International Harvester Company TD-24 User manual

Other International Harvester Company Tractor manuals

International Harvester Company

International Harvester Company McCORMICK FARMALL Cub User manual

International Harvester Company

International Harvester Company INTERNATIONAL Cub Cadet 73 User manual

International Harvester Company

International Harvester Company 15D-2 User manual

International Harvester Company

International Harvester Company TD-14A User manual

International Harvester Company

International Harvester Company Farmall A User manual

International Harvester Company

International Harvester Company CUB User manual

International Harvester Company

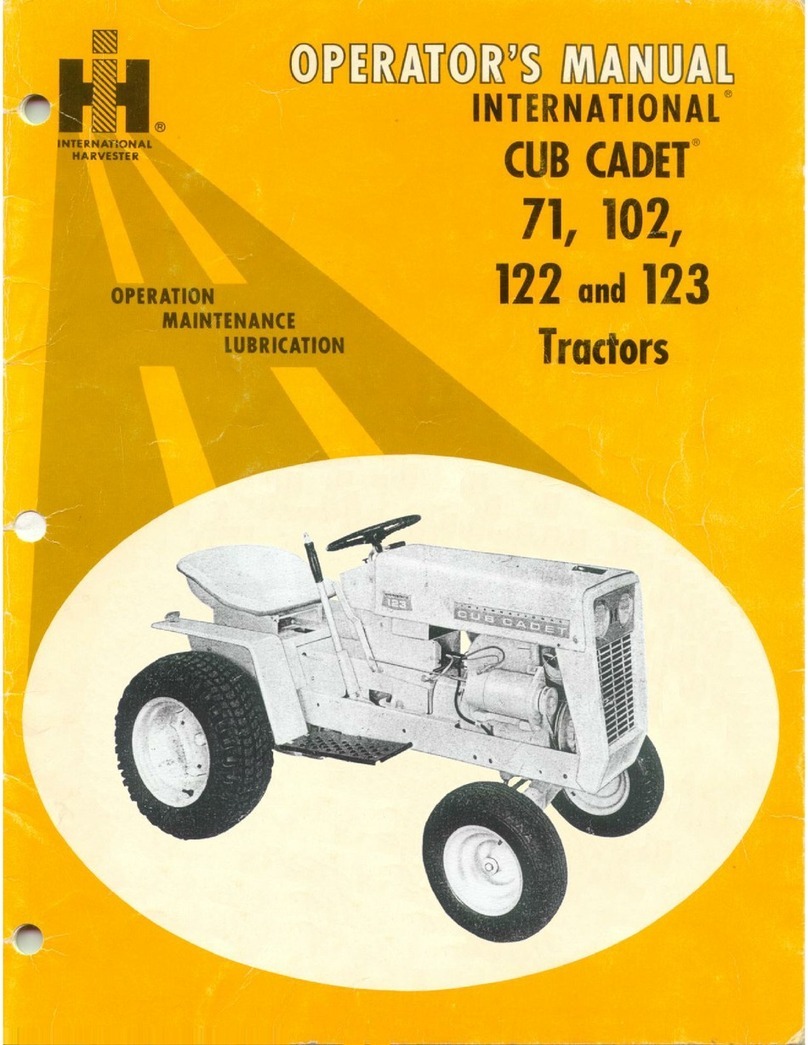

International Harvester Company International 102 User manual

International Harvester Company

International Harvester Company Cub Cadet 682 User manual

International Harvester Company

International Harvester Company McCormick Farmall Super C User manual

International Harvester Company

International Harvester Company International 102 User manual