Inter-Track IT-E240 User manual

IT-E240 INTER-TRACK

Luxury Magnetic

Elliptical Machine

To ensure your safe, reliable and comfortable use of this exercise

bike, please read the following important matters and all operation

instructions before use.

1.

This fitness bike is a fixed fitness equipment and is an aerobic training equipment for improving

cardiovascular function.

2.

The exercise bike should be placed on the flat ground when in use.

3.

Before use, please check that all bolts, and other parts are properly installed andlocked.

4.

Please wear appropriate clothes, shoes and socks, please do not wear a dress or too long blouse, so

as that is doesn't hook on the exercise bike.

5.

The activity space of this machine should be larger than 120*100*200cm.

6.

Children should be supervised to ensure that they do not play with utensils.

7.

This appliance is not intended for use by persons (including children) who are physically weak, slow in

response or have mental disorders, unless it is safely used under the guidance or with the help of a

person responsible for their safety.

8.

The maximum weight of the user of the machine shall not exceed 130Kg.

9.

The braking device of the machine is magnetic resistance type.

10.

The machine meets the requirements of EN957-5HC class.

Warning: Violation of the above safety regulations will result in personal and equipment injuries.

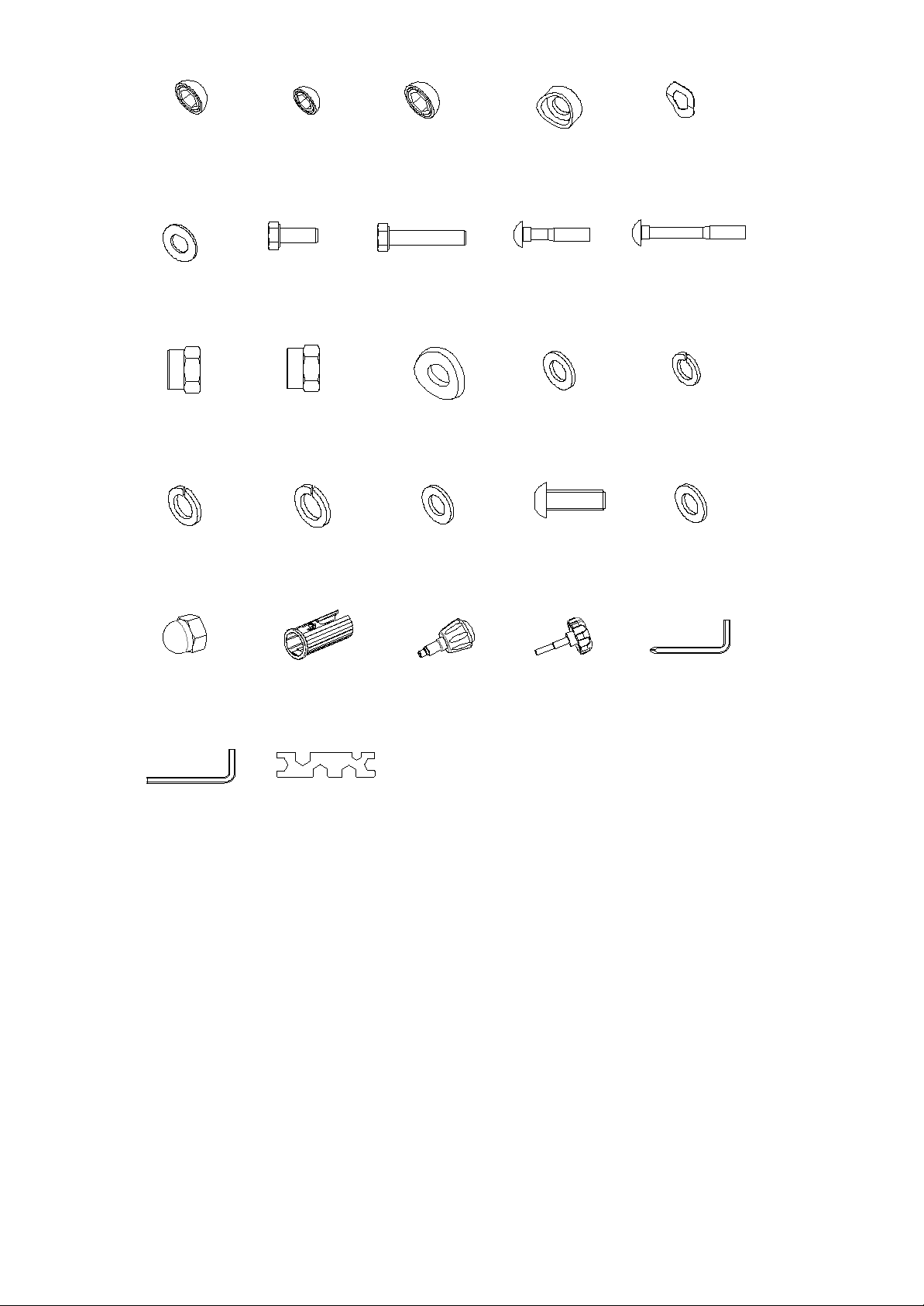

Tools and accessories

(53)D-washer

2pcs

(43)Wave Washer

4pcs

(59)Hexagon head bolt

M8*20 2pcs

(13)Nut capS=17

8pcs

(20)Nut capS=13

2pcs

(16)Arc Spacer

2pcs

(21)Nut cap S=19

2pcs

(61)Hexagon head bolt

M8*45 4pcs

(67)

Locknut M8

4pcs

(66)

Locknut M10

4pcs

((71)flat washerΦ10

6pcs

(88)D-shaped transition

sleeve 1pcs

(86)Spring knob

1pcs

(87)shot knob

1pcs

(78)Wrench S=5

1pcs

(79)Wrench S=8

1pcs

(80)Screw driver

1pcs

(65)Cap nut M8

8pcs

(54)Square Neck Screw

M8X75 4pcs

(55)Square Neck Screw

M8X45 4pcs

(56)Half-Roundhead

Hex bolt M8X20 8pcs

(77)Spring washer Φ12

2pcs

(75)Spring washer Φ8

12pcs

(76)Spring washer Φ10

6pcs

(52)Arc washerΦ8

12pcs

(71)flat washerΦ8

4pcs

(72)Large flat

washerΦ8 2pcs

Part list

serial

number

NAME QTY

serial

number

NAME QTY

1

Frame weldment

1

48

F33.4 square plug

2

2 Front bracket weldment 1 49 Off-center foot cover 2

3

Left swing arm weldment

1

50

Left pedal shaft 1/2

'

1

4 Right swing arm weldment 1 51 Right pedal shaft 1/2'1

5 Hand held heart rate weldment 1 52 Arc washer Ф8 12

6

Roller frame weldment

1

53

D-shaped washer

2

7 Welded parts of rear clamp seat 2 54

Semi-round head square neck bolt

M10×75

4

8

U-shaped seat weldment

2

55

Semi-round head square neck bolt M8×45

4

9 Foot tube 2 56 Hexagonal bolt cup head M8×16 9

10

Rotatable foot cover

2

57

Hexagonal bolt cup head M10×55

2

11 Pedal tube 2 58 Hexagonal bolt cup head M6×10 1

12 Footboard 2 59 Hexagonal-head bolt M8×20 2

13

Nut cap S=17

8

60

Hexagonal-head bolt M10×70

2

14 Left hand handle tube 1 61 Hexagonal-head bolt M8×45 4

15

Right hand handle tube

1

62

Pan head screws with cross recess M5X35

1

16 Arc spacer 2 63

Cross recessed pan head tapping screws

ST4X20

11

17 Electronic watch 1 64

Cross recessed pan head tapping screws

ST4X10

2

18

Power output fine tuning

connection

1 65 Cap nut M8 8

19 Eight-section trimmer body 1 66 Locknut M10 6

20

Nut cap S=13

2

67

Locknut M8

5

21 Nut cap S=19 2 68 Hexagonal nutM6 2

22

Swing arm sleeve

4

69

Hexagon nuts with flange M10

2

23

Axle sleeve

8

70

Flat washer Ф10

8

24 Internal magnetic flywheel 1 71 Flat washer Ф8 4

25

Hold-on handle sleeve of heart rate

tube in hand

2 72 Large washer Ф8 2

26 Nylon washer 4 73 Arc washer Ф5 1

27

Heart rate sensor

2

74

Spring washer Ф6

1

28 Large end plug of Ф29 pipe 2 75 Spring washer Ф8 12

29 F30 square plug 2 76 Spring washer Ф10 6

30

Left lock nut 1/2

'

1

77

Spring washer Ф12

2

31 Right lock nut 1/2'1 78 Dual-purpose screwdriver s=5 1

32

Crank spacer

2

79

Hex wrench s=8

1

33 Nine bowls 1 80 Multi-mouth wrench 2

34 Pinch roller 1 81

35

A section of crank

1

82

Seat cushion bracket weldment 1

36 6V belt 1 83

Welding part of seat cushion adjusting

frame 1

37

Large pulley

1

84

Seat cushion tube decorative cover 1

38 Right shield 1 85

Seating washer 1

39 Left shield 1 86

Stretching rotating handle 1

40

Heart rate line

2

87

Torx handwheel 1

41 Sensing line 1 1 88

D-shape hollow plug 1

42

Sensing line 2

1

89

Great round end plug 2

43 Wave elastic washer 4

Pan head screws with cross recess M5X12 4

44

Adjusting pull rod

1

45

Adjusting pull gear

2

46 Adjusting drawing 2

47

Handle sleeve of handle pipe

2

Note:

(1) Please refer to the schematic diagram and install it step by step.

(2) All plugs, foot pads and shields have been installed before leaving the factory. The swing arm, U-shaped clamp,

pedal tube and rear clamp seat have been assembled to form a swing rod assembly.

(3) When connecting parts with bolts and nuts, assemble them directly by hand. After all parts are assembled, use tools

to tighten them in place one by one when making final adjustment.

(4) Open the packing box, take out the parts and put them in different categories, and carry out the following

installation with reference to the installation diagram and parts list.

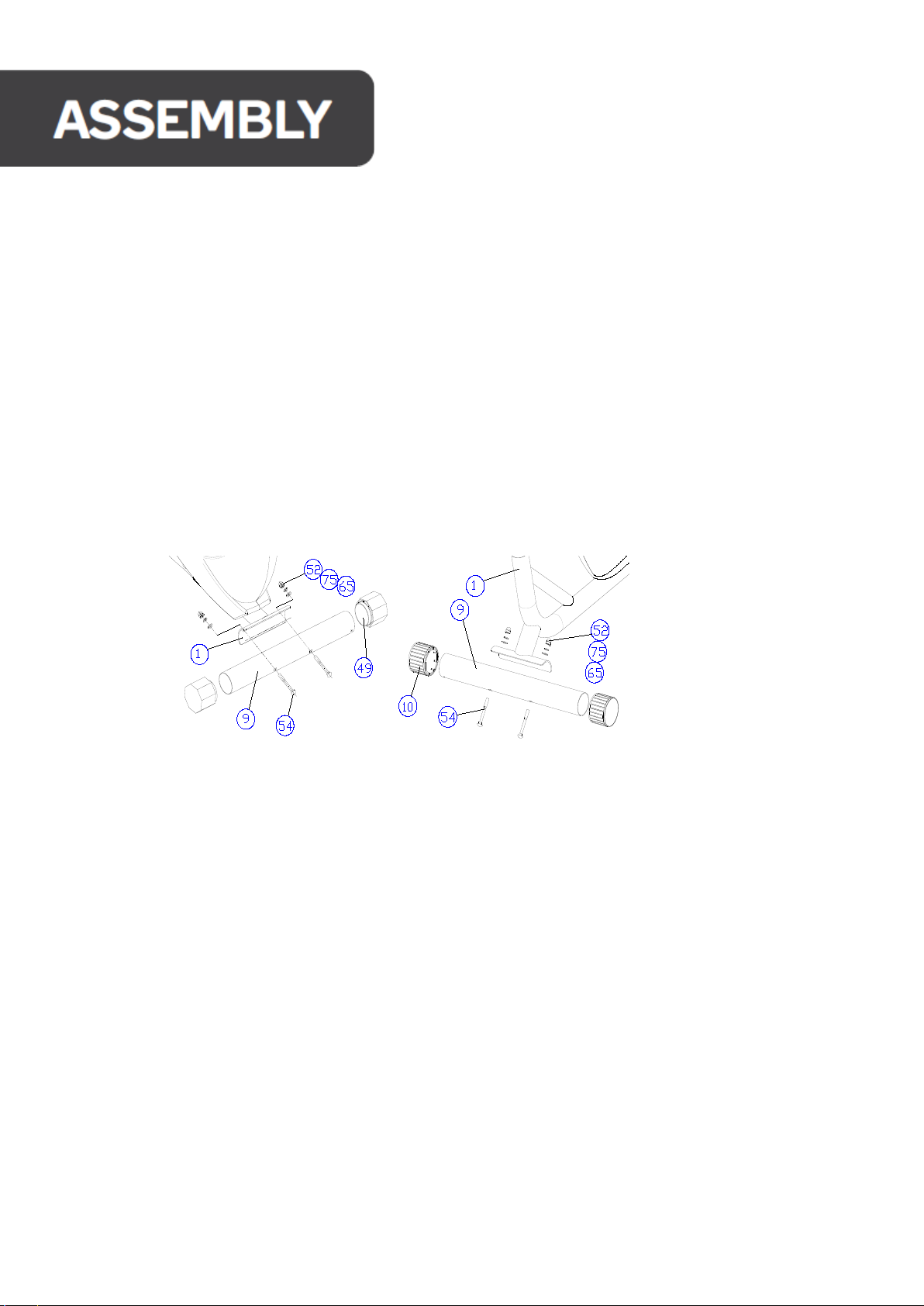

1. Install the rear bottom pipe

Install the rear bottom pipe (2) on the rear connecting plate of the frame (1) with two sets of semicircular head square

neck bolts M8×75(54), arc washer ф 8 (52), spring washer ф 8 (75) and cap nut M10(65). (see fig.1)

2. Install the front bottom pipe

Use two sets of semicircular head square neck bolts M8×75(54), arc washer ф 8 (52), spring washer ф 8 (75) and cap nut

M8(65) to install the

front foot pipe (2) on the front connecting plate of the frame (1). (see fig.2)

Figure 1 Figure 2

3.Installing front bracket

A. Connect the terminal at the lower end of the eight-section trimmer body (19) firmly with the output fine

adjustment connecting line (18). (Note: firstly, turn the output trimmer knob all the way to the "-"direction (at this

time, the connector terminal of the output trimmer body extends to the longest), tighten the connector terminal

on the connecting hook of the output trimmer connecting wire connector as shown in the figure, and pull it up hard

to clamp the upper end of the output trimmer body into the groove of the adjusting frame. In case that the upper

end of the output fine adjustment body line cannot be just clamped into the groove of the adjusting frame, please

screw the nut at the lower end of the adjusting frame to a proper position, so that the upper end of the output fine

adjustment body line is just clamped into the groove of the adjusting frame. (see fig. 4-A, b and c)

B. Connect the sensor line 2(41) joint at the lower end of the front bracket (2) and the sensor line 1(42) joint at the

upper end of the frame (1) firmly. (see fig.3-D)

C. Set the front bracket (2) on the frame (1) and lock it with 6 sets of hexagon socket head bolts M8×16(56), spring

washers ф 8 (75) and arc washers ф 8 (52). (see fig.3-D)

Figure 3

4.Install the hand-held heartrate tube

Pass the heart rate wire (40) through the small hole on the back of the upper end of the front bracket (2), and then

pass out from the upper port,Then align the hand-held heart rate tube weldment (5) with the screw hole on the front

bracket (2), and lock it with two sets of hexagon socket head bolts M8×20(56), spring washers ф 8 (75) and arc

washers ф 8 (52). (see fig.4)

5.Installing electronic watch

A. Connect the heart rate line (40) and the sensing line 2(41) with the corresponding connectors of the electronic watch

(17) and insert the redundant lines into the tube.

B. Align the hole position of the electronic watch (17) with the hole on the instrument panel on the front bracket (2).

And locked with four corner bolts M5×12(90). (see fig.5)

Figure 4Figure 5

6.Install the left and right swing arm assemblies

Two arc spacers (16) are respectively sleeved on both ends of the swing rod shaft on the front bracket (the arc

mouth is inward), then a wave elastic washer (43) is sleeved on the swing rod shaft on the front bracket (one end of

the long sleeve is inward). Put on plastic flat washer ф 8 (53), large flat pad ф 8 (72), spring washer ф 8 (75), lock

hexagon bolt M8×20(59), and then fasten nut cap (20),At this time, the swing rod should be able to swing freely.

(see fig.6)

Figure 6

Metal

Bracket

R esistan ce

c a b le

Lo w er

c a b le

R esistan ce

c a b le

Lo w er

c a b le Lo w er

c a b le

R esistan ce

c a b le

7

.

Pedal shaft installation (same left and right)

the pedal pipe rear clamp weldment (35), and then put on the wave elastic washer Pass the pedal shaft (30) through

(28) and pedal shaft spacer (54) in turn, then screw the pedal shaft (30) onto a crank (67), tighten the pedal shaft with a

booster rod and lock it with a lock nut (as

shown in fig.7)

Figure 7Figure 8

Note: The left and right threads must be installed in a matching way, and there are left and right marks on the

corresponding spare parts: left thread "L" and right thread "R".

8. Install foot pedals

Align the pedals (5) (one on the left and one on the right) back and forth, and fix them on the pedal tube (4) with four

sets of hexagon-head bolts M8×50(37), flat washers ф 8 (50) and locknuts M8(42). (see fig.8)

9.Left and right hand handle

Use four sets of hexagon-head bolts M8×45(55), arc washers ф 8 (52), spring washers ф 8 (75) and cap nuts M8(65) to

connect the two handle tubes (14, 15) to the upper ends of the left and right swing arms (3). (see fig.9)

Note: Hexagon head bolts must be inserted into hexagonal holes of swing arms.

10.Install the nut cover

After the whole machine is installed and adjusted, the nut cap (13) is clamped at the joints of the U-shaped seat

weldment (8), the swing arm (3) and the pedal tube (11). (see fig.10)

Figure 9 Figure 10

11.Seat cushion installation

Install the seat cushion (85)onthe seat cushion adjusting frame (83)with three sets of

nylon nuts M8(67), spring washers ф 8 (75)andflat washers ф 8 (71). (see fig.11)

Figure 11

12.Seat cushion frame installation

A.Then insert the lifting cushion frame weldment (82) into the D-shaped transition

sleeve (88), and insert the lifting cushion frame weldment (82)into the seat branch

pipe of the main frame (1), sothat the upper end screw seat hole of the seat branch

pipe of the main frame (1) is aligned with a certain hole position on the lifting cushion

frame weldment (82); Then insert the stretching knob (86)into the hole, and tighten

the handwheel with force. (see fig.12)

Figure 12

B. insert the seat cushion adjusting frame (83) into the upper end of the lifting seat cushion frame weldment

(87) after

(82) according to the direction shown inthe figure, and lock itwith a plum blossom handwheel

adjusting a certain position. (see fig.12)

Remarks:

1. When lifting the seat cushion frame weldment (82)at high and low positions, just unscrew the stretching

knob (86), and then tighten the hand wheel with force after lifting the seat cushion frame weldment (82) to a

suitable position.

2. When adjusting the front and rear position ofthe seat cushion frame (83), just screw out the plum hand

wheel (87), adjust the seat cushion frame (83)to a proper position, and then tighten the hand wheel hard.

3. If the seat cushion isfound to be skewed, loosen the fixing nut at the lower end ofthe seat cushion, adjust

the seat cushion and lock it again.

1.

Load adjustment: resistance fine tuning knob, clockwise rotation, resistance increase, according to your own

needs to adjust the level of resistance.

2.

Adjusting the height of the seat: loosen and pull back the hand screw on the seat cushion cannula, lift or lower the seat

cushion tube to an appropriate position according to the needs of the wearer. Then, the hand screw will be

automatically inserted into the seat cushion tube hole to tighten the hand screw.

3.

When riding a bike, sit on the cushion, fasten the pedal strap and hold the handle with both hands. The upper body can

freely change its position

FUNCTION KEYS/MANUAL MODE:

1. MODE: Push down for selecting functions. If the MODE button is held down for a long time, all

values will return to 0 except the ODO.

2. SET: To set the values of time, distance,pulse and calories when not in scan mode.

3. RESET: Push down for resetting time, distance & calories, the current data change to 0.

WINDOW DISPLAY

•TIME: Displays the elapsed using time (0:00-99:59 MIN).

•SPEED: The speed range is 0.0-999.9KM/H (or Mile/H).

•DISTANCE: Displays the total distance traveled (0.0-9999KM or MILES).

•CALORIES: Displays total calories burned (0.0-9999 CAL).

•PULSE (if have): Displays your pulse data when hands are placed on the sensors (40-240BPM).

I. Installation method

1.

Remove the battery door on the back shell of the meter and install two new 1.5V AA batteries in the

positive and negative directions of the battery box (for battery products not installed).

2.

Fix the instrument on the pipe in front of the fitness equipment with screws.

3.

Connect the sensor wire plug with the outlet connector on the back of the instrument or insert the

signal input jack on the back of the instrument.

4.

Quick step on the fitness equipment and the displayed speed changes indicate that the installation

is qualified; otherwise, check whether the magnet seat and the sensor are installed correctly and

whether the sensor wire plug and the lead wire of the watch head are connected reliably.

II: Method of use:

Hint: Sometimes there will be signal interference when the palm holds the metal sheet. The

heart rate displayed in the first 2~3 seconds may not be correct and appear high, which is a

normal phenomenon. Then the heart rate will return to normal measurement. This method

of heart rate detection is mainly helpful to determine the amount of exercise you do, not as

a basis for disease treatment.

III:The battery replacement

When the display darkens or shows no display, remove the battery cover and install two new

1.5V AA batteries in the positive and negative direction of the battery. Install the battery cover.

1.

Press the MODE key to select the display window that needs to be SET or cleared, and the "SET"

symbol on the corresponding window flashes. Press the SET key to SET the time, distance or

calories required. Press the RESET key to clear the corresponding window display value.

2.

Step on the fitness equipment to start measuring, and observe your exercise parameters

according to the contents displayed in the window.

3.

Heart rate measurement: press any key, then grasp the corresponding position of heart rate

sensor metal plate with the left and right palms respectively (note: each palm should touch

two metal plates at the same time). The monitor in the heart rate display window will show

your current heart rate in seconds or less. When the heartbeat signal is received during the

measurement, the heartbeat corresponds to the "❤". In order to prevent the influence of

palm movements on heart rate measurement and ensure the accuracy of heart rate

measurement, it is suggested that the heart rate measurement should be carried out after

the exercise is suspended or stopped, and the heart rate measurement should not be carried

out at the same time of running.

(1) Maintenance

1.

Regularly check whether the bolts and nuts of each part are fastened, whether the adjusting

knob is locked, whether the rotating part is flexible, and whether there are any worn or damaged

parts. Ensure that all parts are in good condition to ensure the safety of the equipment.

2.

Parts that are worn or damaged should be replaced immediately or sent to the maintenance

center for replacement before use after repair.

3.

Keep the equipment clean, but do not wipe it with acid, alkaline or organic solution.

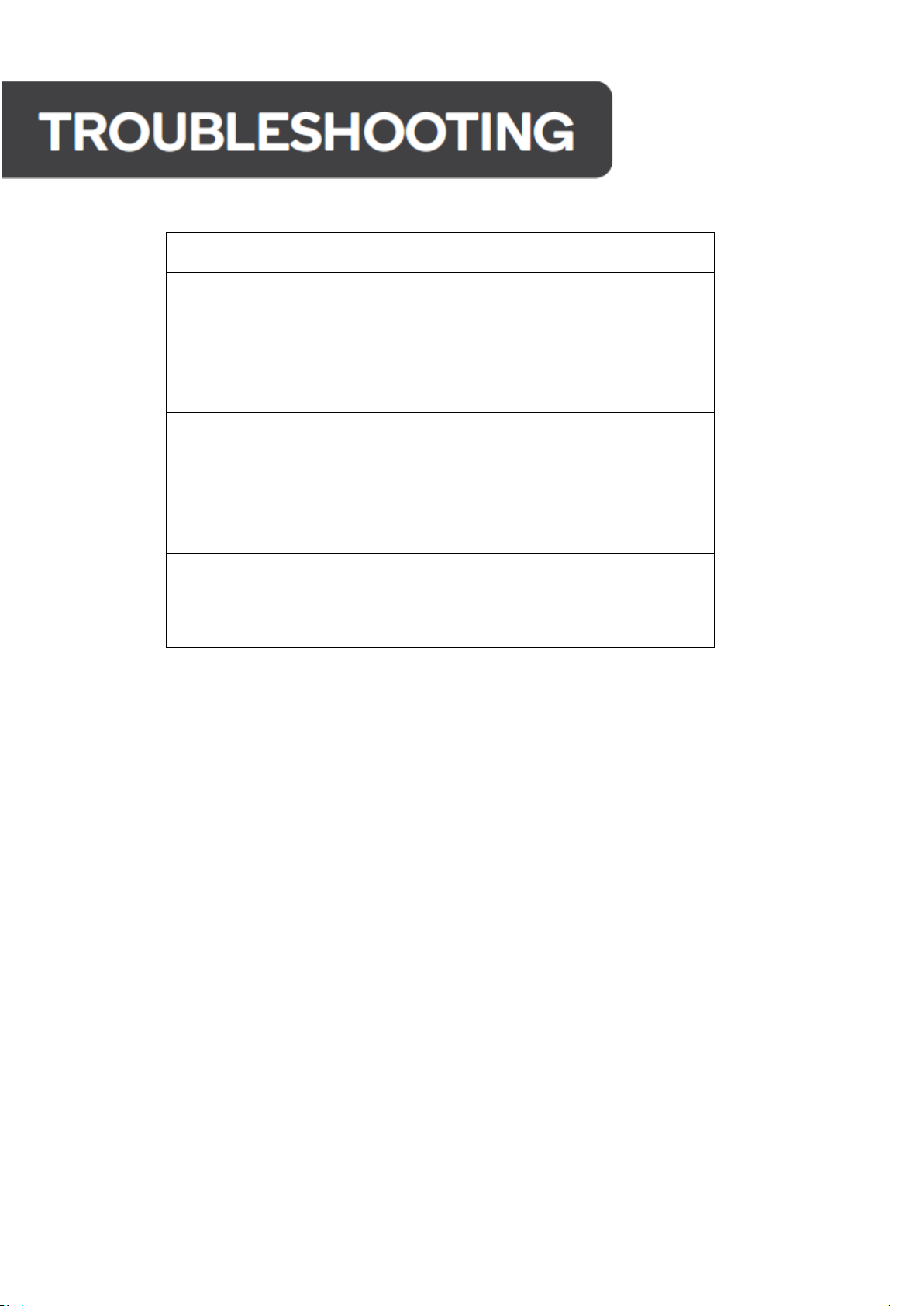

If you couldn't solve any of the following problems,

you can contact "Intertrack.net"

Causal

barrier Original cause Exclusion method

Uneven

frame

1. uneven ground or sundries

2. The base is not leveled

when the frame is assembled

1. Eliminate sundries

2. Loosen the frame connecting

bolts, level the base, and then

tighten the bolts

3. Adjust the eccentric foot

sleeve of the rear bottom pipe

Unstable

handle Loose threads Tighten bolts

Rotating

parts have

abnormal

noise

Gap imbalance Open the shield adjustment

Rotational

weakness

1. the magneto resistance

gap increases

2. The trimmer is damaged

3. The belt slips

1. Open the guard to adjust

2. Replace

3. Open the guard to adjust

•

Resistance Type: Magnetic resistance.

•

Max User Weight: 130kg.

•

Flywheel: 4kg.

•

Driving Mechanism: Belt Driven.

•

Seat Adjustment: Horizontal and vertical.

•

Display: LCD display.

•

Display features: Speed, Time, Distance, Calories burnt, and Heart rate.

•

Assembly size: 130*60*157.5 cm.

•

Resistance levels: 8 levels.

•

Gross Weight/Net Weight: 37kg/33kg.

SPECIFICATIONS

Table of contents

Other Inter-Track Exercise Bike manuals