InterPuls Combifast Instruction Manual

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 2

MANUFACTURER

InterPuls S.p.A

ADDRESS

Via: F. Maritano, 11

Postal code 42020 - Albinea (RE) - ITALY

Tel.: +39 0522 347511

Telefax: +39 0522 348516

Website: www.milkrite-interpuls.com

E-mail: [email protected]

TYPE OF DOCUMENT

Instruction, Use and Maintenance Manual

DOCUMENT CODE

1420066_EN

EDITION

02.17

PRODUCT

Combifast®

YEAR OF MANUFACTURE

2017

InterPuls is a registered trade mark of InterPuls SpA.

The information contained in this document is not binding and can be modified without notice. References in

this document to manufacturer trademarks are for identification only. Certain company and product names

used throughout the document are trademarks of their respective owners.

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 3

Summary

Combifast®........................................................................................................................................................ 1

1GENERAL INFORMATION .................................................................................................................... 4

1.1 General information and safety warnings...................................................................................... 4

1.1.1 Important warnings .................................................................................................................... 4

1.1.2 Symbol used in this manual....................................................................................................... 4

1.1.3 Rules and regulations for the user............................................................................................. 4

1.1.4 Limitation of liability.................................................................................................................... 4

1.2 Prior using the product................................................................................................................... 4

1.2.1 Requirements and rules for personnel and Safety Rules.......................................................... 4

1.3 Disposal......................................................................................................................................... 5

1.3.1 General regulation ..................................................................................................................... 5

1.4 Fire prevention............................................................................................................................... 5

1.4.1 Fire prevention........................................................................................................................... 5

1.4.2 Safety regulations...................................................................................................................... 5

1.4.3 Characteristic of extinguishers................................................................................................... 5

2DESCRIPTION OF THE DEVICE........................................................................................................... 6

2.1 General characteristics.................................................................................................................. 6

3TECHNICAL FEATURES ....................................................................................................................... 7

4FORESEEN AND UNFORESEEN USE................................................................................................. 7

4.1 Foreseen use................................................................................................................................. 7

4.2 Unforeseen use.............................................................................................................................. 7

5INSTALLATION ...................................................................................................................................... 8

5.1 Operations for milking.................................................................................................................. 10

6COMBIFAST WITH PORTABLE .......................................................................................................... 11

6.1 Combifast with Portable iMilk401 and Portable iMilk401 Lite...................................................... 11

6.1.1 Connection without data download.......................................................................................... 11

6.1.2 Connection with data download............................................................................................... 12

6.2 Combifast with Portable Acr Smart.............................................................................................. 13

7MAINTENANCE.................................................................................................................................... 14

7.1 Daily maintenance ....................................................................................................................... 14

7.2 Periodical maintenance ............................................................................................................... 14

8TROUBLE SHOOTING......................................................................................................................... 15

9SPARE PARTS DIAGRAM................................................................................................................... 16

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 4

1 GENERAL INFORMATION

1.1 General information and safety warnings

1.1.1 Important warnings

To safeguard the operator and prevent any damage to the equipment, before carrying out any kind of

operation it is important to have read and fully understood the instruction manual.

1.1.2 Symbol used in this manual

The following symbols are used in this manual to highlight indications and warnings which are of particular

importance:

WARNING

This symbol indicates health and safety regulations designed to protect operators and/or any

exposed persons.

CAUTION

This symbol indicates that there is a risk of causing damage to the equipment and/or its

components.

NOTE

This symbol is used to highlight useful information.

1.1.3 Rules and regulations for the user

WARNING

Any failure to observe the warnings provided in this manual may lead to equipment

malfunctions or damage to the system.

1.1.4 Limitation of liability

InterPuls S.p.A. declines all liability for damage to persons, animals and/or things caused by incorrect use of

the equipment.

1.2 Prior using the product

1.2.1 Requirements and rules for personnel and Safety Rules

WARNING

Before using the device, the operator must carefully read the manual.

The person using the device must be of legal age and be trained and physically and mentally

fit. He or she must also have been provided with adequate information on how to operate the

device.

During the assembly and activation of the device, follow the instructions in the manual and

rules and regulations applying to health and safety at the workplace.

As the Portable ACR-SMART is an operator hand-held device, the operator must wear non-

slip safety shoes during use to prevent damage from accidental falls of the device

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 5

1.3 Disposal

1.3.1 General regulation

The appliances must be disposed of only and exclusively by specially authorized waste disposal companies

in accordance with all relative legislation and prescriptions.

The packaging must be consigned to the relative authorized companies to be recycled.

1.4 Fire prevention

1.4.1 Fire prevention

NOTE

The device is not equipped with fire extinguishers.

The operator must make sure that the place in which the appliance is installed is equipped

with an adequate number of suitable fire extinguishers. The extinguishers must be positioned

where they are clearly visible and protected from damage and improper use.

1.4.2 Safety regulations

WARNING

It is strictly prohibited to extinguish fires involving electrical equipment with water!

1.4.3 Characteristic of extinguishers

Use powder, foam or halogen extinguishers which must be positioned next to the device.

Operating personnel must receive adequate instruction on how to use the extinguishers.

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 6

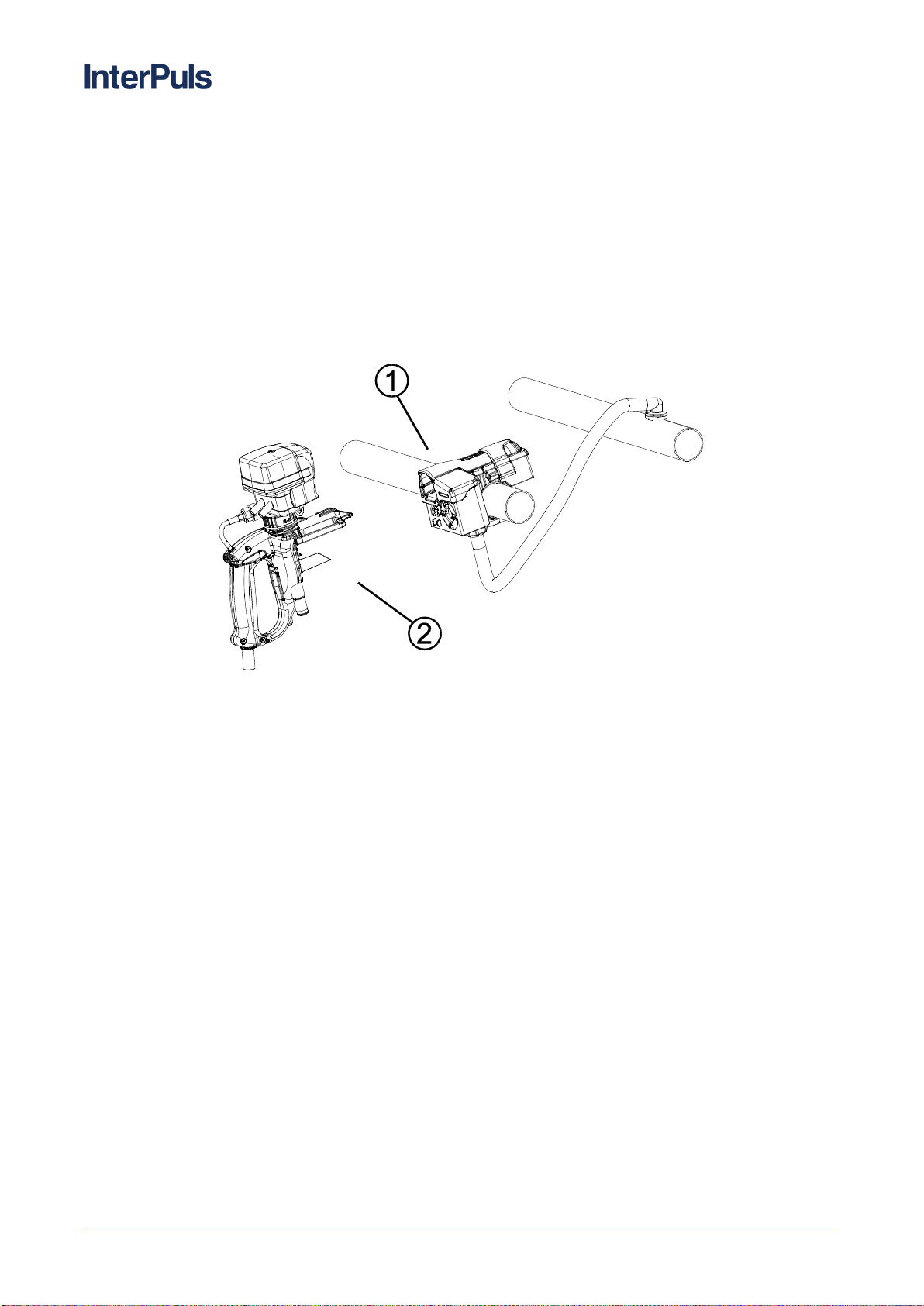

2 DESCRIPTION OF THE DEVICE

2.1 General characteristics

CombiFast®is a connecting system designed to simultaneously connect milk, vacuum, electrical power

supply and data transfer lines.

It is made of light, shock absorbent thermoplastic and features a practical handle which makes it easy to

transport and use.

Combifast®consists of a fixed part (rif. 1), assembled on the milk line, and a mobile one (rif. 2).

Combifast is available in different versions:

With milk and vacuum connectors.

With milk, vacuum and electrical power supply connectors.

With milk, vacuum, electrical power supply and data transfer connectors.

Suitable for use with air pulsator.

Suitable for use with electronic pulsator.

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 7

3 TECHNICAL FEATURES

Technical specifications

MOVABLE component

Milk Line (IDxOD)

16x18 mm (0.63x0.7 in)

Vacuum Line (IDxOD)

14x19 mm (0.55x0.74 in)

Dimensions (LxWxH)

240x240x89 mm (9.44x9.44x3.5 in)

Weight

0.146 Kg (0.32 lb)

FIXED component

Milk Line

OD 40 –50,8 –52 –63

Diameter stainless steel milk tube

opening

22 mm (0.86 in)

Diameter vacuum tube opening

22 mm (0.86 in)

Vacuum Connector (IDxOD)

14x19 mm (0.55x0.74 in)

Dimensions (LxWxH)

173 x 148 x 102 mm (6.81x5.82x4.01 in)

Weight

0.506 kg (1.11 lb)

Operation specifications

Operating vacuum

between 36 and 60kPa (typically 50kPa)

between 10.63 and 17.71 “Hg (typically 14.76 “Hg)

Operating temperatures

(environment)

-5ºC ÷ +40ºC (23°F ÷ 104°F)

Transport/storage temperatures

-20ºC ÷ +50ºC (-4°F ÷ 122°F)

Temperature of the washing

mixture

Min 60°C - Max 90°C (Min 140°F –Max 194°F)

4 FORESEEN AND UNFORESEEN USE

4.1 Foreseen use

CombiFast®is a connecting system designed to simultaneously connect milk, vacuum, electrical power

supply and data transfer lines.

Suitable for any round-the-shed milking system, CombiFast®can be used in conjunction with Portable

iMilk401, iMilk401 Lite and Acr Smart. They allow pulsation control, measurement of milk extracted (only with

Portable iMilk401 and iMilk401 Lite) and automatic cluster removal

NOTE

For further information see chapter 6 - COMBIFAST WITH PORTABLE.

4.2 Unforeseen use

The machinery, as outlined in this manual, must not be used for purposes other than those foreseen and

indicated in the 4.1 - Foreseen Use section.

WARNING

Any use other than the one covered in this manual is considered improper use and is

therefore forbidden. InterPuls S.p.A. declines any liability associated with any use of the

device other than the one covered in this manual.

WARNING

Application of loads is forbidden.

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 8

5 INSTALLATION

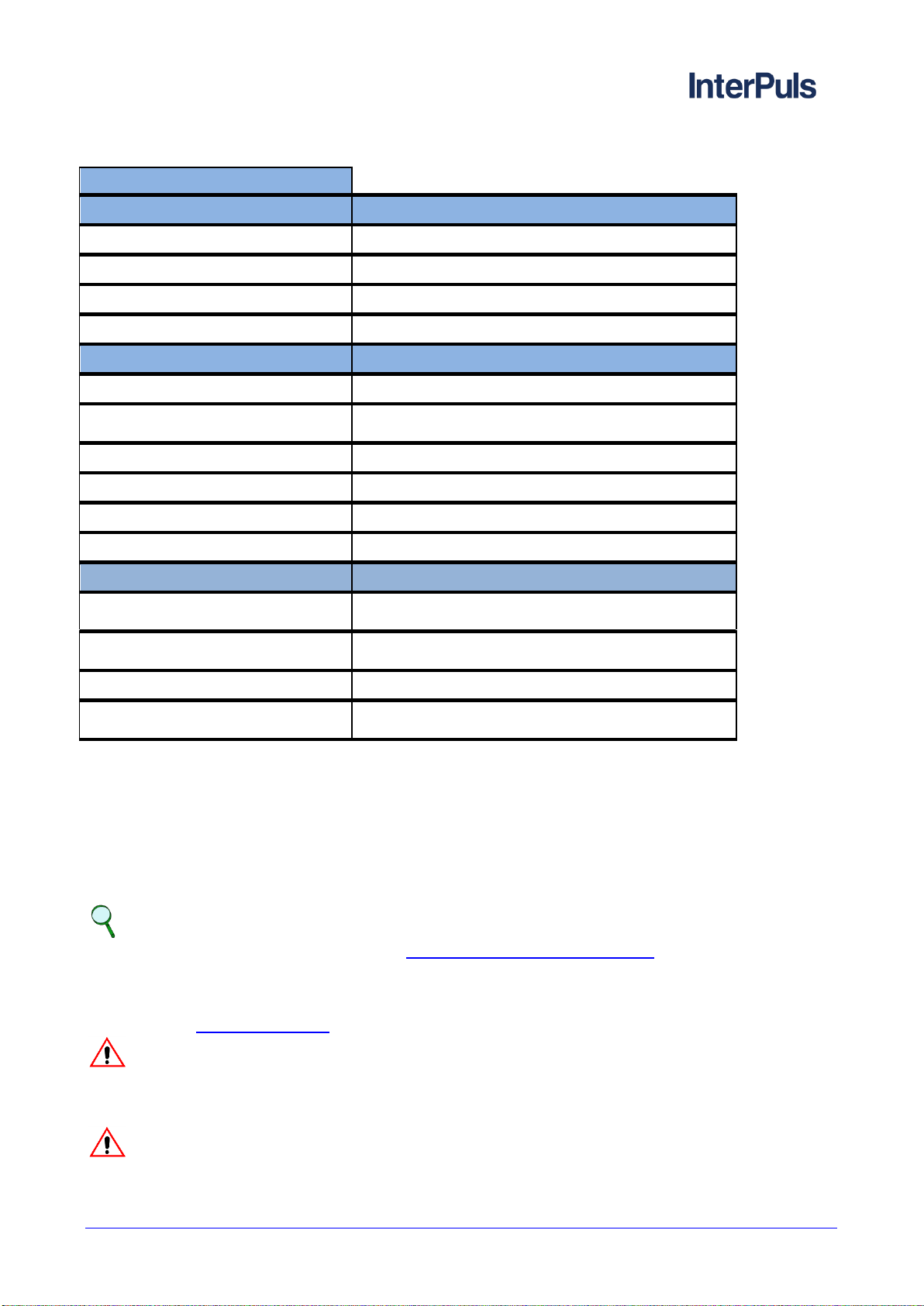

Step

Description

1

Foresee the installation of one fixed component for

every 2 animals.

Pierce the milk (ref. 3) and vacuum (ref. 4) lines

with a 22 mm (0.86 in) diameter drill bit.

CAUTION

Carefully sand the holes to avoid damaging the

gaskets.

Fig. 1 –Piercing and installation of lines

NOTE

Foresee one movable component

for every 5 fixed components.

Fig. 2 –Layout example

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 9

Step

Description

2

Install the fixed component on the milk line by

twisting the pair of screws (ref. 5) to the end;

carefully tighten the nut (ref. 6) located on the lower

half-shell to fully fasten.

CAUTION

To not over tighten the nut (ref. 6).

For optimal fastening, fully twist the nut once

after contact with the milk tube.

NOTE

In order to facilitate the installation, it is

suggested that the movable component be put

at an angle of 10 ~ 15° to the horizontal surface.

Fig. 3 –Suggested angle for fixed

components

3

Install the gasket (ref. 7) onto the vacuum line (ref. 4) and therefore, subsequently, the vacuum

withdrawal nipple (ref. 8) at a 90° angle.

4

Connect the fixed component to the vacuum nipple

(ref. 8) with the piece of tube (ref. 9). The length of

this piece must be adapted, in order to avoid harsh

curves or the partial twisting of the tube on itself.

Connect the claw’s milk tube to the Combifast’s

movable component ID 14 milk tube using a

suitable piece of milk tube (2.5m –8.2 ft

suggested).

Connect the pulsator to the claw with an equivalent

pulsator tube.

WARNING

The tube (ref. 9) must be positioned at a

distance from the animals.

Fig. 4 –Connection of fixed component to

the vacuum nipple

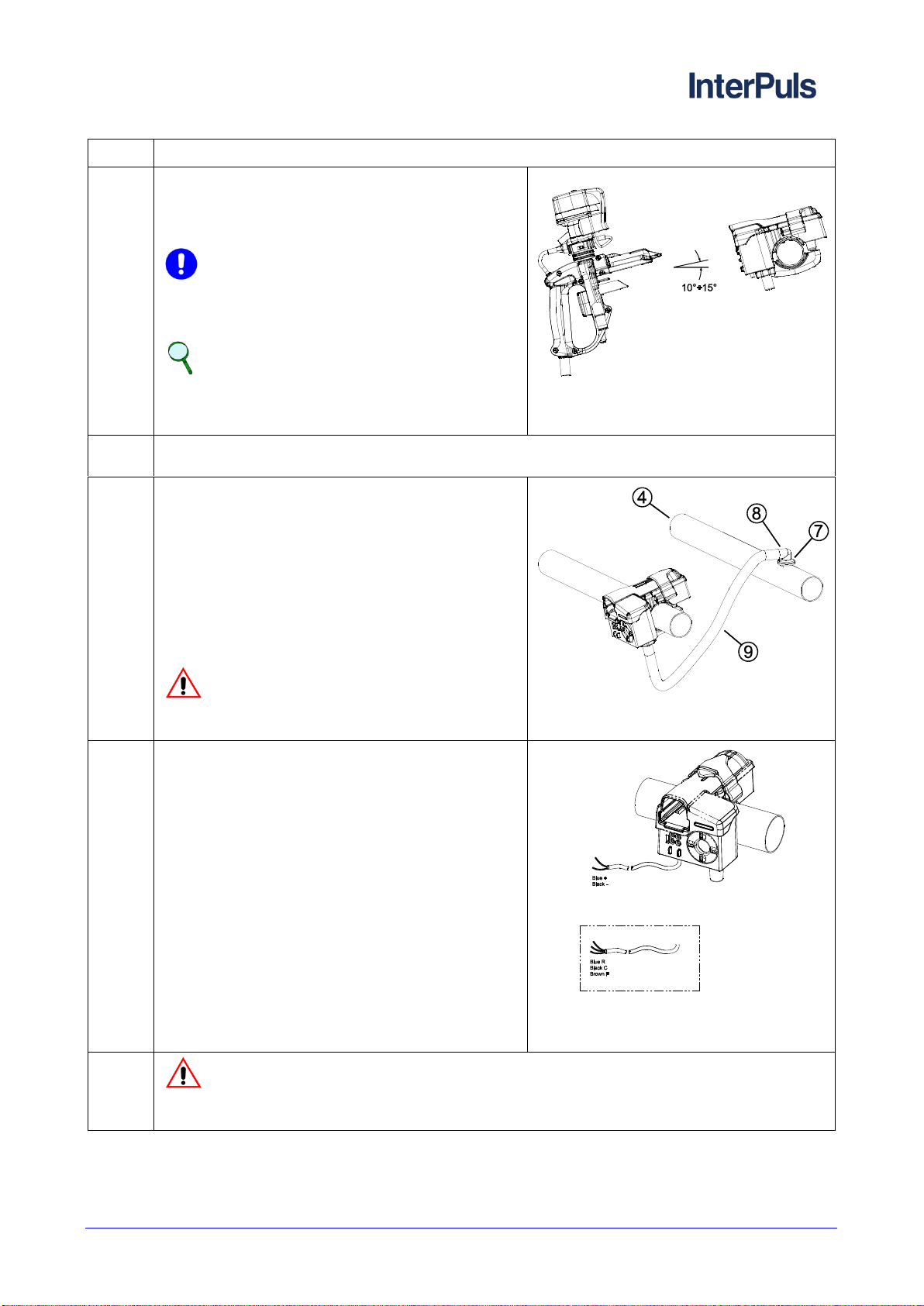

5

For systems which foresee milking with LP20 /

LP30 electronic pulsators, the fixed component’s

power supply must be connected to the IT

transformer.

Fig. 5 –Connection of pulsator’s power

supply / data transfer lines to the IT

junction box

6

WARNING

For the electrical version, verify that the connection of the cable to the main line is

perfectly isolated from the surrounding environment.

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 10

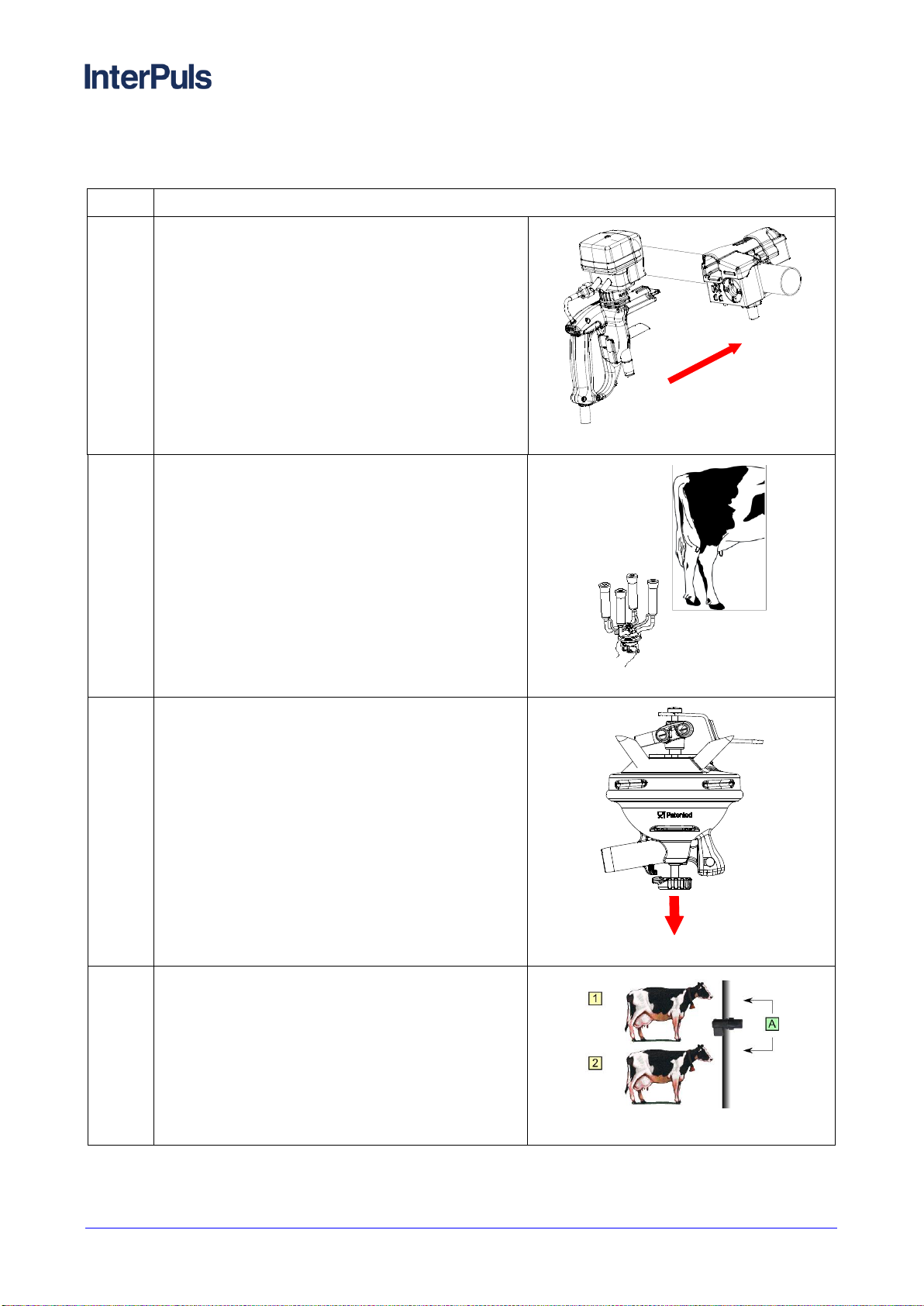

5.1 Operations for milking

Milking with Combifast is carried out as follows:

Step

Description

1

Insert the movable component in the fixed

component angled horizontally to facilitate insertion.

Fig. 1 –Insertion movable component

2

Attach the milking cluster to the animal (1) and

begin milking.

Fig. 2 –Application of milking cluster

3

Upon termination of milking, close the milking claw

valve and remove the cluster from the animal (1).

Fig. 3 –Valve closure

4

Open the claw valve and attach the cluster to the

next animal (2).

Milk the animal (2).

Upon termination of milking, close the milking claw

valve and remove the cluster from the animal.

Fig. 4 –Milking 1 and 2

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 11

Step

Description

5

Remove the movable component

from the first fixed component (A)

and insert it into the subsequent fixed

component (B).

Continue with the milking of animals

3 and 4.

Fig. 5 –Milking 3 and 4

6 COMBIFAST WITH PORTABLE

As shown in the following diagrams, CombiFast®can be connected to Portable iMilk401, oMilk401 Lite and

Acr Smart.

NOTE

For further details of use relating to Portable iMilk401, iMilk401 Lite and Acr Smart refer to the

relevant manuals.

6.1 Combifast with Portable iMilk401 and Portable iMilk401 Lite

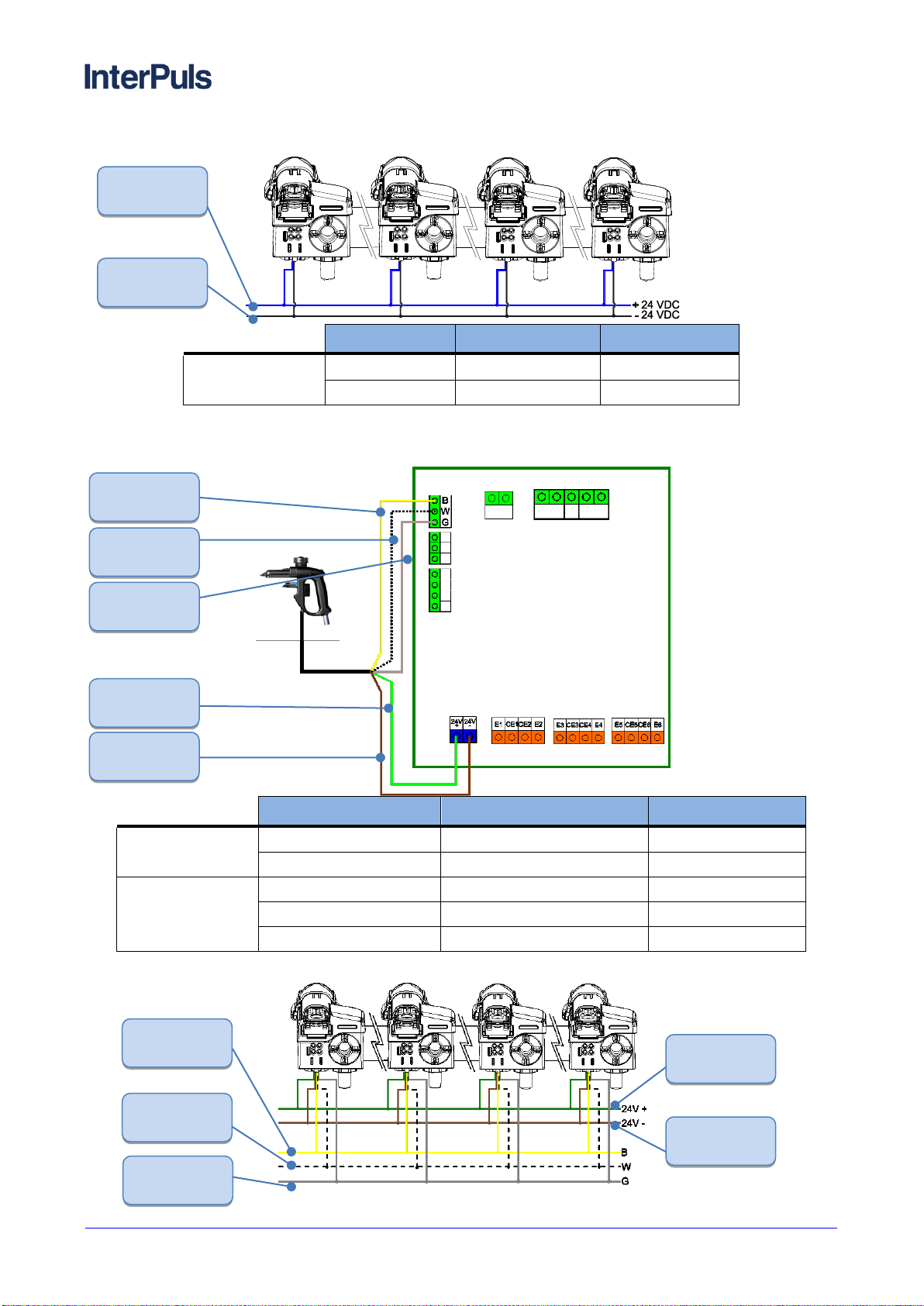

6.1.1 Connection without data download

6.1.1.1 Movable part

Terminal

Description

Cable Colour

POWER SUPPLY

SUPP.

24V +

BLUE

SUPP.

24V -

BLACK

BLUE

BLACK

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 12

6.1.1.2 Fixed Part

Terminal

Description

Cable Colour

POWER SUPPLY

SUPP.

24V +

BLUE

SUPP.

24V -

BLACK

6.1.2 Connection with data download

6.1.2.1 Movable Part

Terminal

Description

Cable Color

POWER SUPPLY

+24VDC

24VDC POWER SUPPLY

GREEN

-24VDC

CAN BUS

BROWN

CAN BUS

B

DATA DOWNLOAD

YELLOW

W

DATA DOWNLOAD

WHITE

G

DATA DOWNLOAD

SCREEN

6.1.2.2 Fixed Part

BLUE

BLACK

BROWN

WHITE

YELLOW

GREEN

SCREEN

GREEN

YELLOW

BROWN

WHITE

SCREEN

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 13

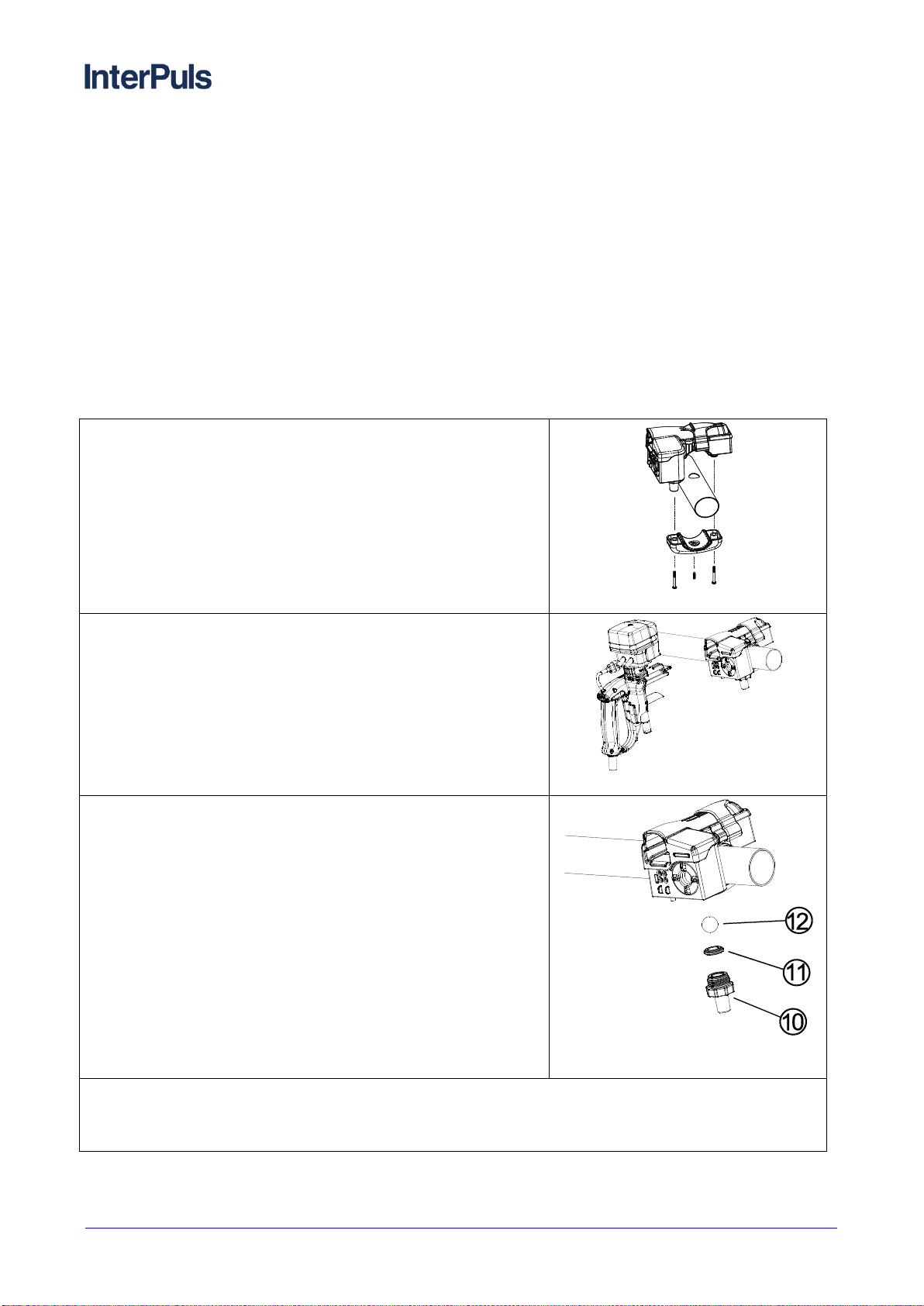

Terminal

Description

Cable Colour

POWER SUPPLY

+24VDC

SUPP.

GREEN

-24VDC

SUPP.

BROWN

SUPPLY

B

DATA DOWNLOAD

YELLOW

W

DATA DOWNLOAD

WHITE

G

DATA DOWNLOAD

SCREEN

6.2 Combifast with Portable Acr Smart

CN2 Terminal

Description

Cable Colour

POWER SUPPLY

1

24VDC (+)

BLUE

2

24VDC (-)

BLACK

GLOBE

3

GLOBE

BLUE

4

BLACK

CN1 Terminal

Description

Cable Colour

LE30

PULSATOR

9

Rear Pulsations

BLUE

10

Common

BLACK

11

Front Pulsations

BROWN

LE30

CONTROL

VALVE

12

Shut-off Valve

BLUE

13

CV20 Common

BLACK

14

DVC 1000

BROWN

SENSOR

15

HFS SENSOR

BLUE

16

BLACK

BLUE

BLACK

BROWN

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

BLACK

BLACK

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 14

7 MAINTENANCE

7.1 Daily maintenance

The product must be washed after every milking session:

Fixed component:

The areas of milk flow within the fixed component are automatically washed after every milking

session, when the system’s washing program is activated.

Movable component:

Every movable component is placed in the washing room on special fixed ledges dedicated to the

washing and stocking of the product until the following milking session.

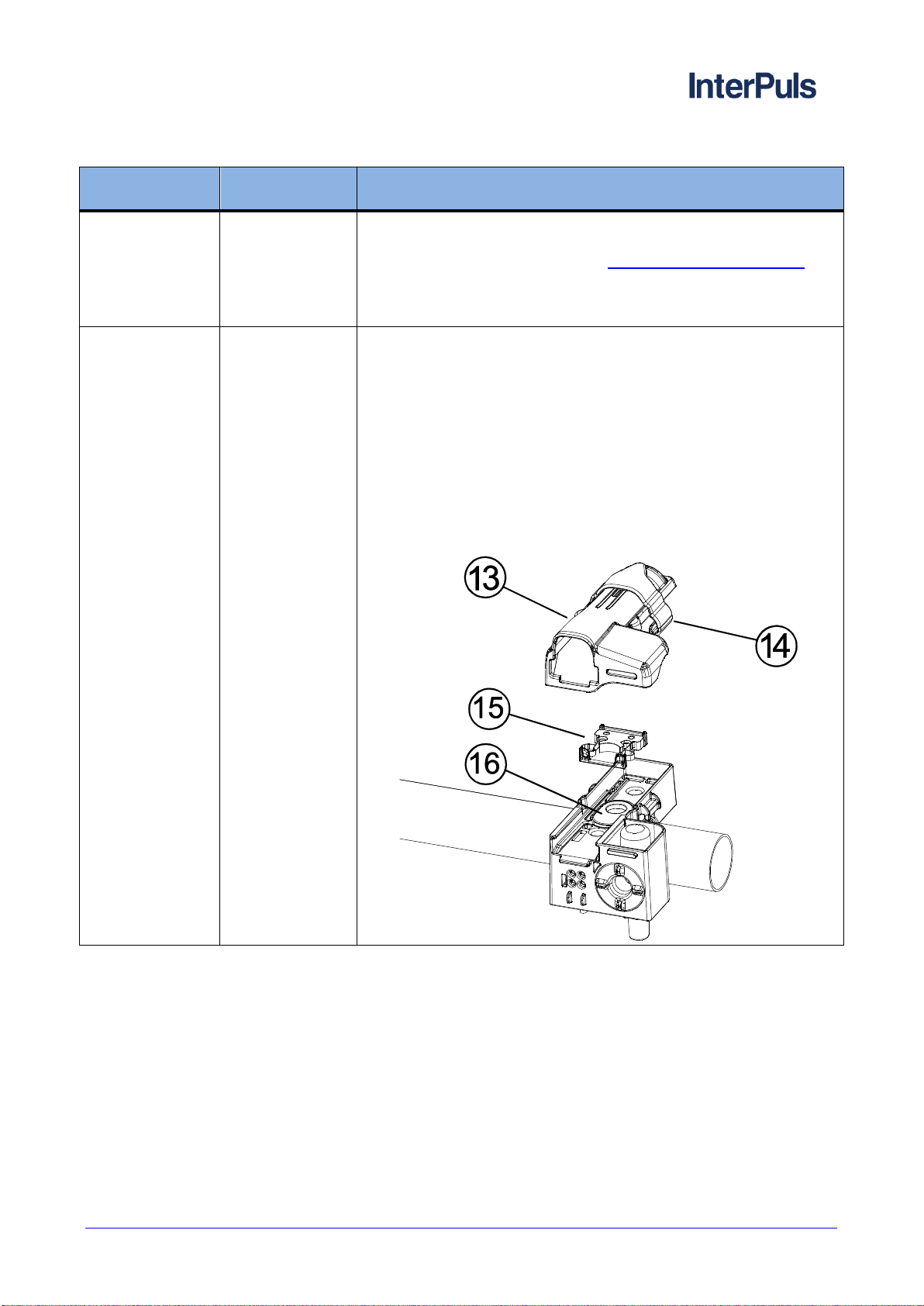

7.2 Periodical maintenance

Combifast requires the following maintenance interventions on an annual basis:

Check the tightness of nut and screws:

- Check that the fastening nut and screws are correctly tightened.

Fig. 1 –Tightening of screws

External cleaning:

- Insert the movable component in the fixed component.

- Clean using a stream of room temperature water.

- Upon completion of the washing program, remove the

movable component from the fixed component.

Fig. 2 –External cleaning

Periodic cleaning of compartment containing the vacuum

float ball:

- Disconnect the vacuum line from the straight nipple (ref. 10).

- Unscrew the straight nipple (ref. 10) avoiding that the black

gasket (ref. 11) and vacuum float ball (ref. 12) fall.

- Clean the compartment containing the vacuum float ball and the

edge of the gasket, where the ball sits, with warm water and a

neutral detergent.

- Carefully dry the components and insert the gasket (ref. 11)

onto the apposite part of the straight nipple (ref. 10), until

connected.

- Rest the ball (ref. 12) on the nipple complete with gasket.

- Tighten all components.

- Reconnect the vacuum line.

Fig. 3 –Cleaning of compartment

containing vacuum float ball

Check the tightness of the nipple (ref. 10):

Ensure the nipple (ref. 10) is screwed in.

This verification is vital to avoid the breaking of the movable component’s nipple.

Combifast® - Instruction Manual, Operation and

Maintenance original instructions

1420066_02.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 15

8 TROUBLE SHOOTING

PROBLEM

DETECTED

POSSIBLE

CAUSE

SOLUTION

Problems

interesting the

movable

component

Incorrect

positioning of the

ball (ref 12, see

figure previous

page) ) in the

fixed component

Position the ball as indicated in the 7.2 - Periodical maintenance

section of this manual.

Problems

interesting /

removing of fixed

/ movable

component

Poor lubrication

upper surface of

milk gasket

Lubricate the sliding surface of the fixed component ‘s rectangular

drawer with vaseline oil or silicone spray as detailed below:

Dismantle the hood (ref. 13) by sliding the attached slider

(ref. 14).

Extract the rectangular drawer complete with steel spring

(ref 15).

Lubricate the upper surface (ref. 16) of the milk gasket in

contact with the drawer with a small quantity of vaseline oil

or silicone spray.

Reposition the drawer (ref. 15).

Reposition the hood (ref. 13) blocking it with the slider (ref.

14).

1420066_02.17_EN

Combifast® - Instruction Manual, Operation and Maintenance

original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 16

9 SPARE PARTS DIAGRAM

Table of contents

Other InterPuls Farm Equipment manuals

Popular Farm Equipment manuals by other brands

MacDon

MacDon FlexDraper FD2 Series installation instructions

Alamo

Alamo Bush Hog AGR Series Operator's manual

LMC

LMC RXT Series Operator's manual

Finn

Finn HydroSeeder T75 Operator Instructions And Parts Manual

Sulky

Sulky Tramline CE 300 Original instructions

Cumberland

Cumberland PNEG-240 Installation and operation manual