Intelligent Motion Systems MDrive17Plus Application guide

Hardware

REFEREnCE

Excellence in Motion

www.imshome.com

TM

17 TM

23TM

The information in this book has been carefully checked and is believed to be accurate; however, no responsibility is

assumed for inaccuracies.

Intelligent Motion Systems, Inc., reserves the right to make changes without further notice to any products herein to

improve reliability, function or design. Intelligent Motion Systems, Inc., does not assume any liability arising out of the

application or use of any product or circuit described herein; neither does it convey any license under its patent rights of

others. Intelligent Motion Systems and are trademarks of Intelligent Motion Systems, Inc.

Intelligent Motion Systems, Inc.’s general policy does not recommend the use of its products in life support or aircraft

applications wherein a failure or malfunction of the product may directly threaten life or injury. Per Intelligent Motion

Systems, Inc.’s terms and conditions of sales, the user of Intelligent Motion Systems, Inc., products in life support or

aircraft applications assumes all risks of such use and indemnies Intelligent Motion Systems, Inc., against all damages.

TM

MDrivePlus Motion Control Hardware Reference Revision R052506

Copyright © 2006 Intelligent Motion Systems, Inc., All Rights Reserved

MDrive34Plus Motion Control Hardware Reference Change Log

Date Revision Changes

05/04/2006 R050406 Removed Ambient Temperature Specication

05/25/2006 R052506 Replaced USB to RS-422 Comminications Cable driver installation instructions in Appendix F with instructions relevant

to Windows XP Service Pack 2.

i

Table Of Contents

Getting Started - MDrivePlus Motion Control..............................................................................1-1

Before You Begin....................................................................................................................... 1-1

Tools and Equipment Required................................................................................................. 1-1

Connecting the Power Supply ................................................................................................... 1-1

Connecting Communications ................................................................................................... 1-1

Install IMS Terminal Software................................................................................................... 1-1

Establishing Communications................................................................................................... 1-2

Testing the MDrivePlus Motion Control................................................................................... 1-3

Apply Power to the MDrivePlus Motion Control...................................................................... 1-3

Make the MDrivePlus Motion Control Move ........................................................................... 1-3

Motion Control Example Using Program Mode........................................................................ 1-4

Programming Notes .................................................................................................................. 1-4

Part 1: Hardware Specifications

Section 1.1: MDrive17Plus Motion Control Product Introduction ....................................................1-6

Introduction to the MDrive17Plus Motion Control System...................................................... 1-6

Standard Feature Summary.................................................................................................... 1-6

The MDrive17Plus Motion Control Key Differences and Enhanced Features........................... 1-7

Section 1.2: MDrive17Plus Detailed Specifications ........................................................................1-8

Standard Electrical Specifications .............................................................................................. 1-8

Thermal Specifications.............................................................................................................. 1-8

Standard Motion Specifications................................................................................................. 1-8

Software Specifications .............................................................................................................. 1-9

Motor Specifications ................................................................................................................. 1-9

P1 Connector - I/O and Power Connections .......................................................................... 1-10

Mechanical Specifications........................................................................................................ 1-10

Pin/Wire Assignments............................................................................................................. 1-10

P2 Connector - RS-422/485 Communications ...................................................................... 1-11

Options and Accessories.......................................................................................................... 1-11

Section 1.3: MDrive17Plus2 Detailed Specifications ....................................................................1-12

Standard Electrical Specifications ............................................................................................ 1-12

Enhanced Electrical Specifications........................................................................................... 1-12

Thermal Specifications............................................................................................................ 1-12

Standard Motion Specifications............................................................................................... 1-13

Enhanced Motion Specifications ............................................................................................. 1-13

Software Specifications ............................................................................................................ 1-13

Motor Specifications ............................................................................................................... 1-14

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-14

P1 Connector - I/O and Power Connections .......................................................................... 1-15

Pin/Wire Assignments............................................................................................................. 1-15

P2 Connector - RS-422/485 Communications ...................................................................... 1-15

Options and Accessories.......................................................................................................... 1-16

Section 1.4: MDrive17Plus2-65 Detailed Specifications ...............................................................1-17

Standard Electrical Specifications ............................................................................................ 1-17

Enhanced Electrical Specifications........................................................................................... 1-17

Thermal Specifications............................................................................................................ 1-17

Standard Motion Specifications............................................................................................... 1-18

Enhanced Motion Specifications ............................................................................................. 1-18

Software Specifications ............................................................................................................ 1-18

Motor Specifications ............................................................................................................... 1-19

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-19

Pin/Wire Assignments............................................................................................................. 1-20

P1 Connector - I/O and Power Connections..................................................................1-20

P2 Connector - RS-422/485 Communications...............................................................1-21

Options and Accessories.......................................................................................................... 1-21

ii

iii

Section 1.5: MDrive23Plus Motion Control Product Introduction ..................................................1-22

Introduction to the MDrive23Plus Motion Control System.................................................... 1-22

Standard Feature Summary ..................................................................................................... 1-22

The MDrive23Plus Motion Control Key Differences and Enhanced Features......................... 1-23

Section 1.6: MDrive23Plus Detailed Specifications ......................................................................1-24

Standard Electrical Specifications ............................................................................................ 1-24

Thermal Specifications............................................................................................................ 1-24

Standard Motion Specifications............................................................................................... 1-24

Software Specifications ............................................................................................................ 1-25

Motor Specifications ............................................................................................................... 1-25

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-26

Pin/Wire Assignments............................................................................................................. 1-26

P1 Connector - I/O and Power Connections .......................................................................... 1-26

P2 Connector - RS-422/485 Communications ...................................................................... 1-27

Options and Accessories.......................................................................................................... 1-27

Section 1.7: MDrive23Plus2 Detailed Specifications ....................................................................1-28

Standard Electrical Specifications ............................................................................................ 1-28

Enhanced Electrical Specifications........................................................................................... 1-28

Thermal Specifications............................................................................................................ 1-28

Standard Motion Specifications............................................................................................... 1-29

Enhanced Motion Specifications ............................................................................................. 1-29

Software Specifications ............................................................................................................ 1-29

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-30

Motor Specifications ............................................................................................................... 1-30

Pin/Wire Assignments............................................................................................................. 1-31

P1 Connector - I/O and Power Connections .......................................................................... 1-31

P2 Connector - RS-422/485 Communications ...................................................................... 1-31

Options and Accessories.......................................................................................................... 1-32

Section 1.8: MDrive23Plus2-65 Detailed Specifications ...............................................................1-33

Standard Electrical Specifications ............................................................................................ 1-33

Enhanced Electrical Specifications........................................................................................... 1-33

Thermal Specifications............................................................................................................ 1-33

Standard Motion Specifications............................................................................................... 1-34

Enhanced Motion Specifications ............................................................................................. 1-34

Software Specifications ............................................................................................................ 1-34

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-35

Motor Specifications ............................................................................................................... 1-35

Pin/Wire Assignments............................................................................................................. 1-36

P1 Connector - I/O and Power Connections .......................................................................... 1-36

P2 Connector - RS-422/485 Communications ...................................................................... 1-37

Options and Accessories.......................................................................................................... 1-37

Section 1.9: MDrive17Plus CANopen ..............................................................................................1-38

Standard Electrical Specifications ............................................................................................ 1-38

Thermal Specifications............................................................................................................ 1-38

Motor Specifications ............................................................................................................... 1-38

Mechanical Specifications (Non-Sealed Versions)Dimensions in Inches (mm)......................... 1-39

P1 Connector - I/O and Power Connections - Plus Versions ................................................... 1-39

P1 Connector - I/O and Power Connections - Plus2 Versions ................................................. 1-40

P2 Connector - CANopen Communications .......................................................................... 1-40

Mechanical Specifications (Sealed -65 Version)........................................................................ 1-41

Pin/Wire Assignments............................................................................................................. 1-41

P1 Connector - I/O and Power Connections .......................................................................... 1-41

P2 Connector - CANOpen Communications......................................................................... 1-42

Section 1.10: MDrive23Plus CANopen ............................................................................................1-43

Standard Electrical Specifications ............................................................................................ 1-43

Thermal Specifications............................................................................................................ 1-43

Motor Specifications ............................................................................................................... 1-43

Mechanical SpecificationsDimensions in Inches (mm) ............................................................ 1-44

ii

iii

P1 Connector - I/O and Power Connections - Plus Versions ................................................... 1-44

P1 Connector - I/O and Power Connections - Plus2 Versions ................................................. 1-45

P2 Connector - CANopen Communications .......................................................................... 1-45

Mechanical Specifications (Sealed -65 Version)........................................................................ 1-46

P1 Connector - I/O and Power Connections -65 Version........................................................ 1-46

P2 Connector - CANopen Communications - M12 Connector.............................................. 1-47

Part 2: Connecting and Interfacing

Section 2.1: MDrivePlus Mounting and Connection Recommendations ...........................................2-3

Mounting Recommendations.................................................................................................... 2-3

MDrive23Plus Microstepping................................................................................................. 2-3

DC Power Recommendations ................................................................................................... 2-3

MDrive17Plus Motion Control .............................................................................................. 2-3

MDrive23Plus Motion Control .............................................................................................. 2-3

Layout and Interface Guidelines................................................................................................ 2-3

Recommended Wiring ............................................................................................................ 2-4

Recommended Mating Connectors and Pins............................................................................. 2-4

Securing Power Leads and Logic Leads .................................................................................... 2-4

Section 2.2: Interfacing MDrivePlus Communications .....................................................................2-5

Available Communications Cables/Converters .......................................................................... 2-5

Interfacing Single Mode Communications ................................................................................ 2-5

Single Mode Communications Full Duplex (RS-422)............................................................... 2-5

Single Mode Communications Half Duplex (RS-485).............................................................. 2-6

Interfacing Party Mode Communications.................................................................................. 2-6

Data Cable Termination Resistors ........................................................................................... 2-7

MDrivePlus Motion Control Communication Format ............................................................. 2-7

MDrivePlus Motion Control (MDI) Response to Echo Mode .................................................... 2-8

Using Check Sum .................................................................................................................. 2-9

MDrivePlus Motion Control Party Mode Sample Codes......................................................... 2-10

MDrivePlus Motion Control Immediate Party Mode Sample Codes ........................................ 2-11

Section 2.3: Interfacing and Using the MDrivePlus Motion Control I/O .........................................2-12

The MDrivePlus Motion Control Digital I/O......................................................................... 2-12

Standard I/O Set - All MDrivePlus Motion Control Models ................................................... 2-12

Enhanced I/O Set - MDrivePlus2/Plus2-65........................................................................... 2-12

Uses of the Digital I/O............................................................................................................ 2-12

MDrivePlus Motion Control Digital Input Functions............................................................. 2-13

Programmable Input Functions............................................................................................. 2-13

Dedicated Input Functions ................................................................................................... 2-13

Active States Defined............................................................................................................ 2-13

MDrivePlus Motion Control Digital Output Functions.......................................................... 2-14

Programmable Output Functions.......................................................................................... 2-14

Dedicated Output Functions................................................................................................. 2-14

MDrivePlus Motion Control I/O Ratings ............................................................................... 2-15

MDrivePlus Motion Control I/O Connection Map ................................................................ 2-15

I/O Usage Examples — MDrivePlus Standard I/O Set............................................................ 2-16

Input Interface Example - Switch Input Example (Sinking Input)........................................... 2-16

Input Interface Example - Switch Input Example (Sourcing Input) ......................................... 2-17

Output Interface Example (Sinking Output) ......................................................................... 2-18

General Purpose I/O Usage Examples — Enhanced I/O Set ................................................... 2-19

Input Interface Example - Switch Input Example (Sinking Input)........................................... 2-19

Input Interface Example - Switch Input Example (Sourcing Input) ......................................... 2-20

Output Interface Example (Sinking Output) ......................................................................... 2-21

Output Interface Example (Sourcing Output)........................................................................ 2-22

Dedicated Digital I/O - Enhanced I/O Set.............................................................................. 2-23

Step/Direction/Clock I/O ...................................................................................................... 2-23

Capture/Trip ....................................................................................................................... 2-23

Interfacing the Analog Input ................................................................................................... 2-24

Sample Usage ...................................................................................................................... 2-24

iv

v

Appendices

Appendix A: MDrivePlus Motion Control Motor Performance ......................................................... A-3

MDrive17Plus Motor Specifications..........................................................................................A-3

MDrive17Plus Speed-Torque ....................................................................................................A-3

MDrive23Plus Motor Specifications..........................................................................................A-3

Appendix B: Recommended Power and Cable Configurations .......................................................... A-4

Example A – Cabling Under 50 Feet, DC Power.......................................................................A-4

Example B – Cabling 50 Feet or Greater, AC Power to Full Wave Bridge ..................................A-4

Example C – Cabling 50 Feet or Greater, AC Power to Power Supply .......................................A-4

Recommended IMS Power Supplies ..........................................................................................A-5

Recommended Power Supply Cabling.......................................................................................A-5

Appendix C: MDrive with Planetary Gearbox.................................................................................. A-6

Section Overview ......................................................................................................................A-6

Product Overview .....................................................................................................................A-6

Selecting a Planetary Gearbox ...................................................................................................A-6

Calculating the Shock Load Output Torque (TAB)...................................................................A-7

System Inertia .........................................................................................................................A-10

Planetary Gearbox Inertia........................................................................................................A-14

MDrive17Plus with Planetary Gearbox ...................................................................................A-15

MDrive23Plus with Planetary Gearbox ...................................................................................A-16

Appendix D: I/O Application Guide ............................................................................................... A-17

Standard I/O Set Interfacing and Application..........................................................................A-17

NPN Sinking Input .............................................................................................................A-17

PNP Sourcing Input ............................................................................................................A-18

Mixed Input/Output Example ..............................................................................................A-19

Sinking Output ...................................................................................................................A-19

Enhanced I/O Set Interfacing and Application........................................................................A-20

NPN Sinking Input .............................................................................................................A-20

PNP Sourcing Input ............................................................................................................A-20

Sourcing Output..................................................................................................................A-21

Mixed Input/Output Example ..............................................................................................A-22

Interfacing Inputs as a Group Example ...................................................................................A-22

Interfacing Outputs as a Group Example ................................................................................A-23

Appendix E: MDrivePlus Motion Control Closed Loop Control...................................................... A-24

MDrive Motion Control Closed Loop Options.......................................................................A-24

Internal Encoder .......................................................................................................... A-24

Remote Encoder............................................................................................................ A-25

Appendix F: Optional Cables and Cordsets..................................................................................... A-25

Communications Converter Cables.........................................................................................A-25

USB to 10-Pin IDC (MD-CC400-000)...............................................................................A-25

USB to 5-Pin M12 (MD-CC401-000) (Sealed Version)........................................................A-26

Installation Procedure for the MX-CC40x-000 .......................................................................A-27

Installing the Cable/VCP Drivers..........................................................................................A-27

Determinig the Virtual COM Port (VCP).............................................................................A-29

Prototype Development Cable for MDrive17Plus2 - PN PD16-1417-FL3 .............................A-30

Cordsets (Sealed Version Only) ...............................................................................................A-31

iv

v

List of Figures

Part 1: Hardware Specifications

Figure GS.1: IMS Terminal Main Screen................................................................................... 1-2

Figure GS.2: IMS Terminal Prefrences Dialog ........................................................................... 1-2

Figure GS.3: MDrivePlus Motion Control Sign-On Message.................................................... 1-3

Figure GS.4: Download the Program ........................................................................................ 1-4

Figure 1.1.1: MDrive17Plus...................................................................................................... 1-6

Figure 1.1.2: MDrive17Plus2-65............................................................................................... 1-6

Figure 1.2.1: MDrive17Plus Mechanical Specifications ........................................................... 1-10

Figure 1.2.2: P1 - 12 in/304.8 cm Flying Leads....................................................................... 1-10

Figure 1.2.3: P1 7-Pin Pluggable Connector ........................................................................... 1-10

Figure 1.2.4: P2 10-Pin IDC Communications Connector ..................................................... 1-11

Figure 1.2.5: P2 10-Pin Wire Crimp Communications Connector ......................................... 1-11

Figure 1.3.1: MDrive17Plus2 Mechanical Specifications ......................................................... 1-14

Figure 1.3.2: P1 16-Pin Wire Crimp - Enhanced I/O Configuration ...................................... 1-15

Figure 1.3.3: P1 16-Pin Wire Crimp - Optional Remote Encoder Configuration.................... 1-15

Figure 1.3.4: P2 10-Pin IDC Communications Connector ..................................................... 1-15

Figure 1.3.5: P2 10-Pin Wire Crimp Communications Connector ......................................... 1-15

Figure 1.4.1: MDrive17Plus2-65 Motion Control................................................................... 1-19

Figure 1.4.2: P1 19-Pin M23 (male) - Enhanced I/O Configuration....................................... 1-20

Figure 1.4.3: P1 19-Pin M23 (male) - Optional Remote Encoder Configuration .................... 1-20

Figure 1.4.4: P2 5-Pin M12 (Female) RS-422/485 Communications Connector .................... 1-21

Figure 1.5.1: MDrive23Plus.................................................................................................... 1-22

Figure 1.5.2: MDrive23Plus2-65............................................................................................. 1-22

Figure 1.6.1: MDrive23Plus Mechanical Specifications ........................................................... 1-26

Figure 1.6.2: P1 12 in/304.8 cm Flying Leads......................................................................... 1-26

Figure 1.6.3: P1 7-Pin Pluggable Connector ........................................................................... 1-26

Figure 1.6.4: P2 10-Pin IDC Communications Connector ..................................................... 1-27

Figure 1.6.5: P2 10-Pin Wire Crimp Communications Connector ......................................... 1-27

Figure 1.7.1: MDrive23Plus2 Mechanical Specifications ......................................................... 1-30

Figure 1.7.2: P1 14 Pin Wire Crimp - Enhanced I/O Configuration...................................... 1-31

Figure 1.7.3: P1 14-Pin Wire Crimp - Optional Remote Encoder Configuration.................... 1-31

Figure 1.7.4: P2 10-Pin IDC Communications Connector ..................................................... 1-31

Figure 1.7.5: P2 10-Pin Wire Crimp Communications Connector ......................................... 1-31

Figure 1.8.1: MDrive23Plus2-65 Motion Control................................................................... 1-35

Figure 1.8.2: P1 19-Pin M23 (male) - Enhanced I/O Configuration....................................... 1-36

Figure 1.8.3: P1 19-Pin M23 (male) - Optional Remote Encoder Configuration .................... 1-36

Figure 1.8.4: P2 5-Pin M12 (Female) RS-422/485 Communications Connector .................... 1-37

Figure 1.9.1: MDrive17Plus Motion Control CANopen Mechanical Specifications................ 1-39

Figure 1.9.2: P1 - 12 in/304.8 cm Flying Leads....................................................................... 1-39

Figure 1.9.3: P1 7-Pin Pluggable Connector ........................................................................... 1-39

Figure 1.9.4: P1 16-Pin Wire Crimp - Enhanced I/O Configuration ...................................... 1-40

Figure 1.9.5: P1 16-Pin Wire Crimp - Optional Remote Encoder Configuration.................... 1-40

Figure 1.9.6: P2- DB-9 CANopen Communications............................................................... 1-40

Figure 1.9.7: CANopen Network using MDrivePlus Motion Control..................................... 1-40

Figure 1.9.8: MDrive17Plus2-65 Motion Control................................................................... 1-41

Figure 1.9.9: P1 19-Pin M23 (male) - Enhanced I/O Configuration....................................... 1-41

Figure 1.9.10: P1 19-Pin M23 (male) - Optional Remote Encoder Configuration .................. 1-41

Figure 1.9.11: P2 5-Pin M12 (Female) RS-422/485 Communications Connector .................. 1-42

Figure 1.10.2: P1 - 12 in/304.8 cm Flying Leads..................................................................... 1-44

Figure 1.10.1: MDrive23Plus2 Mechanical Specifications........................................................ 1-44

Figure 1.10.2: P1 - 12 in/304.8 cm Flying Leads..................................................................... 1-44

Figure 1.10.3: P1 7-Pin Pluggable Connector ......................................................................... 1-44

Figure 1.10.4: P1 14 Pin Wire Crimp - Enhanced I/O Configuration.................................... 1-45

Figure 1.10.5: P1 14-Pin Wire Crimp - Optional Remote Encoder Configuration,................. 1-45

Figure 1.10.6: P2- DB-9 CANopen Communications............................................................. 1-45

Figure 1.10.7: MDrive23Plus2-65 Motion Control................................................................. 1-46

Figure 1.10.8: P1 19-Pin M23 (male) - Enhanced I/O Configuration..................................... 1-46

Figure 1.10.9: P1 19-Pin M23 (male) - Optional Remote Encoder Configuration .................. 1-46

Figure 1.10.10: P2 5-Pin M12 (Male) CANopen Communications Connector ...................... 1-47

Figure 1.10.11: CANopen Network using MDrivePlus Motion Control................................. 1-47

Figure 2.1.2: MDrive23Plus Motion Control Current Requirements ........................................ 2-3

Figure 2.1.1: MDrive17Plus Mounting Screw Depth ................................................................ 2-3

Figure 2.1.3: MDrive Motion Control Power Connections ....................................................... 2-4

Figure 2.1.4: Typical MDrive Shown with Leads Secured .......................................................... 2-4

vi

vii

Part 2: Connecting and Interfacing

Figure 2.2.1: Full Duplex Communications (RS-422)............................................................... 2-5

Figure 2.2.2: Half Duplex 2 Wire Communications (RS-485) .................................................. 2-6

Figure 2.2.3: RS-485 Interface, Multiple MDrivePlus Motion Control System ......................... 2-7

Figure 2.3.1: Uses for the Digital I/O...................................................................................... 2-12

Figure 2.3.2: I/O Connection Map ......................................................................................... 2-15

Figure 2.3.3: Sinking Input Example using a Push Button Switch ........................................... 2-16

Figure 2.3.4: Sourcing Input Example using a Push Button Switch ......................................... 2-17

Figure 2.3.5: Sinking Output Example.................................................................................... 2-18

Figure 2.3.6: Switch Interface to Input, Sinking ...................................................................... 2-19

Figure 2.3.7 Sourcing Input Example using a Push Button Switch .......................................... 2-20

Figure 2.3.8: Sinking Output Example.................................................................................... 2-21

Figure 2.3.9: Sourcing Output Example.................................................................................. 2-22

Figure 2.3.10: MDrivePlus Motion Control Clock Functions ................................................. 2-23

Figure 2.3.11: Analog Input - Voltage Mode ........................................................................... 2-24

Figure 2.3.12: Analog Input - Current Mode .......................................................................... 2-25

Appendices

Figure A.1: MDrive17Plus Motion Control Speed-Torque Curves ............................................A-3

Figure A.2: MDrive23Plus Motion Control Speed-Torque Curves ............................................A-3

Figure B.1: DC Cabling - Under 50 Feet...................................................................................A-4

Figure B.2: DC Cabling - 50 Feet or Greater - AC To Full Wave Bridge Rectifier......................A-4

Figure B.3: AC Cabling - 50 Feet or Greater - AC To Power Supply..........................................A-4

Figure C.1: MDrive23 Torque-Speed Curve..............................................................................A-8

Figure C.2: Lead Screw System Inertia Considerations ............................................................A-10

Figure C.3: Rack and Pinion System Inertia Considerations....................................................A-11

Figure C.4: Conveyor System Inertia Considerations ..............................................................A-11

Figure C.5: Rotary Table System Inertia Considerations..........................................................A-12

Figure C.6: Chain Drive System Inertia Considerations ..........................................................A-13

Figure C.7: Planetary Gearbox Specifications for MDrive17Plus.............................................A-15

Figure C.8: Planetary Gearbox Specifications for MDrive23Plus.............................................A-16

Figure D.1: NPN Interface to an MDI Sinking Input .............................................................A-17

Figure D.2: PNP Interface to a Sourcing Input .......................................................................A-18

Figure D.3: Sinking Output to Relay ......................................................................................A-19

Figure D.4: Mixed Output Example- Standard I/O Set...........................................................A-19

Figure D.5: NPN Sinking Input on an MDrivePlus2 Motion Control ...................................A-20

Figure D.6: PNP Sourcing Input on an MDrivePlus2 Motion Control...................................A-20

Figure D.7: Sourcing Output to Sourcing Input......................................................................A-21

Figure D.8: Mixed Input/Output Example - Enhanced I/O ....................................................A-22

Figure D.9: TTL Interface to an Input Group.........................................................................A-22

Figure D.10: Outputs Interfaced to LED’s as a Group.............................................................A-23

Figure E.1: Connecting a Remote Encoder..............................................................................A-24

Figure F.1: MD-CC400-000 ...................................................................................................A-25

Figure F.2: MD-CC400-000 Mechanical Specifications ..........................................................A-25

Figure F.3: Typical Communications Interface.........................................................................A-26

Figure F.4: MD-CC401-000 ...................................................................................................A-26

Figure F.5: MD-CC401-000 Mechanical Specifications ..........................................................A-27

Figure F.6: Typical Communications Interface........................................................................A-27

Figure F.7: Hardware Update Wizard ......................................................................................A-27

Figure F.8: Hardware Update Wizard Screen 2 ........................................................................A-28

Figure F.9: Hardware Update Wizard Screen 3 ........................................................................A-28

Figure F.10: Windows Logo Compatibility Testing..................................................................A-28

Figure F.11: Hardware Update Wizard Finish Installation .......................................................A-28

Figure F.12: Hardware Properties ............................................................................................A-29

Figure F.13: Windows Device Manager ...................................................................................A-29

Figure F.14: Prototype Development Cable PD16-1417-FL3..................................................A-30

Figure F.15: Prototype Development Cable PD16-1417-FL3 Mechanical Specifications .........A-30

Figure E.9: MD-CS10x-000....................................................................................................A-31

vi

vii

List Of Tables

Part 1: Hardware Specifications

Table 1.2.1: MDrive17Plus P1 I/O and Power ........................................................................ 1-10

Table 1.2.2: MDrive17Plus P2 RS-422/485 Communications................................................ 1-11

Table 1.3.1: MDrive17Plus2 P1 16-Pin Wire Crimp............................................................... 1-15

Table 1.3.2: MDrive17Plus2 P2 RS-422/485 Communications.............................................. 1-15

Table 1.4.1: MDrive17Plus2-65 P1 19-Pin M23 Connector................................................... 1-20

Table 1.4.2: MDrive17Plus2-65 P2 - RS-422/485 Communications ...................................... 1-21

Table 1.6.1: MDrive23Plus P1 I/O and Power ........................................................................ 1-26

Table 1.6.2: MDrive23Plus P2 RS-422/485 Communications................................................ 1-27

Table 1.7.1: MDrive23Plus2 P1 & P3 14-Pin Wire Crimp and 2-Pin Wire Crimp................. 1-31

Table 1.7.2: MDrive23Plus2 P2 RS-422/485 Communications.............................................. 1-31

Table 1.8.1: MDrive23Plus2-65 P1 19-Pin M23 Connector................................................... 1-36

Table 1.8.2: MDrive23Plus2-65 P2 RS-422/485 Communications......................................... 1-37

Table 1.9.1: MDrive17Plus P1 I/O and Power ........................................................................ 1-39

Table 1.9.2: MDrive17Plus2 P1 16-Pin Wire Crimp............................................................... 1-40

Table 1.9.3: MDrive17Plus P2 CANopen Communications ................................................... 1-40

Table 1.9.4: MDrive17Plus2-65 P2 - CANopen Communications.......................................... 1-42

Table 1.9.5: MDrive17Plus2-65 P1 19-Pin M23 Connector................................................... 1-42

Table 1.10.1: MDrive17Plus P1 I/O and Power ...................................................................... 1-45

Table 1.10.2: MDrive23Plus2 P1 & P3 14-Pin Wire Crimp and 2-Pin Wire Crimp............... 1-45

Table 1.10.3: MDrive23Plus P2 CANopen Communications ................................................. 1-45

Table 1.10.4: MDrive17Plus2-65 P1 19-Pin M23 Connector................................................. 1-47

Table 1.10.5: MDrive17Plus2-65 P2 - CANopen Communications........................................ 1-47

Part 2: Connecting and Interfacing

Table 2.2.1: MDI Response to Echo Mode -Party and Check Sum are Zero (0)........................ 2-8

Table 2.2.2: MDI Response to Echo Mode -Party is One (1) and Check Sum is Zero (0) ........ 2-8

Table 2.2.3: MDI Response to Echo Mode -Party is Zero (0) and Check Sum is One (1) ........ 2-8

Table 2.2.4: MDI Response to Echo Mode -Party and Check Sum are One (1) ........................ 2-9

Table 2.3.2: Programmable Input Functions ........................................................................... 2-13

Table 2.3.3: Dedicated Input Functions .................................................................................. 2-13

Table 2.3.4: Programmable Output Functions ........................................................................ 2-14

Table 2.3.5: Dedicated Output Functions ............................................................................... 2-14

Table 2.3.6: MDrivePlus Motion Control I/O and Protection Ratings.................................... 2-15

Appendices

Table B.1: Recommended Supply Cables ..................................................................................A-5

Table C.1: Planetary Gearbox Operating Factor ........................................................................A-9

Table C.2: Planetary Gearbox Inertia Moments.......................................................................A-14

Table D.1: Output Bit Weight Examples - Outputs set as a group...........................................A-23

Table F.1: MD-CC400-000 Electrical Specifications ...............................................................A-25

Table F.2: MD-CC401-000 Electrical Specifications ...............................................................A-26

Table F.3: PD16-1417-FL3 Wire Color Codes........................................................................A-30

Table E.4: MD-CS10x-000 Wire Color Chart ........................................................................A-31

viii

Page Intentionally Left Blank

1-1

Part 1: Hardware Specications

Getting Started

Getting Started - MDrivePlus Motion Control

Before You Begin

The Quick Start guide is designed to help get you connected and communicating with the MDrivePlus Mo-

tion Control. The following examples will help you get the motor turning for the fist time and introduce you

to Immediate and Program modes of operation.

Tools and Equipment Required

• MDrivePlus Motion Control Unit

• Communications Converter Cable or equivalent (USB to RS-422)

• MDrivePlus Product CD or Internet access to www.imshome.com

• An Unregulated Power Supply (See specifications for your exact MDrivePlus Motion Control and

required voltage.)

• Basic Tools: Wire Cutters / Strippers / Screwdriver

• Wire for Power Supply (See specifications for your exact MDrivePlus Motion Control.)

• A PC with Windows 9x, Windows 2000, Windows XP Service Pack 2

• 10 MB hard drive space

• A free serial communications port

Connecting the Power Supply

Using the recommended wire (see the specifications for your MDrivePlus Motion Control), connect the DC

output of the power supply to the +V input of the connector appropriate for your MDrivePlus model.

Connect the power supply ground to the Power Ground pin appropriate for your MDrivePlus.

Connecting Communications

Connect the Host PC to the MDrivePlus Motion Control using the IMS Communications Converter Cable

or equivalent.

Install IMS Terminal Software

1. Insert the MDrive CD into the CD Drive of your PC.

If not available, go to http://www.imshome.com/software_interfaces.html.

2. The CD will autostart.

3. Click the Software Button in the top-right navigation Area.

4. Click the IMS Terminal link appropriate to your operating system.

5. Click SETUP in the Setup dialog box and follow the on-screen instructions.

6. Once IMS Terminal is installed, the Communications Settings can be checked and/or set.

WARNING! Please

ensure that you

read the sections of

the product manual

pertaining to the MDrivePlus

model you purchased in their

entirety prior to placing the unit

into full operation.

1-2 MDI Hardware Manual Revision R052506

1-3

Part 1: Hardware Specications

Establishing Communications

1. Open IMS Terminal by clicking Start>Programs>IMS Terminal>IMS Term. The Program Edit

Window (left) and Terminal Window (right) will be displayed.

2. On the Menu Bar click Edit / Preferences to open the Preferences dialog box.

3. Click on the Comm Settings tab to open the Comm Settings page.

a. Set Scroll Back to desired range of text lines to be displayed.

b. Under Device, verify that MDrive has been selected, and also verify the Comm Port being

used. Do not change any other settings. Click “OK”.

W A R N I N G :

Do not connect

or disconnect

DC input to the

MDrivePlus with power

applied! Disconnect the AC

power side to power down

the DC Supply.

For battery operated

systems, conditioning

measures should be taken

to prevent device damage

caused by in-rush current

draws, transient arcs and

high voltage spikes.

Figure GS.1: IMS Terminal Main Screen

Figure GS.2: IMS Terminal Prefrences Dialog

1-2 MDI Hardware Manual Revision R052506

1-3

Part 1: Hardware Specications

Apply Power to the MDrivePlus Motion Control

1. Verify that all connections have been made, then apply power to the MDrivePlus Motion Control.

Click on the Phone icon or the Disconnect status box to establish communications between IMS

Terminal and the MDrivePlus. The following sign-on message should appear in the Terminal

Window:

“Copyright 2001-2006 by Intelligent Motion Systems, Inc.”

2. If you can see the sign-on message, then the MDrivePlus is properly powered-up and

communicating.

a. If the sign-on message does not appear, try using a software reset. Hold down the “Ctrl” key

and press “C”. If the sign-on message still does not appear, check all connections, as well as all

hardware and software configurations, then start IMS Terminal again.

3. You are now connected and communicating to the MDrivePlus Motion Control.

Note: There are indicators at the bottom of the Terminal Window that show whether you are

connected or disconnected, the current Baud Rate, and the type of device (MDrive) for which the

IMS Terminal is configured. These three items may be changed directly from this screen by double

clicking on each of them.

Testing the MDrivePlus Motion Control

1. Click in the Terminal Window, and type (followed by ENTER):

PR VM

2. The MDrivePlus Motion Control will return a value of 768000

3. Type the following in the Terminal Window (followed by ENTER):

VM=360000

PR VM

4. The MDrivePlus Motion Control will return a value of 360000

5. Type FD and press ENTER. (FD = Factory Defaults)

“Copyright 2001-2006 by Intelligent Motion Systems, Inc.”

should appear in the Terminal Window within a few seconds.

Make the MDrivePlus Motion Control Move

1. Type MR 51200 into the Terminal Window and press ENTER. (MR = Move Relative)

a. With the default settings, the MDrive Motion Control should move one revolution in

approximately 0.066 seconds, or at a velocity of 15 revolutions per second.

2. Type SL 102400 and press ENTER. (SL = Slew)

a. With the default settings, the MDrivePlus Motion Control should run constantly at a speed of

approximately 2 revolutions per second or 120 revolutions per minute.

3. Type SL 0 and press ENTER. The MDrivePlus Motion Control should decelerate to a full stop.

Note: Entering

MDrivePlus commands

directly into the Terminal

Window is called

“Immediate Mode”.

The MDrivePlus Motion Control

command set is not case sensitive

except for command DN = < >

Warning: If you

have installed the

MDrivePlus to a load,

be sure the load can

safely be moved before testing.

Tip: A small piece of tape on the

motor shaft is a visual aid to help

see the shaft turning.

Figure GS.3: MDrivePlus Motion Control Sign-On Message

1-4 MDI Hardware Manual Revision R052506

1-5

Part 1: Hardware Specications

Motion Control Example Using Program Mode

1. Click on drop-down menu View > New Edit Window to open the Program Edit Window.

2. Type “XYZ Test” into the “Open a New file for editing” dialog box, and click “OK”.

3. Click anywhere within the Program Edit Window, and type (followed by ENTER):

VA LP=0 ‘user variable name LP = start count 0

A=100000 ‘set acceleration to 100000 steps/sec2

D=100000 ‘set deceleration to 100000 steps/sec2

PG 1 ‘enter program mode, start program at address 1

LB AA ‘label program AA

MR 250000 ‘move motor 250000 steps in the positive direction

H ‘hold program execution until motion completes

H 1000 ‘hold 1000 milliseconds

MR –250000 ‘move motor 250000 steps in the negative direction

H ‘hold program execution until motion completes

H 1000 ‘hold 1000 milliseconds

IC LP ‘increment user variable LP

PR ” LP=”,LP; ‘print axis position, 4 characters used, the

‘terminal will display LP=1 LP=2 LP=3

BR AA, LP<3 ‘branch to process label AA, if user variable LP< 3

E ‘end program execution

PG ‘exit program, return to immediate mode

4. Type FD in the Terminal Window and press ENTER to clear the MDrive buffer to factory

defaults before downloading any program.

5. Click on drop-down menu Transfer > Download to transfer the program from the Program

Edit Window to the Terminal Window. (Under “Source Type” choose “Edit Window”.)

6. Type EX 1 in the Terminal Window and press ENTER to execute the program.

(EX = Execute at address 1.)

7. The MDrivePlus Motion Control will turn 250,000 microsteps in a clockwise direction,

accelerating at 100,000 microsteps per sec2, then decelerating at 100,000 microsteps per sec2,

pausing for 1000 milliseconds, then reversing the sequence in a counterclockwise direction,

repeating the motion cycle 3 times until the program ends.

Programming Notes

The example above demonstrates basic commands that verify that your MDrivePlus Motion Control is com-

municating with your PC. More complex commands and movement may require that your I/O and/or Analog

Input be interfaced and configured. Refer to MDrivePlus Motions Control Software Reference for details.

For more information on MDrivePlus Motion Control Programming and Command Control Sets, refer to the

Software Section of this manual.

NOTE: Entering

MDrivePlus

commands into the

Program Edit Window,

to be edited and saved, is

called “Program Mode”.

NOTE: The program

can be stopped by

pressing the Escape Button or

by pressing Ctrl+C.

Figure GS.4: Download the Program

1-4 MDI Hardware Manual Revision R052506

1-5

Part 1: Hardware Specications

TM

Excellence in Motion

Section 1.1: MDrive17Plus Motion Control Product Introduction

Section 1.2: MDrive17Plus Motion Control Detailed Specications

Section 1.3: MDrive17Plus2 Motion Control Detailed Specications

Section 1.4: MDrive17Plus2-65 Motion Control Detailed Specications

Section 1.5: MDrive23Plus Motion Control Product Introduction

Section 1.6: MDrive23Plus Motion Control Detailed Specications

Section 1.7: MDrive23Plus2 Motion Control Detailed Specications

Section 1.8: MDrive23Plus2-65 Motion Control Detailed Specications

Part 1:

Hardware

Specifications

TM

1-6 MDI Hardware Manual Revision R052506

1-7

Part 1: Hardware Specications

Section 1.1

MDrive17Plus Motion Control Product Introduction

Introduction to the MDrive17Plus Motion Control System

The MDrive17Plus Motion Control offers system

designers a low cost, intelligent motion controller

integrated with a NEMA 17 high torque brushless

motor and a +12 to +48 volt microstepping driver.

The unsurpassed smoothness and performance

delivered by the MDrive17Plus Motion Control are

achieved through IMS's advanced 2nd generation

current control. By applying innovative techniques

to control current flow through the motor, resonance

is significantly dampened over the entire speed range

and audible noise is reduced.

The MDrive17Plus accepts a broad input voltage

range from +12 to +48 VDC, delivering enhanced

performance and speed. Oversized input capacitors

are used to minimize power line surges, reducing

problems that can occur with long runs and multiple

drive systems. An extended operating temperature range of –40° to +85°C provides long life, trouble free service

in demanding environments.

Standard features available in the MDrive17Plus Motion Control include four +5 to +24 volt general purpose

I/O lines, one 10 bit analog input, 0 to 5MHz step clock rate, 20 microstep resolutions up to 51,200 steps per

revolution, and full featured easy-to-program instruction set.

Expanded features in the MDrive17Plus2

version include up to eight +5 to +24 volt general purpose I/O lines

and the capability of electronic gearing by following a rotary or linear axis at an electronically controlled ratio,

or an output clock can be generated fixed to the internal step clock.

For use in environments where exposure to chemical, dust and liquids may occur, a sealed assembly

MDrive17Plus2-65 version is designed to meet IP65 speci-

fications.

All MDrive17Plus Motion Control are available with

optional closed loop control. This increases functionality by

adding stall detection, position maintenance and find index

mark.

The closed loop configuration is added via a 512 line (2048

edge) magnetic encoder with index mark, internal to the

unit so there is no increase in length. Or, for an expanded

choice of line counts and resolutions with MDrive17Plus2

versions only, closed loop control is available with an inter-

face to a remotely mounted user-supplied external encoder.

The MDrive communicates over RS-422/485 which allows

for point-to-point or multiple unit configurations utilizing

one communication port. Addressing and hardware support

up to 62 uniquely addressed units communicating over a

single line. Baud rate is selectable from 4.8 to 115.2kbps.

Available motor configurations are available in three motor

lengths. Interface connections are accomplished using 12.0”

(30.5cm) flying leads or a 7 position terminal strip. Plus2 versions come with pluggable locking wire crimp con-

nectors. Plus2-65 sealed versions come with M12/M23 circular connectors.

The MDrive17Plus is a compact, powerful and inexpensive solution that will reduce system cost, design and

assembly time for a large range of brushless motor applications

Standard Feature Summary

n Highly Integrated Microstepping Driver, Motion Controller and NEMA 17 High Torque Brushless

Motor

n Advanced 2nd Generation Current Control for Exceptional Performance and Smoothness

n Single Supply: +12 to +48 VDC

n Low Cost

n Extremely Compact

Note: The

MDrivePlus Motion

Control is available

in a CAN communications

conguration. For more

information and Hardware

Specications see Appendix G

of this document.

For detailed descriptions of

supported CANopen objects

please refer to the MDrive

CANpen Software Reference.

Figure 1.1.1: MDrive17Plus

Figure 1.1.2: MDrive17Plus2-65

1-6 MDI Hardware Manual Revision R052506

1-7

Part 1: Hardware Specications

n Available Options:

- Internal Magnetic Encoder for Closed Loop Control

- Integrated Planetary Gearbox

- Control Knob for Manual Positioning

- Linear Slide

n Three Rotary Motor Lengths Available

n Auxiliary Logic Power Supply Input

n 20 Microstep Resolutions up to 51,200 Steps Per Rev Including: Degrees, Metric, Arc Minutes

n Open or Optional Closed Loop Control

n Programmable Motor Run and Hold Currents

n Four +5 to +24 VDC I/O Lines Accept Sourcing or Sinking Outputs

n One 10 Bit Analog Input Selectable: 0 to

+10 VDC, 0 to +5 VDC, 0-20 mA, 4-20 mA

n 0 to 5MHz Step Clock Rate Selectable in 0.59Hz Increments

n RS-422/485 Communications

n 62 Software Addresses for Multi-Drop Communications

n Simple 1 to 2 Character Instructions

n Interface Options:

- Pluggable Terminal Strip

- 12.0” (30.5cm) Flying Leads

The MDrive17Plus Motion Control Key Differences and Enhanced Features

There are three different variants of the MDrive17Plus Motion Control, these are:

1. MDrive17Plus Motion Control

The MDrive17Plus Motion Control is the standard version of the MDrive17Plus and is drop-in

compatible with the legacy MDrive17 Motion Control product. The key feature additions from

the original MDrive17 Motion Control are:

n Improved current control.

n 20 Microstep resolutions to 51,200 steps per rev including degrees, metric and arc minutes.

n 4 +5 to +24 VDC I/O lines which accept sinking or sourcing inputs.

n One 0 to +10 VDC Analog input.

n Optional pluggable strip for interface.

See Section 1.2 of this document for detailed specifications on the MDrive17Plus Motion Control.

2. MDrive17Plus2 Motion Control

The MDrive17Plus2 Motion Control adds expanded functionality to the MDrive17Plus in the

form of:

n Enhanced and expanded I/O set (8 lines) which can be configured as sinking or sourcing inputs or

outputs.

n Remote Encoder option (Reduces I/O set to 4 lines).

n High speed position capture input or trip output.

n Pluggable wire crimp interface.

n Electronic gearing.

See Section 1.3 of this document for detailed specifications on the MDrive17Plus2 Motion Control.

3. MDrive17Plus2-65 Motion Control

The MDrive17Plus2-65 Motion Control adds protection against the ingress of fluids and dust to

the MDrive17Plus2 by changing the motor-drive enclosure to meet IP65 specifications. With this

change the connector configuration changes to industry standard M12/M23 circular connectors.

See Section 1.4 of this document for detailed specifications on the MDrive17Plus2-65 Motion Control.

1-8 MDI Hardware Manual Revision R052506

1-9

Part 1: Hardware Specications

WARNING!

The maximum

+48 VDC Input

Voltage of the

MDrive17Plus series includes

motor Back EMF, Power

Supply Ripple and High Line.

WARNING! Because the

MDrivePlus consists of two

core components, a drive

and a motor, close attention

must be paid to the thermal

environment where the

device is used. See Thermal

Specications.

SECTION 1.2

MDrive17Plus Detailed Specications

Standard Electrical Specifications

Input Voltage (+V)

Range....................................................................................................................+12 to +48 VDC

Power supply current requirements (max. per MDrive17Plus).....................................................2A

(Actual power supply current will depend on voltage and load)

Aux. Logic Input Voltage

Range....................................................................................................................+12 to +24 VDC

(Maintains power to control and feedback circuits [only] when input voltage is removed)

Analog Input (IN5)

Resolution..............................................................................................................................10 Bit

Voltage Range .................................................. 0 to +5 VDC, 0 to +10 VDC, 4 - 20mA, 0 - 20mA

General Purpose I/O

Number/Type

Plus (1-4) ........................................................... 4 Sinking Outputs / 4 Sourcing or Sinking Inputs

Voltage Range

Input................................................................................... TTL level compatible, up to +24 VDC

Output ................................................................................................... (Sinking) up to +24 VDC

Logic Threshold

Logic 0.............................................................................................................................<0.8VDC

Logic 1.............................................................................................................................>2.2VDC

Output Sink Current (per channel)* .........................................................................Up to 600 mA

Protection ..............................Over Temp, Short Circuit, Transient Over Voltage, Inductive Clamp

Communication

Protocol (Standard) ....................................................RS-422/RS-485, Full/Half Duplex Selectable

Baud Rate ............................................................................... 4.8k, 9.6k, 19.2k, 38.4k, 115.2kbps

* See I/O Ratings on In Section 2.3: Interfacing the MDrivePlus Motion Control I/O

Thermal Specifications

Motor Temperature ............................................................................................100°C (maximum)

Operating Temperature ...............................................................................................-40 to +85°C

Standard Motion Specifications

Microstep Resolution – Open Loop Configuration

Number of Microstep Resolution Settings................................................................................. 20

Available Microsteps Per Revolution

200 400 800 1000 1600 2000 3200 5000 6400 10000

12800 20000 25000 25600 40000 50000 51200 360001216002254003

1=0.01 deg/µstep 2=1 arc minute/µstep 3=0.001 mm/µstep

Encoder (Optional)

Type ....................................................................................................................Internal, Magnetic

Resolution............................................................................512 Lines/2048 counts per Revolution

1-8 MDI Hardware Manual Revision R052506

1-9

Part 1: Hardware Specications

Counters

Type .................................................................................................... Position (C1), Encoder (C2)

Resolution..............................................................................................................................32 Bit

Edge Rate (Max) ..................................................................................................................5 MHz

Velocity

Range................................................................................................. ±5,000,000 Steps per Second

Resolution................................................................................................. 0.5961 Steps per Second

Acceleration/Deceleration

Range................................................................................................... 1.5 x 109 Steps per Second2

Resolution....................................................................................................90.9 Steps per Second2

† Adjusting the microstep resolution can increase the range.

Software Specifications

Program Storage, Type/Size ...................................................................................Flash/6384 Bytes

User Registers................................................................................................................... (4) 32 Bit

User Program Labels and Variables ............................................................................................ 192

Math, Logic and Conditional Functions ............ +, –, x,÷, >, <, =, <=, >=, AND, OR, XOR, NOT

Branch Functions ...................................................... Branch & Call (conditonal or unconditional)

Predefined I/O Functions...................................Inputs Home, Limit Plus, Limit Minus, Go, Stop,

Pause, Jog Plus, Jog Minus, Analog In

Outputs ................................................................................Moving, Fault, Stall, Velocity Change

Trip Functions ....................................Trip on Input, Trip on Position, Trip on Time, Trip Capture

Party Mode Addresses ................................................................................................................. 62

Encoder Functions ............................................Stall Detection, Position Maintenance, Find Index

Motor Specifications

Single Length

Holding Torque................................................................................................ 32 oz-in/22.6 N-cm

Detent Torque............................................................................................... 1.66 oz-in/1.17 N-cm

Rotor Inertia ................................................................................0.00053 oz-in-sec2/0.038kg-cm2

Weight (Motor + Driver)...........................................................................................9.8 oz/277.8 g

Double Length

Holding Torque................................................................................................ 60 oz-in/42.4 N-cm

Detent Torque............................................................................................... 2.08 oz-in/1.47 N-cm

Rotor Inertia ................................................................................0.00080 oz-in-sec2/0.057kg-cm2

Weight (Motor + Driver).........................................................................................10.5 oz/297.7 g

Triple Length

Holding Torque............................................................................................. 74.9 oz-in/52.9 N-cm

Detent Torque............................................................................................... 3.47 oz-in/2.45 N-cm

Rotor Inertia ................................................................................0.00116 oz-in-sec2/0.082kg-cm2

Weight (Motor + Driver).........................................................................................15.1 oz/428.1 g

WARNING!

When using the

MDrivePlus Motion

Control with

optional internal magnetic

encoder, no axial force may

be applied to the motor shaft

without use of a load bearing

isolation coupling.

1-10 MDI Hardware Manual Revision R052506

1-11

Part 1: Hardware Specications

Mechanical Specications

Dimensions in Inches (mm)

Pin/Wire Assignments

P1: I/O & POWER CONNECTOR

Pluggable

Terminal Strip

Flying Leads

Wire Colors Function

Pin 1 White/Yellow I/O 1

Pin 2 White/Orange I/O 2

Pin 3 White/Violet I/O 3

Pin 4 White/Blue I/O 4

Pin 5 Green Analog Input

Pin 6 Black Power/Aux-Ground

Pin 7 Red +V (+12 to +48 VDC)

P1 Connector Options

LMAX LMAX2

Motor Length SINGLE SHAFT or

ENCODER VERSION

CONTROL

KNOB VERSION

Single 2.20 (55.9) 2.79 (70.9)

Double 2.43 (61.7) 3.02 (76.7)

Triple 2.77 (70.4) 3.37 (85.6)

MDrive17Plus Lengths Inches (mm)

Ø 0.97

(Ø 24.6)

Control Knob

LMAX2 Option

7-Pin Pluggable Clamp

Type Terminal Strip

Flying Leads

P2 Connector Options MDrivePlus

10-Pin IDC

10-Pin Friction Lock

Wire Crimp

Figure 1.2.1: MDrive17Plus Mechanical Specifications

P1

1

2

3

4

5

6

7

+V (+12 to +48 VDC)

Power Ground

I/O 1

I/O 2

I/O 3

I/O 4

Analog Input

Table 1.2.1: MDrive17Plus P1 I/O and Power

Figure 1.2.2: P1 - 12 in/304.8 cm Flying Leads Figure 1.2.3: P1 7-Pin Pluggable Connector

P1 Connector - I/O and Power Connections

This manual suits for next models

5

Table of contents

Other Intelligent Motion Systems DC Drive manuals

Popular DC Drive manuals by other brands

Siemens

Siemens SINAMICS SH150 Operating instructions & installation instructions

sauter

sauter AVM Series instructions

Eaton

Eaton DB1-122D3 Series Instruction leaflet

Danfoss

Danfoss VLT AutomationDrive FC 301 instruction manual

Drivecon

Drivecon XT Series owner's manual

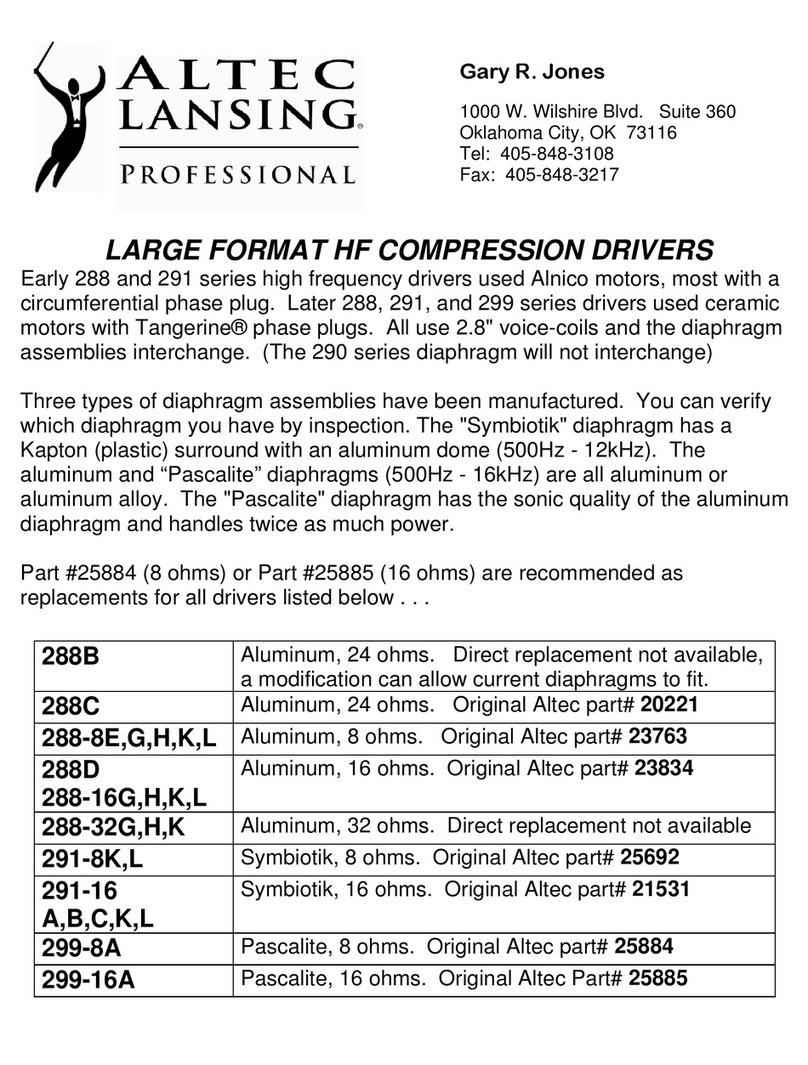

Altec Lansing

Altec Lansing HF DRIVER CROSS REFERENCE MASTER LIST Reference

LSIS

LSIS SV-iS7 series manual

Automatismi CAB

Automatismi CAB PRESTIGE PS.13M User handbook

Copley Controls

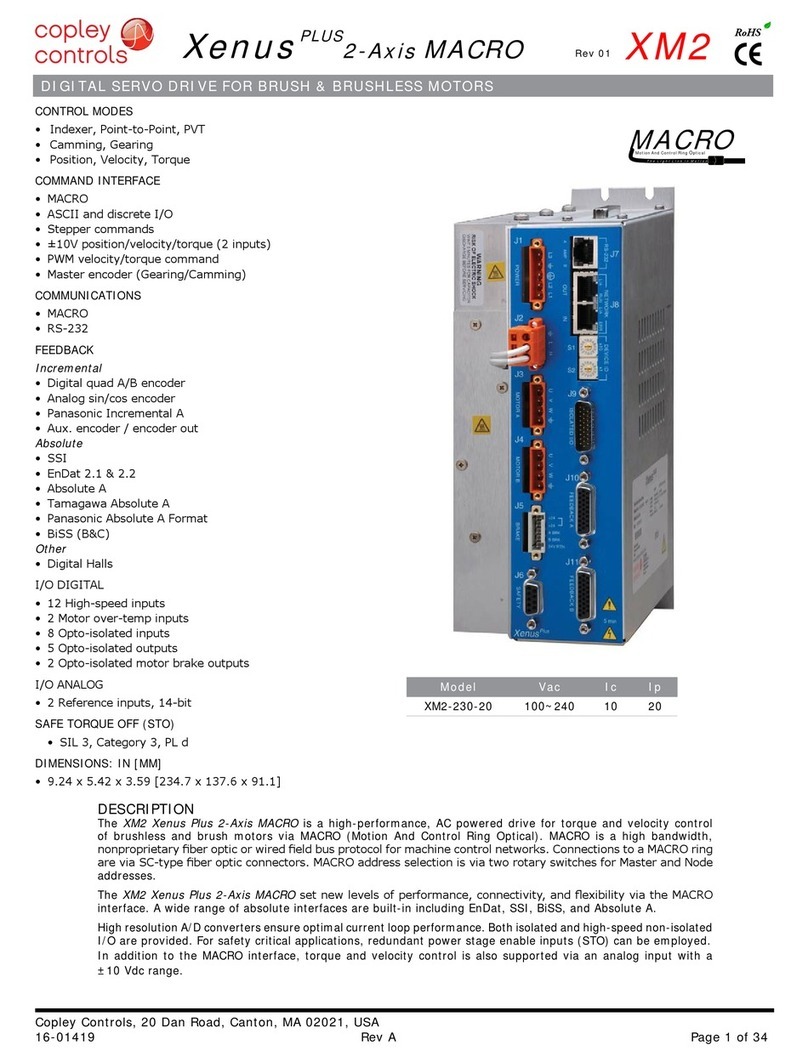

Copley Controls XM2-230-20 Instruction

LS ELECTRIC

LS ELECTRIC LSLV-H100 Series user manual

Phoenix Mecano

Phoenix Mecano DewertOkin MEGAMAT P installation instructions

YASKAWA

YASKAWA H6R B Series manual