-***N/NAN 800

DC brush-less motor Incremental

RCD-RA1R/GRSN 400

RCD-RA1DA/GRSNA 480

Supported eld networks DeviceNet, CC-Link, CC-Link IE Field, PROFIBUS-DP,

EtherCAT, EtherNet/IP, PROFINET IO

Conguration units Gateway unit, driver unit, expansion unit,

simple absolute unit P. 20

SIO interface

Teaching port

Communication method RS485

-

Communication speed 9.6/19.2/38.4/57.6/115.2/230.4kbps

USB port

Communication method USB

Communication speed 12Mbps

Emergency stop/Enable operation Collective system support with gateway unit STOP signal input, equipped with connectors capable of

shutting off the drive power supply to individual axes of each driver unit -

Data recording device Position data and parameters are saved in non-volatile memory

(Unlimited rewrites) -

Calendar function Retention function: About 10 days Charging time: About 100 hours -

Safety category compliance B (The safety category specication supports up to category 4 external circuits) -

Protection functionality Overcurrent, abnormal temperature, encoder disconnection, overload -

Preventative/predictive maintenance

function Low electrolytic capacitor capacity and low fan rotation speed -

Ambient operating temperature 0~55°C *0~40°C for simple absolute units -

Ambient operating humidity 85% RH or less, non-condensing -

Operating atmosphere Avoid corrosive gas and excessive dust -

Vibration resistance Frequency: 10~57Hz / Amplitude: 0.075mm, Frequency: 57~150Hz / Acceleration: 9.8m/s2

XYZ directions Sweep time: 10 minutes Number of sweeps: 10 times -

Shock resistance Drop height: 800mm 1 corner, 3 edges, 6 faces -

Electric shock protection mechanism Class III -

Degree of protection IP20 -

Insulation withstanding voltage 500VDC 10MΩ -

Generated heat

(per unit)

RCON-PC

PowerCON: No 5.0W

-

PowerCON: Yes 8.0W

RCON-PCF PowerCON: No 19.2W

RCON-AC Standard / High accel/decel / Energy saving 4.5W

RCON-DC Standard 3.0W

Cooling method Natural cooling and forced cooling by fan unit (option) -

Connections between each unit Unit connection method -

Installation/mounting method DIN rail (35mm) mounting -

Regulations/standards CE Marking, UL Certication (planned), RoHS -

18

Power Capacity

Item Specications

Power supply voltage 24VDC±10%

Control power capacity

(per unit)

Gateway unit

(includes terminal unit) 0.8A

Driver unit

(common for all types)

Brake: No 0.2A

Brake: Yes (1-axis specication) 0.4A

Brake: Yes (2-axis specication) 0.6A

Expansion unit 0.1A

Simple absolute unit (common to all types) 0.2A

Motor power capacity

(per 1-axis actuator)

Actuator/driver unit

Rated

current

Max. current

Series Motor type When energy-

saving is set

Stepper motor/

RCON-PC

RCP2

RCP3

20P/20SP/28P

Without PowerCON

0.8A - -

28P*1.9A - -

RCP4

RCP5

RCP6

28P/35P/42P/

42SP/56P

Without PowerCON 1.9A - -

With PowerCON 2.3A - 3.9A

Stepper motor/

RCON-PCF

RCP2

RCP4

RCP5

RCP6

56SP/60P/86P Without PowerCON 5.7A - -

AC servo motor/

RCON-AC

RCA

RCA2

5W Standard / Hi-accel./decel. 1.0A - 3.3A

10W

Standard / High accel/decel /

Energy saving

1.3A 2.5A 4.4A

20W 1.3A 2.5A 4.4A

20W(20S) 1.7A 3.4A 5.1A

30W 1.3A 2.2A 4.0A

RCL

2W

Standard / Hi-accel./decel.

0.8A - 4.6A

5W 1.0A - 6.4A

10W 1.3A - 6.4A

DC brush-less motor/

RCON-DC RCD 3W Standard 0.7A - 1.5A

Item Current limit value

Control power 9.0A or less

Motor power 37.5A or less

Based on the connection conguration, make sure for each unit that the calculated results for control power and

motor power do not exceed the current limit value for selection calculation.

Power supply capacity by unit

· For operation patterns where acceleration/deceleration operation is performed simultaneously on all axes, and where

operating duty is 100%: Motor power must be calculated at the maximum current value.

(If the maximum current is not listed, calculate with the rated current.)

Caution

* Applicable models: RCP2-RA3, RCP2-RGD3

* Do not include the power supply to SCON-CB RC.

19

Table of contents

Popular Control System manuals by other brands

Conviron

Conviron CMP6050 Operator's manual

Toshiba

Toshiba BMS-SM1280HTLE Service manual

Balboa

Balboa Revolution System Overview Manual

Mountz

Mountz E-DRIV MD-Series CALIBRATION PROCEDURE

Idex

Idex Knight ILCS EDGE installation manual

Magnetic Autocontrol

Magnetic Autocontrol MAGSTOP MBE35 operating instructions