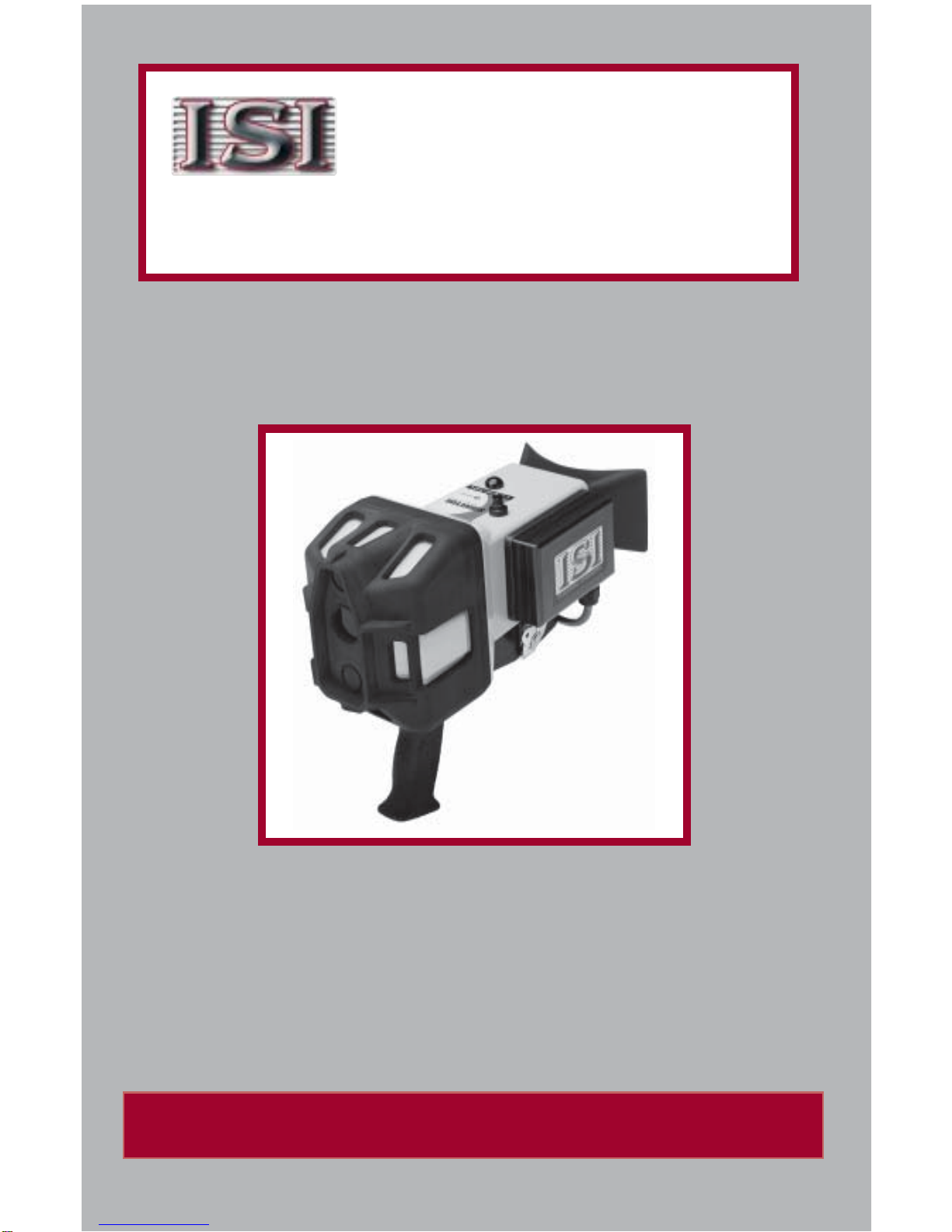

International Safety Instruments Surveyor Instructions for use

Copyright 2001 International Safety Instruments, Inc. 17

Owners Operation Manual

Thermal Imaging System

International Safety Instruments, Inc.

Copyright 2001

SURVEYOR

Copyright 2001 International Safety Instruments, Inc. 15

Owner’s Operation Manual

WARNING

Disassembly of the components beyond the procedures described

herein shall not be performed. Additional disassembly may cause

component damage and shall be performed only by authorized

personnel or ISI.

INTERNATIONAL SAFETY INSTRUMENTS, INC.

922 Hurricane Shoals Road Lawrenceville, GA 30043

770-962-2552 888-ISI-SAFE (toll free) FAX 770-963-2797

Part Number 084061 Issue A September 2001

Artwork Number A49089 Issue A September 2001

Thermal Imaging System

SURVEYOR

Copyright 2001 International Safety Instruments, Inc.

14

TABLE OF CONTENTS

Preface

Warnings and Exclusions 1

1.0 Specifications 3

2.0 System Components 4

3.0 General Operation 4

3.1 Battery Installation 4

3.2 Red Button Operation 5

3.3 Black Button Operation 5

3.3.1 Videomix

3.3.2 Reverse Polarity

3.4 Kevlar Handstrap 5

3.5 Kevlar Neckstrap 6

3.6 Battery Life Indicator 6

3.7 SensorTemperatureWarning 6

3.8 SettingTime & Date 7

3.9 SettingTemperature Scale 7

4.0 Options & Accessories 8

4.1 Pyrometer 8

4.2 Video Mix 8

4.3 Reverse Polarity 9

4.4 Pistol Grip Handle 9

4.5 Surveyor Transmitters 9

5.0 Inspection and Maintenance 10

5.1 General Inspection After Each Use 10

5.2 Periodic Inspection 11

5.3 Battery Maintenance 11

5.4 Cleaning 12

6.0 Warranty 13

Copyright 2001 International Safety Instruments, Inc. 1

PREFACE

______________________________________________________________________________________

IMPORTANT POINTS - PLEASE READ CAREFULLY

THE ISI SURVEYOR THERMAL IMAGING SYSTEM IS NOT LIFE

SUPPORT EQUIPMENT AND SHOULD NOT BE USED AS SUCH.

FAILURETO PROPERLY MAINTAIN AND OPERATETHIS PROD-

UCT COULD RESULT IN ITS’FAILURE LEADINGTO POSSIBLE

INJURY AND/OR DEATH.

INTENT

This manual is intended to acquaint owners’and users’with the operation

of the SURVEYOR Thermal Imaging System and to provide important

safety information and limitations.All information, illustrations and specifi-

cations in this manual are based on the latest product information avail-

able at the time of printing.The right is reserved to make changes at any

time without notice.

IMPORTANT

All personnel using this product shall be thoroughly familiar

with the operation, inspection and safety precautions out-

lined in this manual.

Equipment should be thoroughly checked and cleaned after

exposure to intense heat or harsh chemicals.

The ISI SURVEYOR is designed to be simple to use and easy to maintain

and will operate for many years if properly handled, maintained and

cleaned.The instructions for care and use given in this manual must be

read, understood and carefully followed before the equipment is used.

The procedures in this manual DO NOT render ISI liable for any losses or

injury arising from actions based on use of same.

Spare parts and accessories are available through your local ISI autho-

rized distributor. Service beyond the scope of this manual is not recom-

mended.If a problem arises, the equipment should be removed from

service, tagged for repair and forwarded to the factory for evaluation and/

or repair.

Copyright 2001 International Safety Instruments, Inc.

2

DESCRIPTION

The SURVEYORThermal Imaging System is designed to provide the

trained user with the ability to see in dark and smoke filled environments.

Engineered to withstand the rigors of firefighting, the SURVEYOR can be

used for search and rescue, size-up, seat of fire location, HazMat and

overhaul operations.Once integrated into the Standard Operating Proce-

dures, the SURVEYOR will become one of the most important firefighting

tools used to save lives and property.

OPERATOR INFORMATION,WARNINGS, LIMITATIONS &

TRAINING REQUIREMENTS

All operators must read, understand and be thoroughly familiar with the

operation and use of the equipment and the contents of this operators

manual prior to first use.

WARNING: Improper use or abuse of this equipment in a hazard-

ous environment or atmosphere could result in serious injury or

even death.

As with all fire service equipment, standard operating procedures must be

written, implemented and followed for the thermal imaging systems.

Priority should be given to proper egress should the equipment malfunc-

tion or fail while inside the fire scene.

All operators and potential operators should receive training in a con-

trolled fire scene simulation (i.e.training tower or live burn) before actual

use in a fire environment.Training shall include egress procedures should

the camera system fail.

Thermal Imaging Cameras and their accessories are not life support

equipment and shall not be used as such.

The service life or battery duration of this camera can be reduced by

heavy usage or extreme environmental conditions.Every fire scene and

environment is unique and therefore battery duration can not be predeter-

mined to an exact time limit.The “Low Battery Indicator” warning SHALL

be adhered to and requires IMMEDIATE egress upon implementation.

Users’should only enter a hazardous environment with a fully charged

battery.The fire environment affects the duration of the battery and

therefore exact duration time will vary from incident to incident.

Exposure to extreme high heat environments for an extended period of

time and repeated exposures to high heat environments may result in the

Copyright 2001 International Safety Instruments, Inc. 3

degradation of the thermal image and possible damage to the camera

sensor.Allow for adequate cool down when exposed to extreme high heat

before reusing the camera.The user shall adhere to the “SensorTem-

peratureWarning”section (3.7) of this manual.The thermal imaging

camera is not capable of seeing through glass, water or reflective objects.

Although IP67 waterproof, the camera cannot be used underwater.

The SURVEYOR is not rated as “intrinsically safe.” Use extreme caution

and avoid explosive atmospheres when operating this camera.

Radio transmissions and other electromagnetic radiation may cause

interference with the SURVEYOR.

WARNING:NEVER point the thermal imaging camera directly at

the sun.

1.0 SPECIFICATIONS

CONFIGURATION: HAND HELD

CASE CONSTRUCTION: ULTEM

DIMENSIONS:

Height 7.25 inches with visor

Width 6.5 inches

Length 13.0 inches

SENSOR: DIGITAL BST SOLID STATE

ARRAY SIZE: 320 x 240

WEIGHT: 6 lbs, 1 oz. with battery

POWER SOURCE: 6V Rechargeable NiMH Battery

OPERATINGTIME: up to 3 hours

FIELD OFVIEW: 59o

NETD: < 0.1oC

VIDEO OUTPUT: EIA, 525 lines, 60Hz

Copyright 2001 International Safety Instruments, Inc.

4

2.0 SYSTEM COMPONENTS

THE SURVEYOR COMES STANDARDWITH:

(1)Thermal Imaging Camera

(2) Rechargeable NiMH Batteries

(1) External Battery Charger

(1) Internal Battery Charger

(1) Kevlar® Neckstrap

(1) Carrying Case

(1) Cigarette Lighter Adapter

(1) Operation Manual

(1) External Battery Charger Manual

(1) Warranty Card

3.0 GENERAL OPERATION

3.1 BATTERY INSTALLATION

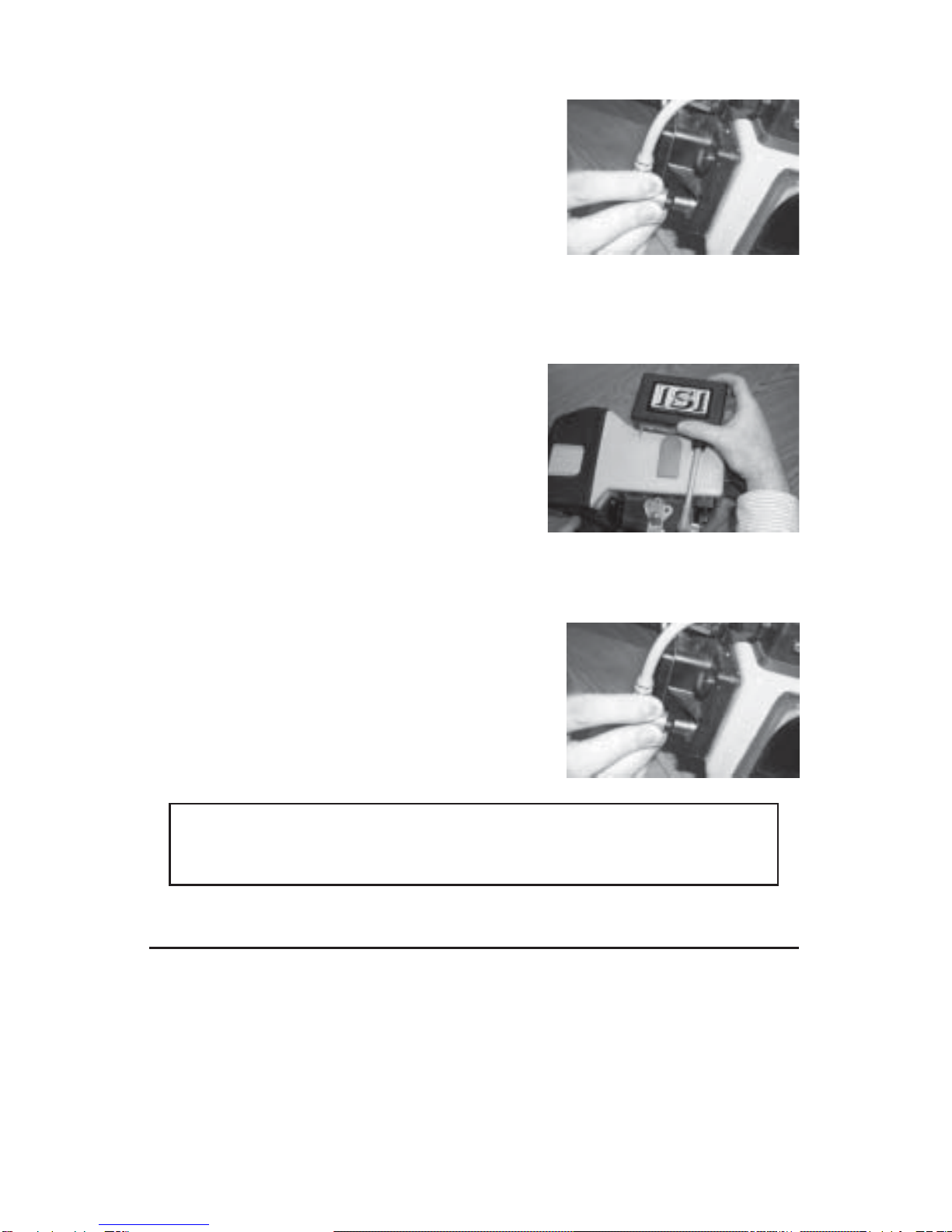

3.1.1 Place the camera upside

down with the LCD screen facing

you. Loosen the cam-lock fas-

tener by pulling up on the butterfly

shaped handle until it is perpen-

dicular to the battery compart-

ment.Turn the handle towards

you until the cam-lock hook

separates from the latch plate.

Open battery compartment lid.

3.1.2 Place the battery, contact

side down, into the compartment.

With the Duracell battery, it does

not matter which direction the

battery is placed as long as the

contact side is facing down.

3.1.3 Close the lid. Line the cam-

lock hook up with the latch plate

and turn butterfly handle away

form you until totally secure.Push

down on the butterfly handle to

lock.Be sure the butterfly handle

is facing towards the top of the

camera when in the locked

position.

Copyright 2001 International Safety Instruments, Inc. 5

WARNING: Replacement batteries must exactly match the con-

figuration and ratings of the original batteries supplied with the

Surveyor. Use of unapproved batteries may result in system

malfunction or failure which could lead to injury or death.

3.2 RED BUTTON OPERATION - ON/DELAY OFF MODE

3.2.1 To turn the camera on, push

the red button for about one

second then release.The camera

will take between 15 to 30 seconds

to warm up and provide a thermal

image. To turn the camera off,

push and hold the red button until

theimage disappears.

3.3 BLACK BUTTON OPERATIONS

3.3.1VIDEO MIX (if installed)

3.3.1.1 To initiate theVideo Mix

feature, push and hold down

the black button.To endVideo

Mix feature, release the black

button.(See section 4.2 for

explanation of this feature.)

3.3.2 REVERSE POLARITY (if in-

stalled)

3.3.2.1 To initiate the Reverse

Polarity feature, push or click

the black button.(See section

4.3 for explanation of this

feature.)

3.4 KEVLAR® HANDSTRAP

3.4.1 On the right side of the camera is a fire retardant adjust-

able handstrap by which to hold the camera.(See maintenance

section for replacement procedures.)

3.4.2 The handstrap can be used by either sliding your hand

through it and gripping the camera or, grasping the handstrap by

placing your hand over and through the top of the straps.

3.4.3 To loosen the hand strap, grip the buckle tab and push

away from your body parallel to the strap.To tighten, simply pull

on the free end of the strap to pull through the buckle.

Copyright 2001 International Safety Instruments, Inc.

6

3.5 KEVLAR® NECKSTRAP

3.5.1 Attach neckstrap to “D” ring located at the rear handstrap

connection.Neckstrap can be worn several different ways and is

up to the users discretion.

3.6 BATTERY LIFE INDICATOR

3.6.1 A battery life icon is visible on the lower left hand side of

the screen and indicates the level of battery power available.

NOTE:It is recommended to have a full battery indicated before

entering a fire scene.

3.6.2 When the battery level decreases to approximately 5

minutes of battery life left, the words “Low Battery” will flash on

the screen.Operator should immediately leave the hazardous

environment.

3.7 SENSORTEMPERATURE WARNING

3.7.1 Should the internal temperature of the camera begin to

reach it’s operating limit, the words“Critical Failure Immanent” will

appear on the screen.Operator must immediately leave the

hazardous environment when warning appears.

NOTE:Due to the numerous environmental variations between

fire scenes, there is no way to predict the amount of time before

sensor shutdown after the warning appears on screen.

Connecting External Battery Charger

Internal Battery

Compartment and

pods for setting

time, date, and

temperature

Illustration 1

12

3

Copyright 2001 International Safety Instruments, Inc. 7

3.8 SETTING DATE & TIME (see Illustration 1)

3.8.1 Place the camera upside down with the LCD screen facing

you. Loosen the cam-lock fastener by pulling up on the butterfly

shaped handle until it is perpendicular to the battery compart-

ment.Turn the handle towards you until the cam-lock hook

separates from the latch plate.Open battery compartment lid.

Remove battery if present.

3.8.2 Plug the power cord to the external charger. Remove the

dust cap from the external charging jack on the top side of the

camera (1).Line up the charger plug with the jack using the

guide.With very little force, slide the plug into jack (2). Screw the

lock ring down.Plug the external charger into an AC outlet.

3.8.3 Turn the camera on by pushing the red button.Locate the

cursor pods “A” and “B” inside the battery compartment (3).Using

a toothpick or end of a paper clip, depress and hold pod ”B” down

until the date and time appear on the screen.The hour should be

highlighted and blinking.Adjust the hour by pressing the“A” pod

until displayed hour is shown.To move to the next setting, press

pod “B” and to adjust the setting press the “A” pod.This process

will take you through minutes, seconds, month, date, century (first

two digits of the year) and the decade (last two digits of the year).

If no button is depressed for a short time, all the changes are

saved and the date and time disappear from the screen.

3.8.4 Place the battery (contact side down) into the compart-

ment.With the Duracell battery, it does not matter which direction

the battery is placed as long as the contact side is facing down

(see section 3.1).

3.8.5 Close the lid.Line the cam-lock hook up with the latch plate

and turn butterfly handle away from you until totally secure.Push

down on butterfly handle to lock. Be sure the butterfly handle is

facing towards the top of the camera when in the locked position.

3.9 SETTINGTEMPERATURE SCALE (see Illustration 1)

3.9.1 Place the camera upside down with the LCD screen facing

you. Loosen the cam-lock fastener by pulling up on the butterfly

shaped handle until it is perpendicular to the battery compart-

ment.Turn the handle towards you until the cam-lock hook

separates from the latch plate.Open battery compartment lid.

Remove battery if present.

3.8.2 Plug the power cord to the external charger. Remove the

dust cap from the external charging jack on the top side of the

camera (1).Line up the charger plug with the jack using the

Copyright 2001 International Safety Instruments, Inc.

8

guide.With very little force, slide the plug into jack (2). Screw the

plug down.Plug the external charger into an AC outlet.

3.8.3 Turn the camera on by pushing the red button.Locate the

cursor pods “A” and “B” inside the battery compartment (3).Using

a toothpick or end of a paper clip, depress and hold both the “A”

and “B” pods buttons simultaneously until the screen reads

“Select Crosshairs”.Press the “A”pod down twice.The screen

should read “SelectTemp Scale”.Press the “B” pod down to

reveal the current scale.Press the “A” pod to switch between °F

and °C.If no button is pressed for a short period of time, the

change will be saved and the “SelectTemp Scale” will disappear

from the screen.

4.0 OPTIONS & ACCESSORIES

4.1 PYROMETER

4.1.1 The pyrometer is a non-

contact temperature measurement

feature that allows firefighters to

estimate the surface temperature of

objects from a remote location.When

the pyrometer is installed, the

internal view finder will be equipped

with small crosshairs in the center of

the screen.To measure the tempera-

ture of an object, place the

crosshairs on the center of the

object. The approximate surface

temperature of the object is displayed on the bottom right corner

of the view finder, and also transmitted to a remote monitor when

used in conjunction with the internal transmitter.

The Pyrometer measures the temperature of an area one foot in

diameter to every 30 feet of distance.For example, if the object is

90 feet away, a 3 foot diameter is used to determine the tempera-

ture.If the object is 7.5 feet away, the diameter is only 3 inches.

The further away the object, the more ambient air influences the

temperature reading.The readout is in graduations of approxi-

mately 4oF or 2oC.

4.2VIDEO MIX (see Illustration 1)

4.2.1TheVideo Mix option is a combination of a thermal and

video image.The Video Mix ratio is user settable between 80%

and20%.

Copyright 2001 International Safety Instruments, Inc. 9

4.2.2To adjust its setting, place the camera upside down with the

LCD screen facing you.Loosen the cam-lock fastener by pulling

up on the butterfly shaped handle until it is perpendicular to the

battery compartment.Turn the handle toward you until the cam-

lock hook separates from the latch plate.Open battery compart-

ment lid.Remove battery if present.

4.2.3 Plug the power cord to the external charger.Remove the

dust cap from the external charging jack on the top side of the

camera (1).Line up the charger plug with the jack using the

guide.With very little force, slide the plug into jack (2). Screw the

locking ring down.Plug the external charger into an AC outlet.

Turn the camera on by pushing the red button.

4.2.4 Locate pod “D” inside the battery compartment and using a

jewelers screwdriver, adjust the mixture to your desired setting

(3).Test the setting by pushing and holding down the black

button.

4.3 REVERSE POLARITY

4.3.1The reverse polarity option changes the heat signature from

white hot to black hot.Provides greater clarity and definition to

the scene. Black-hot or white-hot is indicated on the video display.

Polarity is transmitted to the video receiver.

4.4 PISTOL GRIP HANDLE

4.4.1 To install the pistol grip handle, line up the handle with the

three threaded inserts and use the three screws to secure the

handle to the camera.Use the supplied washers on the screws.

4.4.2 To use the handle, place your hand through the wrist strap

and grip firmly.

4.5 SURVEYORTRANSMITTERS

4.5.1 CONNECTING THEVIDEO-LINK PLUS.

4.5.1.1 TheVIDEO-LINK PLUS

transmitter connects to the side

rail connector on the left side of

the Surveyor camera. You must

line up the side rail connector -

it can only go in one way.DO

NOT FORCE.

4.5.1.2 Connect the 8 inch di-pole antenna to theVIDEO-

LINKPLUSTransmitter.

Copyright 2001 International Safety Instruments, Inc.

10

4.5.1.3 Remove the cap from the 4 way wire connector on

the camera.

4.5.1.4 Connect theVIDEO-

LINK PLUSTransmitter to the

Surveyor using the 4 way wire

connection located below the

view finder, toward the back of

the Surveyor.

4.5.1.5 Turn the Surveyor ON - this automatically turns on

theVIDEO-LINK PLUS.

4.5.2 CONNECTING THE DUAL-

CHANNEL 2.4

4.5.2.1 Slide the transmitter

onto the side rail on the left

hand hide of the camera.You

must line up the side rail

connector - it can only go in

one way.DO NOT FORCE.

4.5.2.2 Remove the cap (if present) off the 4 pin connector of

the camera.

4.5.2.3 Attach theTransmitter’s

cable to the 4 pin camera

connector by lining up the slot in

the transmitter’s connector with

the rail of the camera’s connec-

tor. Be sure NOT to force the

connection.

For receiver set-up and operation, see the appropriate

wireless communication manual.

5.0 INSPECTION AND MAINTENANCE

5.1 GENERAL INSPECTION AFTER EACH USE

NOTE: The thermal imaging camera should be tested before

each use.

5.1.1 Inspect the camera, batteries and optional transmitter for

structural, heat and/or chemical damage.Cameras with signs of

damage should be taken out of service and returned to the

factory for repair.(Call ISI customer service at 888-474-7233 for a

return authorization number.)

Copyright 2001 International Safety Instruments, Inc. 11

5.1.2 Inspect side strap, wrist strap and neckstrap along with

neckstrap clip and “D” ring for damage and/or fraying.If any strap

is frayed or damaged, replace before next use.Check that all

screws are tight.

5.1.2.1 To replace side strap, using the proper torx driver,

remove the two screws and washers.Attach the new side

strap and secure in place with the washer and screw.

5.1.3 Inspect visor and front bumper for cracks, rips or wear.

Special attention should be given to the areas used for side strap

connection.

5.1.4 Inspect the battery compartment gasket for cracks and/or

misalignment.Replace before next use if cracks are present.

5.1.5 Check that warning labels are intact and legible.

5.1.6 Inspect charging port for visible damage.Ensure dust cover

is attached.

5.1.7 Inspect pyrometer window for cracks.

5.2 PERIODIC INSPECTION

5.2.1 WEEKLY INSPECTION

5.2.1.1 Inspect battery charger for proper operation and

LED indicators. (See battery charger manual for details.)

Check charger contact points for corrosion or damage.

5.2.1.2 Inspect all batteries for damage, leakage, and

corrosion, and for damage to the contacts.

5.3 BATTERY MAINTENANCE

5.3.1 INTERNAL BATTERY CHARGING

5.3.1.1 Place battery in camera (see section 3.1).

5.3.1.2 Plug the power cord to the external charger. Remove

the dust cap from the camera charging jack.Line up the

charger plug with the jack.With very little force, slide the plug

into the jack.Screw the plug down.Plug the external charger

into an AC outlet.Depending on the existing battery power

level and the age of the battery, a full charge will take be-

tween 3 to 5 hours.The LED light on the camera will be solid

red while charging and solid green while cooling down.When

the battery has been fully charged, the LED light will flash

between red and green.

Copyright 2001 International Safety Instruments, Inc.

12

5.3.2 EXTERNALBATTERYCHARGING

5.3.2.1 All new batteries must be fully charged before first

use.A normal battery will take between three to five hours to

charge. Simply place battery in the charger, check to see the

green light is on, and allow to fully charge.

NOTE:A fully or partially

charged battery will indicate

“empty” when first put into

charger.Time to register or fully

charge will depend upon the

amount of charge in battery

when first placed onto the

charger.

5.3.2.2 It is not recommended

that a battery be left in the

camera when not in use unless it

is being externally charged for

the battery will drain more rapidly

than if stored outside of the

camera.

5.3.3 BATTERY REFRESHING

5.3.3.1 To refresh the battery, simply place on the charger

and push the refresh button.The yellow light should be on to

indicate the refresh cycles.A complete refresh should take a

minimum of eight to ten hours.

5.3.2.2 Refreshing of batteries should take place about every

three to six months depending upon usage.When a notice-

able difference in time performance is apparent on fully

charged batteries, a refresh of the battery(s) is recom-

mended.

NOTE:Please read the battery charger manual included with

the camera for additional information.

5.4 CLEANING

5.4.1 CAMERA HOUSING

5.4.1.1To clean the camera housing use a medium bristle

brush or sponge and a mild non-detergent dishwashing soap.

Do not use bleach or any other compound containing chlo-

rine.

Copyright 2001 International Safety Instruments, Inc. 13

5.4.2 OPTICAL LENS & PYROMETER WINDOW

5.4.2.1 To clean the optical lens use lens paper and photog-

raphy grade lens cleaner available at your local camera store.

Do not use paper towels or any other abrasive material for

they will scratch the lens.

6.0 WARRANTY

International Safety Instruments, Inc.warrants this product to the original

owner to be free of defects in material and workmanship for one year

from the date of purchase. ISI’s obligation under this warranty is limited to

the replacement or repair, at ISI’s option, of any proven defective part if

returned to ISI in Lawrenceville, GA, or an authorized distributor.Shipping

charges shall be prepaid by the owner.Upon inspection, ISI will repair all

products that prove to have been defective from normal use and service.

This warranty does not apply to equipment malfunction or damage

resulting from accident, alteration, misuse, or abuse of the equipment

including, but not limited to, power surges, over exposure to heat, defec-

tive power supply, abnormal wear and tear or other perils outside the

design tolerances of the system.In addition, this warranty does not apply

to elastomer or rubber components since they can be adversely affected

by undue exposure to heat, sun, water, ozone, or other deteriorative

elements.The decision as to what constitutes normal use shall be made

solely by ISI.

To maintain this warranty, the purchaser must perform maintenance and

inspections as prescribed in the operation and maintenance manual

which shall include prompt replacement or repair of defective parts.

This warranty is expressed in lieu of all other warranties, expressed or

implied, and all other obligations and liabilities on ISI’s part.ISI neither

assumes nor authorizes any other firm or person to assume on ISI’s

behalf any liability in any way connected to the sale of ISI Products.

Batteries, battery charger, and cables are covered by separate

manufacturer’s warranties and are not covered by this ISI warranty.

Copyright 2001 International Safety Instruments, Inc.

16

ATTENTION

ByorderoftheUnitedStatesDepartmentofCommerce

BureauofExportControl,thisThermalImagingCamera

maynotbeshippedorhand carried outside theborders

ofthe owner’shomecountrywithoutfirstobtainingthe

properexportlicensefromtheirrespectivegovernment

departmentortheUnitedStatesDepartmentofCom-

merce. Violation ofthiswarning may resultinfine or

imprisonmentaccordingtotheUnitedStatesExport

AdministrationRegulations,15CFR,Parts730-774.

INTERNATIONAL SAFETY INSTRUMENTS, INC.

922 Hurricane Shoals Road Lawrenceville, GA 30043

770-962-2552 888-ISI-SAFE (toll free) FAX 770-963-2797

Thermal Imaging System

SURVEYOR

Table of contents

Other International Safety Instruments Thermal Camera manuals