Intermec 851-040-001 User manual

Vehicle

Power Supply

Installation Guide

VehiclePowerSupply

INSTALLATION GUIDE

""""""""""""""""""""""""""""

NPN:962-054-004

Revision C

October 2002

"NOTICEThispublication containsinformation proprietarytoIntermec Corporation.It isbeing supplied

to you withthe express understanding that theinformation contained hereinisforthebenefit

ofthe contracting party only,and may notbe copied,distributed,ordisplayedtothird parties

without the express writtenconsentof Intermec Corporation,and shall bereturnedtotheCor-

poration upon writtenrequest.If apurchase,license,ornondisclosure agreementhasbeen

executed,thetermsofthatagreementshall governthisdocument.

Thispublication isfurnishedforinformation only,and theinformation init issubject tochange

withoutnotice.Although everyefforthasbeenmadeto provide complete and accurate

information,Intermec Corporation assumesno responsibility orliabilityforany errorsor

inaccuraciesthatmayappearinthisdocument.

Wewelcomeyourcommentsconcerning thispublication.Although everyefforthasbeenmade

to keepit free oferrors,somemay occur.Whenreporting aspecificproblem,pleasedescribeit

brieflyand includethebook title and partnumber,aswell astheparagraph or figurenumber

and thepagenumber.

Send yourcommentsto:PublicationsDepartment

Intermec Corporation

Norand MobileSystemsDivision

550 Second StreetSE

CedarRapids,Iowa52401

Ó1998 Intermec TechnologiesCorporation.All rightsreserved.

Acknowledgements

MICRO-CLEANII isaregisteredtrademarkofForesightInternational,Inc.

ChargeGuardisaregisteredtrademarkofChargeGuard,Inc.

"NOTICEThisequipmentmeetsClass Bdigitaldevice limitsperPart15 ofFCC Rules.Theselimits

protectagainst interference inaresidentialarea.Itemits,uses,and canradiateradiofrequency

energy.If you do not install and usethe equipmentaccording toitsinstructions,it mayinter-

ferewithradiosignals.However,theseisno guarantee that interference will notoccurina

particularinstallation.

CONTENTS"

VehiclePowerSupplyInstallation Guide i

CONTENTS

SECTION1

General Information

AboutThisManual1-1..................................

InstallationPractices1-1................................

Considerations1-1...................................

PowerSupplies1-1...............................

InputPowerCable1-4............................

InlineFuse1-4..................................

OutputPowerCable1-4..........................

SECTION2

Installation Procedures

About thisInstallation2-1...............................

InstallationSummary2-1................................

ToolsRequired2-2...................................

BeforeyouBegin2-3....................................

PowerSupplies2-3...............................

ConnectPowerInputCable2-3...........................

Mount thePowerSupply2-4.............................

PowerCableInstallation2-5.............................

PowerCableConnections2-6.............................

CableTermination2-6...............................

CutandStripthePowerCable2-7....................

HeatshrinkTubing2-8...........................

PreparetheCableEnds2-9.......................

PowerSourceConnections2-9............................

Direct toBatteryConnections2-10.....................

Side-mountedBatteryTerminals2-10...............

ConnectiontoTop-mountedTerminals2-12..........

CablesClamps2-14...................................

FinalConnections2-14...................................

CONTENTS"

ii VehiclePowerSupplyInstallation Guide

SECTION3

Troubleshooting Information

Procedures3-1..........................................

BasicDiagnosticProcedures3-1...............

Inspection3-1.......................................

PowerSupply3-1................................

Cables,Connections3-2..........................

Fuse3-2.........................................

ElectricalMeasurements3-2.........................

Voltage3-2......................................

Continuity3-2...................................

Substitution3-3.....................................

Advantages3-3..................................

Disdvantages3-3................................

Whentosubstitute3-3...........................

TroubleCharts3-3...................................

Powersupplyreset3-3...........................

FIGURES

Figure1-1PowerSupplies1-3............................

Figure2-1CutandStripCableEnds2-7..................

Figure2-2HeatshrinkLocations2-8......................

Figure2-3Side-MountBatteryTerminals2-11..............

Figure2-4Top-MountBatteryTerminals2-13..............

Figure2-5CableClamp2-14..............................

Figure3-1InputPowerCable3-7.........................

TABLES

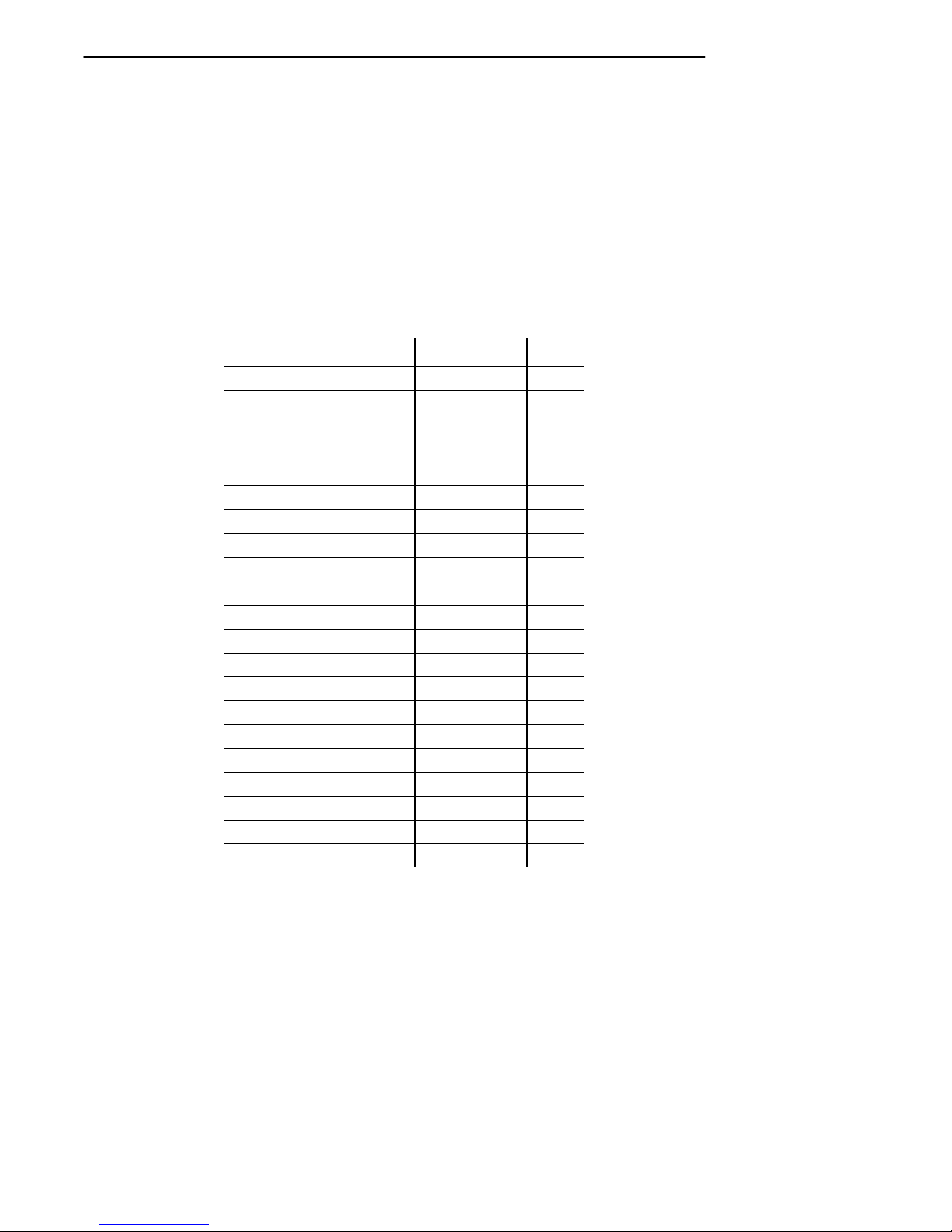

Table1-1PowerSupplyIdentification1-2................

Table2-1PartsList2-2.................................

Table3-1PowerFailureTroubleChartI3-4..............

Table3-2PowerFailureTroubleChartII 3-5..............

Table3-3PowerSupplyPinouts3-6.....................

SECTION 1"GeneralInformation

VehiclePowerSupplyInstallation Guide 1-1

Section 1

GeneralInformation

""""""""""""""""""""""""""""

AboutThisManual

Thismanual isdividedintothree sections.SectionOne

describesinstallationpracticesanduniquecomponentsin

thiskit.SectionTwocontainsmechanicalandelectrical

installationinstructions.SectionThree containsbasic

troubleshootinginformationand pin-outsfor connectors.

Installation Practices

Installers shouldbefamiliarwiththeparticularbrandsand

modelsofequipmentwherethiskitisinstalled.Theyshould

betrainedandexperiencedonvehicle electricalsystems.

InstallersmustfollowtheseguidelinesandtheInstallation

Procedurespreciselytoensureasafeandreliableinstallation.

Failuretofollowall oftheinstructionshereincanresultin

damagedordestroyedequipment,degradedequipment

performance,prematurefailures,andvoidthewarranty.

Considerations

PowerSupplies

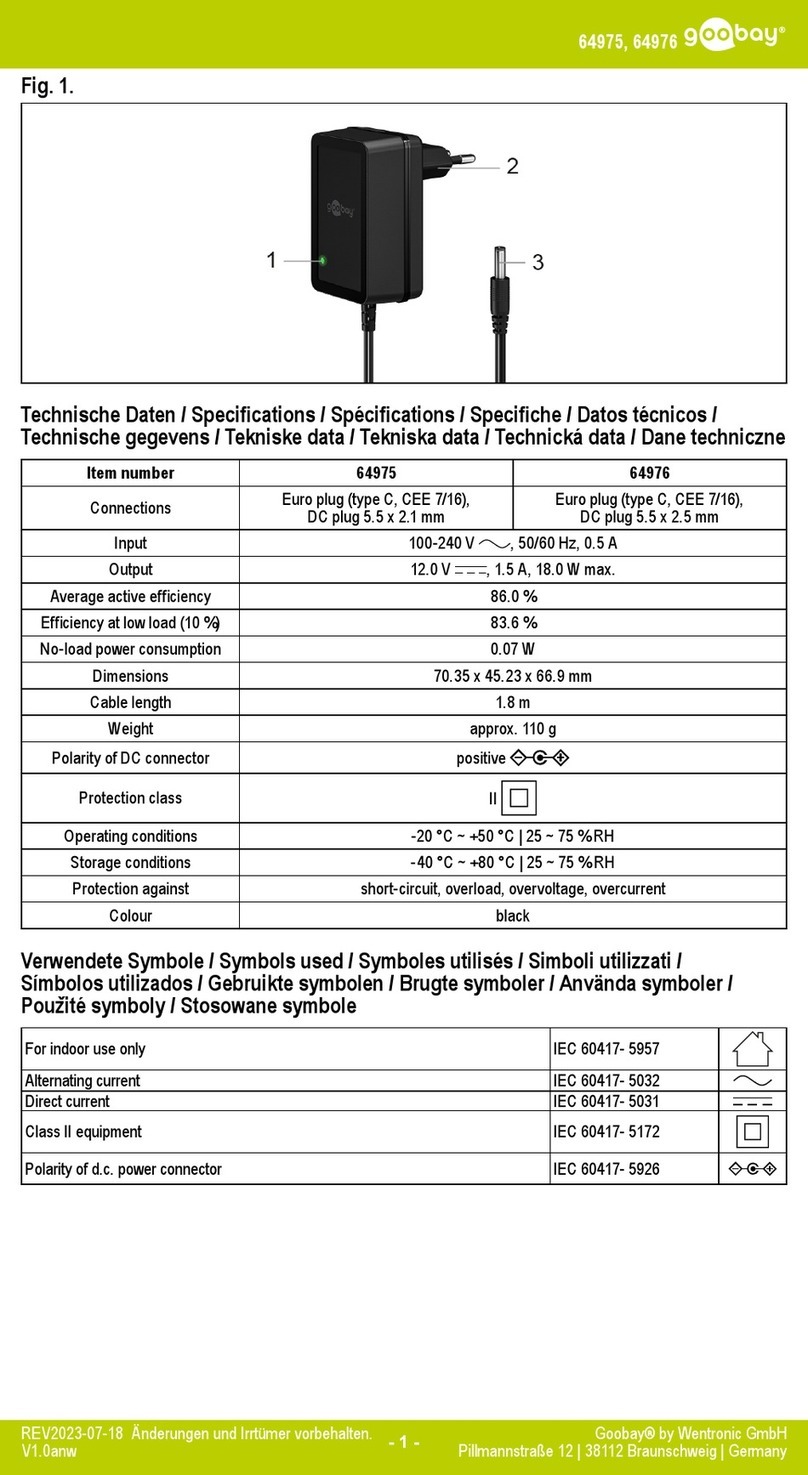

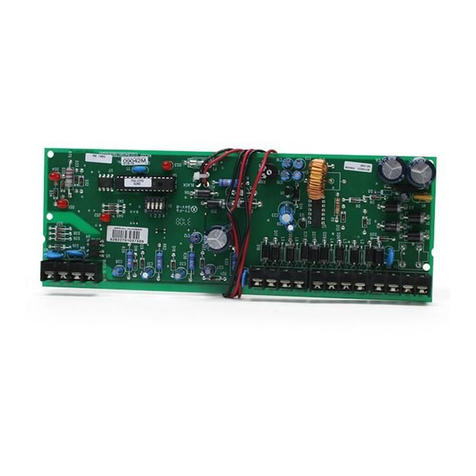

Twopower converters(“supplies”)areavailablethatshould

meet mostelectricalrequirements.Verifythatyou havethe

correctsupplyforaparticularinstallationbeforebeginning.

Onepowersupplyacceptsinputvoltagesrangingfrom6--36

SECTION 1"GeneralInformation

1-2VehiclePowerSupplyInstallation Guide

Vdc(typically gas-poweredvehicles:12 &24 volts)andthe

otheraccepts15--96 Vdc(typicallyelectric-poweredve-

hicles:24,36,48,&72 volts).Bothsuppliesprovide12 V

dcoutputwhichisfilteredandregulated.Bothsupplies

alsoprovideshortcircuit,overvoltage,andovertempera-

tureprotection.

Youcandistinguishbetweenthetwosuppliesinseveral

ways.Eachsupplydisplaystheinternationalsymbologies

forinputandoutputconnectors,including voltageinforma-

tion.Inaddition,thetablebelowprovidesothermeansof

identification.

Table1-1

PowerSupplyIdentification

Model

NumberPart

NumberInput

ConnectorInput

Voltage

851-040-001 066776-01 4-pin,keyed6--36 Vdc

851-041-001 066777-01 2-pin,keyed15--96 Vdc

Thepowersupplyshall bemountedtothevehiclechassis

ground,or connected(electrically)viaexternalwiretothe

vehiclechassis.Chassisgroundtothecomputerorother

equipmentisthenestablishedviathepowersupplyoutput

cable.

Sincethepowersupplywill produceheat,itisadvisableto

mountitonaminimumof130--160 squareinches(approxi-

matelyonesquarefootormore)ofmetallicsurface.This

locationshould notbeinthevicinityofsourcesofvehicle-

generatedheat.Useonlythehardwaresuppliedinthe

kittomount thepowersupply;donotuse sheet-metal

screws.

Agreenlight-emittingdiode(LED)indicator,locatednear

the outputconnectoronthepowersupply, will belighted

whenevervoltageis suppliedtothe outputpower cable.

SECTION 1"GeneralInformation

VehiclePowerSupplyInstallation Guide 1-3

Figure1-1

PowerSupplies

Model: 851-040-001 P/N: 066776-01

6-36 V; 10 A

Model: 851-041-001 P/N: 066777-01

15-96 V; 3,5 A

InputConnector

OutputConnector

Green LED

(poweroutputindicator)

""

""

""

""

SECTION 1"GeneralInformation

1-4VehiclePowerSupplyInstallation Guide

InputPowerCable

NOTE:The inputpowercablemaybe shortened asneeded. It SHOULD

NOTbe extended underany circumstances.

Theinputpower cableisapproximately9feetlong. One end

hasa4-pinconnector,theotherendhasa2-pinconnector.By

cuttingofftheunneededconnector,asinglecablecanmeetei-

therloworhighvoltageinput-rangepowersupplyrequire-

ments.Thecutendisthenterminatedfor connectiontothe

vehiclepowersource.

Inline Fuse

Asnap-twistinlinefuseholderisfurnishedaspartofthiskit.

It mustbeconnectedascloseaspossible(electricallyand

physically)tothevehiclepowersource.Itprovides short-cir-

cuitprotectionfortheentireinputpowercableandthepower

supplyinput.Thefuseholdercontainsa3AB,20ampere/250

Vdc(1/4”x1-1/4”) fuse.Shoulditfail,diagnosetheproblem

andcorrectit,thenreplacewithexactlythesamesizeandtype

fuse.

OutputPowerCable

NOTE:Ensurethatyou havethe correctoutputpowercableforthe comput-

er(s)being installed inyourlocation.

Outputpower cablesareapproximately6feetlongandhave

adurable3-pinconnectortomatewiththepowersupply.The

connectoronthefarendofthecableis specifictotheteminal

(computer)ordockingdeviceinyourparticularinstallation.

Theseruggedconnectorshaveheavydutymetalhousingsand

enhancedstrainrelieftoprovideaddedreliabilityinthemo-

bile environment.

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-1

Section 2

Installation Procedures

""""""""""""""""""""""""""""

About thisInstallation

Followtheproceduresinthis sectionascloselyaspossible

whilekeepingthefollowingasprimaryconsiderations:

"PowerSupplymustbesecurelymounted.

"Mountingsurfacemustbesturdy.

"Mountingsurfacemustbeabletosinkpowersupply

heat.

"Fusemustbeclosetovehiclepowersource.

"Keepcablesas shortaspractical.

"Securecablesatleastevery18 inches.

Installation Summary

Installationconsistsoffive(5)primarysteps,whichshouldbe

undertakeninthefollowingorder:

1.Connect theinputcabletothepowersupply.

2.Mechanicallyinstall thepowersupply.

3.Routeandsecurethepower cable.

4.Shortencableasappropriate,thencrimpthefuse

holdertothejoinedREDandBLACK wires(positive).

CrimpaterminalringtothejoinedWHITEand

GREENwires(negative).Insulateasinstructed.

5.Makefinalconnectionstothevehiclepowersource.

SECTION 2"Installation Procedures

2-2VehiclePowerSupplyInstallation Guide

ToolsRequired

"WireCrimpingandstrippingtool.

"Electricdrill,drill bits.

"Common handtools.

"Heatgun forshrinksleevetubing.

Table2-1

PartsList

DescriptionNPN Qty

powercable226-340-001 1

fuseholderassembly 315-075-001 1

fuse,20 AceramicFB315-074-001 1

bolt,3/8--16 X1-1/2”800-099-001 2

washer,3/8”803-099-001 4

nut,3/8--16 802-099-001 4

adjustablewire clamps808-011-001 8

self-tapscrew#6 X5/8”800-008-001 8

3/8”terminalring 809-165-001 2

#10 terminalring 809-083-009 3

self-tapscrew#8 X5/8”800-012-000 1

#8 flatwasher803--084-000 1

snap-in bushing 807-065-003 1

screw,m/s1/4--20 x 1-1/4”801-194-002 2

flatwasher,1/4”801-100-000 2

locking nut,1/4--20 802-117-000 2

lockwasher,1/4”803-042-001 2

cabletie,locking 808-002-001 6

h/stubing,blk,1/8”dia.321-042-000 12 in.

h/stubing,blk,3/8”dia.321-143-001 6 in.

ferritebead 309-388-001 1

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-3

Beforeyou Begin

WARNING:Equipment failureordamagewill resultif the vehiclepower

source voltagedoes not fall withintheinputvoltagerating of

thepowersupplyfurnishedtoyou.

PowerSupplies

Readthenomenclature onthepowersupplyandverifythat

theinputvoltageratingiscorrectforthevehicleyouwill be

installingitin.See SectionOneforidentifyinginformation.

Rememberthat thesupplywiththelowerinputvoltagerat-

ing(6--36 Vdc)hasa 4-pininputconnectorwhilethepower

supplywiththehigherinputvoltagerating(15-96 Vdc)has

a 2-pininputconnector.

ConnectPowerInputCable

Onlyone oftheinputconnectorswill fit thepowersupply:

1.Matethecorrespondingcableconnectortothepower

supplyconnector.

2.SlidethecableconnectorINasfarasitwill go.

3.Turnthecableconnector collarclockwise tosecureit.

4.Clamptheferritebeadontotheinputcablenearthe

powersupply.Makesuretabsarefullyengaged.

5.Cutcableat theunusedcableconnector.

Discardthis connector.

SECTION 2"Installation Procedures

2-4VehiclePowerSupplyInstallation Guide

Mount the PowerSupply

Theinputpower cableisapproximately9feetlongandcan

beshortenedasneeded.ItmustNOTbe extendedun-

deranycircumstances.The outputpower cableis

approximately6feetinlongandcannotbe shortened.You

must taketheselengthsandtheintendedlocationofyour

electronicequipmentintoconsiderationwhenchoosinga

mountinglocationforthepowersupply.

Themountinglocationmustprovide130--160 squareinches

ofmetallicsurfacetosinkheatgeneratedbythepowersup-

ply.Thismetallicmountingsurfacemustbeconnectedto

thevehiclechassiselectrically.Inrareinstances,youmay

havetofabricateaflexiblewire orbraidtobondthe

mountingsurfacetovehiclechassisground.

Appropriatehardwareisfurnishedinthisinstallationkit

formountingthepowersupply.UsemountingMethodAin

situationswhereyoucaneasilyaccess thebackside ofthe

mountinglocationtoinstall alocknutandwasher.

UseMethodBwherethebackside ofthemountinglocation

isinaccessible.Notethat thismethodrequiresthat the

mountingplatebethickenoughtoacceptandretainsuffi-

cient threadstoprovideasecureandreliablemechanical

installation.

Method A:

1.Markandcenterpunchthetwomountingholeloca-

tions.

2.Usea 1/4-inchdrill bit tomakethetwomounting

holes.

3.Use1/4”hexboltswithflatwashersandlockingnuts

toinstall thepowersupply.

Method B:

1.Markandcenterpunchthetwomountingholeloca-

tions.

2.Usea#7drill bit tomakethemountingholes.

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-5

3.Usea 1/4--20 taptothreadthemountingholes.

4.Placealockwasheroneachbolt.

5.Insert thebolt/lockwasherassembliesthroughthe

powersupplyholesandintothethreadedmounting

holes.

PowerCableInstallation

Followtheseguidelinesandotherinstructionscloselywhen

installingpower cables.

"Completelyinstall power cablesbefore makingconnec-

tionsto equipment.

"Routethepower cablesfromthegeneralareawhere

thepowersupplywill bemounted.

"Useasnap-inbushing(requires9/16”hole)ifthe

power cablepassesthroughafirewall orothersheet-

metal.

"Makesurethatcableroutingdoesnotinterferewith

otherequipmentorvehiclecontrols.

"Makesurethatcableroutingdoesnotinvitedamage

tothecable.

"Securethecablesatleastevery18 inchesthroughout

thecablerun:useadjustableclamps(see lastpagein

this section)orwire-tieto existing vehiclecableruns.

WARNING: If thisinstallation will beon agas -poweredvehicle, you

MUST install eitheranOn/Offswitch(minimum15Adcrating,

suchas ITWpartnumber163-900-034),oranautomatic shut

offdevice,inseries withthein-linefuse holder.Charge-

Guard,Inc., 400 Highland Avenue,Altoona,PA16602

(814-941-4100)manufactures a“CHARGEGUARD

ÒÒ“device for

thispurpose.

SECTION 2"Installation Procedures

2-6VehiclePowerSupplyInstallation Guide

PowerCableConnections

Thefuseholderfrom theinputpower cablemustbecon-

nectedasclose(physicallyandelectrically)aspossibleto

thepositive sideofthevehiclepowersource.Theremaining

coloredwire(s)mustbeconnectedtothenegativeside ofthe

vehiclepowersource.Inthisinstallation,the shieldwire

mustbe connectedtothevehicle chassis.Instructionsare

notincludedfor connectingtovariouspossiblevehiclepow-

ersources.Itisassumedthat thetrained professional in-

stallerwill beknowledgeable onthebrandsandmodelsof

vehiclesheisworkingwith.Bothlarge(3/8-inch)and

smallerterminalringsareprovidedtoaccomodatemost

installation needs.Thiskitcontainsadditionalbolts,nuts,

andwashersinthe eventyouwill connect theinputpower

cabledirectlytoavehiclebattery.Theintendedusefor

thesepartsisdetailedintheinstructionsthatfollow.

CableTermination

Youmustcut thecabletolength,cutoff aportionofthe out-

er cablejacketandstriptheindividualwire endsofthe

cableasinstructed.Heatshrinktubingisfurnishedinthis

kitandmustbe slippedontothe cableorwires before termi-

natingthem.Then,youmustinstall thefuseholderinse-

rieswiththepositivewiresandinstall aterminalringon

thenegativewires.Finally,youmust mechanicallycom-

pletetheconnectionstothevehiclepowersource orbattery

andelectricallyconnect theshieldwiretovehiclechassis

groundusingaself-tappingscrewandflatwasher.

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-7

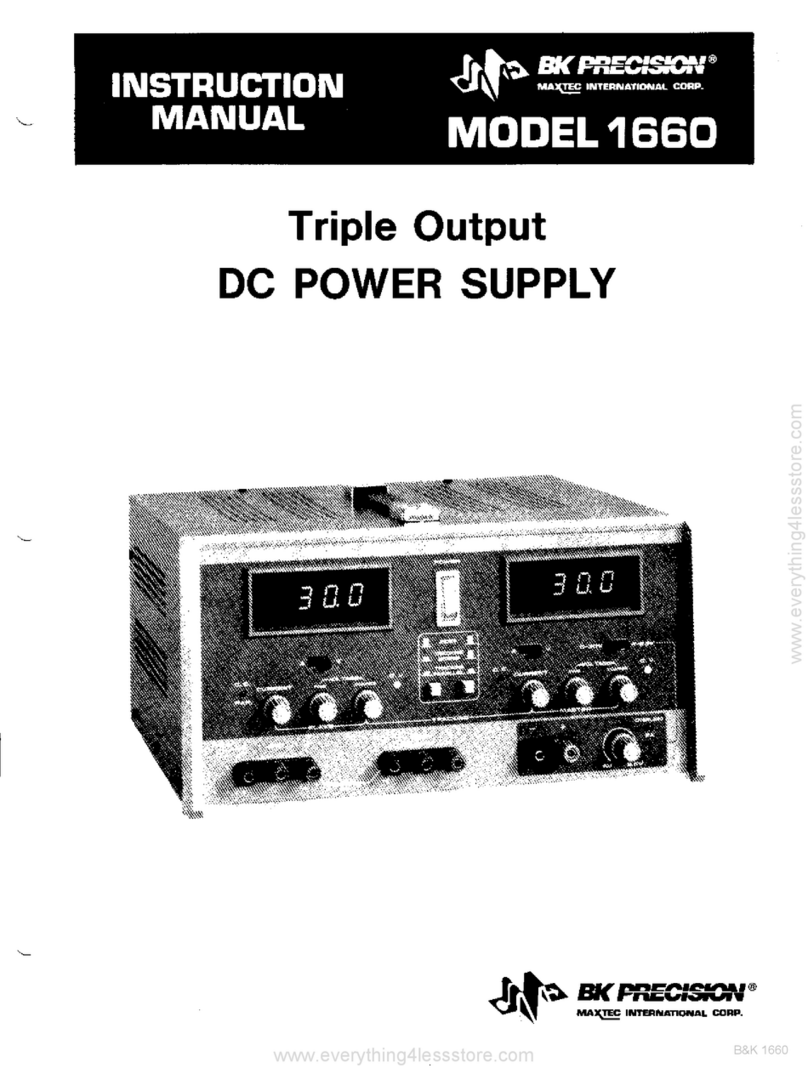

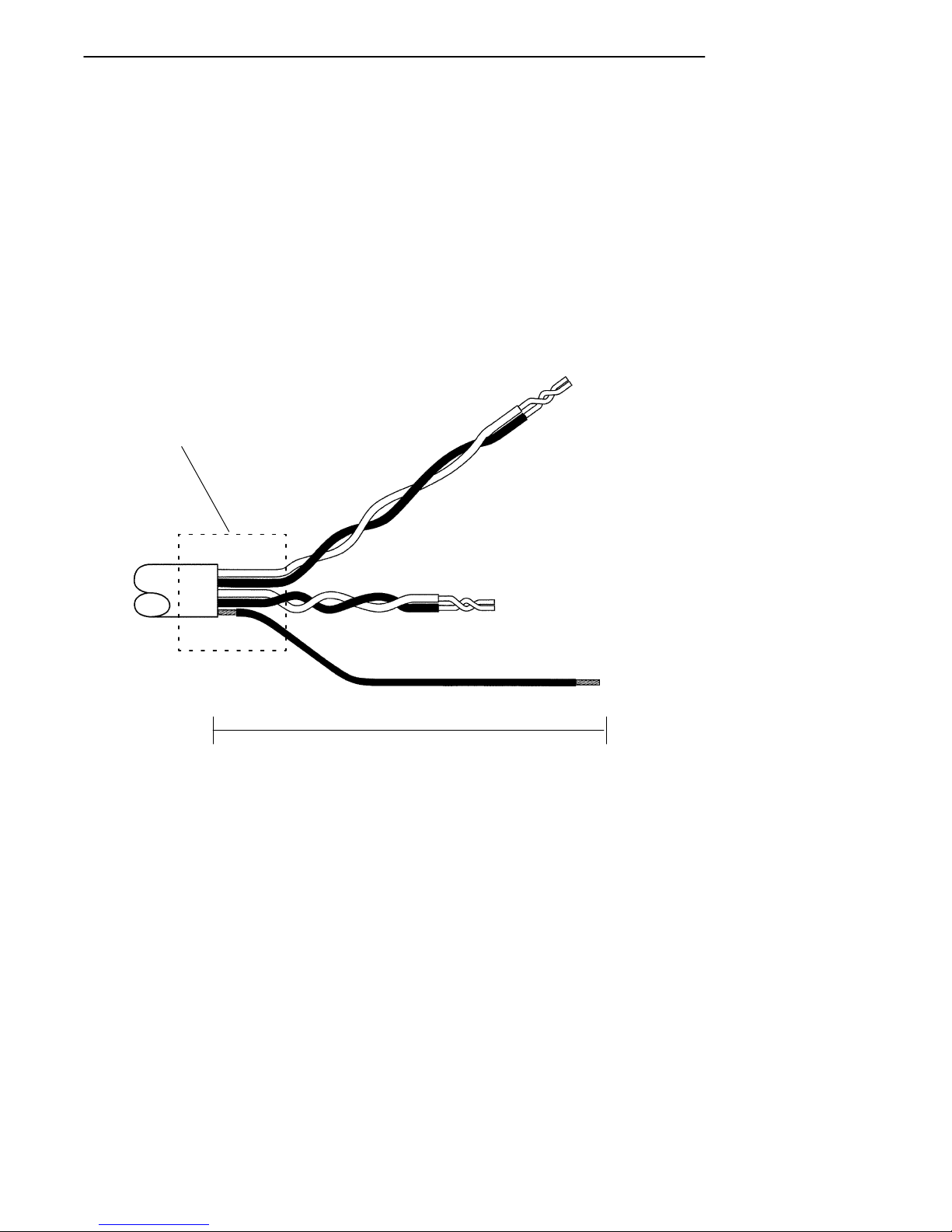

Cutand Stripthe PowerCable

1.Cut thepower cablenearthepowersource orbattery.

2.Stripthecablejacketback12--14 inches.

3.Slideheatshrinktubingover cablejacket.

4.Strip1/4”ofinsulationfromindividualwires.

5.Twist thewhiteandgreen(negative)wirestogether.

6.Twist theredandblack(positive)wirestogether.

7.Twist theshieldwireandslidethe1/8”heatshrink

tubingontoit.

Input

Power

Cable

Figure 2-1

Cutand StripCableEnds

Heatshrinktubing

Redand Black Wires

(positive)

Greenand WhiteWires

(negative)

Shieldwirew/heatshrink applied

StriptheCableJacket12--14 inches

NOTE:See “Note”on page 2-5wheninstalling on gas-poweredvehicles.

SECTION 2"Installation Procedures

2-8VehiclePowerSupplyInstallation Guide

Heatshrink Tubing

Thiskitcontainsa6inchlengthof3/8”heatshrinktubing

whichyouwill cutintothree pieces,anda12inchlengthof

1/8”heatshrinktubingfortheshieldwire.Tubingmustbe

inplacebefore terminatingwire ends.Crimpterminalrings

andfuseholderends,thenpositionall heatshrinktubingin

thelocations shown.Useaheatgun toshrinktubing.

1.Greenand Whitetwisted pair

2.Redand Black twisted pair

3.Shieldwire,twisted

Figure 2-2

Heatshrink Locations

b

1

2

3

b

3/8”

b

b

3/8”3/8”

Arrowsdenote heatshrink

locationsand diameter.

1/8”

b

b

NOTE:See “Note”on page 2-5wheninstalling on gas-poweredvehicles.

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-9

Preparethe CableEnds

Bothlarge(3/8inch)andsmaller(#10)terminalringsare

providedforyourselectionanduseinthefollowingsteps.A

small (#10)terminalringshouldbecrimpedtotheshield

wireandthenfastenedtovehiclechassisground.

1.Crimpaterminalringontothewhite-greentwisted

pair(negative)ofwires.

2.Cut thered-blacktwisted pair(positive)ofwiresat the

midpoint.Stripexposedends.

3.Positionshortlengthsofheatshrinktubingasinindi-

catedinFigure2-2.

4.Crimpthefuseholdertothepositivewiresfrom the

cable.

5.Shortentheremainingpositivewires(pigtail)ifde-

siredand positionashortlengthofheatshrinktubing

ontothispigtail.

6.Crimpthispositivepigtail tothefuseholder.

7.Securelycrimpaterminalringto endofthepositive

pigtail from thefuseholder.

8.Slideheatshrinkover crimps,shrinkwith heatgun.

PowerSource Connections

Thenextfourpages showyoutheintended purpose ofnuts,

bolts,andwashersthatareincludedinthiskitifyouwill be

connectingthepower cabledirectlytoavehiclebattery.

Additionalhardwareisnotprovidedinthiskitforconnecting

thepower cableto othervehiclepowersources.Refertothe

manufacturer’stechnicalmanualforthevehicleifnecessary.

SECTION 2"Installation Procedures

2-10 VehiclePowerSupplyInstallation Guide

Direct toBatteryConnections

Side-mounted BatteryTerminals

1.Removebothterminalscrewsfrom thevehiclebattery.

2.Screwa 3/8”nutasfarasitwill go ontoa 3/8”X1-1/2”

boltfurnishedinkit.

3.Slipa 3/8”washerontothebolt.

4.Slidethepositive(fuseholder)terminalringontothe

positivebatteryterminalbolt.

5.Slipasecond3/8”washerontothebolt.

6.Slidethevehiclepositivebatterycable ontothebolt.

7.Threadtheboltassembly(steps1--6,above)intothe

positivebatteryterminal.Tightentheboltuntil itbot-

tomsoutbutdonotovertightenthebolt.

8.Tightenthenutsecurelyagainst thewashersand

cables.

9.Useself-tappingscrewandaflatwashertoconnect

shieldwiretovehiclechassisground.

Repeatsteps2through 8 forthenegative (white--green pair)wirefromtheinput

powercable,hooking up thenegative cablestothenegative (--)batteryterminal.

NOTE:See “Note”on page 2-5wheninstalling on gas-poweredvehicles.

SECTION 2"Installation Procedures

VehiclePowerSupplyInstallation Guide 2-11

1.Bolt

2.Nut

3.Vehiclebattery

4.Vehiclebattery cable

5.Fuse holder

6.Washers

1

Figure 2-3

Side-MountBatteryTerminals

2

6

3

4

5

NOTE:See “Note”on page 2-5wheninstalling on gas-poweredvehicles.

This manual suits for next models

1

Table of contents

Other Intermec Power Supply manuals