Intermec 203-880-002 User manual

Forklift Power Supply

Installation

Guide

ii Forklift Power Supply Installation Guide

Intermec Technologies Corporation

Worldwide Headquarters

6001 36th Ave.W.

Everett, WA 98203

U.S.A.

www.intermec.com

The information contained herein is provided solely for the purpose of allowing

customers to operate and service Intermec-manufactured equipment and is not to be

released, reproduced, or used for any other purpose without written permission of

Intermec Technologies Corporation.

Information and specifications contained in this document are subject to change

without prior notice and do not represent a commitment on the part of Intermec

Technologies Corporation.

© 2008-2009 by Intermec Technologies Corporation. All rights reserved.

The word Intermec, the Intermec logo, Norand, ArciTech, Beverage Routebook,

CrossBar, dcBrowser, Duratherm, EasyADC, EasyCoder, EasySet, Fingerprint, INCA

(under license), i-gistics, Intellitag, Intellitag Gen2, JANUS, LabelShop, MobileLAN,

Picolink, Ready-to-Work, RoutePower, Sabre, ScanPlus, ShopScan, Smart Mobile

Computing, SmartSystems, TE 2000, Trakker Antares, and Vista Powered are either

trademarks or registered trademarks of Intermec Technologies Corporation.

There are U.S. and foreign patents as well as U.S. and foreign patents pending. Wi-Fi is

a registered certification mark of the Wi-Fi Alliance.

Forklift Power Supply Installation Guide iii

Document Change Record

This page records changes to this document. The document was

originally released as Revision 001.

Version

Number Date Description of Change

002 6/2009 Updated to include new printer models

and output cable number.

001 4/2008 First release of document

iv Forklift Power Supply Installation Guide

Contents

Forklift Power Supply Installation Guide v

Contents

Before You Begin . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . viii

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . .viii

Global Services and Support . . . . . . . . . . . . . . . . . . . .viii

Warranty Information . . . . . . . . . . . . . . . . . . . . viii

Web Support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ix

Telephone Support . . . . . . . . . . . . . . . . . . . . . . . . ix

Service Location Support. . . . . . . . . . . . . . . . . . . ix

Who Should Read This Manual . . . . . . . . . . . . . . . . . . .x

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Understanding the DC Power Supply Kit . . . . . . . . . . . . . . . 2

Installation Guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Power Supply Considerations . . . . . . . . . . . . . . . . . . . . . . . . . 3

Understanding Power Supply LEDs . . . . . . . . . . . . . . 3

Using the Input Power Cable. . . . . . . . . . . . . . . . . . . . . 4

Using the Inline Fuse. . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Using the Output Power Cable . . . . . . . . . . . . . . . . . . . 6

Contents of the Forklift Power Supply Kit . . . . . . . . . . . . . . 6

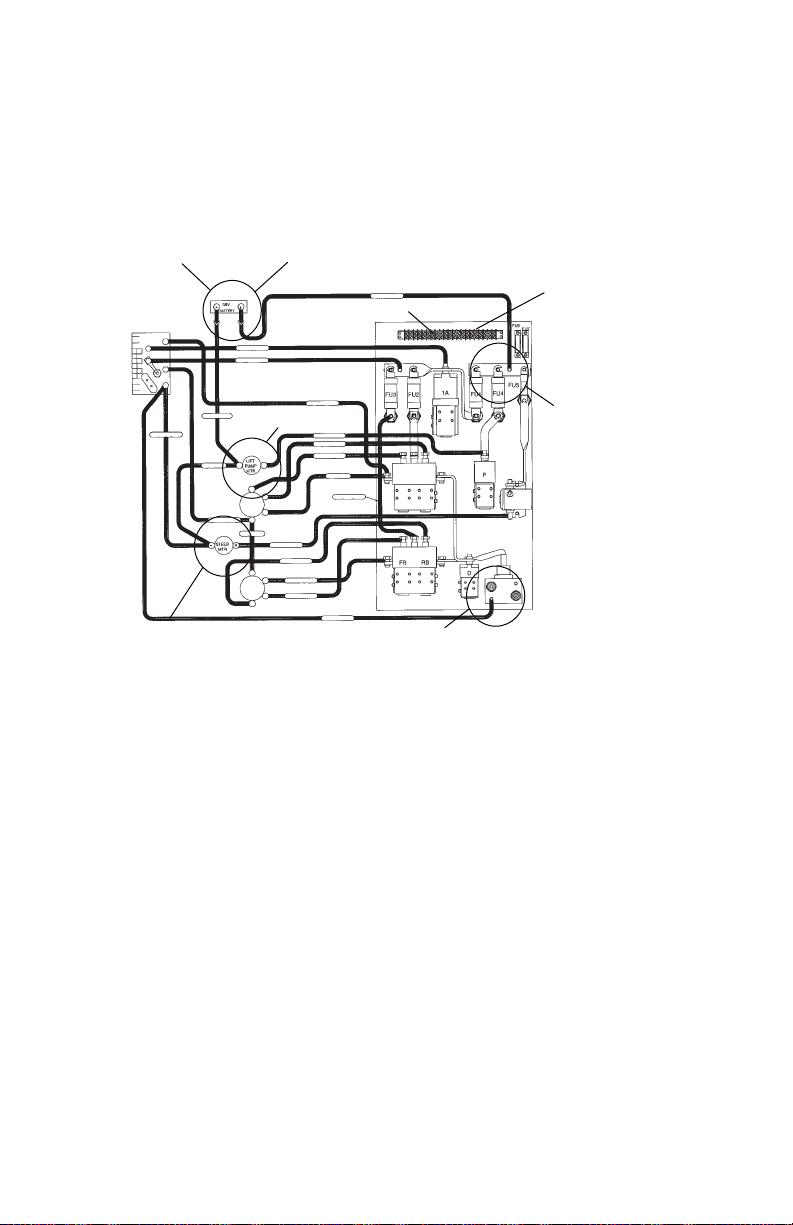

Wiring Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

2 Installing the Forklift Power Supply . . . . . . 9

Installation Recommendations . . . . . . . . . . . . . . . . . . . . . . . 10

Installation Overview. . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Tools List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Preparing the Power Input Cable . . . . . . . . . . . . . . . . . . . . . 11

Mounting the Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . 11

Direct Versus Isolation Mounting on the

Lift Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Creating a Custom Electrical Isolation Mount. . . . 13

Using a Standard Power Supply Mount . . . . . . . . . . 14

Contents

vi Forklift Power Supply Installation Guide

Installing the Input Power Cable. . . . . . . . . . . . . . . . . . . . . . 14

Connecting the Power Cable to the Forklift. . . . . . . . . . . . 15

Terminating the Input Cable . . . . . . . . . . . . . . . . . . . . . . . . . 16

Cutting and Stripping the Input Power Cable . . . . 16

Attaching Heat Shrink Tubing . . . . . . . . . . . . . . . . . . 17

Preparing the Cable Ends . . . . . . . . . . . . . . . . . . . . . . . 18

Connecting to the Forklift Battery . . . . . . . . . . . . . . . . . . . . 19

Connecting to Side-Mount Battery Terminals . . . . 19

Connecting to Top-Mount Battery Terminals . . . . 20

Securing the Battery Cable . . . . . . . . . . . . . . . . . . . . . . 21

Connecting the Output Power Cable . . . . . . . . . . . . 21

Sample Installations . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3 Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Identifying and Correcting Problems. . . . . . . . . . . . . . . . . . 26

Inspecting the Hardware. . . . . . . . . . . . . . . . . . . . . . . . 26

Checking the Electrical Measurements. . . . . . . . . . . 26

Measuring the Voltage . . . . . . . . . . . . . . . . . . . . 26

Performing Continuity Testing . . . . . . . . . . . . 26

Substituting Components . . . . . . . . . . . . . . . . . . . . . . 27

Troubleshooting Charts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Contents

Forklift Power Supply Installation Guide vii

Before You Begin

viii Forklift Power Supply Installation Guide

Before You Begin

This section provides you with safety information, technical

support information, and sources for additional product

information.

Safety Information

Your safety is extremely important. Read and follow all warnings

and cautions in this document before handling and operating

Intermec equipment. You can be seriously injured, and

equipment and data can be damaged if you do not follow the

safety warnings and cautions.

This section explains how to identify and understand warnings,

cautions, and notes that are in this document.

Global Services and Support

Warranty Information

To understand the warranty for your Intermec product, visit the

Intermec web site at www.intermec.com and click Support >

Returns and Repairs > Warranty.

A warning alerts you of an operating procedure, practice,

condition, or statement that must be strictly observed to

avoid death or serious injury to the persons working on the

equipment.

A caution alerts you to an operating procedure, practice,

condition, or statement that must be strictly observed to

prevent equipment damage or destruction, or corruption or

loss of data.

Note: Notes either provide extra information about a topic or

contain special instructions for handling a particular condition

or set of circumstances.

Before You Begin

Forklift Power Supply Installation Guide ix

Disclaimer of warranties: The sample code included in this

document is presented for reference only. The code does not

necessarily represent complete, tested programs. The code is

provided “as is with all faults.” All warranties are expressly

disclaimed, including the implied warranties of merchantability

and fitness for a particular purpose.

Web Support

Visit the Intermec web site at www.intermec.com to download

our current manuals (in PDF). To order printed versions of the

Intermec manuals, contact your local Intermec representative or

distributor.

Visit the Intermec technical knowledge base (Knowledge Central)

at www.intermec.com and click Support > Knowledge Central

to review technical information or to request technical support

for your Intermec product.

Telephone Support

In the U.S.A. and Canada, call 1-800-755-5505.

Outside the U.S.A. and Canada, contact your local Intermec

representative. To search for your local representative, from the

Intermec web site, click About Us > Contact Us.

Service Location Support

For the most current listing of service locations, go to

www.intermec.com and click Support > Returns and Repairs

> Repair Locations.

For technical support in South Korea, use the after service

locations listed below:

AWOO Systems

102-1304 SK Ventium

522 Dangjung-dong

Gunpo-si, Gyeonggi-do Korea, South 435-776

Contact: Mr. Sinbum Kang

Telephone: +82-31-436-1191

E-mail: [email protected]

Before You Begin

x Forklift Power Supply Installation Guide

IN Information System PTD LTD

6th Floor

Daegu Venture Center Bldg 95

Shinchun 3 Dong

Donggu, Daegu City, Korea

Who Should Read This Manual

This document is for the person who is responsible for installing,

configuring, and maintaining the Forklift Power Supply. The

Forklift Power Supply Installation Kit can be used with the PB21,

PB22, PB31, PB32, PB50, PB51, and PW50 mobile printers.

This document provides you with information about the

features of the forklift power supply, and how to install,

configure, operate, maintain, and troubleshoot it.

Before you work with the forklift power supply , you should be

familiar with your network and general networking terms, such

as IP address.

Chapter 1 — Introduction

2 Forklift Power Supply Installation Guide

Understanding the DC Power Supply Kit

Use the DC power to help supply power to your mobile printer

when it is on a forklift. The DC power supply kits include these

items:

•Power supply

•Power supply input cable, 2.44 m (8 feet)

•Fused power cable, 46 cm (18 inch)

•#10 terminal ring

•3AB, 20A/250 Vx fuse for 12 V installations

•Insulated quick-connect tabs (2)

The power supply provides 12 Vx output that is filtered and

regulated. It also provides over-current, over-voltage, over

temperature, and shorted-output protection.

Installation Guidelines

You should be familiar with the brands and models of

equipment where this kit is installed. You should also be trained

and experienced in forklift electrical systems.

Follow these guidelines and the installation procedures as well as

those of the lift manufacturer to ensure a safe and reliable

installation:

•Make sure the power supply is securely mounted.

•Make sure the mounting surface is sturdy.

•Make sure the mounting surface provides power supply heat

sink.

•Make sure the fuse is close to vehicle power source and is in

line with Intermec equipment only.

•Keep cables as short as possible, and secure them at least

every 46 cm (18 inch).

Before installing the power supply, familiarize yourself with the

forklift manufacturer’s requirements and make sure you have the

proper qualifications to perform the installation. For procedures

on how to properly mount the forklift power supply, see

“Mounting the Power Supply” on page 11.

Chapter 1 — Introduction

Forklift Power Supply Installation Guide 3

Order the Smart UPS kit (P/N 203-788-xxx) for a universal power

supply (UPS) that provides backup power during battery change

out.

Power Supply Considerations

Follow these guidelines when installing the power supply:

•The power supply (P/N 851-070-003) accepts input voltage

ranging from 6 to 60 Vx for use with forklifts using electrical

systems running 12 to 60 Vx. It provides 12 Vx output which

is filtered and regulated. It also provides short-circuit, over-

voltage, and over-temperature protection.

•You should mount the power supply to the forklift chassis or

connect it (electrically) through external wire to the forklift

chassis. Chassis ground to the printer or other equipment is

then established through the power supply output cable.

•Since the power supply produces heat, Intermec advises that

you mount it on a metallic surface that is a minimum of 838

to 1032 square cm (130 to 160 square inches which is

approximately one square foot or more) to disperse heat.

This location should not be in the vicinity of sources of

forklift generated heat.

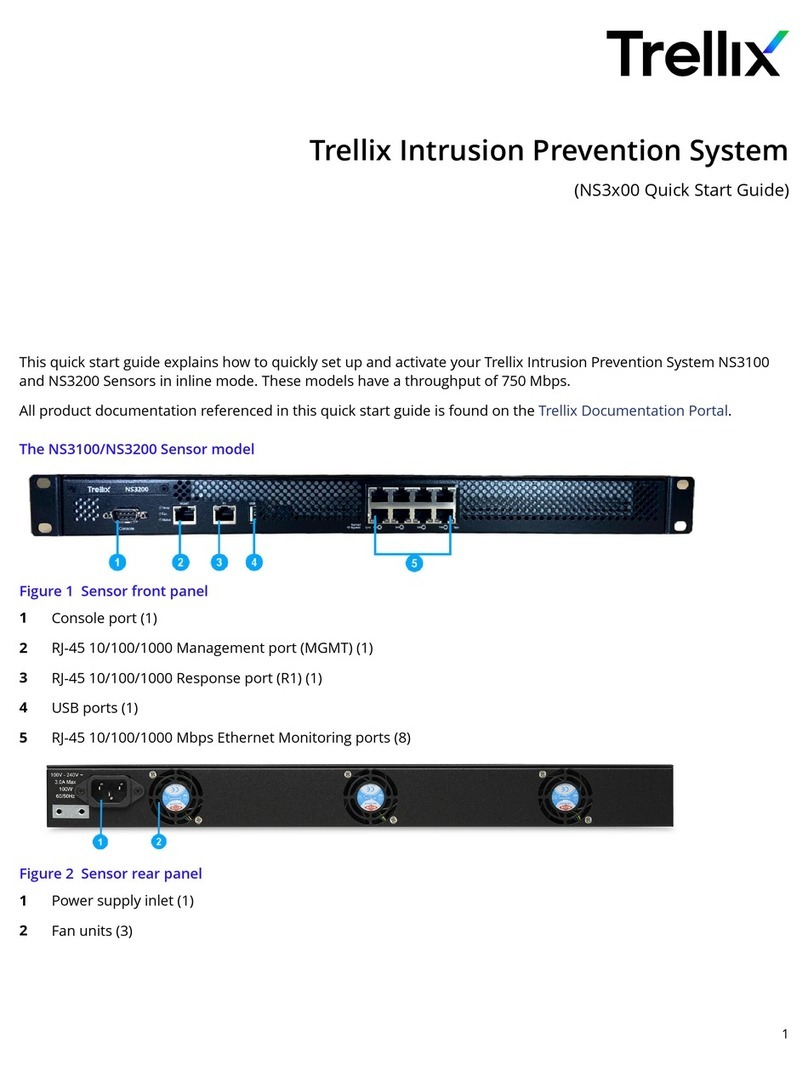

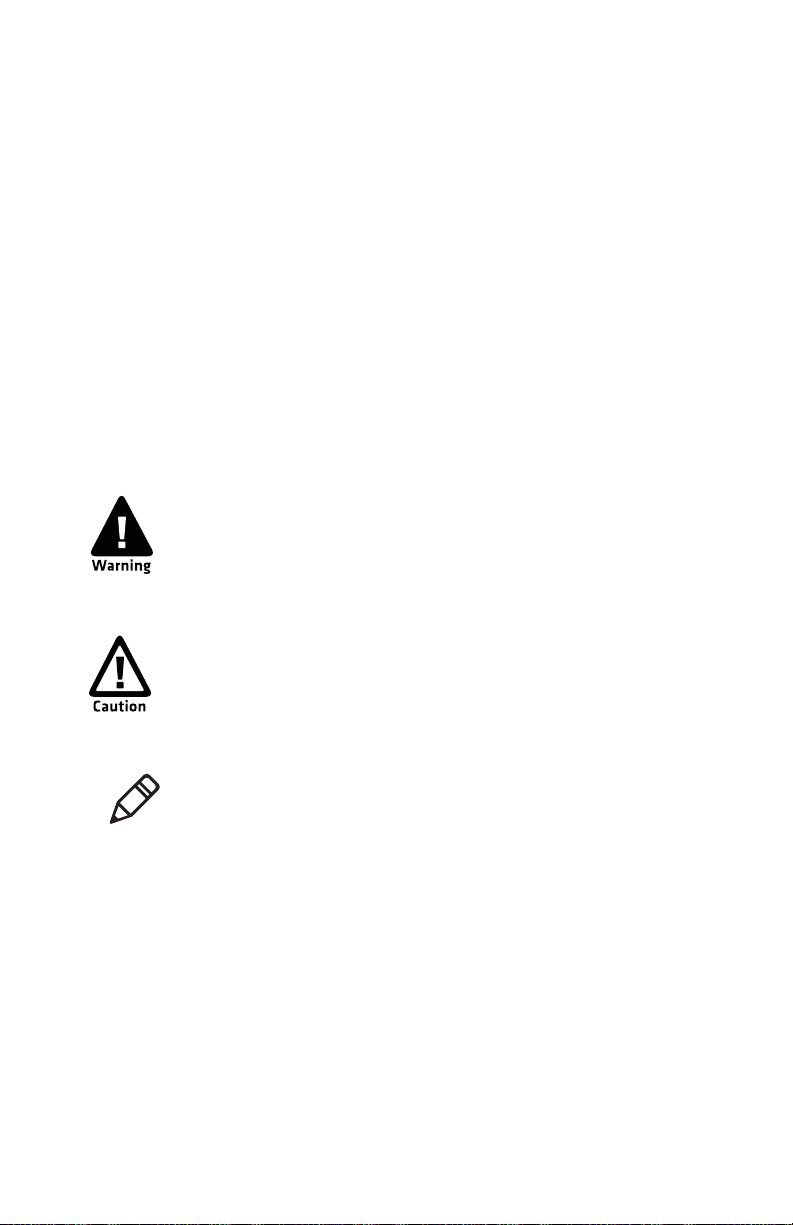

Understanding Power Supply LEDs

A single or a pair of green light-emitting diodes (LEDs), located

near the output connectors on the power supply

(P/N 851-070-003), light up whenever you apply voltage to the

output power cable. Mount the power supply in a location that

allows easy visibility to LEDs for troubleshooting.

Note: This document assumes that you have already installed

the vehicle mount printer on your forklift and that you have the

correct power supply and power supply input cable for your

forklift before you proceed with the installation.

Note: Use the hardware supplied in the kit, or equivalent, to

mount the power supply. Do not use sheet metal screws or other

less permanent or rugged mounting solutions.

Chapter 1 — Introduction

4 Forklift Power Supply Installation Guide

The main output LED indicate that the main power is

functioning (3-pin connector). The secondary power LED

indicates the heater power (2-pin connector) is functioning.

Power Supply LED

Using the Input Power Cable

The input cable from the power supply is approximately 2.74 m

(9.0 feet) long. One end has a 4-pin connector, the other has a 2-

pin connector. By cutting off the unneeded connector, a single

cable can meet either 4 or 4.5 A current requirements. The cut

end is then terminated for connection to the forklift power

source. For instructions on attaching the power cable, see

“Mounting the Power Supply” on page 11.

Note: If the secondary LED is not lit, the input power to the

DC-DC converter is less than 9 to 10 Vx. It will continue to

provide 12 V output power to the main power connector.

Output connector

(secondary power)

Green LEDs

(power output indicators)

Output connector

(main power)

Input connector

Note: Keep the cable as short as possible. Extra cable picks up

noise, adds power loss, and can snag on equipment.

The input power cable may be shortened as needed. It should

not be extended on 12 V or lower systems. On higher voltage

systems, extensions should be kept to a minimum and should

be of equivalent or lower gauge (larger diameter) wire. Keep the

cable as short as possible. Extra cable picks up noise, adds power

loss, and can snag on equipment.

Chapter 1 — Introduction

Forklift Power Supply Installation Guide 5

Using the Inline Fuse

A snap-twist inline fuse holder is furnished as part of this kit. It

must be connected as close as possible (electrically and

physically) to the forklift power source. It provides catastrophic

failure, short-circuit protection for the entire input power cable

and the power supply input. The fuse holder contains a 3AB, 20

A/250 Vx (.25 inch x 1.25 inch) fast-blow fuse recommended for

installations with 12 V automotive batteries. For other vehicle

battery voltages, please refer to the table below. These alternate

fuses are not provided with the kit and must be obtained

separately. In general, smaller fuse ratings offer faster acting

protection.

Note: If your fuse fails, diagnose the problem and then correct it

before replacing the fuse with the exact same size and type you

are replacing.

Recommended Fuse Values

Lift Voltage Fuse Ratings Description

12V 20A Fast-blow (ships with power

supply)

24V 10A Slow-blow, maximum fuse value

36V 6A Slow-blow, maximum fuse value

48V 5A Slow-blow, maximum fuse value

Do not replace the fuse with larger fuse values than

recommended. Use of a larger fuse may result in damage to

equipment.

Chapter 1 — Introduction

6 Forklift Power Supply Installation Guide

Using the Output Power Cable

Output power cables (P/N 236-193-001) are approximately 2.2 m

(7.2 feet) long and have a durable 2-pin connector to mate with

the power supply. The connector on the far end of the cable is

specific to the vehicle cradle for the printer. These rugged

connectors have heavy-duty metal housings and enhanced strain

relief to provide added reliability in the mobile environment. For

a diagram of the output cable, see the next section.

Contents of the Forklift Power Supply Kit

Installing the Printer With the Forklift Power Supply Kit

Note: Ensure that you have the correct output power cables for

the mobile printer you are installing.

Contents of Forklift Power Kit (P/N 203-880-002)

Description Part Number Quantity

Installation kit, vehicle power

supply

203-804-002 1

DC/DC converter 6-60 Vin/12

Vout (power supply)

851-070-003 1

Vehicle dock (AV8) forklift cable

(output cable)

236-193-003 1

Forklift Power Supply

Installation Guide

932-011-xxx 1

6-60 V

Fuse

Printer

and vehicle cradle

Cable input

DC/DC power supply

(“converter”)

Cable output

-

-

+

Chapter 1 — Introduction

Forklift Power Supply Installation Guide 7

Cable assembly (input cable) 226-340-004 1

Fuse holder assembly 315-075-003 1

Fuse, 20 A ceramic FB 315-074-003 1

Bolt, 3/8-16 x 1-1/2-inch 800-099-001 2

Washer, 3/8-inch 803-099-001 4

Nut, 3/8-16 802-099-001 4

Adjustable wire clamps 808-011-001 8

Self-tap screw #6 x 5/8-inch 800-008-003 8

3/8-inch terminal ring 809-165-001 2

#10 terminal ring 809-083-009 3

Self-tapping screw, 800-012-000 1

#8 flat washer 803-084-000 1

Snap-in bushing 807-065-003 1

Screw, 1/4-20 x 1-1/4 inch 801-194-002 2

Flat washer 803-100-001 2

Locking nut 802-117-000 2

Washer, split-lock 803-042-001 2

Cable tie, locking 808-002-000 6

H-S tubing, black, 1/8-inch

diameter

321-650-003 30.5 cm

H-S tubing, black, 3/8-inch

diameter

321-650-006 15.2 cm

Bead, split w/sleeve 309-065-006 1

Plug, 2-socket circular 311-638-00 1

Plug, 4-socket circular 311-638-

006 1

311-638-006 1

Cable, 4 cond 18 AWG, foil-

shielded

321-295-005 274.3 cm

Shield bead, .590/.275/1.10L,

300HM 309-091-008 2

309-091-008 2

Contents of Forklift Power Kit (P/N 203-880-002) (continued)

Description Part Number Quantity

Chapter 1 — Introduction

8 Forklift Power Supply Installation Guide

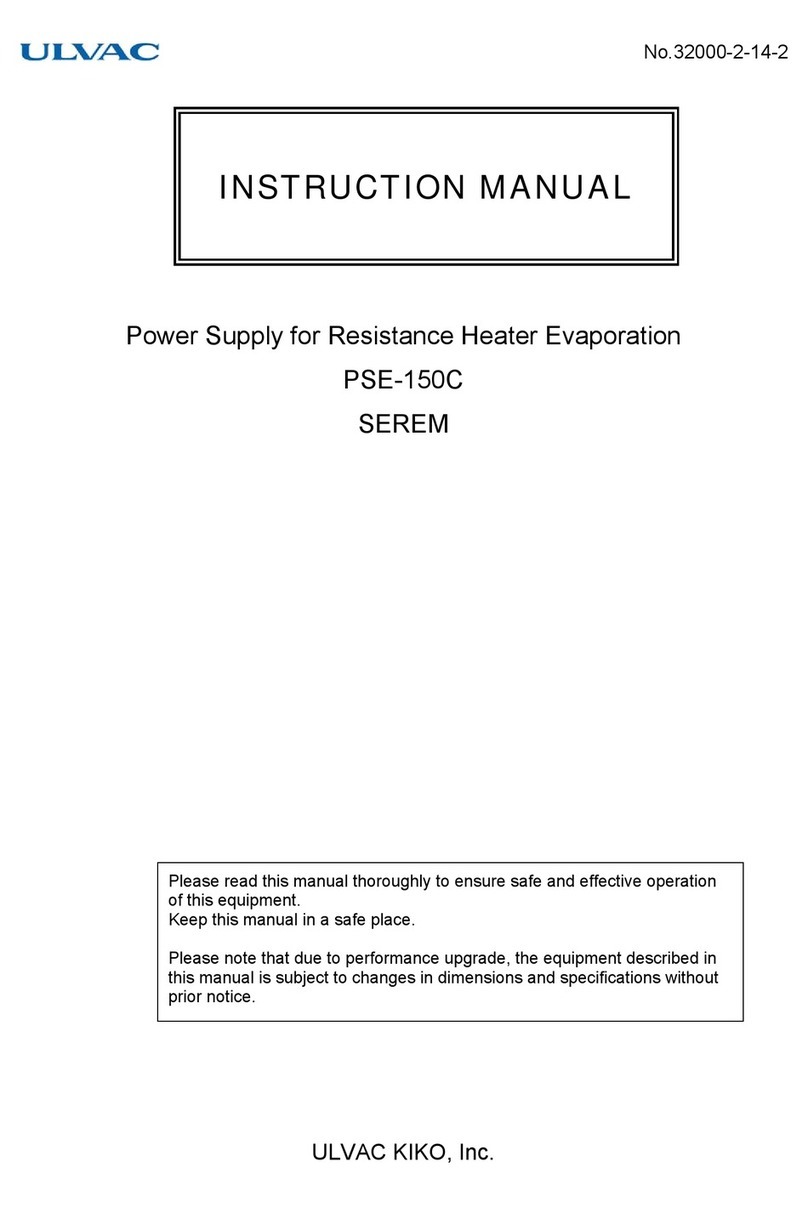

Wiring Diagram

This wiring diagram outlines several possible connections to the

power source in a forklift. Use this illustration as a reference

during the planning phase of your power supply installation.

Power Source Connection Possibilities

Distribution panels

work better than direct

connect to motors

Power-

Acceptable

Negative - Worst

Regenerative Braking System, very

large voltage spikes

Negative - Marginal

Large output spikes

possible on motors

Negative-Marginal

Connector to battery - Best + To DC/DC converter

Power-Acceptable

9

2Installing the Forklift

Power Supply

This chapter describes how to install the

forklift power supply. This chapter contains

these topics:

•Installation Recommendations

•Preparing the Power Input Cable

•Mounting the Power Supply

•Installing the Input Power Cable

•Connecting the Power Cable to the

Forklift

•Terminating the Input Cable

•Connecting to the Forklift Battery

Chapter 2 — Installing the Forklift Power Supply

10 Forklift Power Supply Installation Guide

Installation Recommendations

Review the forklifts you want to use before you start. Plan the

installation by following these safety and utility

recommendations:

•Install the power cable at the forklift power source if possible

or at the point where the connection is first made to the lift.

•Keep the power cable length as short as possible.

•Connect the negative lead to a point on the lift that other

electronic systems use.

•Read the label on the power supply and verify that the input

voltage rating is correct for the forklift in which you will be

installing the printer.

•Remember that the supply with the lower input voltage

rating (6-60 Vx) has a 4-pin input connector. Design a

bracket that would be common to multiple lifts with pre-

attached devices to simplify the device installation and

service. Designing a common bracket would reduce your

installation time because the mounting bracket would be

more straightforward and consistent. It would also simplify

service because you can take the entire bracket down and

replace it with another bracket while troubleshooting the

system away from the lift.

Installation Overview

Carry out the primary installation steps in the order outlined

below. The sections that follow include detailed steps for each

segment of the vehicle power supply installation process.

To install the vehicle power supply

1Connect the input cable to the power supply.

2Mechanically install and secure the power supply.

3Route and secure the power cable.

Equipment failure or damage will result if the vehicle power

source voltage does not fall within the power supply input

voltage rating.

Table of contents

Other Intermec Power Supply manuals

Popular Power Supply manuals by other brands

PowerBox

PowerBox T200 user manual

Sens

Sens EnerGenius DC Installation & operation manual

Fractal design

Fractal design Integra R2 user manual

Matsusada Precision

Matsusada Precision PZJ Series instruction manual

GW Instek

GW Instek GRA-441 Assembly manual

Agilent Technologies

Agilent Technologies 6641A operating guide