215505 iii Revision A

Introduction ................................................................................................................................................i

Chapter 1: Safety ........................................................................................................................................ 1

1.1 Signal Words .........................................................................................................................................1

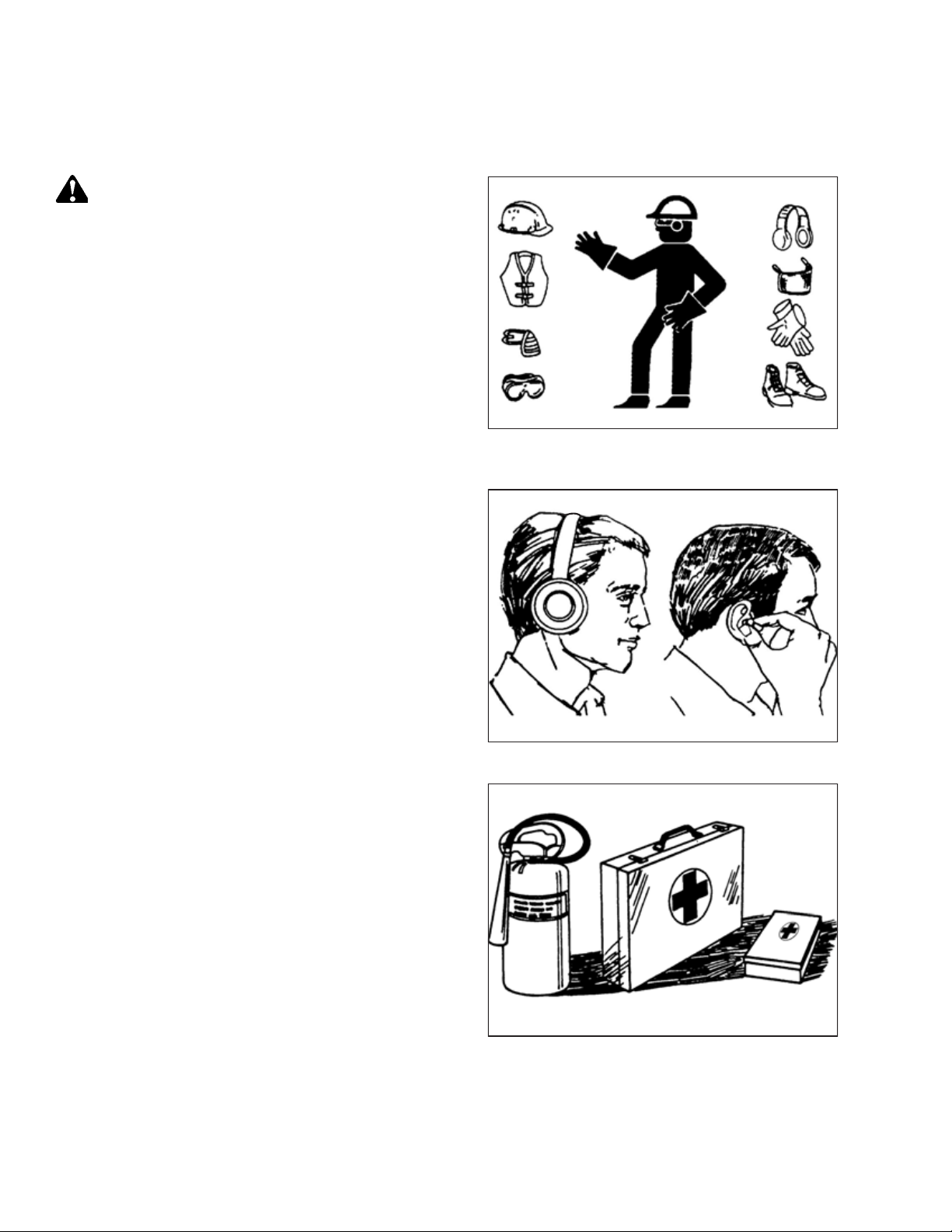

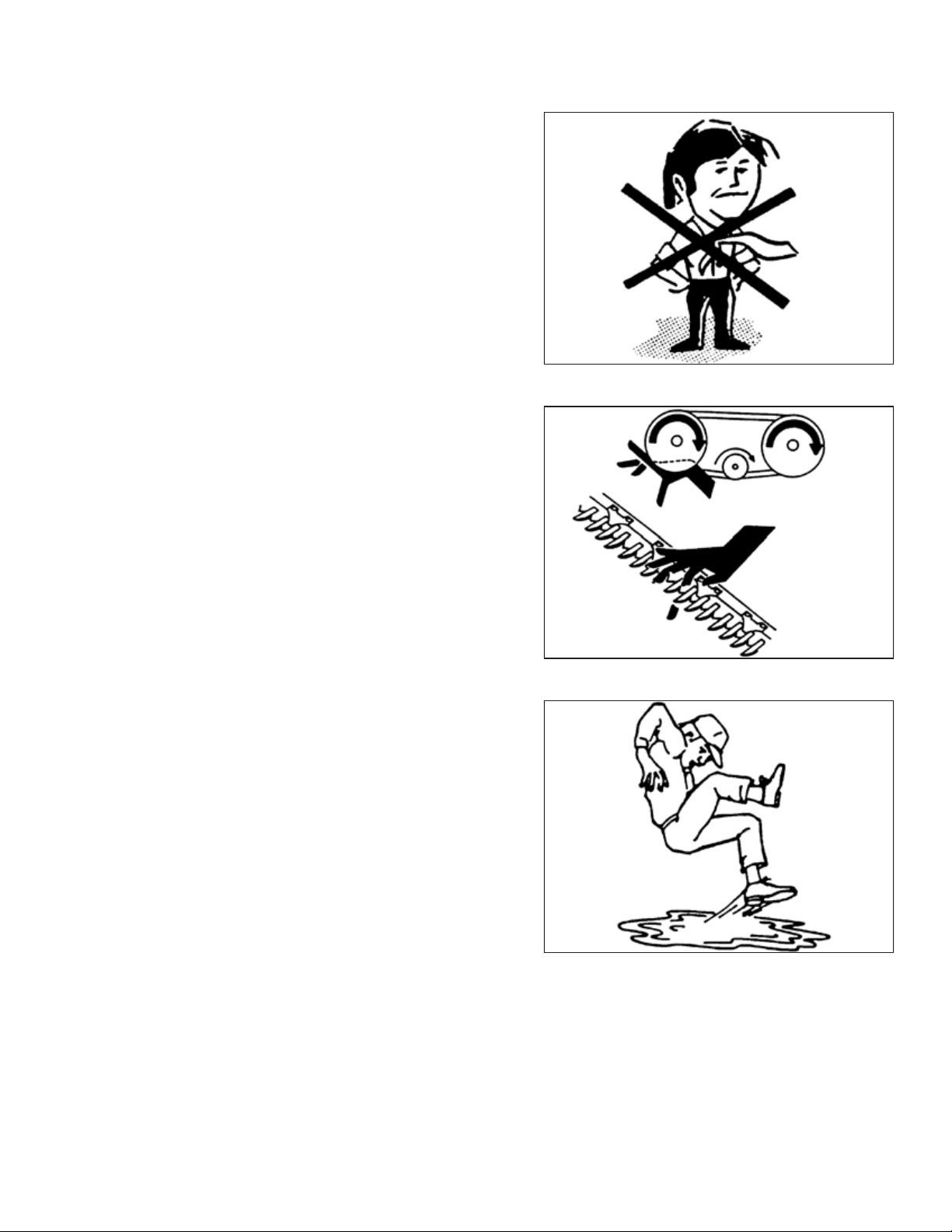

1.2 General Safety .......................................................................................................................................2

Chapter 2: Parts List.................................................................................................................................... 5

2.1 Steel Finger Kit MD #311054 (FD230, Double Reel, Five Bats) .........................................................................5

2.2 Steel Finger Kit MD #311055 (FD230, Double Reel, Six Bats)...........................................................................6

2.3 Steel Finger Kit MD #311068 (FD235, Double Reel, Five Bats) .........................................................................7

2.4 Steel Finger Kit MD #311069 (FD235, Double Reel, Six Bats)...........................................................................8

Chapter 3: Steel Finger Placement............................................................................................................. 9

3.1 FD230, Double Reel, Five and Six Bats –Narrow......................................................................................... 10

3.2 FD230, Double Reel, Five and Six Bats –Wide............................................................................................ 11

3.3 FD235, Double Reel, Five and Six Bats –Narrow......................................................................................... 12

3.4 FD235, Double Reel, Five and Six Bats –Wide............................................................................................ 13

Chapter 4: Removing Existing Fingers and Bushings............................................................................... 15

4.1 Removing Bushings and Steel or Plastic Fingers from Reels .......................................................................... 15

Chapter 5: Installation Instructions ......................................................................................................... 25

5.1 Installing Bushings and Steel Fingers to Reels ............................................................................................ 25

5.2 Installing Reel Endshields ....................................................................................................................... 33

5.2.1 Installing Reel Endshields at Outboard Cam End ................................................................................ 34

5.2.2 Installing Reel Endshields at Inboard Tail End .................................................................................... 39

5.2.3 Installing Reel Endshields at Inboard Cam End................................................................................... 43

5.2.4 Installing Reel Endshields at Outboard Tail End ................................................................................. 48

TABLE OF CONTENTS