Intelligent Energy FCPM User manual

2.4kW UAV Fuel Cell

Power Module

User Manual

Users must read all instructions provided and retain the manual for future reference

Document No. 10010371

2Glossary

This is the user manual for the 2.4kW Fuel Cell Power Module (FCPM)

designed and manufactured by Intelligent Energy.

Users of this product must follow the instructions and warnings laid out in

this user manual at all times and must be aware of the hazards present when

using high pressure ammable gas products and high voltage electronics.

This User Manual is intended as a general guidance only and does not purport

to address the specic situations that could potentially arise from the use of

fuel cell systems and their usage in connection with UAVs. The recipient is

responsible for ensuring that all personnel have read and understood this

User Manual before being allowed to handle, operate, install and store any

equipment supplied by Intelligent Energy.

The recipient must ensure that any personnel responsible for handling

hydrogen cylinders and operating UAVs are suitably trained and certied in

compliance with any applicable local, state and federal laws and regulations

and good industry practice. The recipient is responsible for complying with

any relevant health and safety policies and procedures that may apply to

the operation of UAVs and use and storage of hydrogen on any sites.

Intelligent Energy warrants to the recipient and it will repair and replace any

defective equipment resulting from the authorised use of the equipment

provided. Notwithstanding the above, Intelligent Energy, to the fullest extent

permitted by law, accepts no liability (including liability in respect of any error

or defects in the fuel cell system and UAVs) for any damage caused as a result

of recipient’s unauthorised use of the equipment provided. The recipient

acknowledges that the manner in which the equipment is stored, used or

operated is not under the control of Intelligent Energy Limited. Intelligent

Energy has made every eort to ensure that this User Manual is accurate and

disclaims liability for any inaccuracies or omissions that may have occurred.

Federal Communications Commission (FCC) Statement

This equipment has been tested and found to comply with the limits for a Class A

digital device, pursuant to part 15 of the FCC rules. These limits are designed to

provide reasonable protection against harmful interference in a residential

installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by

turning the equipment o and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit dierent from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

This device complies with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

(1) this device may not cause harmful interference and

(2) this device must accept any interference received, including interference

that may cause undesired operation. You are cautioned that changes or

modications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

CE Marking Statement

The CE label shows that the product complies with the basic requirements of

the applicable directives. For the declaration of conformity contact the

Glossary of terms

Term Denition

Function or

Description

FCPM Fuel Cell Power

Module

The entire fuel

cell system

SPM (1&2) Stack Power Module There are two SPMs

housing the two fuel

cell stacks and

associated power

electronics

PCM Power Control

Module

Digital and analogue

HMI ports, micro SD

card and regulator

interface, part of

centre module

BDM Battery Diagnostic

Module

Not currently used

POM Power Output

Module

Centrally located

board where battery

connections and

output power

connections are

made. Part of centre

module

UART Universal

Asynchronous

Receiver/Transmitter

UART’s main purpose

is to transmit and

receive serial data

CAN Controller Area

Network A & B

Communication

protocol

LW Light Weight Light Weight

Regulator

HFLW High Flow Light

Weight

High Flow Light

Weight Regulator

3Contents

1 Safety warnings 4

2 Key components 5

2.1 Product specication 5

2.2 System diagram 6

3 Assembly 9

3.1 Connecting output power cables 9

3.1.1 Disconnecting SPMs from central module 10

3.1.2 Connecting SPM to central module 11

3.2 Mounting 12

3.2.1 Mounting point information 12

3.2.2 Mounting dimensions 13

3.3 Air ow restrictions 13

3.3.1 Electronics air ow 13

3.3.2 SPM cooling fans 14

4 Hydrogen connection 14

4.1 Connector specication 14

4.2 Hydrogen specication 14

4.3 Hydrogen High Flow Light Weight (HFLW) Regulator 15

4.4 Connecting the FCPM and HFLW Regulator 15

5 Electrical connections 16

6 Operating the FCPM 17

6.1 Startup using the Start button 17

6.2 Startup using digital signal 17

6.3 Shutdown using the Start button 17

6.4 Shutdown using digital signal 17

6.5 Monitoring of data output 17

6.6 Software update procedure 18

6.7 Conguration update procedure 18

6.8 LED states 18

7 Logging and data connections 19

7.1 SD card formatting 19

7.2 SD card data format 19

7.3 Conguration format 19

7.3.1 Conguration parameter denitions 19

7.4 UART format 20

7.5 CAN format 21

7.5.1 CAN data to FCPM 21

7.5.1 CAN Data sent by FCPM 22

8 Electrical considerations 24

8.1 Battery charge limits 24

8.2 Emergency battery usage 24

8.3 Specifying a battery 24

8.4 Specifying a hybrid battery cable 24

9 Storage and maintenance 25

9.1 User maintenance 25

9.2 Recommended storage 25

10 Troubleshooting 26

10.1 Fault codes 26

10.2 Contact Product Support 26

11 End of life treatment and disposal 26

12 Appendix 27

12.1 Connector specications 27

12.1.1 Regulator Interface [Port No 10] 27

12.1.2 HMI Analogue/Digital [Port No 9] 27

12.1.3 UART and CAN [Port No 8] 28

12.1.4 Battery diagnostics module

(Battery Volts or CVM) [Port No 6&7] 28

12.1.5 FCPM In [Port No 4] 28

12.1.6 FCPM Out [Port No 5] 28

12.2 Fault codes 29

12.2.1 PCM fault codes 29

12.2.1 SPM1 & 2 fault codes 32

41 Safety warnings

• Only qualied technicians trained in high pressure ammable gases must carry out

tting of regulators and lling of cylinders and do so in accordance with local laws

and Health and Safety (H&S) regulations.

• The customer is responsible for ensuring all technicians and pilots are suitably

trained, accredited and operate in compliance with local laws and H&S regulations.

• The customer is responsible for ensuring the safe operation of the FCPM in line with

the User Manual at all times.

• This device requires oxygen to operate.

• A minimum of 1m3/min of oxygen is required for operation.

• Up to of 20m3/min air is required for cooling.

• FCPM not to be used in dusty, smoky or corrosive gas environments.

• Do not use FCPM in rain or snow.

• During integration there is a risk of exposed electrical conductors.

• Pressurised hydrogen present. Highly ammable!

• Do not operate the FCPM if the casing is damaged or missing.

• FCPM should be inspected for damage and checked for leaks prior to use.

• Do not transport the FCPM with the hydrogen supply connected.

• Do not remove casing from Module

• Do not use this FCPM if any part has been immersed or ooded with water.

Immediately call the manufacturer or manufacturer’s representative to inspect

the FCPM and to replace any functional part that has been aected.

52 Key components

2.1 Product specication

Power characteristics Maximum continuous fuel cell power 2400W

Peak power with default battery

Maximum power with suitable battery (not to be exceeded)

4800W

8000W

Output voltage (congurable, regulated and steady output) 40 – 70V

Fuel Cell Power Module (FCPM) dimensions 130 × 430 × 230mm

Other characteristics Mass 4400g

Light weight hydrogen regulator mass 250g

Maximum regulator (cylinder) pressure 300Bar

(4350PSI)

Output pressure 0.7Bar ± 0.25Bar

(10PSI ± 3PSI)

Hydrogen consumption rate g/hr @ 2.4kW 160-190g/hr

Hybrid batteries Two default hybrid batteries (congurable) 2 × 6S in series

Dimensions (per battery) 130 × 40 × 40mm

Mass (per battery) 535g

Capacity (per battery) 3300mAh

Environmental

operating conditions

Startup temperature +5°C to 40°C

Operating temperature -5°C to 40°C

Storage temperature -10°C to 70°C

System warranty 1000hrs

Safety features Dual redundant power system and backup battery

Other features Internal data storage for rmware update, performance and

diagnostics SD card communication port; to UAV FCPM or

accessories UART/CAN

FCPM is not IP rated

Output electrical connector M8 ring terminal/AS150

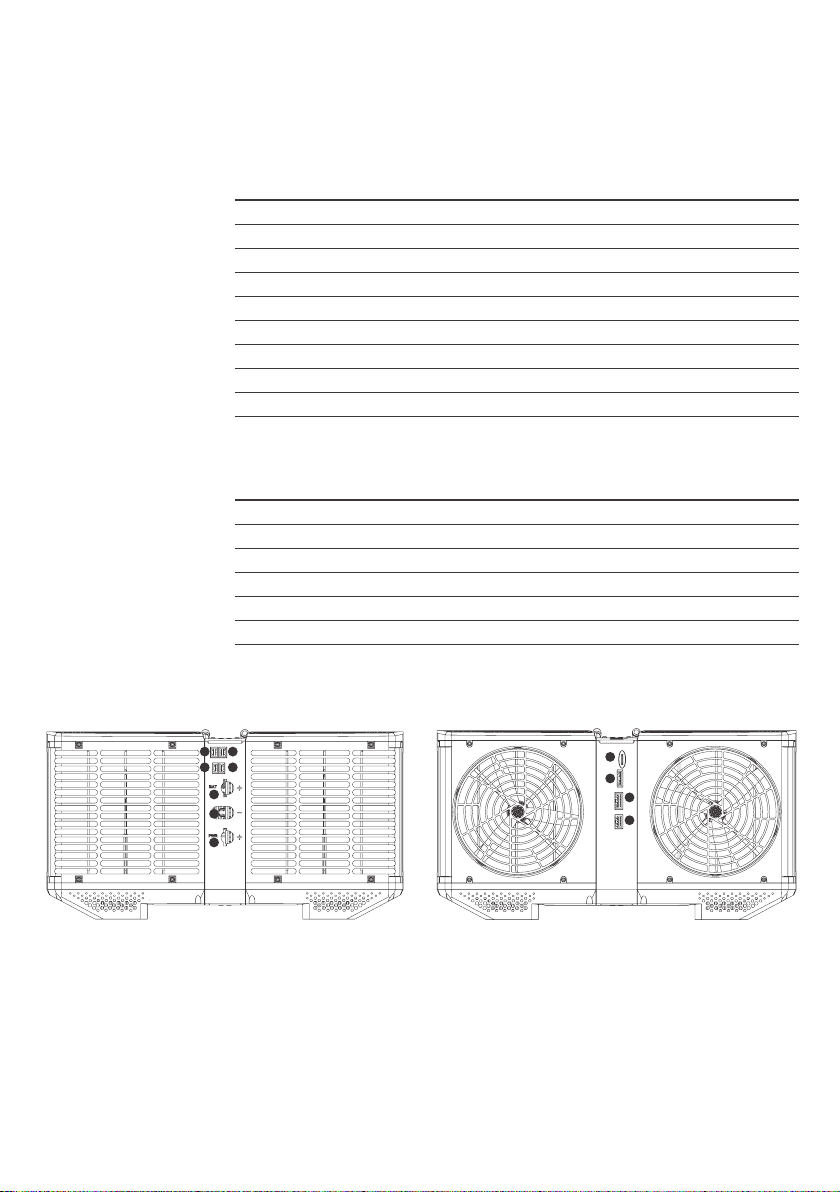

62 Key components

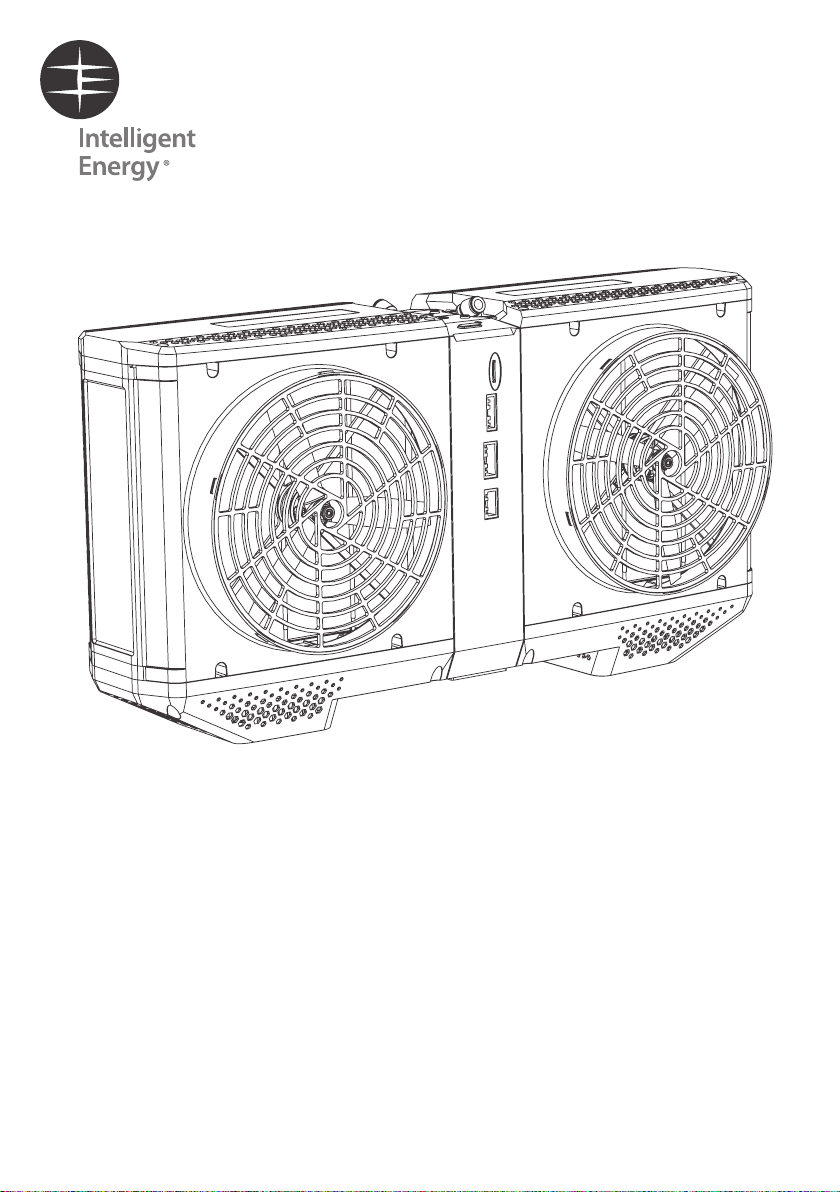

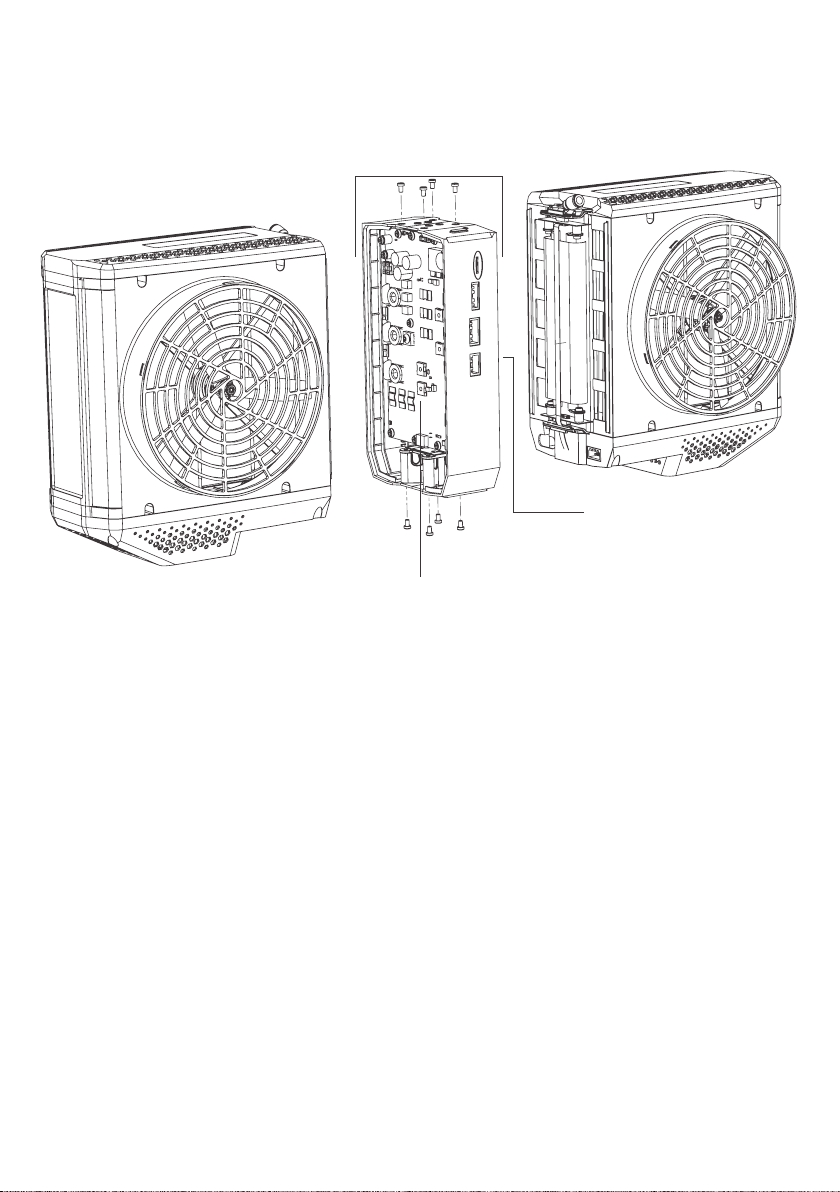

2.2 System diagram

Stack Power Module 1 (SPM 1) Power Output Module

(POM)

FCPM exploded rear view

Central Module

Power Control Module (PCM)

Stack Power Module 2 (SPM 2)

72 Key components

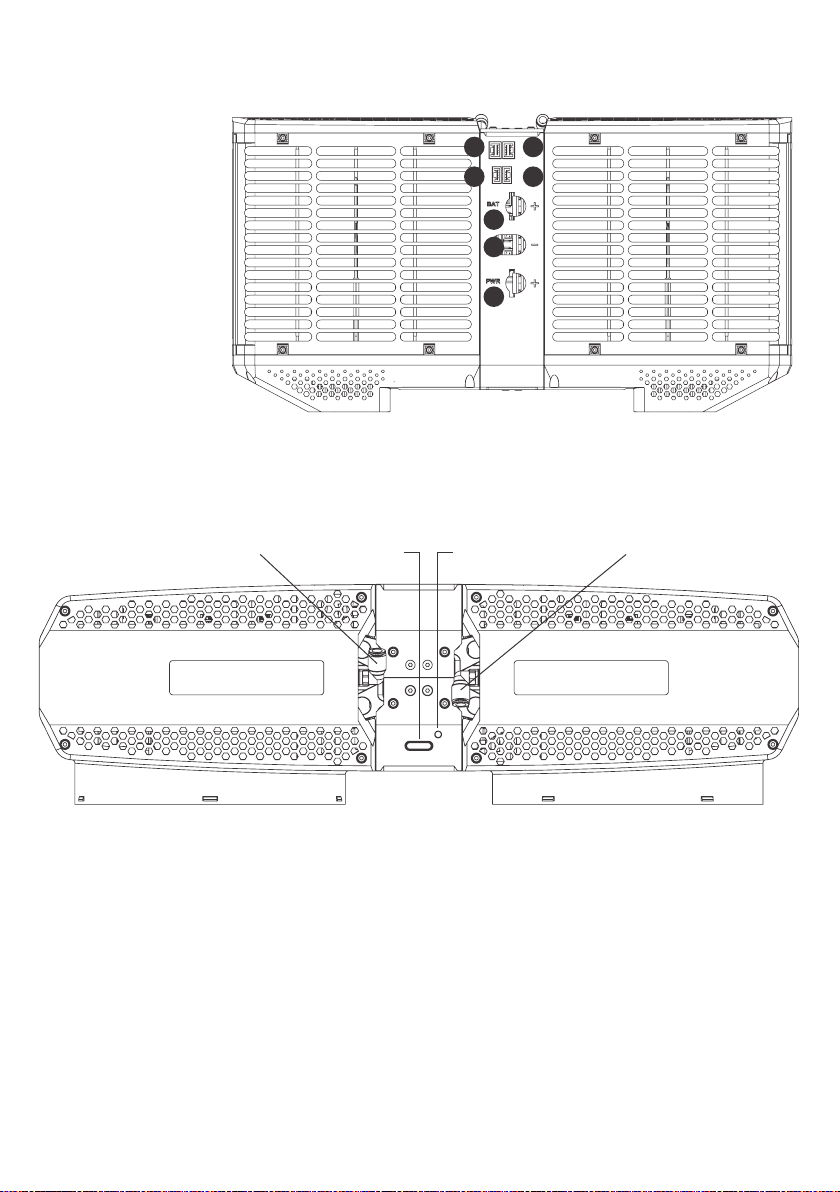

SPM 1 Hydrogen Inlet SPM 2 Hydrogen Inlet

1. Ground

2. Positive Output

3. Battery Positive

4. FCPM In

5. FCPM Out

6. Battery Diagnostic

Module (BDM) 2

7. Battery Diagnostic

Module (BDM) 1

Start Button Status LED

Fuel Cell Power Module (FCPM) Front view

FCPM Top View

SPM 2

SPM 1 Central Module

Central Module SPM 1

SPM 2

6

3

1

2

7

4 5

82 Key components

8. HMI (UART/CAN)

9. HMI (Digital/Analogue)

10. Regulator Interface

11. SD Card

SPM 1 Electronics Cooling Fan SPM 2 Electronics Cooling Fan

Power Control

Module (PCM)

FCPM Rear View

Bottom View

SPM 2 Central Module SPM 1

11

10

9

8

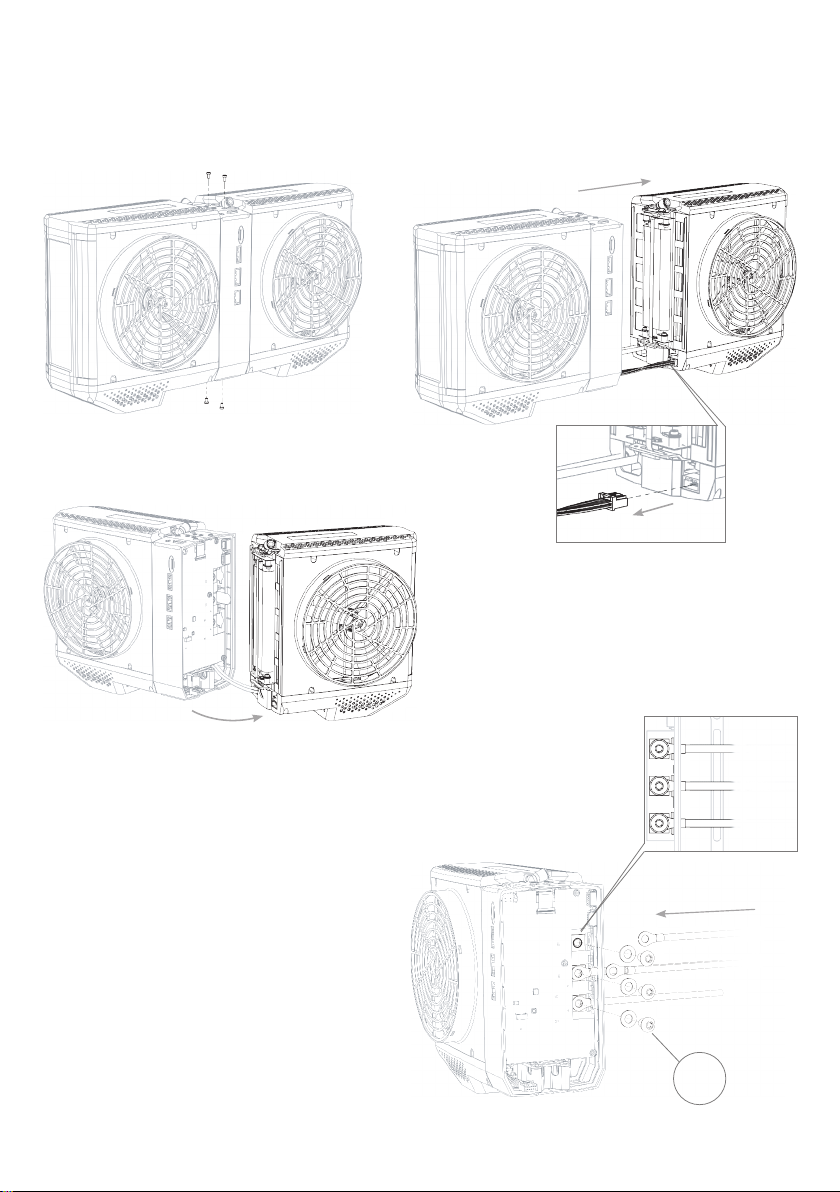

93 Assembly

3.1 Connecting output power cables

The output power leads can be connected to the FCPM once the PCM has

been disconnected.

Note All the power leads require an M8 ring terminal to attach to the POM.

1. Ensure battery is isolated from the cables before connecting to the POM,

use a suitable connector between battery and ring terminals for the power

rating of the application.

2. Complete the steps to open the FCPM section 3.1.1.

3. Feed the cable through the housing, connect battery positive M8 Ring

to ‘Batt +’ and battery negative to common ground ‘GND’.

4. Connect load positive to ‘PWR +’ and load negative to common ground ‘GND’.

5. Use the bottom terminal with an M8 button head screw to attach the cable

(max. torque 1.5Nm).

6. Feed the cable through the housing, battery positive (connector 3).

7. Use the top terminal with an M8 button head screw to attach the cable

(max. torque 1.5Nm).

8. Feed both the battery negative cable and the output negative cable through

the housing, ground (connector 1).

9. Use the middle terminal with an M8 button head screw to attach the cable

(max. torque 1.5Nm).

10. Once the cables are in place reconnect the SPM as in section 3.1.2.

Note The negative stud is common to the battery and output

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * Steps 1-3 in reverse

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * Steps 1-3 in reverse

STEP 1 STEP 2

STEP 4

STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity

* Steps 1-3 in reverse

10 3 Assembly

3.1.1 Disconnecting SPMs from central module to allow power connection

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * S

teps 1-3 in reverse

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * Steps 1-3 in reverse

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * Steps 1-3 in reverse

STEP 1 STEP 2

STEP 4 STEP 5

STEP 3

BAT +

GND x2

PWR +

1.5 N/m

* SPM 2 removed for clarity * Steps 1-3 in reverse

113 Assembly

3.1.2 Connecting SPM to central module

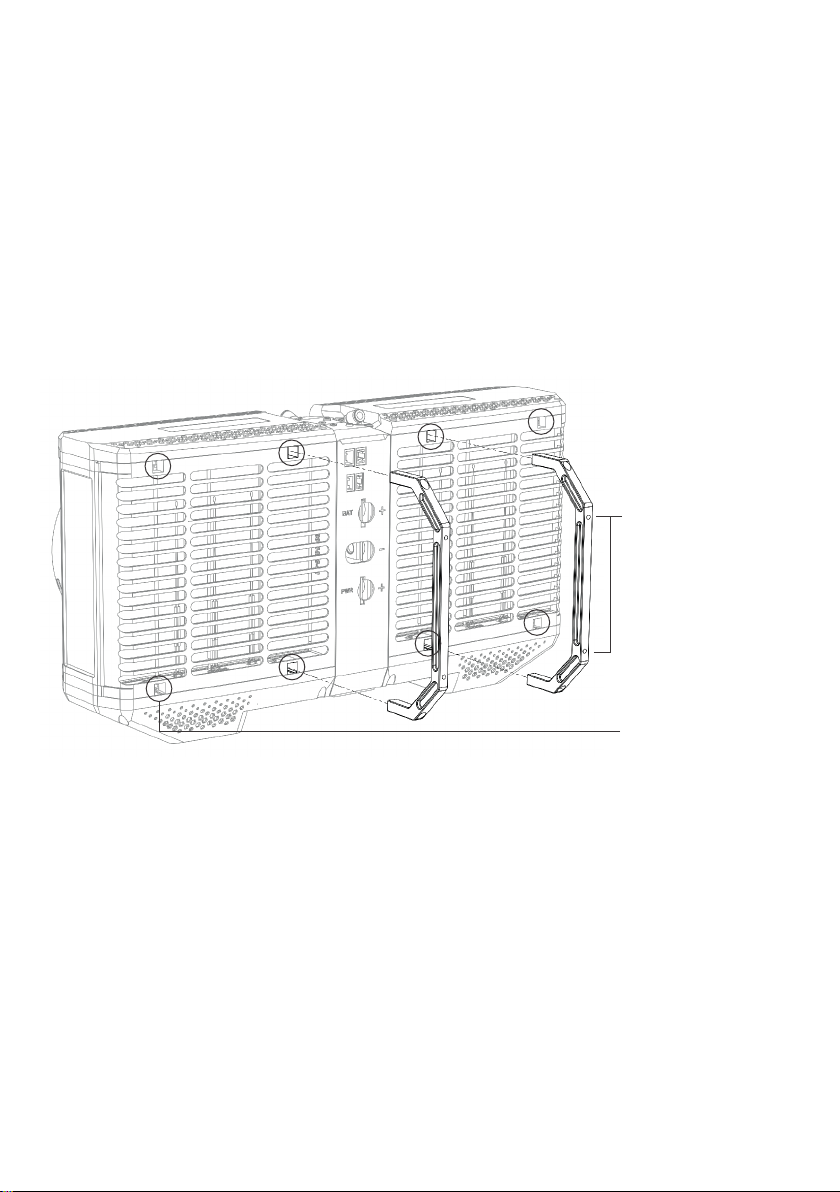

12 3 Assembly

3.2 Mounting

3.2.1 Mounting point information

Each SPM has four mounting points which accept an M3 thread. Mounting brackets

are provided which can be xed to the SPMs and have two M4 through holes for

customer use. The complete assembly must have a minimum of two mounting

brackets in total. Each SPM must have at least one support.

Recommended mounting points on the system are labelled in the gure below.

Two optional mounting brackets are included. These can be used to aid integration

and can be attached to any of the labelled mounting points.

The 2.4kW unit must be securely attached to the vehicle or test xture.

Mounting bracket: 2x M4

tapped threads per bracket

Mounting bracket: 8x M3 x 5mm

threaded holes per system

131,0

363,0

168,0

100,0

116,0

34,0

133 Assembly

3.2.2 Mounting dimensions

The locations of the mounting points are shown in the diagram below:

3.3 Air ow restrictions

3.3.1 Electronics air ow

Up to 1m3/min of airow is required to the power electronics located at the bottom of

each SPM. Do not cover the vents when mounting, airow must not be blocked when

operating the FCPM.

SPM 1 Power electronics fans

Do not cover

SPM 2

14 3 Assembly

4 Hydrogen connection

3.3.2 SPM cooling fans

The two mounting brackets are included to aid the creation of an air gap. This is

required to allow up to a 20m3/min of airow through the FCPM. It is important

to have an even airow distribution to both SPMs allowing the system to work

eciently, if the air is being recirculated a minimum of 1m3/min of supplemental

oxygen is required.

4.1 Connector specication

The hydrogen is supplied to each SPM via 6mm OD x 4mm ID push t tube.

A hydrogen compatible material with anti-static and low hydrogen permeability

is required.

Recommended tubing: 6mm OD x 4mm ID, anti-static, polyurethane

SMC TAU0604B-20

4.2 Hydrogen specication

When installing and operating hydrogen systems, hydrogen general safety guidance

should be considered:

ISO/TR 15916 – basic considerations for the safety of hydrogen systems for more

detailed information.

The hydrogen purity should comply with the specication in the table below:

Fuel Characteristics Fuel Requirements

Hydrogen concentration > 99.90%

Nitrogen, Helium, Argon < 0.10%

Oxygen < 50ppm

Carbon Dioxide < 2ppm

Carbon Monoxide < 0.2ppm

Ammonia < 0.1ppm

Sulphur containing compounds < 4ppb

Max particle concentration < 1mg/kg

Max particle diameter < 75µm

Refuelling Port

Hydrogen Output Port

Pressure Relief Valve

Pressure Transducer

Burst Disc

Cylinder Thread

154 Hydrogen connection

4.3 Hydrogen High Flow Light Weight (HFLW) Regulator

The 2.4kW FCPM is designed to be operated with an Intelligent Energy HFLW Regulator.

Note The FCPM could be permanently damaged if operated with incorrect hydrogen

inlet pressure or insucient hydrogen ow.

4.4 Connecting the FCPM and HFLW Regulator

The HFLW Regulator is designed to be connected to an Intelligent Energy FCPM.

Please refer to the Light Weight (LW) Regulator user manual for details of how to

mount the Regulator to the cylinder. The HFLW regulator gas connections are

identical to the LW Regulator so may be used for reference.

https://www.intelligent-energy.com/uploads/product_guides/53527_IE_-_

Lightweight_Hydrogen_Regulator_User_Manual_August_2019.pdf

Note Ensure the hydrogen cylinder and FCPM are securely mounted

before proceeding.

1. Verify the connector O-rings are in place

and free from damage or debris.

2. Align the hose connector path with

the regulator pins.

3. Push the hose connector and twist anti-clockwise.

It will click when located.

16 5 Electrical connections

In order to function, the FCPM must have the following attached to the unit.

See section 2.2 for reference to connection locations.

Connection No. Description Comments

1Output negative Common ground

1Battery negative Common ground

2Output positive Output is live once battery connected

3Battery positive Ensure battery has isolating connector

8HMI UART/CAN At least one HMI interface must be in place

9HMI Analogue/Digital At least one HMI interface must be in place

10 Regulator interface

H2 SPM1 Hydrogen in 1 Hydrogen connection SPM1

H2 SPM2 Hydrogen in 2 Hydrogen connection SPM2

Current ports that are not used or are optional for operation are:

Connection No. Description Comments

4FCPM Out Do not use – If connected unit is slave

5FCPM In Do not use – unit is master if not connected

6Battery diagnostics out Do not use

7Battery diagnostics in Do not use

8HMI UART/CAN At least one HMI interface must be in place

9HMI Analogue/Digital At least one HMI interface must be in place

For details of the pin outs for all connectors see appendix section 12.1

10. Regulator Interface 8. HMI (UART/CAN)11. SD Card 9. HMI (Digital/

Analogue)

FCPM Rear view

SPM 2 Central Module SPM 1

11

10

9

8

6. Battery Diagnostic

Module (BDM) 2

7. Battery Diagnostic

Module (BDM) 1

4. FCPM In

3. Battery

Positive

5. FCPM Out

2. Positive

Output

1. Ground

FCPM Front view

SPM 2 Central Module SPM 1

6

3

1

2

7

4 5

176 Operating the FCPM

6.1 Startup using the Start button

Note When the battery is connected, the output is live!

1. Check at least one HMI is connected.

2. Check regulator interface is connected.

3. Check fuel lines are connected to both SPMs.

4. Check that there is sucient fuel available.

5. Connect battery.

Note Output is now live

6. Press the start button until audible fan noise is heard (max 5 seconds).

7. Fuel cell startup process will begin.

8. Check error codes to ensure the system has started correctly.

9. When the LED is green fuel cell power is available (approx. 5 seconds after

starting system).

6.2 Startup using digital signal

For remote operation via a digital signal, use the process as outlined in section 6.1

Startup using the Start button. However, step 6 must be changed to:

1. Pull up (3.3V) start pins Start 1 and Start 2 on the HMI analogue/digital

connector for 4 seconds.

6.3 Shutdown using the Start button

The procedure to shut down the FCPM:

1. Press button for 4 seconds.

2. Wait until LED stops ashing orange before moving to next step

(removing battery early will corrupt the micro SD card).

3. Disconnect batteries.

4. Isolate hydrogen cylinder.

6.4 Shutdown using digital signal

For remote operation with a digital signal, use the process as outlined in section 6.3

Shutdown using the button. However, step 1 must be changed to:

1. Pull up (3.3V) start pins Start 1 and Start 2 on the HMI Analogue/Digital connector

for 4 seconds.

6.5 Monitoring of data output

See logging and data connections (section 7)

For operational safety during ight it is essential to monitor remaining

hydrogen fuel pressure, battery voltage, run state and error codes.

Not doing so could lead to unexpected loss of power.

18 6 Operating the FCPM

6.6 Software update procedure

To change the software on the SPM or PCM follow the steps below:

1. Power o FCPM.

2. Remove hybrid batteries.

3. Remove micro SD Card and open IntelligentEnergy folder on the micro SD card.

4. Copy the “Load SPM” or “Load PCM” le(s) and image folder into IntelligentEnergy

folder.

5. Re-insert micro SD card to the FCPM.

6. Reconnect batteries.

7. Wait for LED to change from rapid amber ashing to rapid green ashing.

8. Remove hybrid batteries.

9. Software update has been completed.

6.7 Conguration update procedure

To change the conguration of the SPM use the following procedure. The parameters

for the conguration can be found in section 7.3.

1. Power o FCPM.

2. Remove hybrid batteries.

3. Remove micro SD Card and open IntelligentEnergy folder on the micro SD card.

4. Copy the “Load Cong” le and image folder into IntelligentEnergy folder.

5. Re-insert micro SD card to the FCPM.

6. Reconnect batteries.

7. Wait for LED to change from rapid amber ashing to rapid green ashing.

8. Remove hybrid batteries.

9. Conguration update has been completed.

6.8 LED states

FCPM LED (located on top of central module next to start button) colour denotes

specic running states and errors, as follows:

Colour State Description

O Solid FCPM o

Green Flash Normal operation

Green Double Flash Output live fuel cell o

Green Rapid Flash Software update complete

Green Slow Flash Fuel cell starting

Amber Flash Low H2pressure

Amber Rapid Flash Software updating or entering sleep mode

Amber Double Flash Output live fuel cell o H2low pressure

Amber Slow Flash Fuel cell starting H2pressure low

Red Flash Fuel cell stopping

Red Rapid Flash Software update failed

197 Logging and data connections

7.1 SD card formatting

The FCPM takes a micro SD card. This logs health and performance data as well

as fault codes. The micro SD card format must be FAT32. No les are required for

initial operation, the FCPM will create the necessary les for operation.

7.2 SD card data format

The following folder structure must exist for the FCPM to log correctly (the system

automatically generates this folder): \\IntelligentEnergy\data

Micro SD card presence must be detected for the FCPM to start up.

7.3 Conguration format

The behaviour of the FCPM can be adjusted via the conguration le. This is set

at build but can be adjusted if required. Please contact Intelligent Energy Product

Support for the necessary tools.

The conguration le has the following parameters:

Parameter Unit Range Factory Setting (12S)

Target Output Voltage Volt 40.0 to 70.0 51.4

Battery Charging Current Limit Amp 0.0 to 7.5 7.5

SPM Power Limit Watt 500 to 2000 1500

Customer Serial Port –NA NA

Debug Serial Port –NA NA

CAN Data Format –NA NA

Stop System on Software Fault –True/False False

Stop System on Engineering Fault –True/False False

Wait for Start Command –True/False False

Allow Single SPM Running

(reserved functionality)

–True/False False

Expected Slave Count –0 to 7 0

Dynamic Control over Customer Serial –True/False False

Dynamic Control over Debugger Serial –True/False False

Dynamic Control over Customer CAN –True/False False

7.3.1 Conguration parameter denitions

Target Output Voltage The voltage the FCPM will output at if delivering

at or less than rated power (2.4kW).

Battery Charging Current Limit Maximum current that the combined SPMs will

deliver to the batteries.

SPM Power Limit Maximum power that each SPM can deliver to

the output load and the batteries combined.

20 7 Logging and data connections

7.4 UART format

The output format is listed below which is comma separated. The error codes are

hexadecimal which are listed in section 12.2.

The baud rate is 9600, 8 data bit, no parity, 1 stop bit.

The parameters available via UART are:

UART Word

number Description Unit Comments

1Tank Level Bar

2Battery Voltage Volt

3Output Power Watt

4SPM Power Draw Watt

5Battery Power Output Watt

6PSU State NA

7PCM Error Flags A NA See Section 12.2.1

8PCM Error Flags B NA

9PCM Error Flags C NA

10 PCM Error Flags D NA

11 SPM1 Error Flags A NA See Section 12.2.2

12 SPM1 Error Flags B NA

13 SPM1 Error Flags C NA

14 SPM1 Error Flags D NA

15 SPM2 Error Flags A NA See Section 12.2.2

16 SPM2 Error Flags B NA

17 SPM2 Error Flags C NA

18 SPM2 Error Flags D NA

Example data output:

<300,48.7,1600,1700,100,2,0x00000000,0x00000000,0x00000000,0x00000000,

0x00000000,0x00000000,0x00000000,0x00000000,0x00000000,0x00000000,

0x00000000,0x00000000>

<Pressure, Battery Voltage, Output Power, SPM Power, Battery Power, PSU state,

12x error ags>

Other manuals for FCPM

1

Table of contents