Nemic-Lambda ZUP6-33 User manual

USER'S MANUAL

ZERO-UP

200W/400W/800W

Programmable DC Power S pplies

Constant Voltage/Constant C rrent

TESTING EQUIPMENT

65SA

LISTED

USC

TUV Rheinland

geprufte

Sicherheit

.. ..

DENSEI-LAMBDA

B ilt-in RS232 & RS485 Interface

with GPIB option.

We Nemic-Lambda Ltd., located at Karmiel I dustrial Zo e, Israel, declare u der our sole

respo sibility that the product:

Product Name: Programmable Regulated Power Supplies, ZUP Series

Models:

Co forms to the followi g product specificatio s:

Safety: EN61010-1/04.93, EN61010-1 A2/07.95

UL3111-1

Electromag etic Emissio s:

EN55011:1991 Co ducted Emissio s: Class B

Radiated Emissio s: Class A

IEC1000-4-2:1995 4.0KV CD, 4.0KV AD

IEC1000-4-3:1995 3V/m

IEC1000-4-4:1995 1.0KV AC Power Li es

0.5KV Commu icatio Li es

IEC1000-4-5:1995 2.0KV AC Power Li es

1.0KV AC to Grou d

1.0KV Commu icatio Li es

IEC1000-4-6:1996 3V

IEC1000-4-11:1994

IEC1000-3-2:1995 Class A

IEC1000-3-3:1995

The product herewith complies with the requireme ts of the Low Voltage Directive 73/23/EEC a d the

EMC directive 89/336/EEC for Electrical Equipme t used i Measureme t Co trol a d Laboratory

e viro me ts, a d carries the CE mark accordi gly.

Our importer to the EU is Couta t Lambda Limited, located at Ki gsley Ave ue, Ilfracombe, Devo

EX34 8ES, UK. Further, all products covered by this declaratio are ma ufactured by processes which

e sure co ti ued complia ce of the products with the requireme ts of the Low voltage a d the EMC

directives.

Name of Authorized Sig atory:

Sig ature of Authorized Sig atory:

Positio of Authorized Sig atory:

Date:

Place where sig ed:

Adam Rawicz-Szczerbo

Ma agi g Director,Couta t Lambda

Ilfracombe, UK

ZUP6-33

ZUP10-20

ZUP20-10

ZUP36-6

ZUP60-3.5

ZUP6-66

ZUP10-40

ZUP20-20

ZUP36-12

ZUP60-7

ZUP6-132

ZUP10-80

ZUP20-40

ZUP36-24

ZUP60-14

KARMIEL INDUSTRIAL ZONE, POB 500, ZC-20101, ISRAEL.

TEL: 972-4-9887491 FAX: 972-4-9887487

DECLARATION OF CONFORMITY

TABLE OF CONTENTS: ZUP SERIES

SAFETY INSTRUCTIONS .....................................................................

WARRANTY ..........................................................................................

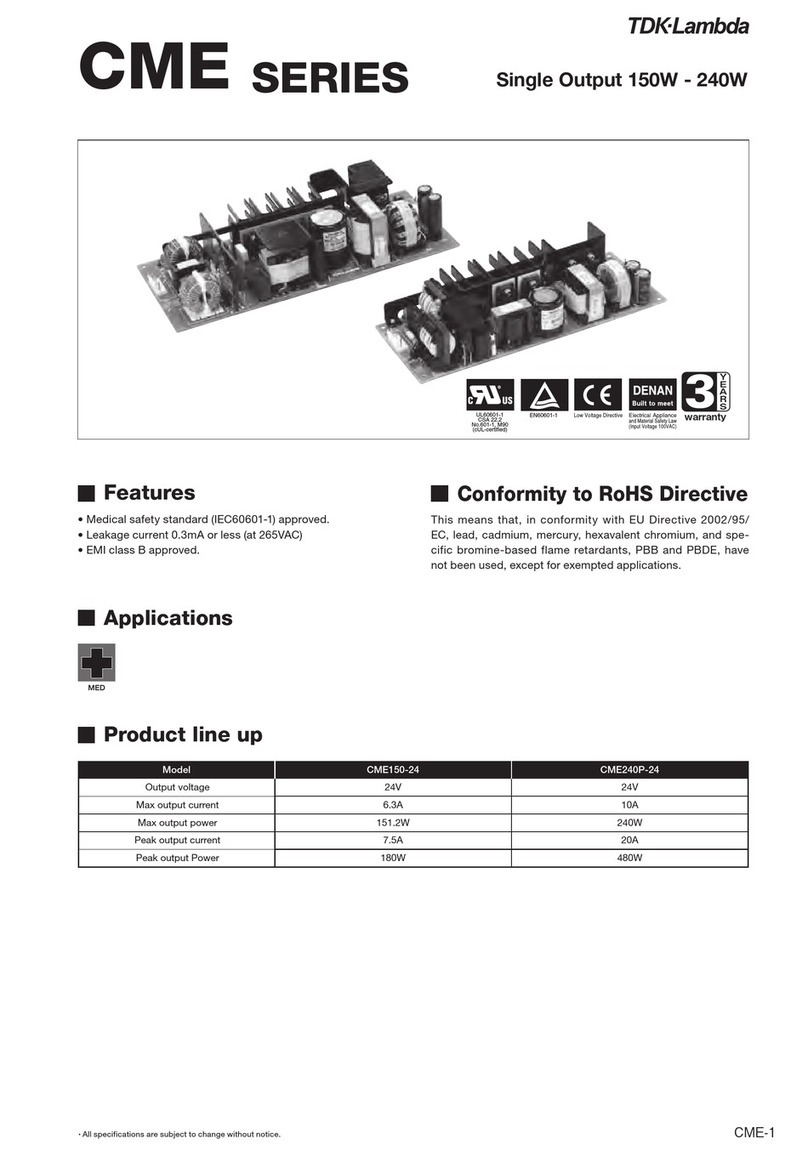

CHAPTER 1. General Information

CHAPTER 2. Specifications

CHAPTER 3. Installation

......................................................

1.1 User manual content

1.2 Introduction

1.2.1 General description

1.2.2 Configurations

1.2.3 Control via the serial communication port

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.7 Cooling and mechanical construction .....................................

1.3 Accessories

1.3.1 General

1.3.2 Serial link cables

1.3.3 AC cables

1.3.4 Front panel outputs option

................................................................

2.1 200W/400W Series

800W Series...................................................................................

2.2 Supplemental characteristics .........................................................

.....................................................................

3.1 General

3.2 Initial inspection

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC source requirements

3.4 Cooling and placement

3.5 Rack mounting

3.6 Power connection

3.7 Connecting the load .......................................................................

3.7.1 Selecting wire size

3.7.2 Wire termination .....................................................................

3.7.3 Single load connection, local sense

3.7.4 Single load connection, remote sensing ................................

3.7.5 Multiple load connections, radial distribution method

3.7.6 Multiple load connections with distribution terminals .............

3.7.7 Grounding outputs

3.8 External control connector

3.8.1 General

3.8.2 Pin description .......................................................................

3.8.3 Technical description

3.8.4 Default connections................................................................

3.9 Repackaging for shipment

pg. 2

pg. 1

pg. 5

pg. 6

pg. 7

pg. 9

pg. 11

pg. 12

pg.13

pg.14

pg.15

pg.16

pg.17

pg.18

Table 4-1: Front panel controls and indicators .......................................

4.2.2 Rear panel ............................................................................

4.2.3 Rear panel connections description .....................................

4.3 Turn-on Checkout Procedure

4.3.1 General

4.3.2 Prior to operation

4.3.3 Constant Voltage check

4.3.4 Constant Current check ........................................................

4.3.5 OVP check

4.3.6 UVP check

4.3.7 Foldback check

4.3.8 Output On/Off

4.3.9 Address setting

4.3.10 Local/Remote Operation

4.4 Local Operation ...............................................................................

4.4.1 Introduction

4.4.2 Constant Voltage Operation

4.4.3 Constant Current Operation

4.4.4 Automatic Crossover ..............................................................

4.4.5 Over Voltage protection (OVP)

4.4.6 Under Voltage Protection (UVP)

4.4.7 Foldback Protection ................................................................

4.4.8 Output On/Off Control

4.4.9 Last Setting memory ...............................................................

4.4.10 Output Voltage & Current programming by external resistor

4.4.11 Output Voltage Programming by external voltage .................

4.4.12 Output Current programming by external voltage

4.4.13 Auto Parallel operation...........................................................

4.4.14 Series Operation ....................................................................

4.4.15 Output good signal.................................................................

.....................................

5.1 Introduction

5.2 Configuration

5.2.1 Address setting

5.2.2 RS232 or RS485 selection

5.2.3 Baud rate setting

5.2.4 Local/remote selection

CHAPTER 5. RS232 & RS485 remote control

.................................................

4.1 Introduction

4.2 Controls and Indicators

4.2.1 Front Panel

CHAPTER 4. Operating Instructions.

pg.23

pg.22

pg.24

pg.25

pg.26

pg.27

pg.28

pg.29

pg.30

pg.32

pg.33

pg.37

pg.38

pg.35

TABLE OF CONTENTS: ZUP SERIES

3.10 Outline drawings: ZUP 200W & 400W series.................................

3.11 Outline drawing: ZUP 800W series...............................................

3.12 Outline drawing: front panel connector option ...............................

pg.19

pg.20

pg.21

5.4.1 Introduction

5.4.2 RS485 cable

5.4.3 Linking power supplies

5.5 ZUP series command set description

5.5.1 ID control commands...............................................................

5.5.2 Initialization control

5.5.3 Output control..........................................................................

5.5.4 Status control ..........................................................................

5.5.4.1 Registers structure

5.5.4.2 Status control commands ....................................................

5.6 Communication Protocol..................................................................

5.6.1 General information

5.6.2 Accessing a ZUP unit

5.6.3 End of message

5.7.Service Request..............................................................................

..................................................................

6.1 Introduction

6.2 Units under warranty

6.3 Periodic Maintenance

6.4 Adjustment and calibration

6.5 Part replacement and repairs

6.6 Fuse ratings

.....................................................................

CHAPTER 6. Maintenance

USER’S MANUAL INDEX

pg.45

pg.42

pg.46

pg.43

pg.47

pg.49

pg.48

pg.50

5.7.1 Service Request (SRQ)

5.7.2 Service Request message

5.7.3 Service Request enable/disable commands

TABLE OF CONTENTS: ZUP SERIES

5.3 Remote programming via RS232.....................................................

5.3.1 Introduction

5.3.2 Rear panel connectors pinout

5.3.3 RS232 cable ............................................................................

5.3.4 Linking power supplies

5.4 Remote programming via RS485 .....................................................

pg.39

pg.40

pg.41

WARRANTY SERVICE

WARRANTY

DISCLAIMER

LIMITATION OF WARRANTY

TRADEMARK INFORMATION

This product must be returned to an authorized Nemic-Lambda service facility for repairs or other

warrantyservice.Forproductsreturnedto Nemic-Lambda for warranty service,thebuyershallprepay

shipping charges to Nemic-Lambda and Nemic-Lambda shall pay the shipping charges to return the

producttothebuyer.

ThisNemic-Lambdaproductiswarrantedagainstdefectsinmaterialsand workmanshipforaperiodof

threeyearsfromdateofshipment.Duringthewarrantyperiod,Nemic-Lambdawill,atit’soption, either

repairorreplaceproductswhichprovetobedefective.

The information contained in this document is subject to change without notice. Nemic-Lambda shall

not be liable for errors contained in this document or for incidental or consequential damages in

connection with the furnishing, performance or use of this material. No part of this document may be

photocopied, reproduced or translated into another language without the prior written consent of

Nemic-Lambda.

Thewarrantyshallnotapplytodefectsresultingfromimproperorinadequateusageormaintenanceby

the buyer , buyer supplied products or interfacing. The warranty shall not apply to defects resulting

from unauthorized modifications or from operation exceeding the environmental specifications of the

product.

Nemic-Lambda does not warrant the buyers circuitry or malfunctions of Nemic-Lambda products

resulting from the buyer’s circuitry. Furthermore, Nemic-Lambda does not warrant any damage

occurringasaresultofthebuyer’scircuitryorthebuyer’s-suppliedproducts.

Nootherwarrantyisexpressedorimplied.

Microsoft andWindows aretrademarksofMicrosoftCorporation.

1

SAFETY INSTRUCTIONS

CAUTION

INSTALLATION CATEGORY

GROUNDING

FUSES

LIVE CIRCUITS

PART SUBSTITUTIONS & MODIFICATIONS

ENVIRONMENTAL CONDITIONS

INPUT RATINGS

The following safety precaution must be observed during all phases of operation, service and repair of

this equipment. Failure to comply with the safety precautions or warnings in this document violates

safetystandardsofdesign,manufactureandintendeduseofthisequipmentandmayimpairthebuilt-in

protectionswithin.

Nemic-Lambdashallnotbeliableforuser’sfailuretocomplywiththeserequirements.

The ZUP Series has been evaluated to INSTALLATIONCATEGORY II. Installation Category (over

voltage category) II: local level, appliances, portable equipment etc.. With smaller transient over

voltagesthanInstallationCategory(overvoltagecategory)III.

ThisproductisaSafety Class1instrument.Tominimizeshockhazard,theinstrumentchassismustbe

connected to an electrical ground. The instrument must be connected to the AC power supply mains

through a three conductor power cable, with the ground wire firmly connected to an electrical ground

(safetyground)atthepoweroutlet.

For instruments designed to be hard - wired to the supply mains, the protective earth terminal must be

connected to the safety electrical ground before an other connection is made. Any interruption of the

protective ground conductor, or disconnection of the protective earth terminal will cause a potential

shockhazardthatmightcausepersonalinjury.

FusemustbechangedbyauthorizedNemic-Lambdaservicepersonnelonly.Forcontinuedprotection

againstriskoffire,replaceonlywiththesametypeandratingoffuse.Refertomaintenanceinstructions

inchapter6forfuserating.

Operating personnel must not remove the instrument cover. No internal adjustment or component

replacement is allowed by non-Nemic-Lambda qualified service personnel. Never replace

components with power cable connected. To avoid injuries, always disconnect power, discharge

circuitsandremoveexternalvoltagesourcesbeforetouchingcomponents.

PartsubstitutionsandmodificationsareallowedbyauthorizedNemic-Lambdaservicepersonnelonly.

Forrepairsormodifications,theinstrumentmustbereturnedtoaNemic-Lambdaservicefacility.

TheZUPseriessafetyapprovalappliestothefollowingoperatingconditions:

*Indooruse * Ambienttemperature:0 Cto50 C

*Maximumrelativehumidity:90%(nodewdrop) * Altitude:upto3,000m

*Pollutiondegree2

OO

Do not use AC supply which exceeds the input voltage and frequency rating of this instrument. The

input voltage and frequency rating of the ZUP Series is; 100-240V~, 50/60Hz. For safety reasons, the

mainssupplyvoltagefluctuationsshouldnotexceed+/-10%ofnominalvoltage.

2

SAFETY INSTRUCTIONS

SAFETY SYMBOLS

Instructionmanualsymbol.Theinstrumentwill bemarkedwiththissymbolwhenitis

necessaryfortheusertorefertotheinstructionmanual.

Indicates hazardous voltage.

Indicates ground terminal.

The WARNING signdenotesahazard.Anattentiontoaprocedureiscalled.

Notfollowingprocedurecorrectlycouldresultinpersonalinjury.

AWARNINGsignshouldnotbeskippedandallindicatedconditionsmustbe

fullyunderstoodandmet.

The CAUTION signdenotesahazard.Anattentiontoaprocedureiscalled.

Not following procedure correctly could result in damage to the equipment.

Do not proceed beyond a CAUTION sign until all indicated conditions are

fullyunderstoodandmet.

FCCCOMPLIANCENOTICE:

Note:Thisequipment has been tested and found to complywiththelimitsforaClass Adigital

device,pursuanttopart15oftheFCCRules.Theselimitsaredesignedtoprovidereasonable

protection against harmful interference when the equipment is operated in a commercial

environment.Thisequipmentgeneratesuses, and can radiate radio frequencyenergyand,if

not installed and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the

interferenceathisownexpense.

!

WARNING

CAUTION

3

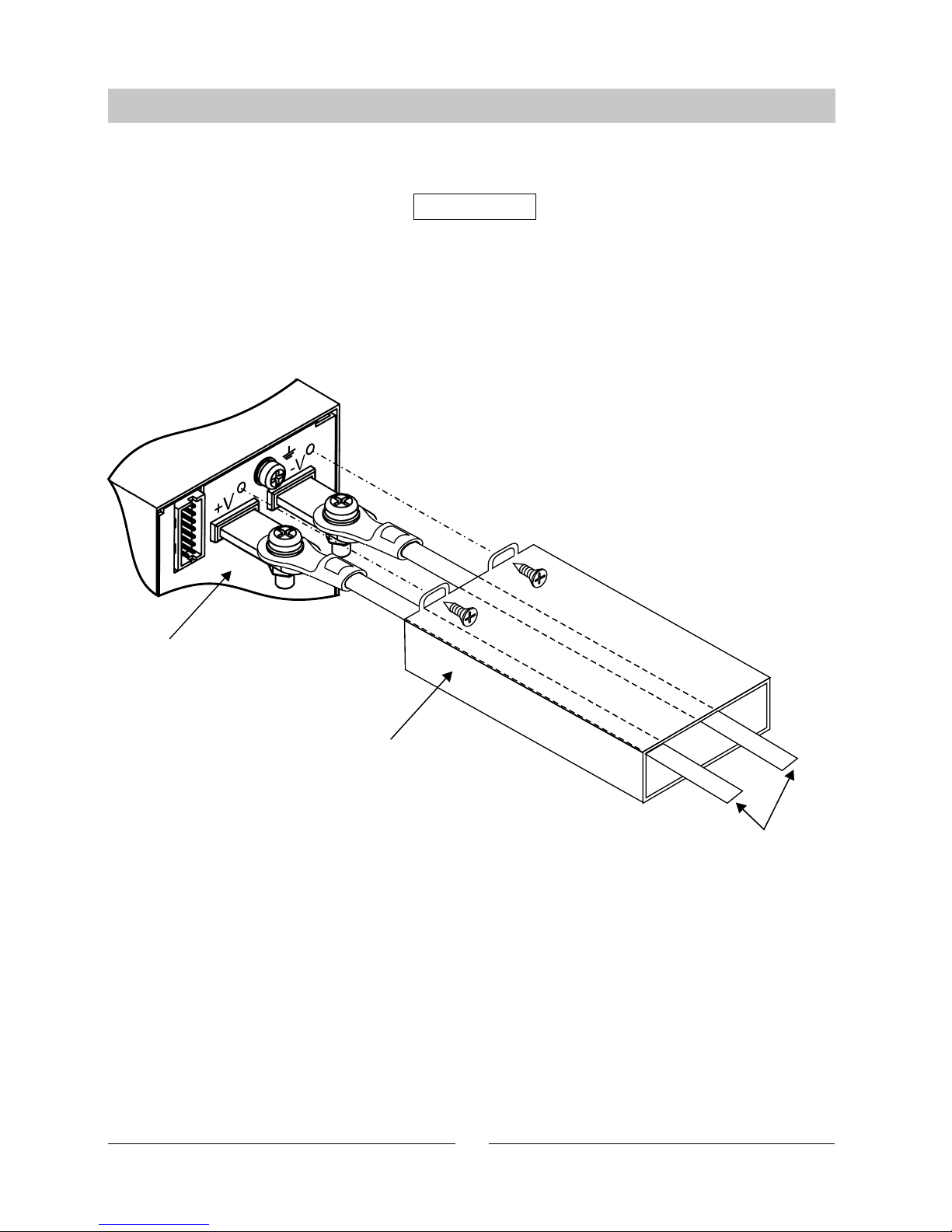

OUTPUT TERMINALS COVER

After connection of the load wires ( refer to par. 3-7 ), attach the plastic cover to the rear panel of the

powersupply,usingtwoselftappingscrewssuppliedwiththeunit.RefertoFig.1-1fordetails.

Fig.1-1:Terminals coverassembly

REAR PANEL

LOAD WIRES

PLASTIC COVER

WARNING

Hazardous voltages may exist at the output terminals of the 60V models.

Attach the terminals cover, supplied with the unit, to the chassis after

connecting the load wires as described below.

SAFETY INSTRUCTIONS

4

CHAPTER 1 GENERAL INFORMATION

1.1 USER’S MANUAL CONTENT

1.2 INTRODUCTION

1.2.1 General description

1.2.2 Configurations

1.2.4 Output connections

1.2.5 Analog voltage programming

1.2.6 Parallel operation

1.2.3 Control via the serial communication port

This user’s manual contains the operating instructions, installation instructions and specifications of

the ZUP series. For information related to operation with GPIB control, refer toNemic-Lambda GP485

user’smanual.

TheZUPseriesarewiderangeoutputswitchingpowersupplieswithlaboratoryperformance.TheZUP

series is power factor corrected and operates from worldwide AC voltage range continuously.Output

voltageandcurrentarecontinuouslydisplayedandLEDindicatorsshowthecompleteoperatingstatus

ofthepowersupply.The frontpanelcontrolsallowtheuser tosettheoutputparameters,theprotection

levels (over-voltage / under-voltage)and arm the foldback protection to disable the output if the unit

switchesfromConstant-voltagemodetoConstant-currentmode.

TheZUPcanbeconfiguredintoaprogrammablepowersystemofupto31DCoutputsusingthebuilt-in

RS232 or RS485 communication port in the power supply.In a GPIB system the GP485 controller can

controlupto31ZUPunitsinasingleGPIBaddress.

Output connections are made to rear panel bus-bars. Either the positive or negative terminal may be

grounded or the output may be floated. The maximum potential (including the output voltage) that

either output terminal is from ground must not exceed 60V. Local or remote sense may be used. In

remotesense,themaximumvoltagedroponeachwireis0.5V.

Analog inputs are provided at the rear panel for analog voltage programming of output voltage and

current, and On/Off control. Inputs are provided for resistive programming of the output voltage and

current.

ZUP unitsofthesameoutputvoltageandcurrentratingcanbe paralleledinmaster-slave

configuration

withautomaticcurrentsharingforpower-uppurposes.

Thefollowingparameterscanbeprogrammedviatheserialcommunicationport:

1.Outputvoltagesetting

2.Outputcurrentsetting

3.OutputOn/Off

4.Armingorreleaseofthefoldbackprotection

5.Over-voltageprotectionsetting

6.‘Soft’under-voltagelimit

7.Outputvoltagemeasurement

8.Outputcurrentmeasurement

9.Powersupplystart-upmode

(lastsettingorsafemode)

10.Over-voltageprotectionsettingread

11.Under-voltagelimitread

12.Remote/LocalControl

5

1.3.1 General

1.3.4 Front Panel Outputs option

1.3.3 AC Cables

1.3.2 Serial link cables

1.3 ACCESSORIES

Accessoriesaredeliveredwiththepowersupplyorseparatelyuponordering.

Belowarelistedpossible accessoriesandorderingnumbers.

PARTNo. DESCRIPTION

NL100 19”rack,3Uheight

NL101 Blankpanelfor19”rack

NL102 Additionalinstructionmanual

PART No. MARKET DESCRIPTION

NC301 USAandJapan 15A,125V,unshielded,2mtyp.length,withIEC320connectoronone

sideandNEMA-5-15Pconnectortheonotherside.

NC302 Europe 10A,250V,unshielded,2mtyp.length,withIEC320connectoronone

sideandINT’L7standardVII,dualearthingontheotherside.

NC303 General 10A,250V,unshielded,2mtyp.length,withIEC320connectoronone

sideandunterminatedstrippedwiresontheotherside.Usethecable

onlywithplugapprovedbythenationalsafetystandardsofthecountry

ofusage.

In cases where load connection at the front panel is required, optional Front Panel output Jacks for a

load current of 20A maximum is available. Please note that the power supply height is increased with

thisoption.Refertooutlinedrawing(par.3.12)fordetails.

ORDERNo. DESCRIPTION

ZUP /L 20AFrontPanelOutput Jacks

Seriallinkcable,forlinkingpowersuppliesbyRS485communicationisprovidedwiththepowersupply

accordingtoorder.Cabledescription:0.5m typ.length,shielded,EIA-568Atypeplugs,8contacts.

Refertopar.5.3.4,fordetails.

1.2.7 Cooling and mechanical construction

The Zup series is fan cooled. Upon installation take careto allow free air flow intothe power supply via

the front panel and out of the power supply via the rear panel. The ZUP series is contained in a

compact, lightweight package which allows for easy installation and space saving in the application

6

V

A

W

-

-

mV

mV

mS

-

-

mS

mS

mS

-

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

-

%

A

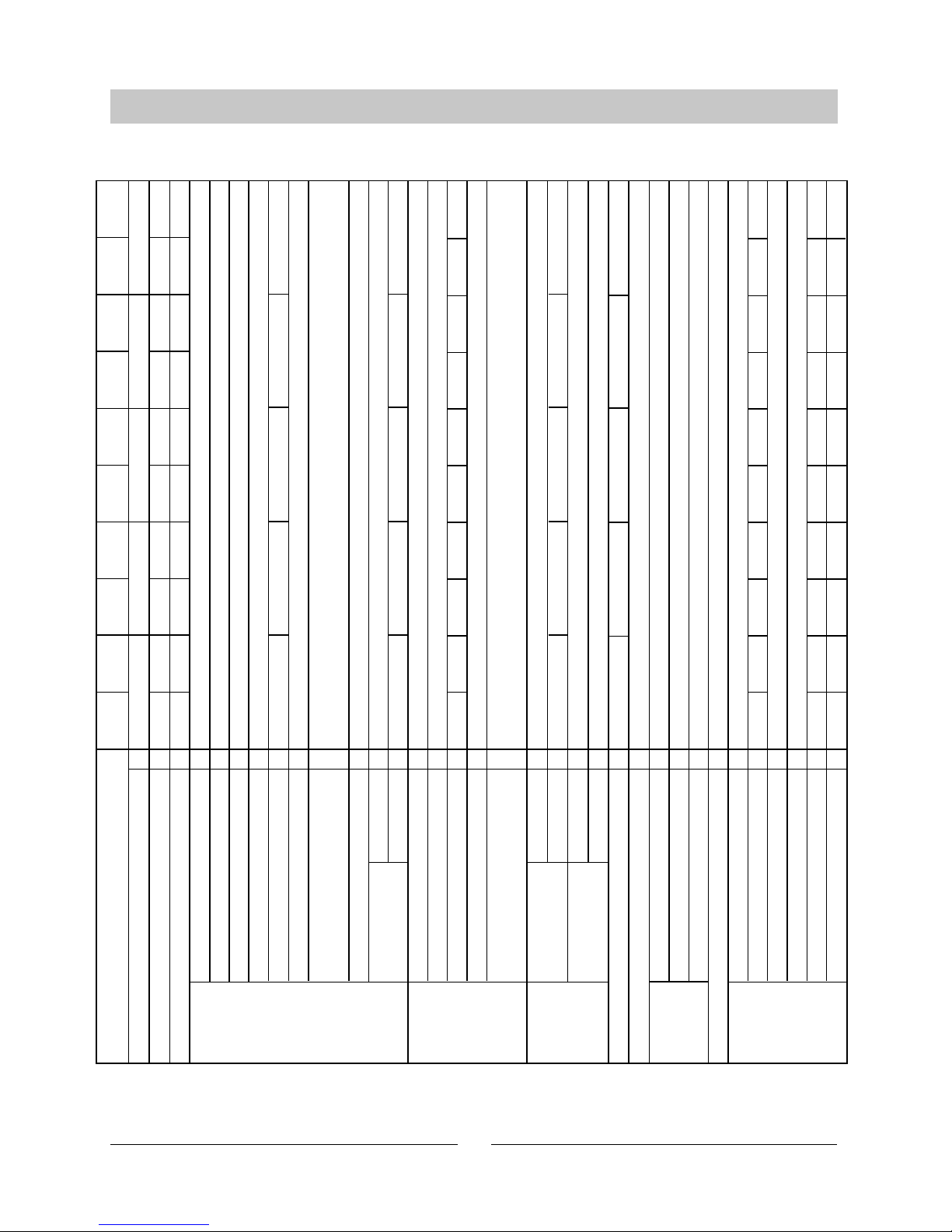

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

(pk to pk 20MHz Bandwidth)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5Hz-1MHz Bandwidth)

INPUT VOLTAGE (*8)

INPUT CURRENT (*6)

INPUT CURRENT HARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUSH CURRENT (*7) 100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRAM-

MING

(*3)

DISPLAY

OVERVOLTAGE PROTECTION (*5)

HOLD UP TIME

OUTPUT PROTECTIONS

INPUT

ZUP60-

7

0 ~ 7

10

5.6 / 2.7

80 / 84

0 ~ 12

15

5.6 / 2.7

80 / 84

0 ~ 20

30

5.6 / 2.7

79 / 83

0 ~ 40

50

5.6 / 2.7

79 / 82

0 ~ 66

0.005% +2mV from no load to full load, constant input voltage

0.005% +1mV from 85-132VAC or 170-265VAC, constant load

5

50

30ppm/ C from rated voltage following 30-minute warm-up

0.01% +2mV change in output over 8-hour interval under constant line, load and ambient

temperature following 30-minute warm-up

50mS (From zero volts to full scale, resistive load, current setting at max.)

50

100

5.6 / 2.7

74 / 77

15 15 15 15 15

ZUP60-

3.5

0 ~ 3.5

5

2.9 / 1.4

75 / 79

0 ~ 6

7.5

2.9 / 1.4

76 / 80

0 ~ 10

15

2.9 / 1.4

74 / 78

0 ~ 20

25

2.9 / 1.4

73 / 77

0 ~ 33

198 396 200 400 200 400 216 432 210 420

50

3.0 / 1.5

69 / 72

15 / 30 15 / 30 15 / 30 15 / 30 15 / 30

ZUP36-

12

ZUP36-

6

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

250

0 - 7.5

1

350

0 -13

0.5

400

0 - 24

0.2

0.01% + 5mA for load voltage change equal to unit voltage rating , constant input voltage.

0.01% +2mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output voltage and output current

100ppm/ C from rated current following 30 minute warm-up

O

Better than 0.028% of rated output voltage

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

0.4% + 40mA

Better than 0.03% of rated output current

0.02% +5mA change in output over 8-hour interval under constant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V) 3.5 digits (10V) accuracy: 0.2% +/- 2 digits

3 digits accuracy: 0.5% +/- 3 digits

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63Hz

Complies with EN61000-3-2, Class A

0.99 at 100/200VAC, 100% Load

500

0 - 40

0.2

750

0 - 66

0.2

0 ~ 6 0 ~ 10 0 ~ 20 0 ~ 36 0 ~ 60

ZUP6-

33

CHAPTER 2 SPECIFICATIONS

2.1 SPECIFICATIONS: 200W/400W Series

7

O

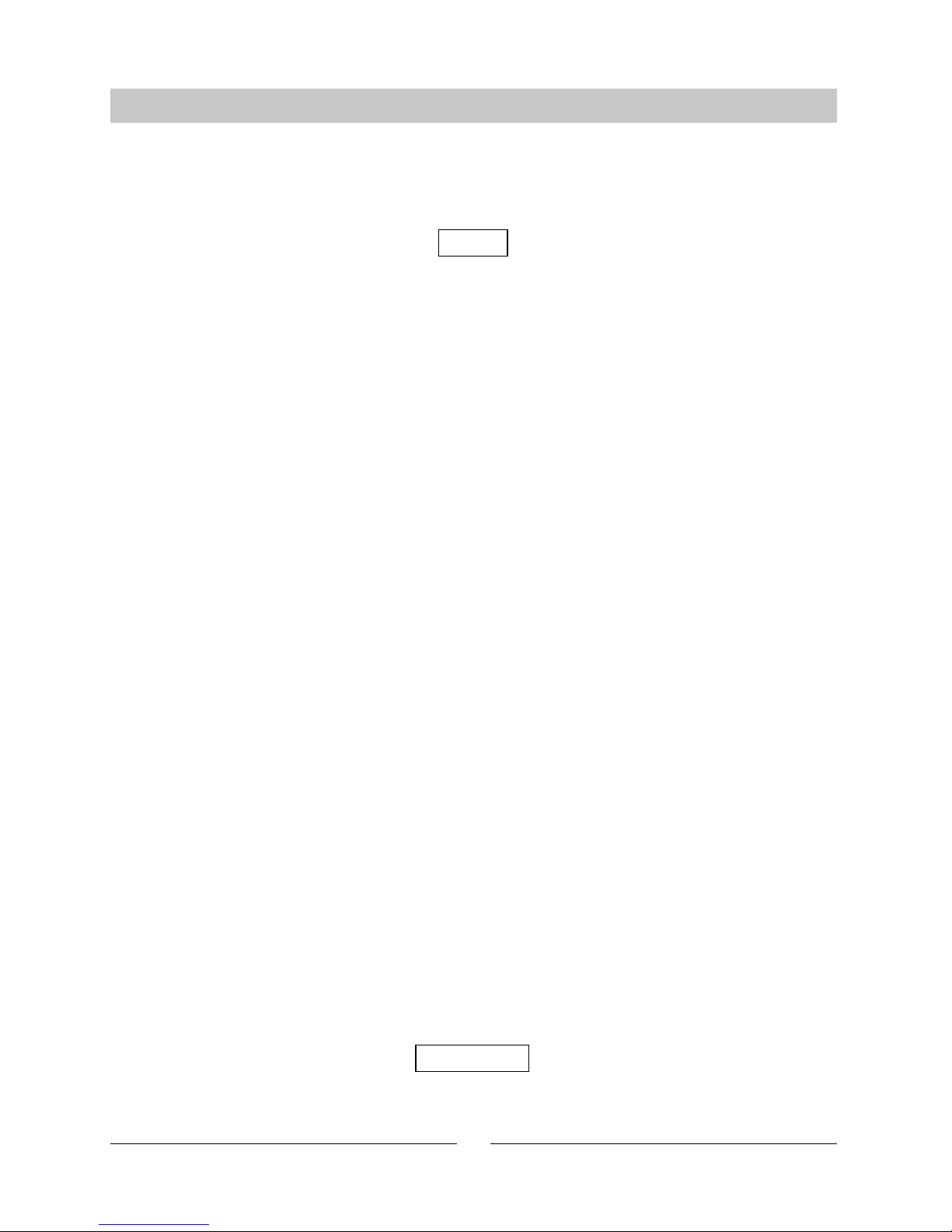

-

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*9)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

SAFETY STANDARDS

EMC STANDARDS

APPROVALS

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL RESET BY AC INPUT RECYCLING.(OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT POWER.

* 7 FOR 200W UNITS - AT COLD START Ta = 25OC.

* 8 FOR CASES WHERE CONFORMANCE TO VARIOUS SAFETY SPECS, (UL, IEC ETC.) ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLATE.

* 9 WHEN MOUNTED WITH MOUNTING SCREWS.

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

ZUP60-

7

3.23.23.23.23.2

ZUP60-

3.5

2.92.92.92.92.9

ZUP36-

12

ZUP36-

6

ZUP20-

20

ZUP20-

10

ZUP10-

40

ZUP10-

20

ZUP6-

66

0 ~ 50 C: 100% Load.

O

-20 ~ 70 C

O

30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude (sweep 1min) Less than 2G, X,Y, Z, 1 hour each.

70 x 124 x 350.

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

Possible, maximum 0.5V drop on each load wire

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC part 15 (class A)

Master - slave method: up to 5 units, refer to instruction manual

Up to 2 units, refer to instruction manual

More than 100MOhm at 25 C and 70% R.H.

O

EN55022-B, FCC-B, VCCI-2

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-1

Input-Chassis: 2.0kVAC 1 min. Input-Output: 3.0kVAC 1 min. Output-Chassis: 500VAC 1min.

ZUP6-

33

2.1 SPECIFICATIONS: 200W/400W Series continued

8

V

A

W

-

-

mV

mV

mS

-

-

mS

mS

mS

-

-

mA

-

-

-

-

-

-

V

-

-

-

-

-

-

A

-

-

%

A

MODEL

OUTPUT VOLTAGE (*1)

OUTPUT CURRENT (*2)

RATED OUTPUT POWER

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

RIPPLE

RECOVERY TIME (*4)

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5 z-1M z Bandwidth)

(pk to pk 20M z Bandwidth)

LOAD REGULATION

LINE REGULATION

RMS RIPPLE

TEMPERATURE COEFFICIENT

TEMPERATURE DRIFT

(5 z-1M z Bandwidth)

INPUT VOLTAGE (*7)

INPUT CURRENT (*6)

INPUT CURRENT ARMONICS

POWER FACTOR (TYP)

EFFICIENCY (*6)

INRUS CURRENT 100/200V

VOLTAGE

CURRENT

STATUS

UP PROGRAMMING RESPONSE TIME

FULL LOAD

NO LOAD

RESOLUTION

ACCURACY

RESOLUTION

ACCURACY

VOLTAGE

CURRENT

CONSTANT

VOLTAGE

CONSTANT

CURRENT

DOWN

PROGRAMMING

RESPONSE TIME

PROGRAM-

MING

(*3)

DISPLAY

OVERVOLTAGE PROTECTION (*5)

OLD UP TIME

OUTPUT PROTECTIONS

INPUT

ZUP60-14

0 ~ 14

20

11.2 / 5.4

80 / 84

0 ~ 24

30

11.2 / 5.4

80 / 84

0 ~ 40

60

11.2 / 5.4

79 / 82

0 ~ 80

100

11.2 / 5.4

77 / 81

0 ~ 132

792 800 800 864 840

200

11.2 / 5.4

74 / 77

30

0.005% +2mV from no load to full load, constant input voltage

0.005% +1mV from 85-132VAC or 170-265VAC, constant load

5

80

30ppm/ C from rated voltage following 30-minute warm-up

O

0.01% +2mV change in output over 8-hour interval under constant line, load and ambient

temperature following 30-minute warm-up

50

ZUP36-24

ZUP20-40

ZUP10-80

ZUP6-132

250

0-7.5

1

100

8

70

5

350

0-13

0.5

90

8

60

5

400

0-24

0.2

0.07% + 10mA for load voltage change equal to unit voltage rating , constant input voltage.

0.01% +5mA from 85-132VAC or 170-265VAC, constant load

20mS at 100V/200VAC, rated output voltage and output current

100ppm/ C from rated current following 30 minute warm-up

O

0.05% +10mA change in output over 8-hour interval under constant line, load and ambient

temperature following 30 minute warm-up

3 digits (6V, 20V, 36V, 60V) 3.5 digits (10V) accuracy: 0.2% +/- 2 digits

3.5 digits (132A), all others 3 digits accuracy: 0.5% +/- 3 digits

CV/CC, Alarm, Fold, Local/Remote, ON/OFF

Over Voltage, Over Temperature, Foldback

85 ~ 265VAC Continuous, 47 ~ 63 z

Complies with EN61000-3-2, Class A

0.99 at 100/200VAC, 100% Load

500

0-40

0.2

750

0-66

0.2

0 ~ 6 0 ~ 10 0 ~ 20 0 ~ 36 0 ~ 60

2.1 SPECIFICATIONS: 800W Series

Better than 0.028% of rated output voltage

0.4% + 40mA

Better than 0.03% of rated output current

60mS (From zero volts to full scale, resistive load, current setting at max.)

0.02% + 5mV 0.02% + 8mV 0.02% + 12mV 0.02% + 26mV 0.02% + 35mV

9

-

-

-

-

-

-

Kg

mm

-

-

-

-

-

-

-

-

-

-

-

-

-

-

-

OPERATING TEMPERATURE

OPERATING HUMIDITY

STORAGE TEMPERATURE

STORAGE HUMIDITY

VIBRATION (*8)

SHOCK

WEIGHT

SIZE (WxHxD)

OUTPUT ON/OFF

OUTPUT GOOD

OUTPUT VOLTAGE PROGR.

OUTPUT CURRENT PROGR.

REMOTE SENSING

COMMUNICATION INTERFACE

ENVIRON-

MENT

MECHANI-

CAL

EXTERNAL

FUNCTIONS

APPLICABLE SAFETY STANDARDS

APPLICABLE EMC STANDARDS

CONDUCTED EMI

RADIATED EMI

SERIAL OPERATION

PARALLEL OPERATION

COOLING

WITHSTAND VOLTAGE

ISOLATION RESISTANCE

ZUP60-

14

5.8

ZUP36-

24

ZUP20-

40

ZUP10-

80

ZUP6-

132

0 ~ 50 C: 100% Load.

O

-20 ~ 70 C

O

30 ~ 90% RH ( No Dewdrop )

10 ~ 95% RH ( No Dewdrop )

Less than 20G

10 ~ 55Hz, Amplitude ( sweep 1min ) Less than 2G, X,Y, Z, 1hour each.

140 x 124 x 350 refer to outline drawing

By TTL Signal or Dry Contact - refer to instruction manual

Open collector - refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

By Voltage ( 0 ~ 4V ) or by Resistance ( 0 ~ 4K ) refer to instruction manual

Possible, maximum 0.5V drop on each load wire

RS232 and RS485 Built-in, IEEE488 Optional

UL 3111-1, EN61010-1

EN 61326-1, IEC 61326 -1, FCC part 15 (class A)

Master - slave method: up to 5 units, refer to instruction manual

Up to 2 units, refer to instruction manual

More than 100MOhm at 25 C and 70% R.H.

O

EN55022-B, FCC-B, VCCI-2

Forced air by blower fan, (blower fan is mounted within unit)

EN55022-A, FCC-A, VCCI-1

Input - Chassis: 2.0kVAC 1 min. Input - Output: 3.0kVAC 1 min. Output - Chassis: 500VAC 1 min.

NOTES:

* 1 MINIMUM VOLTAGE IS GUARANTEED TO MAXIMUM 0.2% OF THE RATED OUTPUT VOLTAGE.

* 2 MINIMUM CURRENT IS GUARANTEED TO MAXIMUM 0.4% OF THE RATED OUTPUT CURRENT.

* 3 GIVEN FOR CONTROL OF THE OUTPUT VIA THE SERIAL COMMUNICATION OR VIA FRONT PANEL CONTROLS.

* 4 TIME FOR RECOVERY TO WITHIN +/- 50mV AGAINST CURRENT CHANGE OF 50% TO 100%.

* 5 INVERTER SHUT DOWN METHOD, MANUAL RESET BY AC INPUT RECYCLING. (OVP WILL SHUT DOWN OUTPUT).

* 6 AT 100V/200V AND MAXIMUM OUTPUT POWER.

* 7 FOR CASES WHERE CONFORMANCE TO VARIOUS SAFETY SPECS, (UL, IEC ETC.) ARE REQUIRED TO BE DESCRIBED

AS 100-240VAC (50/60Hz) ON NAME PLATE.

*8 WHEN MOUNTED WITH MOUNTING SCREWS.

2.1 SPECIFICATIONS: 800W Series continued

10

2.2 SUPPLEMENTAL CHARACTERISTICS

The supplemental characteristics give typical but non-warranted performance characteristics. The

supplementalcharacteristicsareusefulinaccessingapplicationsforthepowersupply.Several kinds

ofsupplementalcharacteristicsarelistedbelow.

1.EVALUATIONDATA: Typicalperformanceofthepowersupply.

2.RELIABILITYDATA: Reliabilityperformanceofthepowersupply.

3.IEC1000DATA: PerformanceofthepowersupplyunderIEC1000testconditions.

4.EMIDATA: TypicalEMI(conductedandradiated)performanceofthepowersupply.

The supplemental characteristics data are held in each Nemic-Lambda sales and service facility.For

furtherdetailspleasecontacttheNemic-Lambdaofficenearestyou.

11

CHAPTER 3 INSTALLATION

3.1 GENERAL

3.2 INITIAL INSPECTION

3.2.1 Mechanical inspection

3.2.2 Preparation for use

3.3 AC SOURCE REQUIREMENTS

3.4 COOLING & PLACEMENT

3.5 RACK MOUNTING

3.6 POWER CONNECTION

NOTE

CAUTION

This chapter contains instructions for initial inspection, preparation for use and repackaging for

shipment.ConnectiontoPC,linkingZUPunitsandsettingtheaddressaredescribedinchapter 5.

Prior to shipment this power supply was inspected and found free of mechanical or electrical defects.

Uponunpackingofthepowersupply,inspectforanydamagewhichmayhaveoccurredintransit.Keep

all packing materials until inspection has been completed. If any damage is detected, file a claim with

thecarrierimmediatelyandnotifytheNemic-Lambdasalesorservicefacilitynearestyou.

Themechanicalinspectionshouldconfirmthatthereisnoexteriordamagetothepowersupplysuchas

brokenknobsorconnectorsandthatthefrontpanelandmeterfacearenotscratchedorcracked.

In order to be operational the power supply must be connected to an appropriate AC source. The line

voltagemustbewithinthepowersupplyspecification. DO NOTapplypowerbeforereadingparagraph

3.3.

The ZUP series can be operated from a nominal 100V to 240V, single phase, 47 ~ 63Hz. The input

voltage range and current required for each model is specified in chapter 2. Make sure that under

heavyload,theACvoltagesuppliedtothepowersupplydoesnotfallbelow“lowlimit”specifications.

This power supply is fan cooled. Upon installation ensure sufficient space for air intake (front panel)

andexhaust(rearpanel).Thepowersupplyshouldbeusedinanareawheretheambienttemperature

doesnotexceed+50 C

O

ZUP models can be mounted in a standard 19” rack (3U height). The 200W and 400W models occupy

1/6 rack length. The 800W model occupies1/3 rack length. The power suppliesshould be fixed by M4

screwsreplacingtherubberfeetonthebottomofthepowersupply.Thescrewsmustnotprotrudemore

than6mmintothepowersupply.Refertotheoutlinedrawinginthischapterformountingdetails.

Connection of this power supply to an AC power source should

be made by an electrician or other qualified personnel.

ZUP series power supplies generate a magnetic field which might affect the

operation of other instruments. If your equipment is susceptible to magnetic fields,

do not position adjacent to the ZUP.

12

This power supply is equipped with a three conductor power cable. The third conductor is the ground

conductor.When the cable is plugged-in to an appropriate receptacle, the power supply is grounded.

Under no circumstances should this power supply be operated without an adequate ground

connection. If a two contact receptacle is encountered, it must be replaced by a three contact

receptacle, properly grounded. This operation should be done by a qualified electrician. It is

recommended to keep the AC input wires separate from the DC output and signal wires to avoid

interference.

Tomeet radiated EMI specification, the EMI suppressor clamp should be attached to the AC cable as

closeaspossibletotheACinletofthepowersupply.

WARNING

WARNING

Some components inside the power supply are at AC voltage even when the

On/Off switch is in the “Off” position. To avoid the hazard of electric shock,

disconnect line cord and load and wait 2 minutes before removing cover.

Turn off the AC input power before making or changing any rear panel connection.

Make sure that all connections are securely tightened before applying power.

3.7 CONNECTING THE LOAD

3.7.1 Selecting wire size

Twofactorsmustbeconsideredinselectingwiresize.

1. Wires should be at least heavy enough to avoid overheating while carrying the power supply load

current at the rated load, or the current that would flow in the event the load wire were shorted,

whicheverisgreater.

2.Wiresizeshouldbeselectedtoenablevoltagedropperleadtobelessthan0.5Vattheratedcurrent.

It is recommended to minimize voltage drop on the wires to prevent excessive output power

consumptionfromthepowersupply.

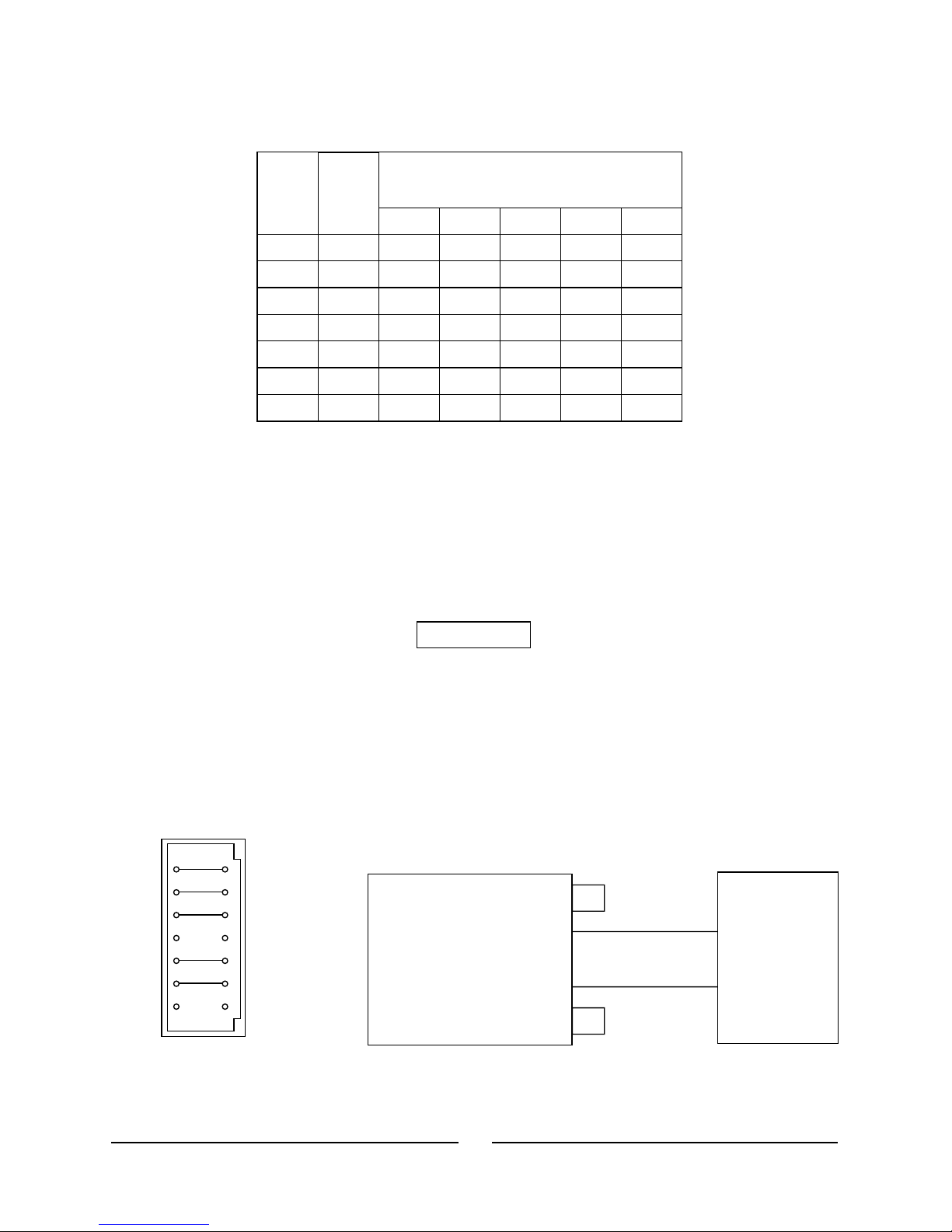

Please refer to Tables 3-1 and 3-2 for maximum wire length to limit voltage drop by American and

Europeanmeasurementsrespectively.

Table 3-1: Maximum wire length for

0.5V drop on lead (in feet)

wire size

AWG

5A

40 20 10 4 1

63 31 15 6 1.7

100 50 25 10 3

160 80 40 16 5

253 126 63 25 8

400 200 100 40 13

640 320 160 64 21

1016 508 254 102 34

14

12

10

8

6

4

2

0

2.526

1.589

0.9994

0.6285

0.3953

0.2486

0.1564

0.0983

Maximum length in feet -

to limit voltage drop to 0.5V or less

10A 20A 50A 150A

Resistivity

Ohm/kft

13

13

Forcurrentnotshownintables3-1and3-2useformula: Maximumlength=500/(current*resistivity)

Wherecurrentisexpressedinampersandresistivityinohms/kmorohms/1000ft.

Table 3-2: Maximum wire length for 0.5V drop on lead (in meters)

cross sect.

area

(mm 2)

5A

12.2 6.1 3.0 1.2 0.4

19.6 9.8 4.9 2.0 0.7

29.5 14.7 7.4 2.9 1.0

51.3 25.6 12.8 5.1 1.7

80.6 40.3 20.2 8.1 2.7

125.8 62.9 31.4 12.6 4.2

177.0 88.5 44.2 17.7 5.9

2.5

4

6

10

16

25

35

8.21

5.09

3.39

1.95

1.24

0.795

0.565

Maximum length in meters -

to limit voltage drop to 0.5V or less

10A 20A 50A 150A

<

Resistivity

Ohm/km

3.7.2 Wire termination

3.7.3 Single load connection, Local Sensing

The wires should be properly terminated with terminals securely attached. DO NOT use non

terminatedwiresforloadconnectionatthepowersupply.

Fig. 3-1 illustrates the connection of a single load to the power supply using local sensing. This

connectionismadeviathe“ExternalControlConnector”locatedon therearpanelofthepowersupply.

Localsensingissuitableforapplicationswhere loadregulationisnotcritical.

Fig.3-1:Singleloadconnection,LocalSensing

14

2

- LS - S

- V

- S +LS

+LS

- LS

+S On/Off +V

- S

COM Output Good

P VRFV

VCVP VRFI

VCCP RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

POWER

SUPPLY

+

_

RCCP

1

CAUTION

At local sensing, short between +LS or +S to -V or -S or -LS will cause damage to the

power supply. Reversing the sense wires might cause damage to the power supply

at local and remote sensing.

14

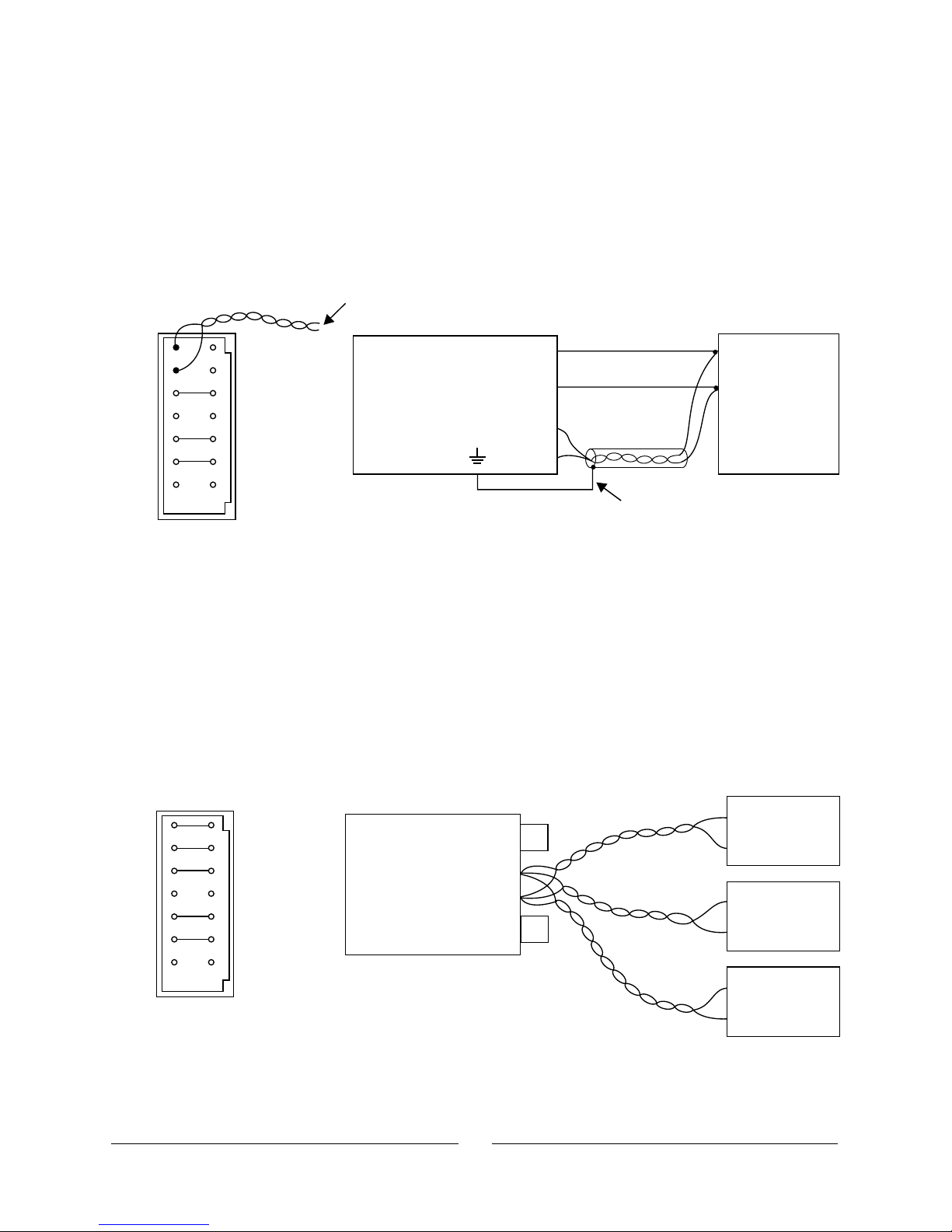

3.7.4 Single load connection, Remote Sensing

3.7.5 Multiple load connections, radial distribution method

Remote Sensing is used in cases where, in Constant Voltagemode the load regulation is important at

the load terminals. Use twisted or shielded wires to minimize noise pick-up. If shielded wires are used,

the shield should be connected to the ground at one point, either the power supply chassis or the load

ground. The optimal point for the shield ground should be determined by experimentation. At Remote

Sensing,themaximumvoltagedropallowedattheloadwiresis0.5Vperwire.

In cases of multiple loads connected to one supply, each load should be connected to the power

supply’s output terminals using separate pairs of wires. It is recommended that each pair of wires will

be as short as possible and twisted or shielded to minimize noise pick-up and radiation. The sense

wiresshouldbeconnectedtothepowersupplyoutputterminalsortotheloadwiththemostcriticalload

regulationrequirement.

Fig.3-2:RemoteSensing,singleload.

Fig.3-3:Multipleloadconnectionswithdistributionterminal

2

2

- LS

- LS

+ S

- V

- S

- S

+LS

+LS

+S

+S

On/Off

On/Off

+ V

- S

COM

COM

Output Good

Output Good

P

P

VRFV

VRFV

VCVP

VCVP

VRFI

VRFI

VCCP

VCCP

RCVP

RCVP

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

EXTERNAL CONTROL

CONNECTOR

(ZUP rear panel view)

LOAD

LOAD #1

LOAD #2

LOAD #3

POWER

SUPPLY

POWER

SUPPLY

To Load Terminals

Shield

+

+

+

+

_

_

_

_

RCCP

RCCP

1

1

+S

- V

+LS

- LS

+V

- S

15

This manual suits for next models

14

Table of contents

Other Nemic-Lambda Power Supply manuals

Popular Power Supply manuals by other brands

Allanson

Allanson AHVPS714-40-MV-PCB Product Specifications and Operating Manual

Huawei

Huawei ETP48400-C9A2 user manual

BEL

BEL TEC800-12-074NA installation instructions

axing

axing ZU 99-22 Operation instructions

Altronix

Altronix OLS180220 installation guide

Streetwize

Streetwize SWPP17 Usage & Safety Instructions