Faulhaber MC 3603 S User manual

WE CREATE MOTION

Technical Manual

MC 3603 S

EN

Imprint

2

Version:

1st edition, 20.04.2021

Copyright

by Dr. Fritz Faulhaber GmbH & Co. KG

Daimlerstr. 23 / 25 · 71101 Schönaich

All rights reserved, including those to the translation.

No part of this description may be duplicated, reproduced,

stored in an information system or processed or

transferred in any other form without prior express written

permission of Dr. Fritz Faulhaber GmbH & Co. KG.

This document has been prepared with care.

Dr. Fritz Faulhaber GmbH & Co. KG cannot accept any

liability for any errors in this document or for the

consequences of such errors. Equally, no liability can be

accepted for direct or consequential damages resulting

from improper use of the equipment.

The relevant regulations regarding safety engineering

and interference suppression as well as the requirements

specified in this document are to be noted and followed

when using the software.

Subject to change without notice.

The respective current version of this technical manual is

available on FAULHABER's internet site:

www.faulhaber.com

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Content

3

1 About this document ....................................................................................................... 5

1.1 Validity of this document ...................................................................................... 5

1.2 Associated documents ............................................................................................ 5

1.3 Using this document .............................................................................................. 5

1.4 List of abbreviations ............................................................................................... 6

1.5 Symbols and designations ...................................................................................... 7

2 Safety ................................................................................................................................ 8

2.1 Intended use ........................................................................................................... 8

2.2 Safety instructions .................................................................................................. 9

2.2.1 Dangers in the event of damages and changes.................................... 9

2.2.2 Correct installation and commissioning ................................................ 9

2.2.3 Heat development ................................................................................ 10

2.3 Environmental conditions .................................................................................... 10

2.4 EC directives on product safety ........................................................................... 11

3 Product description ........................................................................................................ 12

3.1 General product description ................................................................................ 12

3.2 Product information ............................................................................................. 13

3.3 Product variants .................................................................................................... 13

3.3.1 MC 3603 S RS/CO ................................................................................... 14

3.3.1.1 MC 3603 S RS/CO connector pin assignment........................ 15

3.3.1.2 Connection option 6889 for DC-motors with encoders

IE2, IEH2, IEH3, IEH3 L ............................................................ 21

3.3.1.3 Connection option 6890 for DC-motors with encoders

IE3, IE3 L ................................................................................. 26

3.3.2 MC 3603 S ET ......................................................................................... 30

3.3.2.1 Connector pin assignment of MC 3603 S ET extended

version .................................................................................... 32

3.3.2.2 Connection option 6889 for DC-motors with encoders

IE2, IEH2, IEH3, IEH3 L............................................................ 39

3.3.2.3 Connection option 6890 for DC-motors with encoders

IE3, IE3 L ................................................................................. 44

4 Installation ...................................................................................................................... 48

4.1 Mounting .............................................................................................................. 48

4.1.1 Mounting instructions .......................................................................... 48

4.1.2 Attachment via the side plates ............................................................ 49

4.1.3 Installation with top-hat rail clips........................................................ 50

4.2 Electrical connection ............................................................................................ 51

4.2.1 Notes on the electrical connection ...................................................... 51

4.2.2 Drive connections.................................................................................. 52

4.2.3 Connection of the power supply ......................................................... 53

4.2.3.1 Power supply.......................................................................... 53

4.2.4 I/O circuit diagrams ............................................................................... 54

4.2.5 External circuit diagrams ...................................................................... 55

4.3 Electromagnetic compatibility (EMC) .................................................................. 59

4.3.1 Considered systems ............................................................................... 59

4.3.2 Functional earthing .............................................................................. 61

4.3.3 Cable routing ........................................................................................ 62

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Content

4

4.3.4 Shielding................................................................................................ 63

4.3.4.1 Establishing the shield connection ....................................... 64

4.3.4.2 Establishing shield connection with cable lug ..................... 65

4.3.5 Sensor and encoder interfaces ............................................................. 66

4.3.5.1 Analog sensors and analog Hall sensors .............................. 67

4.3.5.2 Incremental encoders / Digital Hall sensors / Digital sensors 67

4.3.5.3 Encoders with absolute interface ......................................... 67

4.3.6 Using filters ........................................................................................... 67

4.3.6.1 Mounting arrangement (example: top-hat rail/DIN rail) .... 68

4.3.6.2 PWM filter (motor-side) ........................................................ 68

4.3.6.3 Emission-reducing, ferrite-based filters (motor side) .......... 68

4.3.6.4 Input-side filters..................................................................... 69

4.3.6.5 Insulation resistance .............................................................. 69

4.3.6.6 Coiling ferrite ring ................................................................. 69

4.3.7 Error avoidance and troubleshooting ................................................. 70

5 Maintenance and diagnostics ........................................................................................ 72

5.1 Maintenance instructions .................................................................................... 72

5.2 Maintenance tasks ................................................................................................ 72

5.3 Diagnosis ............................................................................................................... 72

5.4 Troubleshooting ................................................................................................... 73

6 Accessories ...................................................................................................................... 74

7 Warranty ......................................................................................................................... 75

8 Additional documents .................................................................................................... 76

8.1 Declaration of Conformity ................................................................................... 76

8.2 Declaration of Incorporation ............................................................................... 78

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

About this document

5

1 About this document

1.1 Validity of this document

This document describes the installation and use of the FAULHABER MC 3603 S series.

This document is intended for use by trained experts authorised to perform installation and

electrical connection of the product.

All data in this document relate to the standard versions of the series listed above. Changes

relating to customer-specific versions can be found in the corresponding data sheet.

1.2 Associated documents

For certain actions during commissioning and operation of FAULHABER products additional

information from the following manuals is useful:

These manuals can be downloaded in pdf format from the web page

www.faulhaber.com/manuals.

1.3 Using this document

Read the document carefully before undertaking configuration, in particular chapter

“Safety”.

Retain the document throughout the entire working life of the product.

Keep the document accessible to the operating and, if necessary, maintenance person-

nel at all times.

Pass the document on to any subsequent owner or user of the product.

Manual Description

Motion Manager 6 Operating instructions for FAULHABER Motion Manager PC software

Quick start guide Description of the first steps for commissioning and operation of FAULHABER Motion

Controllers

Drive functions Description of the operating modes and functions of the drive

Accessories manual Description of the accessories

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

About this document

6

1.4 List of abbreviations

Abbreviation Meaning

AC Alternating Current

AnIn Analog input

AGND Analog Ground

CAN_L CAN-Low

CAN_H CAN-High

CLK Clock

CS Chip Select

DigIn Digital input

DigOut Digital output

EFC Electronics Filter Conformity

EFM Electronics Filter Motor

EFS Electronics Filter Supply

EMC Electromagnetic compatibility

ESD Electrostatic discharge

ET EtherCAT (Ethernet for Control Automation Technology)

GND Ground

PLC Programmable Logic Controller

PWM Pulse Width Modulation

RxD Receive Data

TTL Transistor Transistor Logic

TxD Transmit data

NMT CANopen network management

RTR Remote Request

OD Object dictionary

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

About this document

7

1.5 Symbols and designations

DANGER

DANGER

!

Danger with high level of risk: if not avoided, death or serious injury will result.

Measures for avoidance

WARNING

WARNING

!

Danger with medium level of risk: if not avoided, death or serious injury may result.

Measures for avoidance

CAUTION

CAUTION

!

Danger with low level of risk: if not avoided, minor or moderate injury may result.

Measures for avoidance

NOTICE

NOTICE

Risk of damage.

Measures for avoidance

Pre-requirement for a requested action

1. First step for a requested action

Result of a step

2. Second step of a requested action

Result of an action

Request for a single-step action

Instructions for understanding or optimizing the operational procedures

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Safety

8

2 Safety

2.1 Intended use

The Motion Controllers described here are designed for use for control and positioning

tasks for the following motors:

DC-motors

Linear DC-Servomotors

Brushless DC-motors

The Motion Controllers described here are designed for use as slaves for control and posi-

tioning tasks for the following motors:

DC-motors

Linear DC-Servomotors

Brushless DC-motors

The Motion Controller is suitable in particular for tasks in the following fields of applica-

tion:

Robotics

Toolbuilding

Automation technology

Industrial equipment and special machine building

Medical technology

Laboratory technology

When using the Motion Controllers the following aspects should be observed:

The Motion Controller contains electronic components and should be handled in

accordance with the ESD regulations.

Do not use the Motion Controller in environments where it will come into contact with

water, chemicals and/or dust, nor in explosion hazard areas.

The Motion Controller is not suitable for use in combination with stepper motors.

The Motion Controller should be operated only within the limits specified in the data

sheet.

Please ask the manufacturer for information about use under individual special

environmental conditions.

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Safety

9

2.2 Safety instructions

In addition to the safety risks described in this technical manual, machine-specific dangers

could arise that cannot be foreseen by the manufacturer of the Motion Controller (e.g., risk

of injury from driven components). The manufacturer of the machine in which the Motion

Controller is installed must perform a risk analysis in accordance with the regulations appli-

cable to the machine and inform the end user of the residual risks.

2.2.1 Dangers in the event of damages and changes

Damage to the Motion Controller can impair its functions. A damaged Motion Controller

can unexpectedly start, stop or jam. This can result in damage to other components and

materials.

Do not start up a drive system with a defective or damaged Motion Controller.

Appropriately mark a defective or damaged Motion Controller.

Do not replace defective or damaged components of the Motion Controller.

Make no changes (modifications, repairs) to the Motion Controller.

Have loose or defective connections immediately replaced by an electrician.

After replacing a defective or damaged Motion Controller, test and document the cor-

rect function.

2.2.2 Correct installation and commissioning

Errors during the installation and commissioning of the Motion Controller could impair its

function. An incorrectly installed Motion Controller can unexpectedly start, stop or jam.

This can result in damage to other components and materials.

Follow the instructions for installation and commissioning given in these installation

instructions exactly.

Only have work on electrical operating equipment performed by an electrician.

During all work on the electrical equipment, observe the 5 safety rules:

a) Disconnect from power

b) Secure against being switched on again

c) Check that no voltage is present

d) Ground and short-circuit

e) Cover or block-off adjacent parts that are under voltage

Electrostatic discharges can damage the electronics.

Store and transport the Motion Controller in suitable ESD packaging.

Handle the Motion Controller in compliance with the ESD handling regulations (e.g.

wear an ESD wristband, ground surrounding components).

During installation, ensure that components in the surroundings cannot be electrostat-

ically discharged.

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Safety

10

Soiling, foreign bodies, humidity and mechanical influences can damage the electronics.

Keep foreign objects away from the electronics.

Install the Motion Controller in a housing that protects it from mechanical influences

and is adapted to the ambient conditions (protection class determination).

Installation and connection work while supply voltage is applied at the device can damage

the electronics.

Do not insert or withdraw connectors while supply voltage is applied at the Motion

Controller.

During all aspects of installation and connection work on the Motion Controller, switch

off the power supply.

Incorrect connection of the pins can damage the electronic components.

Connect the wires as shown in the connection assignment.

2.2.3 Heat development

Active components may cause the Motion Controller to heat up. If touched, there is a risk of burn-

ing.

Protect the Motion Controller against being touched and cool sufficiently.

If necessary, affix a suitable warning sign in the immediate vicinity of the controller.

Fig. 1: Suitable warning sign acc. to DIN EN ISO 7010

2.3 Environmental conditions

Select the installation location so that clean dry air is available for cooling the Motion

Controller.

Select the installation location so that the air has unobstructed access to flow around

the drive.

When installed within housings and cabinets take particular care to ensure adequate

cooling of the Motion Controller through the base plate.

Select a power supply that is within the defined tolerance range.

Protect the Motion Controller against heavy deposits of dust, in particular metal dust

and chemical pollutants.

Protect the Motion Controller against humidity and wet.

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Safety

11

2.4 EC directives on product safety

The following EC directives on product safety must be observed.

If the Motion Controller is being used outside the EU, international, national and

regional directives must be also observed.

Machinery Directive (2006/42/EC)

The controllers with attached motor described in this technical manual may be drive sys-

tems according to the Machinery Directive. They are therefore to be considered incomplete

machines according to the Machinery Directive. Compliance is documented by the Declara-

tion of Incorporation for the product and by the EC Declaration of the Conformity.

EMC Directive (2014/30/EU)

The directive concerning electromagnetic compatibility (EMC) applies to all electrical and

electronic devices, installations and systems sold to an end user. In addition, CE marking can

be undertaken for built-in components according to the EMC Directive. Conformity with

the directive is documented in the Declaration of Conformity.

Applied standards

Various harmonised standards were applied to the products described in this technical

manual; these standards are documented in the EC Declaration of Conformity. You can find

the Declaration of Incorporation for the product and the EC Declaration of Conformity in

chap. 8, p. 76.

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

12

3 Product description

3.1 General product description

The MC 3603 S products are unhoused versions of the FAULHABER Motion Controllers and

control either DC, LM or BL motors. The Motion Controllers are configured here via the

FAULHABER Motion Manager software V6 (version 6.8 and higher).

The drives can be operated in the network via the CANopen or EtherCAT fieldbus interface.

In smaller setups, networking can also be performed via the RS232 interface. The Motion

Controller operates in the network in principle as a slave; master functionality for actuating

other axes is not provided. After basic commissioning via Motion Manager, the controllers

can alternatively also be operated without communication interface.

The controllers are secured to a flat base plate via the mounting holes. With optional acces-

sories, mounting is also possible on a DIN rail.

The output stages are exchangeable and are matched to the various sizes and types of

motors, i.e. DC, BL and LM motors from 13 – 42 mm, as listed in the FAULHABER product

portfolio.

The following connections are available on the supply side:

Communications interfaces

Common or separate power supplies between motor and controller

Various inputs and outputs

The following connections are available on the motor side, depending on the product com-

bination:

Motor phases

Feedback components such as:

Digital/analog Hall sensors

Incremental encoders with or without line drivers.

Absolute encoder with BiSS-C or SSI interface.

Not all options of the BiSS-C interface are supported by FAULHABER Motion Control-

lers of the V3.0 series. Before using encoders from other manufacturers, clarify the

compatibility with FAULHABER Support.

Motion Controllers with RS232, CANopen or EtherCAT interface can also be operated

independently of the communications interface if a pre-programmed function or

sequence program has been programmed without digital command controls.

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

13

3.2 Product information

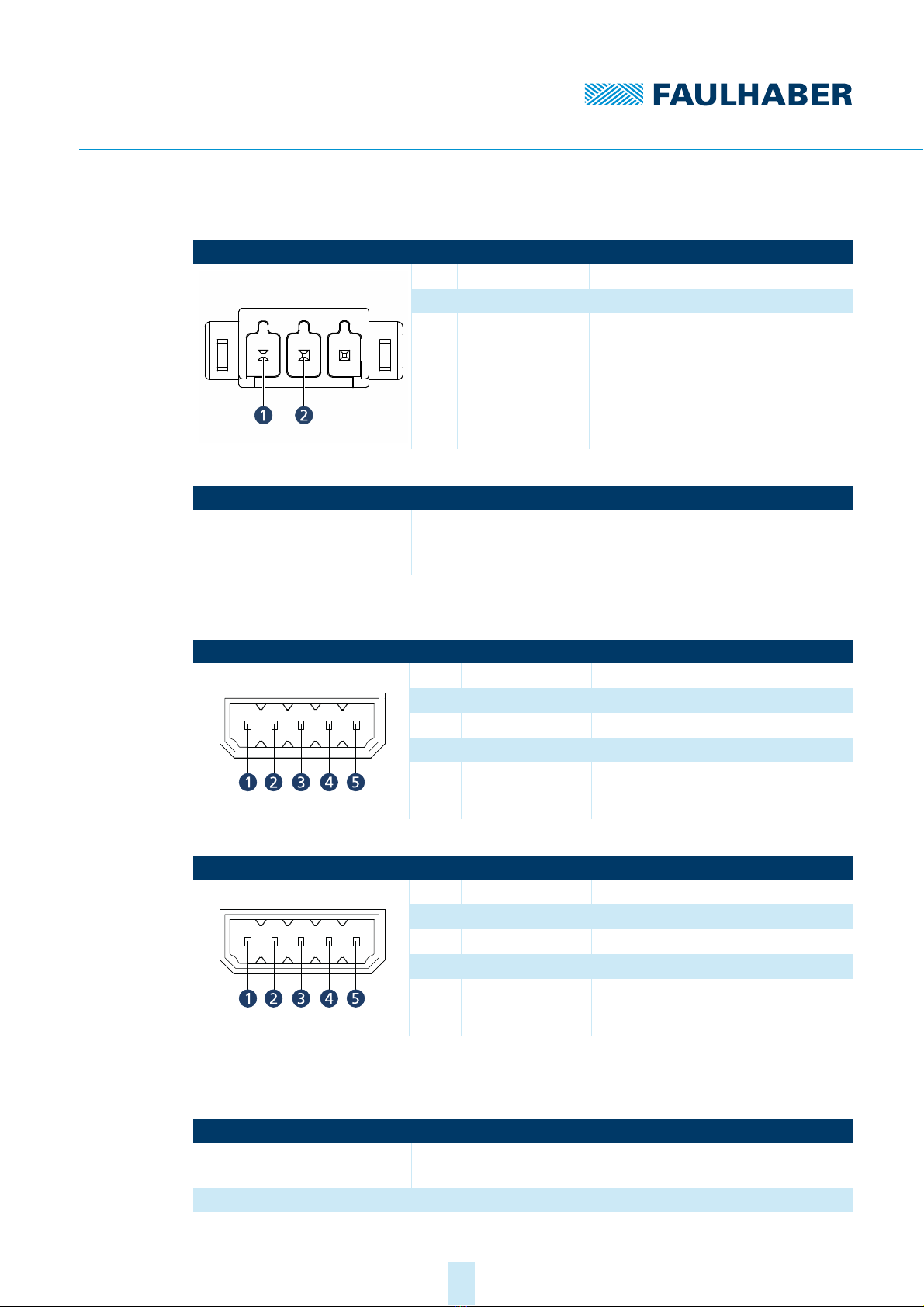

Fig. 2: Designation key

3.3 Product variants

The unhoused variant of the Motion Controller is available in 2 versions.

MC 3603 S RS/CO, see chap. 3.3.1, p. 14

MC 3603 S ET, see chap. 3.3.2, p. 30

In addition to the standard variants, the Motion Controllers can be connected to other

encoder combinations by means of product options:

MC 3603 S RS/CO with connection option 6889 for DC-motors with encoders IE2, IEH2,

IEH3, IEH3L, see chap. 3.3.1.2, p. 21

MC 3603 S RS/CO with connection option 6890 for DC-motors with encoders IE3, IE3 L,

see chap. 3.3.1.3, p. 26

MC 3603 S ET with connection option 6889 for DC-motors with encoders IE2, IEH2, IEH3,

IEH3L, see chap. 3.3.2.2, p. 39

MC 3603 S ET with connection option 6890 for DC-motors with encoders IE3, IE3 L, see

chap. 3.3.2.3, p. 44

…

MC

RS:

CO:

S:

0:3

MC:

36:

36 S

ET:

03

Serial interface RS232

Interface CANopen

Interface EtherCAT

Controller with pin terminals

Max. continuous output current 3 A

Max. power supply 36 V

Motion Controller

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

14

3.3.1 MC 3603 S RS/CO

The MC 3603 S RS/CO Motion Controllers can be addressed via either the RS232 interface or

via the CANopen interface. The USB interface is available in all devices.

Fig. 3: MC 3603 S RS/CO standard version

M2

M1

M3

S1

X1X2X3

1

1

2

1

S2

1

2

1

1

1C

2

3

O

N

Status

57

40 max. 26

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

15

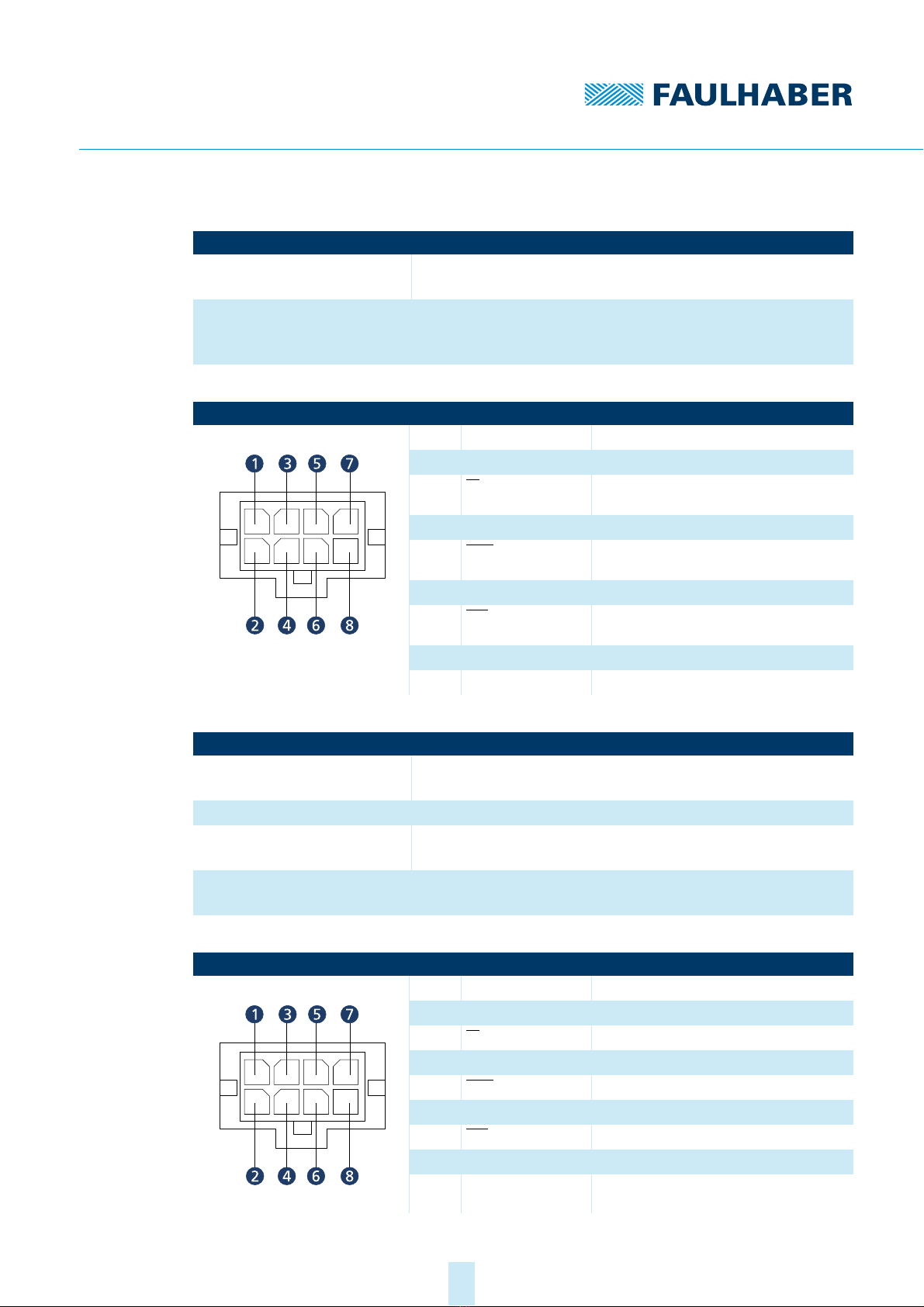

Tab. 1: Connector overview and DIP switch

Tab. 2: LED overview

3.3.1.1 MC 3603 S RS/CO connector pin assignment

Motor connection (M1)

Tab. 3: Pin assignment of the BL motor connection (M1)

Tab. 4: Electrical data of the motor connection (M1)

Designation Function

M1 (motor) Connection of the motor phases

M2 (sensor) Connection of the Hall sensors

M3 (encoder) Connection of an incremental encoder with or without line driver. Alternatively an absolute

encoder can be connected with or without line driver.

X1 (USB) USB interface connection

X2 (COM) CAN/RS232 interface connection

X3 (I/O) Voltage supply of the controller and motor, inputs or outputs for external circuits

S1 (DIP switch

COM)

Selection of the COM interface:

C: CAN

Otherwise: RS232

S2 (DIP switch

Encoder Term)

Encoder terminal resistance:

Encoder with line driver: S2-1, S2-2 and S2-3 in ON position

Encoder without line driver: S2-1, S2-2 and S2-3 in OFF position

Designation Function

State LED Green (continuous light): Device active.

Green (flashing): Device active. However the state machine has not yet reached the Operation

Enabled state.

Red (continuously flashing): The drive has switched to a fault state. The output stage will be

switched off or has already been switched off.

Red (error code): Booting has failed. Please contact FAULHABER Support.

Pin Designation Meaning

1 Motor A Connection of motor, phase A

2Motor B Connection of motor, phase B

3 Motor C Connection of motor, phase C

Designation Value

Motor power supply 0...Umot

Max. 9 A

100 kHz

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

16

Tab. 5: Pin assignment of the DC motor connection (M1)

Tab. 6: Electrical data of the DC motor connection (M1)

Sensor connection (M2)

Tab. 7: Pin assignment at sensor connection (M2) for 3 Hall sensor signals

Tab. 8: Pin assignment at sensor connection (M2) for sin/cos sensor

Only in combination with sin/cos sensors on FAULHABER LM motors or BX4 motors in sin/cos

special version.

Tab. 9: Electrical data of the sensor connection (M2)

Pin Designation Meaning

1 Motor + Connection of motor, positive pole

2Motor – Connection of the motor, negative pole

Designation Value

Motor power supply 0...Umot

Max. 9 A

100 kHz

Pin Designation Meaning

1U

DD Power supply for sensors

2GND Ground connection

3 Sens A Hall sensor A

4Sens B Hall sensor B

5 Sens C Hall sensor C

Pin Designation Meaning

1U

DD Power supply for sensors

2GND Ground connection

3 COS(+) Cosine signal

4SIN(+) Sine signal

5n.c. –

Designation Value

Sensor power supply 5 V

<100 mA

Sensor connection <5 V

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

17

Encoder connection (M3)

The pin assignment of the encoder connector varies depending on the encoder type.

Incremental encoder with or without line driver

Absolute encoder with or without line driver.

The encoder model is selected in the configuration of the Motion Controller during com-

missioning.

With DIP switch S2, a 120 Ωterminating resistor can be activated for each signal.

Tab. 10: Pin assignment for incremental encoder with line driver (M3)

Tab. 11: Electrical data for incremental encoder with line driver (M3)

Tab. 12: Pin assignment for incremental encoder without line driver (M3)

Pin Designation Meaning

1U

DD Power supply for incremental encoder

2GND Ground connection

3ChannelA Encoder channel A (logically inverted sig-

nal)

4Channel A Encoder channel A

5ChannelB Encoder channel B (logically inverted sig-

nal)

6Channel B Encoder channel B

7Index Encoder index (logically inverted signal)

8Index Encoder index

Designation Value

Power supply for incremental

encoder

5V

<100 mA

Connection of the incremental

encoder

<5 V

<2 MHz

5kΩ

Pin Designation Meaning

1U

DD Power supply for incremental encoder

2GND Ground connection

3ChannelA n.c.

4Channel A Encoder channel A

5ChannelB n.c.

6Channel B Encoder channel B

7Index n.c.

8Index Encoder index

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

18

Tab. 13: Electrical data for incremental encoder without line driver (M3)

Tab. 14: Pin assignment for absolute encoder with line driver (M3)

Tab. 15: Electrical data for absolute encoder with line driver (M3)

Tab. 16: Pin assignment for absolute encoder without line driver (M3)

Designation Value

Power supply for incremental

encoder

5V

<100 mA

Connection of the incremental

encoder

<5 V

<2 MHz

5kΩ

Pin Designation Meaning

1U

DD Power supply for absolute encoder

2GND Ground connection

3CS Chip Select for absolute encoder (logically

inverted signal)

4CS Chip Select for absolute encoder

5Data Data for absolute encoder (logically

inverted signal)

6Data Data for absolute encoder

7CLK Clock for absolute encoder (logically

inverted signal)

8CLK Clock for absolute encoder

Designation Value

Absolute encoder power supply 5 V

<100 mA

Connection Chip Select 5V

Connection data <5 V

5kΩ

Connection clock 5V

1MHz

Pin Designation Meaning

1U

DD Power supply for absolute encoder

2GND Ground connection

3CS n.c.

4CS Chip Select for AES

5Data n.c.

6Data Data for AES

7CLK n.c.

8CLK Clock for AES

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

19

Tab. 17: Electrical data for absolute encoder without line driver (M3)

USB (X1)

Tab. 18: USB port

COM port (X2)

The pin assignment of the COM connection differs according to the type of communication.

The distinction is made between the following types of communication:

RS232

CANopen

The interface is selected with DIP switch S1.

Tab. 19: Pin assignment of the COM port (X2) for RS232

Tab. 20: Pin assignment of the COM port (X2) for CANopen

Designation Value

Absolute encoder power supply 5 V

<100 mA

Connection Chip Select 5V

Connection data <5 V

5kΩ

Connection clock 5V

1MHz

Designation Meaning

USB communication (USB micro B)

Pin Designation Meaning

1 TxD RS232 interface transmit direction

2RxD RS232 interface receive direction

3 GND Ground connection

Pin Designation Meaning

1 CAN-H CAN-High interface

2CAN-L CAN-Low interface

3 GND Ground connection

1st edition, 20.04.2021 7000.05072, 1st edition, 20.04.20217000.05072

Product description

20

I/O connection (X3)

Tab. 21: Pin assignment of the I/O connection (X3)

Tab. 22: Electrical data for the I/O connection (X3)

Pin Designation Meaning

1U

DD Power supply for external consumer loads

2GND Ground connection

3 DigOut 1 Digital output (open collector)

4DigOut 2 Digital output (open collector)

5 DigIn 1 Digital input

6DigIn 2 Digital input

7 DigIn 3 Digital input

8AnIn 1 Analog input

9 AnIn 2 Analog input

10 AGND Ground connection for analog inputs

11 UpPower supply of the electronics

12 GND Ground connection

13 Umot Power supply of the motor

14 GND Ground connection

Designation Value

Power supply for external consum-

ers

5V

<100 mA

DigOut low = GND

high = high resistance

27 kΩ

Max. 0.7 A

DigIn <30 V

27 kΩ

<1 MHz

TTL level: low < 0.5 V, high > 3.5 V a)

PLC level: low < 7 V, high > 11.5 V

a) The switching thresholds are set in the configuration of the Motion Controller during commissioning.

AnIn ±10 V

Reference potential: AGND

Power supply for controller 6…36 V

≤100 mA (without external consumer)

Motor power supply 6…36 V

1 3 5 7 9 11 13

2 4 6 8 10 12 14

Table of contents

Other Faulhaber Control System manuals

Popular Control System manuals by other brands

Lutron Electronics

Lutron Electronics homeworks qs Installation checklist

Chamberlain

Chamberlain EL1SS REPAIR PARTS INSTRUCTIONS

Johnson Controls

Johnson Controls FC-2000 introduction

Fagor

Fagor CNC 8070 Hardware configuration

Chromalox

Chromalox MaxPac series user manual

Mitsubishi Electric

Mitsubishi Electric AE-200A Instruction book