Intelligent Motion Systems IM805 User manual

intelligent motion systems, inc.

Excellence in MotionTM

IM805

HIGH PERFORMANCE MICROSTEPPING DRIVE

STANDARD DRIVER

CONNECTOR OPTIONS

COOLING SOLUTIONS

ACCESSORIES

OPERATING INSTRUCTIONS

370 N. MAIN ST., PO BOX 457, MARLBOROUGH, CT 06447

PH. (860) 295-6102, FAX (860) 295-6107

Internet: http://www.imshome.com, E-Mail: [email protected]

© Intelligent Motion Systems, Inc.

All Rights Reserved

IM805 Operating Instructions

Revision R032306

The information in this book has been carefully checked and is believed to be

accurate; however, no responsibility is assumed for inaccuracies.

Intelligent Motion Systems, Inc., reserves the right to make changes without

further notice to any products herein to improve reliability, function or design.

Intelligent Motion Systems, Inc., does not assume any liability arising out of

the application or use of any product or circuit described herein; neither does it

convey any license under its patent rights of others. Intelligent Motion Systems

and are trademarks of Intelligent Motion Systems, Inc.

Intelligent Motion Systems, Inc.’s general policy does not recommend the use of

its products in life support or aircraft applications wherein a failure or malfunction

of the product may directly threaten life or injury. Per Intelligent Motion Systems,

Inc.’s terms and conditions of sales, the user of Intelligent Motion Systems, Inc.,

products in life support or aircraft applications assumes all risks of such use and

indemnies Intelligent Motion Systems, Inc., against all damages.

Change Log

Date Revision Changes

03/23/2006 R032306 Updated IMS Contact info, warranty and disclaimer info on cover.

Added sub-section for status indicator LED, pg 12. Updated recom-

mended IMS Motor Part Numbers, pg 27.

1IM805 Operating Instructions Revision R032306

Table of Contents

Introduction............................................................................................... 5

The IM805 ..................................................................................................................... 5

Features and Benets ................................................................................................... 5

The Product Manual ...................................................................................................... 6

Notes and Warnings...................................................................................................... 7

Hardware Specications........................................................................... 8

Section Overview .......................................................................................................... 8

Mechanical Specications ............................................................................................. 8

Electrical Specications................................................................................................. 9

Thermal Specications ................................................................................................ 10

Pin Assignment and Description ................................................................................. 10

Status Indications ........................................................................................................ 12

Mounting The IM805 .............................................................................. 13

Theory of Operation ............................................................................... 15

Section Overview ........................................................................................................ 15

Circuit Operation ......................................................................................................... 15

Microstep Select (MSEL) Inputs.................................................................................. 16

Stepping ...................................................................................................................... 16

Dual PWM Circuit ........................................................................................................ 17

Fullstep Output Signal ................................................................................................. 18

Timing.......................................................................................................................... 18

Power Supply Requirements.................................................................. 19

Section Overview ........................................................................................................ 19

Selecting a Power Supply ........................................................................................... 19

Selecting an Opto Supply............................................................................................ 21

Recommended Wiring................................................................................................. 22

AC Line Filtering.......................................................................................................... 23

Motor Requirements............................................................................... 24

Section Overview ........................................................................................................ 24

Selecting a Motor ........................................................................................................ 24

Motor Wiring ................................................................................................................ 29

Connecting the Motor .................................................................................................. 29

Interfacing and Controlling the IM805 .................................................... 33

Section Overview ........................................................................................................ 33

Layout and Interface Guidelines.................................................................................. 33

Motor Power Connection (+V)..................................................................................... 34

Conguring and Controlling the Output Current .......................................................... 35

Controlling the Output Resolution ............................................................................... 40

Interfacing and Using the Isolated Logic Inputs .......................................................... 42

Connecting and Using the Fault Output ...................................................................... 48

Full Step Output .......................................................................................................... 49

Minimum Connections................................................................................................. 50

Troubleshooting...................................................................................... 51

Section Overview ........................................................................................................ 51

Basic Troubleshooting................................................................................................. 51

Problem Symptoms and Possible Causes .................................................................. 51

Contacting Technical Support ..................................................................................... 54

The IMS Web Site ....................................................................................................... 54

Returning Your Product to IMS ................................................................................... 54

2 IM805 Operating Instructions Revision R032306

3IM805 Operating Instructions Revision R032306

Standard Connection Options ................................................................ 55

Appendix Overview ..................................................................................................... 55

IM805-34P1................................................................................................................. 56

IM805-8P2................................................................................................................... 61

IM805-34P1-8P2 ......................................................................................................... 62

IM805-PLG .................................................................................................................. 63

Cooling Solutions ................................................................................... 65

H-4X Heat Sink Kit ...................................................................................................... 65

Thermal Non-Isolating Pad (TN-48) ........................................................................... 65

Accessories ............................................................................................ 66

Appendix Overview ..................................................................................................... 66

U3-CLP: Side-Mounting Clip ....................................................................................... 66

BB-34-4P Breakout Board........................................................................................... 68

PLG-R Removable Screw Terminal Set...................................................................... 70

2 IM805 Operating Instructions Revision R032306

3IM805 Operating Instructions Revision R032306

List Of Figures

Figure 2.1 IM805 Dimensions .................................................................................. 8

Figure 2.2 IM805 Pin Conguration ....................................................................... 10

Figure 2.3 Stautus Indicator LED........................................................................... 12

Figure 3.1 Mounting Recommendations ................................................................ 13

Figure 4.1 IM805 Block Diagram ........................................................................... 15

Figure 4.2 Recirculating PWM ............................................................................... 17

Figure 4.3 Non-Recirculating PWM ....................................................................... 17

Figure 6.1 Per Phase Winding Inductance ............................................................ 26

Figure 6.2 8 Lead Motor Series Connections ........................................................ 30

Figure 6.3 8 Lead Motor Parallel Connections....................................................... 30

Figure 6.4 6 Lead Motor Half Coil (Higher Speed) Connections ........................... 31

Figure 6.5 6 Lead Motor Full Coil (Higher Torque) Connections ........................... 31

Figure 6.6 4 Lead motor Connections.................................................................... 32

Figure 7.1 IM805 Motor Power Connctions ........................................................... 35

Figure 7.2 Current Adjust Resistor Placement....................................................... 38

Figure 7.3 Current Reduction Adjust Resistor Placement ..................................... 39

Figure 7.4 MSEL Switch Showing 50 Microsteps/Step Selected........................... 40

Figure 7.5 Optically Isolated Inputs........................................................................ 42

Figure 7.6 Switch Interface .................................................................................... 45

Figure 7.7 Open Collector Interface....................................................................... 46

Figure 7.8 TTL Interface ........................................................................................ 46

Figure 7.9 LYNX Interface ..................................................................................... 47

Figure 7.10 The Fault Output Connected to an LED ............................................... 48

Figure 7.11 The Full Step Output Connected to an Up/Down Counter ................... 49

Figure 7.12 IM805 Minimum Connections ............................................................... 50

Figure A.1 IM805-34P1 Connector P1 Mechanical Drawing.................................. 56

Figure A.2 IM805-34P1 Connector P1 Pin Locations ............................................ 56

FIgure A.3 MSEL Connection Using TTL Interface ................................................ 59

Figure A.4 Cascading IM805-34P1 Drives Using the Step/Direction Outputs ....... 60

Figure A.5 IM805-8P2 - Connector P1 ................................................................... 61

Figure A.6 IM805-8P2 - Connector P2 ................................................................... 61

Figure A.7 IM805-34P1-8P2 - Connector P1 ......................................................... 63

Figure A.8 IM805-34P1-8P2 - Connector P2 ......................................................... 63

Figure A.9 IM805-PLG Connectors ........................................................................ 65

Figure A.10 IM805-PLG Pin Location and Orientation............................................. 66

Figure B.1 H-4X Heat Sink ..................................................................................... 67

Figure C.1 U3-CLP Mounting Hole Locations ........................................................ 68

Figure C.2 Attaching the U3-CLP to the IM805 ...................................................... 69

Figure C.3 Panal Mounting an IM805 Using the U3-CLP Clip Set ......................... 69

Figure C.4 BB-34-4P Breakout Board Mechanical Specications.......................... 70

Figure C.5 BB-34-4P Pin Locations........................................................................ 71

Figure C.6 BB-34-4P Mounting Diagram................................................................ 71

4 IM805 Operating Instructions Revision R032306

5IM805 Operating Instructions Revision R032306

List Of Tables

Table 2.1 Electrical Specications .......................................................................... 9

Table 2.2 IM805 Thermal Specications .............................................................. 10

Table 2.3 Connector P1 - Pin Assignment and Description.................................. 11

Table 2.4 Connector P2 - Pin Assignment and Description.................................. 12

Table 3.1 IM805 Mounting Screw/Washer Requirements ................................... 14

Table 5.1 Motor Power Supply Requirements ...................................................... 20

Table 5.2 +5 VDC Power Supply Requirements .................................................. 21

Table 7.1 Current Adjust Resistor Values............................................................. 38

Table 7.2 Microstep Resolution Switch Settings................................................... 41

Table 7.3 Recommended Input Current Limiting Resistor Values........................ 43

Table 7.4 Logic Input Timing ................................................................................ 44

Table A.1 IM805-34P1 - Connector P1 Pin Assignment and Description ............ 57

4 IM805 Operating Instructions Revision R032306

5IM805 Operating Instructions Revision R032306

Features and Benefits

n Low Cost.

n Small Size 2.75” x 3.00” x 1.20”

(69.9 x 76.2 x 30.5 mm).

n Advanced Surface Mount and ASIC Technology.

n High Input Voltage (+24 to +75VDC).

n High Output Current (5A RMS, 7A Peak).

n No Minimum Inductance.

n FAULT Output.

n Optically Isolated Inputs.

Section 1

Introduction

The IM805

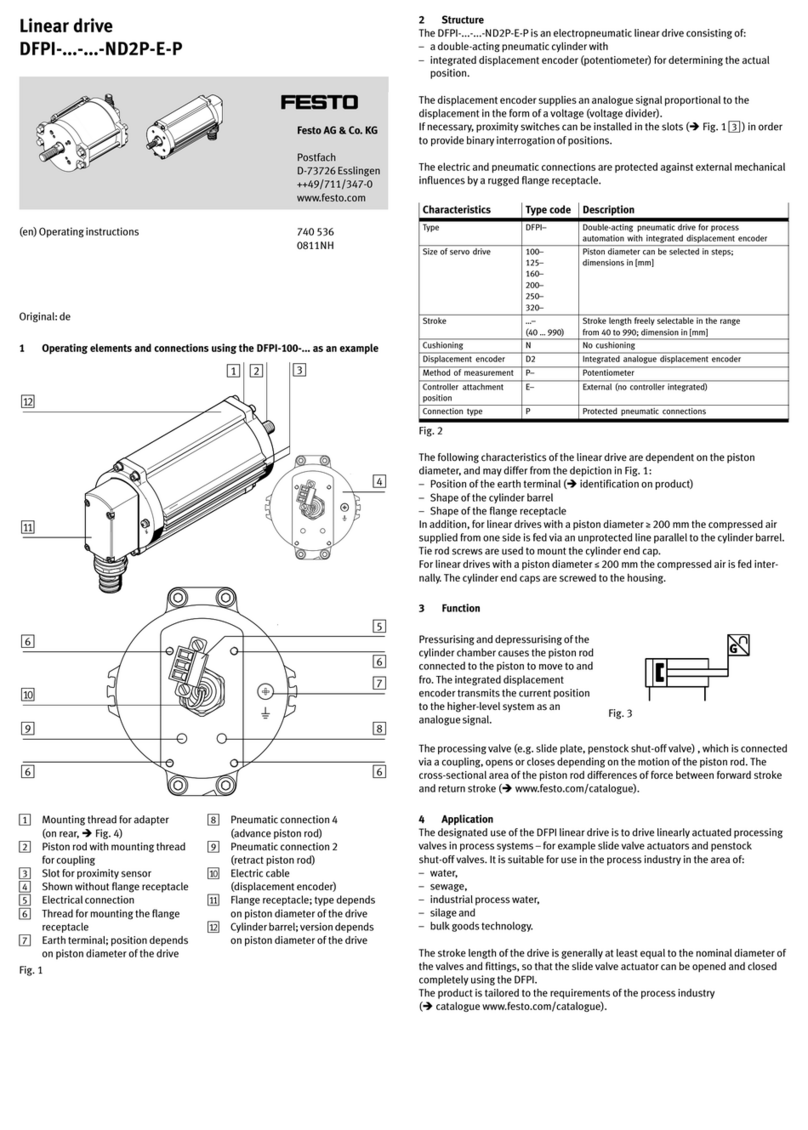

The IM805 is a high performance,

yet low cost microstepping driver

that utilizes surface mount ASIC

technology. The IM805 is small,

easy to interface and use, yet

powerful enough to handle the

most demanding applications.

The IM805 has 14 built-in mic-

rostep resolutions (both binary

and decimal). The resolution can

be changed at any time without

the need to reset the driver. This

feature allows the user to rapidly

move long distances, yet precisely position the motor at the end of travel without

the expense of high performance controllers.

With the development of proprietary and patented circuits, ripple current has

been minimized to reduce motor heating common with other designs, allow-

ing the use of low inductance motors to improve high speed performance and

system efciency.

The IM805, because of its small size and low cost, can be used to increase

accuracy and smoothness in systems using higher step angle motors. In many

instances mechanical gearing can be replaced with microstepping, reducing

cost and eliminating potential maintenance.

Available as options for the IM805 are a variety of connector styles, a heat sink

and thermal pad.

The IM805 was developed to provide designers with affordable, state-of-the-art tech-

nology for the competitive edge needed in today’s market.

6 IM805 Operating Instructions Revision R032306

7IM805 Operating Instructions Revision R032306

n Single Supply.

n Up to 10MHz Step Clock Rate.

n Short Circuit Protection.

n Microstep Resolution to 51,200 Steps/Rev.

n Microstep Resolutions can be Changed “On-The-Fly” With-

out Loss of Motor Position.

n 20 kHz Chopping Rate.

n Automatically Switches Between Slow and Fast Decay for

Unmatched Performance.

n 14 Selectable Resolutions Both in Decimal and Binary.

n Adjustable Automatic Current Reduction.

n At Full Step Output.

The Product Manual

The main sections of this manual address the standard IM805 driver, which

come with 8 position screw terminals as a connection medium. The different

connector, input options and accessories are covered in detail in the appendices.

The Bookmarks

The IB Series product manual in it’s electronic format (ib.pdf) can be down-

loaded from the IMS website at www.imshome.com. This version includes a

Bookmark feature that allows the reader to link from a Bookmarked Topic in

the Table of Contents to a full description of that feature’s

attributes and functions. You can also select a Topic directly

from the Table of Contents Pages. Topics with a Bookmark

function are further identiable because the cursor changes

from a normal pointer to a “nger” pointer when placed over

the word.

6 IM805 Operating Instructions Revision R032306

7IM805 Operating Instructions Revision R032306

WARNING! The IM805 components are sensitive to ElectroStatic

Discharge (ESD). All handling should be done at an ESD protected

workstation.

WARNING! Hazardous voltage levels may be present if using an

open frame power supply to power the IM805.

WARNING! Ensure that the power supply output voltage does not

exceed the maximum input voltage of the IM805.

WARNING! A current adjustment resistor is always necessary to

keep the Driver and/or Motor in a safe operating range.

DO NOT operate the IM805 Driver without a current adjustment

resistor in place.

Notes and Warnings

WARNING! Turn off the AC power side to power down the DC

power supply.

WARNING! For battery operated systems connect a “transient

suppressor” across the power switch to prevent arcs and high

voltage spikes. Also place a “transorb” across the +V and GND of

the battery connections at the Driver.

8 IM805 Operating Instructions Revision R032306

9IM805 Operating Instructions Revision R032306

0.150

(3.8)

2.600

(66.0)

2.750

(69.9)

0.290

(7.4)

2.710

(68.8)

3.000

(76.2)

4X Ø 0.160

(4X Ø 4.1)

0.410

(10.4)

17

34

1

0.025

(0.6)

18

12345678

1.00

(25.4)

0.312

(7.92)

0.030

(0.8)

1.320

(33.53)

IM805-34P1

Section 2

Hardware Specifications

Section Overview

This section will acquaint you with the dimensional information, pin de-

scription, power, environmental and thermal requirements of the IM805.

It is broken down as follows:

n Mechanical Specications.

n Electrical Specications.

n Thermal Specications.

n Pin Assignment and Description.

Mechanical Specifications

Shown are the standard 8 position screw terminal set and the Optional 34

Pin Connector for the IM805. Specications for the 34 Pin Connector are

available in Appendix A: Standard Connection Options, of this document.

Dimensions are in inches, parenthesis dimensions are in millimeters.

Figure 2.1: IM805 Dimensions

8 IM805 Operating Instructions Revision R032306

9IM805 Operating Instructions Revision R032306

Electrical Specifications

Test Condition: TA=25°C, +V=75VDC

Table 2.1: IM805 Electrical Specications

* Includes motor back EMF.

**Lower currents may be used for current reduction.

Ω

10 IM805 Operating Instructions Revision R032306

11IM805 Operating Instructions Revision R032306

Thermal Specifications

Table 2.2: IM805 Thermal Specications

NOTE! Additional cooling may be required to limit the plate

temperature to 70°C! An optional heat sink and thermal pad is

available, see Appendix C: Cooling Solutions for details.

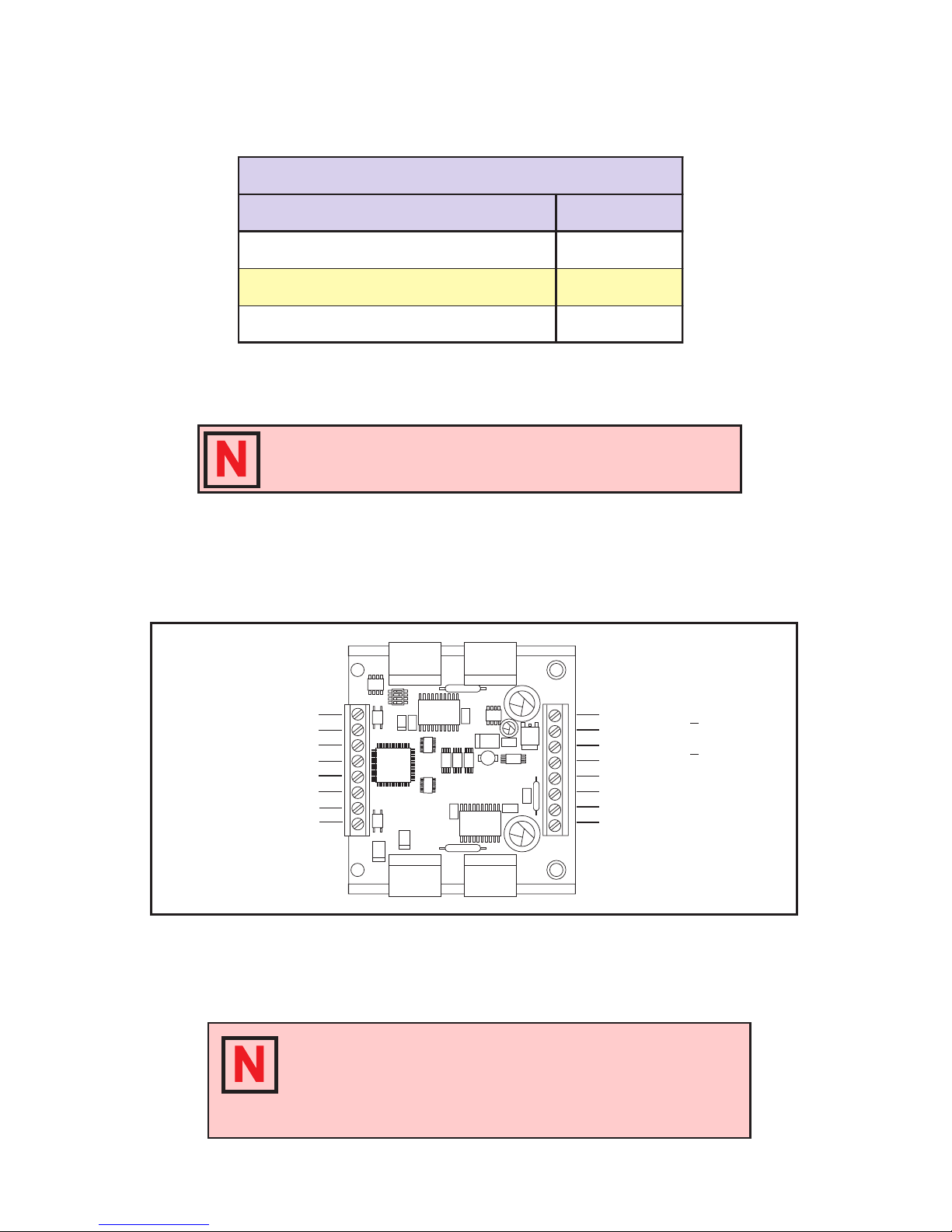

Pin Assignment and Description

Figure 2.2: IM805 Pin Conguration

NOTE! This pin conguration diagram and table represent

the pinout of any 8 position connector used for P1. If you

purchased the IM805-34P1 option (34 Position Header) the

pin conguration diagram and table is located in Appendix A:

Standard Connection Options.

N/C - P1:1 P2:8 - Motor ØA

P2:6 - Motor ØB

P2:5 - Motor ØB

P2:4 - +V (+12 to +48 VDC)

P2:3 - GND

P2:2 - Current Adjust

P2:1 - Current Reduction Adjust

P2:7 - Motor ØA

Step Clock - P1:2

Direction - P1:3

Opto Supply - P1:4

Enable - P1:5

Reset - P1:6

Fault Output - P1:7

On-Full-Step Output - P1:8

10 IM805 Operating Instructions Revision R032306

11IM805 Operating Instructions Revision R032306

Connector P1

Table 2.3: Connector P1 - Pin Assignment and Descriptions

WARNING! The IM805 components are sensitive to ElectroStatic

Discharge (ESD). All handling should be done at an ESD protected

workstation.

WARNING! Hazardous voltage levels may be present if using an

open frame power supply to power the IM805.

WARNING! Ensure that the power supply output voltage does not

exceed the maximum input voltage of the IM805.

12 IM805 Operating Instructions Revision R032306

13IM805 Operating Instructions Revision R032306

Connector P2

Table 2.4: Connector P2 - Pin Assignment and Descriptions

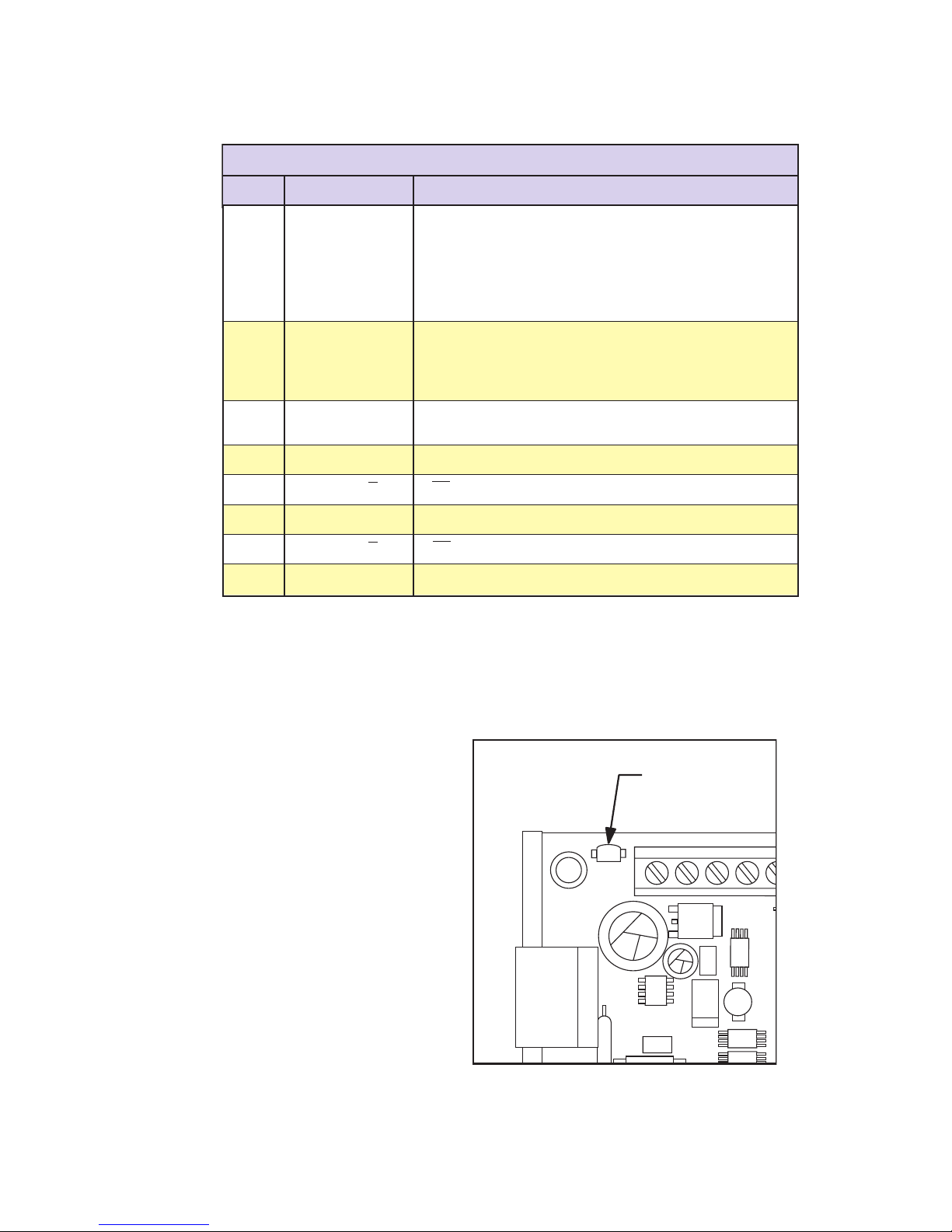

Status Indicators

Green: Power On

Red: Fault

Figure 2.3: Status Indicator LED

The IM805 features a two-

color LED mounted to the

left of connector P2 for status

indication.

When the drive is powered

and operating normally, the

LED will be green. When in

a fault condition, the LED

will be red.

12 IM805 Operating Instructions Revision R032306

13IM805 Operating Instructions Revision R032306

Section 3

Mounting The IM805

This section has recommended mounting instructions for the standard

IM805. For additional connector options for the IM805 see Appendix A:

Standard Connection Options, of this document. An optional heat sink

and thermal pad, the H-4X and TN-48, are available for the IM805. See

Appendix C: Cooling Solutions, for details.

The IM805 has limited available clearance for mounting screws. If a

mounting screw has a head diameter greater than 0.230 inches (5.8

mm), an insulating washer MUST be used to maintain proper electrical

isolation between the mounting screw and the IM805’s components. The

washer must have a minimum thickness of 0.060 inches (1.52 mm) and

a maximum diameter of 0.270 inches (6.86 mm). See Table 3.1 for screw

recommendations/washer requirements.

Thermal Pad

TN-48 or Equivalent

Mounting Plate

or Heat Sink Surface

4 X #6 (M3) Threaded

Holes. (See Mechanical,

Figure 2.1 for Hole Pattern

Dimensions) The torque specification

for the mounting screws

is 5.0 to 7.0 lb-in (0.60 to

0.80 N-m). Do not over-

tighten screws!

12345678

See Table 3.1 for

Mounting Hardware

Requirements

Figure 3.1: Mounting Recommendations

14 IM805 Operating Instructions Revision R032306

15IM805 Operating Instructions Revision R032306

Table 3.1: IM805 Mounting Screw/Washer Requirements

WARNING! Use of any mounting hardware other than that

recommended may result in damage to the driver circuitry! Use

ONLY the hardware recommended by this document to mount

the IM805 to your panel or heat sink plate!

The following insulating washers (listed by vendor and part #) are suit-

able for use in mounting the IM805:

n Accurate Screw Machine Co.

P/N 88-.062 N

n Micro Plastics, Inc.

P/N 17W02504

n Seastrom Manufacturing

P/N 5610-250-62

14 IM805 Operating Instructions Revision R032306

15IM805 Operating Instructions Revision R032306

Section 4

Theory of Operation

Section Overview

This section will cover the circuit operation for the IM805 microstepping

driver.

n Circuit Operation.

n Microstep Select Inputs.

n Stepping.

n Dual PWM Circuit.

n Fullstep Output.

n Timing.

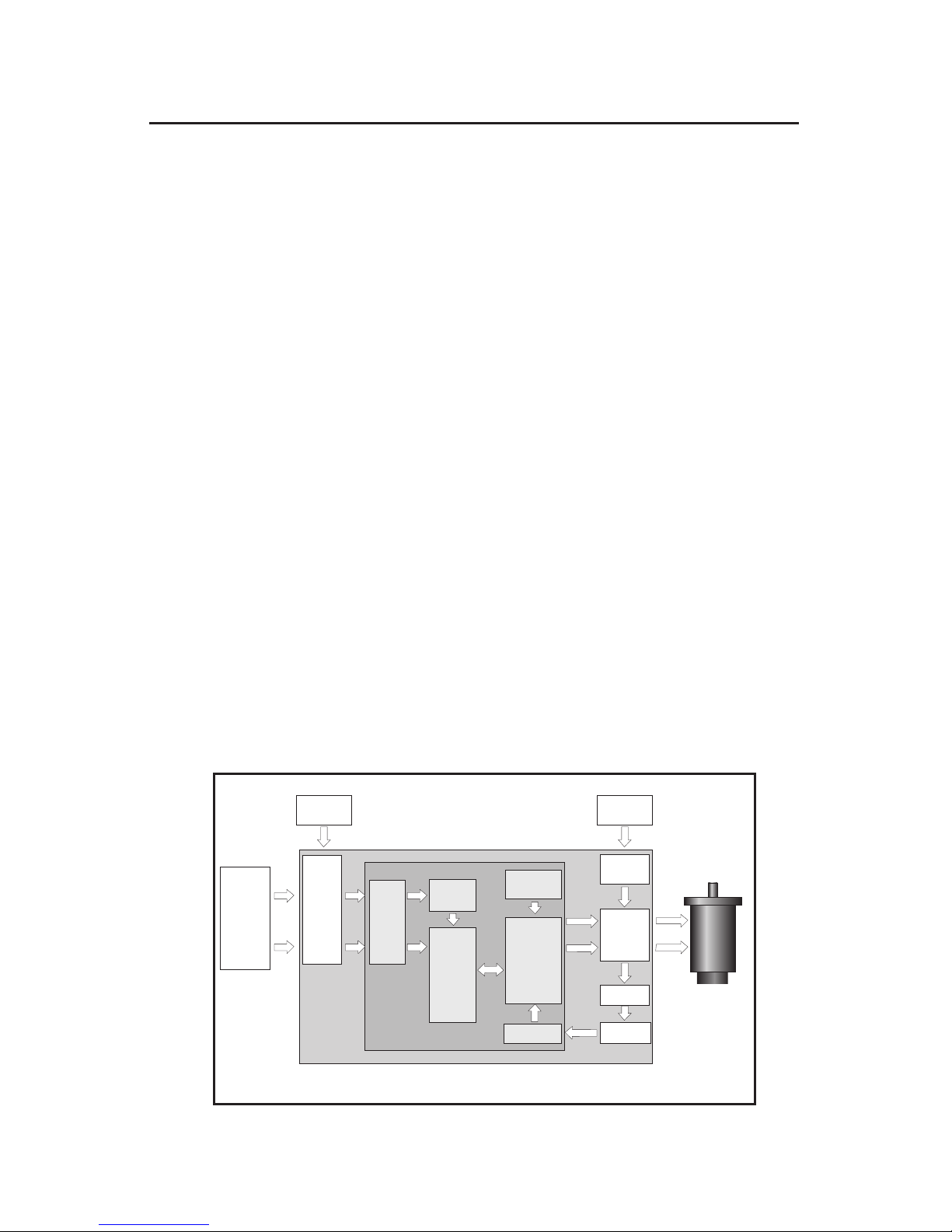

Circuit Operation

Microstepping drives have a much higher degree of suitability for ap-

plications that require smooth operation and accurate positioning at low

speeds than do half/fullstep drivers and reduction gearing. The IM805,

which can be set to microstep resolutions as high as 51,200 microsteps/rev

(256 microsteps/step) using a 1.8° stepping motor, is ideal for such appli-

cations.

In order to subdivide motor steps into microsteps while maintaining

positional accuracy, precise current control is required. The IM805 ac-

complishes this by the use of a unique Dual PWM circuit built into the

patented IM2000 Microstep Controller ASIC, which resides at the heart of

the IM805. This PWM circuit uses alternating recirculating/non-recircu-

lating modes to accurately regulate the current in the windings of a two

phase stepping motor.

Figure 4.1: IM805 Block Diagram

INPUT

LOGIC

INPUT

LOGIC

ISOLATION

CIRCUITRY

SINE/COSINE

POSITION

GENERATOR

MICROSTEP

RESOLUTION

SELECTION

STEP CLOCK

DIRECTION

ENABLE

RESET

CURRENT

CONTROL

USER

INTERFACE

POWER

SUPPLY

OPTO

SUPPLY

20kHz CHOP.

OSC

PROTECTION

CIRCUIT

IM2000 MICROSTEP

CONTROLLER

IM805 MICROSTEPPING DRIVER

PHASE A/B

OUTPUT

CIRCUITRY

CURRENT

SENSING

STEPPING

MOTOR

SHORT

CIRCUIT

PROTECTION

OVER CURRENT

PROTECTION

16 IM805 Operating Instructions Revision R032306

17IM805 Operating Instructions Revision R032306

Microstep Select (MSEL) Inputs

Another unique feature of the IM2000 is the ability to change resolutions

at any time. A resolution change can occur whether the motor is being

clocked or is at rest. The change will not take place until the rising edge

of the next step clock input. At this time, the new resolution is latched

and implemented before the step clock pulse takes effect.

If a resolution is chosen such that the sine/cosine output of the IM2000

would not land on an electrical fullstep of the motor, then the IM2000

will automatically align itself to the full step position on the step clock

pulse that would have caused the motor to rotate past the full step. The

step clock pulses, from that point forward, will be equal to the selected

resolution. This feature allows the user to switch resolutions at any time

without having to keep track of sine/cosine location. Because of this, the

On-Full-Step output of the IM805 can easily be used to monitor position.

Conguration settings for the Microstep Resolution are located in Section

7 of this document, Interfacing and Controlling the IM805.

Stepping

The IM2000 contains a built-in sine/cosine generator used for the genera-

tion of Phase A and Phase B position reference. This digitally encoded

9 bit sine and 9 bit cosine signal is directly fed into a digital to analog

converter.

The step clock (SCLK) and direction (DIR) inputs are buffered using

Schmidt triggered buffers for increased noise immunity and are used to

increment or decrement the sine/cosine position generator. The position

generator is updated on the rising edge of the step clock input. It will

increment or decrement by the amount specied by the microstep resolu-

tion select (MSEL) inputs.

The direction (DIR) input determines the direction of the position genera-

tor and hence the direction of the motor. The DIR input is synchronized

to the SCLK input. On the rising edge of the SCLK input the state of the

DIR input is latched in. The position generator will then look to see if

there has been a change in direction and implement that change be-

fore executing the next step. By utilizing this method to implement the

direction change, the noise immunity is greatly increased and no physical

change in the motor occurs if the direction line is toggled prior to the

step clock input.

The enable/disable input does not affect the step clock input. The sine/

cosine generator will continue to update if a signal is applied to the step

clock input.

The IM2000 outputs both sine and cosine data simultaneously when

applying a step clock input. Dual internal look-up tables are used to

output a unique position for every step clock input to enhance system

performance.

16 IM805 Operating Instructions Revision R032306

17IM805 Operating Instructions Revision R032306

Dual PWM Circuit

The IM2000 contains a unique dual PWM circuit that efciently and accu-

rately regulates the current in the windings of a two phase stepping motor.

The internal PWM accomplishes this by using an alternating recirculating/

non-recirculating mode to control the current.

Recirculating

In a recirculating PWM, the cur-

rent in the windings is contained

within the output bridge while

the PWM is in its OFF state. (After

the set current is reached.) This

method of controlling the current

is efcient when using low induc-

tance motors, but lacks response

because of its inability to remove

current from the windings on the

downward cycle of the sine/

cosine wave (See Figure 4.1).

Non-Recirculating

In a non-recirculating PWM, the

current ows up through the bridge and back to the supply in the OFF

phase of the cycle. This method of controlling current allows for much

better response but reduces efciency and increases current ripple, espe-

cially in lower inductance motors (See Figure 4.3).

The IM2000’s PWM utilizes the best features of both by combining recir-

culating and non-recirculating current control. On the rising edge of the sine/

cosine waveform, the PWM will

always be in a recirculating mode.

This mode allows the driver to

run at peak efciency while main-

taining minimum current ripple

even with low inductance motors.

On the downward cycle of the

sine/cosine waveform, the PWM

operates in a two part cycle. In

the rst part of its cycle, the PWM

is in a non-recirculating mode

to pull current from the motor

windings. In the second part of

the cycle the PWM reverts back

to recirculating mode to increase

efciency and reduce current

ripple.

Figure 4.3: Non-Recirculating PWM

DRIVE CURRENT

RECIRCULATION

Figure 4.2: Recirculating PWM

DRIVE CURRENT

RECIRCULATION

18 IM805 Operating Instructions Revision R032306

19IM805 Operating Instructions Revision R032306

The IM2000 will automatically change the non-recirculating pulse widths

to compensate for changes in supply voltage and accommodate a wide

variety of motor inductances. This method also allows for the use of very

low inductance motors with your IM805 driver, while utilizing a 20kHz

chopping rate which reduces motor heating but maintains high efciency

and low current ripple.

Fullstep Output Signal

The fullstep output signal from the IM805 is an active high output at

connector P1:8. This output will be TRUE for the duration of the full

step. A full step occurs when either Phase A or Phase B crosses through

zero (i.e. full current in one motor winding and zero current in the other

winding). This fullstep position is a common position regardless of the

microstep resolution selected.

The fullstep output can be used to count the number of mechanical

fullsteps that the motor has traveled without the need to count the num-

ber of microsteps in between. A controller that utilizes this output can

greatly reduce its position tracking overhead, thus substantially increasing

its throughput.

Interface guidelines and a sample application for the fullstep output are

located in Section 7 of this document, Interfacing and Controlling the

IM805.

Timing

The direction and microstep resolution select inputs are synchronized

with the positive going edge of the step clock input. When the step clock

input goes HIGH, the direction and microstep resolution select inputs are

latched. Further changes to these inputs are ignored until the next rising

edge of the step clock input.

After these signals are latched, the IM805 looks to see if any changes

have occurred to the direction and microstep resolution select inputs. If

a change has occurred, the IM805 will execute the change before taking

the next step. Only AFTER the change has been executed will the step

be taken. If no change has occurred, the IM805 will simply take the next

step. This feature works as an automatic debounce for the direction and

microstep resolution select inputs.

The reset and enable inputs are asynchronous to any input and can be

changed at any time.

Table of contents

Other Intelligent Motion Systems DC Drive manuals