InterPuls PORTABLE IMILK401 Instruction Manual

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 2

MANUFACTURER

InterPuls S.p.A

ADDRESS

Via: F. Maritano, 11

Postal code: 42020 - Albinea (RE) - ITALY

Tel.: +39 0522 347511

Telefax: +39 0522 348516

Website: www.milkrite-interpuls.com

E-mail: [email protected]

TYPE OF DOCUMENT

Instruction, Use and Maintenance Manual

DOCUMENT CODE

5640015_EN

EDITION

07.17

PRODUCT

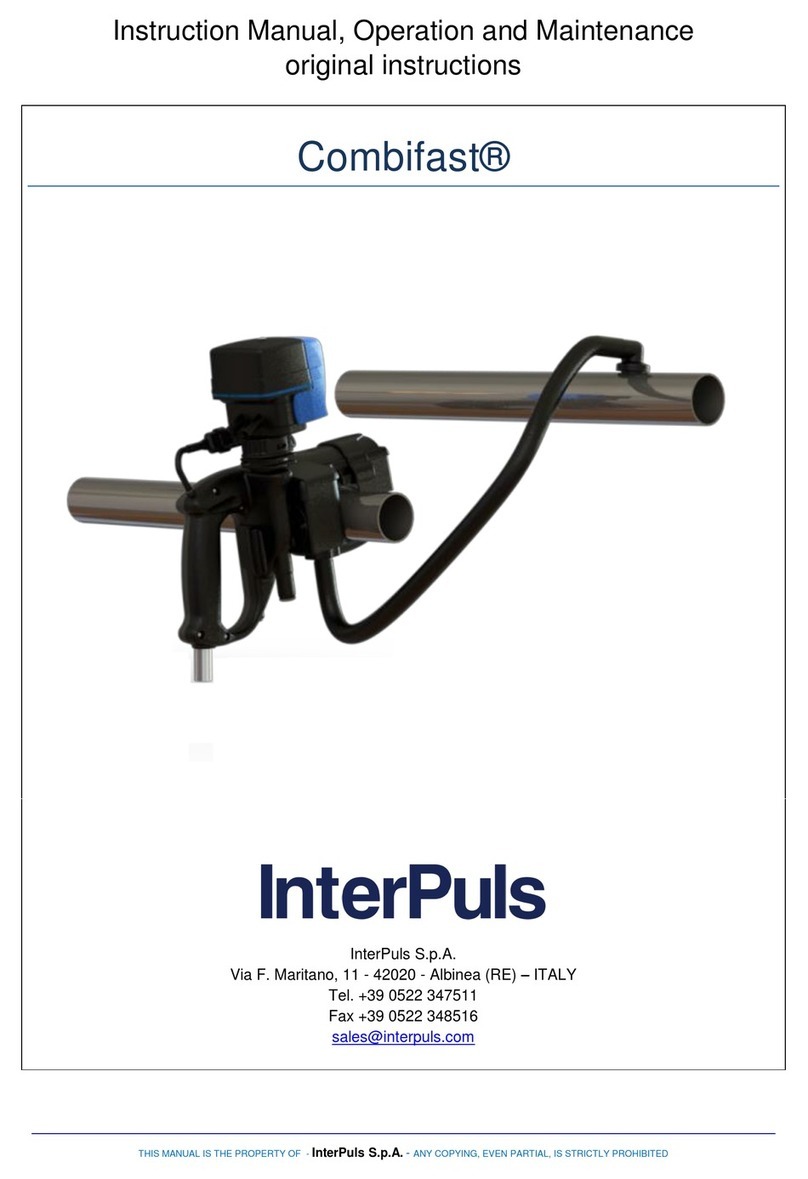

Semi-automatic milking system for milk transport systems

MODEL

Portable iMilk401

YEAR OF MANUFACTURE

2017

InterPuls is a registered trade mark of InterPuls SpA.

The information contained in this document is not binding and can be modified without notice. References in

this document to manufacturer trademarks are for identification only. Certain company and product names

used throughout the document are trademarks of their respective owners.

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 3

Summary

PORTABLE IMILK401....................................................................................................................................... 1

1GENERAL INFORMATION .................................................................................................................... 6

1.1 General information and safety warnings...................................................................................... 6

1.1.1 Important warnings .................................................................................................................... 6

1.1.2 Symbol used in this manual....................................................................................................... 6

1.1.3 Rules and regulations for the user............................................................................................. 6

1.1.4 Limitation of liability.................................................................................................................... 6

1.2 Prior using the product................................................................................................................... 6

1.2.1 Requirements and rules for personnel and Safety Rules.......................................................... 6

1.3 Disposal......................................................................................................................................... 7

1.3.1 General regulation ..................................................................................................................... 7

1.4 Fire prevention............................................................................................................................... 7

1.4.1 Fire prevention........................................................................................................................... 7

1.4.2 Safety regulations...................................................................................................................... 7

1.4.3 Characteristic of extinguishers................................................................................................... 7

1.5 Normative references applied........................................................................................................ 7

1.6 Marking.......................................................................................................................................... 8

1.6.1 Dataplates affixed to the machine ............................................................................................. 8

1.7 Safety decals ................................................................................................................................. 8

2DESCRIPTION OF THE MACHINE ....................................................................................................... 9

2.1 General features............................................................................................................................ 9

2.2 Technical characteristics ............................................................................................................. 12

3INTENDED AND NON-INTENDED USE.............................................................................................. 13

3.1 Intended use................................................................................................................................ 13

3.2 Non-intended use ........................................................................................................................ 13

4RESIDUAL RISKS................................................................................................................................ 13

5SYSTEM ............................................................................................................................................... 15

5.1 Washing mode............................................................................................................................. 15

5.2 Milking mode................................................................................................................................ 16

6FIRST USE OF THE MACHINE ........................................................................................................... 17

6.1 General description...................................................................................................................... 17

6.2 Pneumatic Connections............................................................................................................... 18

6.3Electrical connections.................................................................................................................. 21

6.3.1 iMilk401 - Components............................................................................................................ 21

6.3.2 iMilk401 connection - Combifast mobile part without data download...................................... 22

6.3.3 iMilk401 connection Combifast mobile part with data download............................................. 23

6.4 Combifast fixed part..................................................................................................................... 24

6.4.1 Connection of the Combifast fixed part during washing.......................................................... 25

6.4.2 Washing the Combifast fixed part without data download....................................................... 25

6.4.3 Washing the Combifast fixed part with data download............................................................ 26

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 4

6.4.4 Connection of the Combifast fixed part in milking ................................................................... 27

6.5 Positioning of the Portable iMilk401 during milking..................................................................... 28

6.6 Positioning of the Portable iMilk401 during washing ................................................................... 29

6.7 Handling of the Portable iMilk401................................................................................................ 30

6.8 Adjustment for first use................................................................................................................ 31

7IMILK401 OPERATION PANEL ........................................................................................................... 32

7.1 Detachment.................................................................................................................................. 33

7.2 Milking.......................................................................................................................................... 33

7.2.1 Insert animal ID........................................................................................................................ 33

7.2.2 Automatic milking with automatic detachment......................................................................... 34

7.2.3 Diagram of automatic milking (program P1)............................................................................ 35

7.2.4 Drip .......................................................................................................................................... 35

7.2.5 Automatic drip milking diagram (programs P3 –P5 –P7 –P9).............................................. 36

7.2.6 Manual Milking......................................................................................................................... 37

7.3 Alarms.......................................................................................................................................... 37

7.3.1 Conductivity alarm ................................................................................................................... 37

7.3.2Temperature alarm .................................................................................................................. 38

7.4 Detachment procedure ................................................................................................................ 38

7.4.1 Automatic detachment............................................................................................................. 39

7.5 Stimulation................................................................................................................................... 39

7.5.1 Manual..................................................................................................................................... 39

7.5.2 Forced...................................................................................................................................... 39

7.6 Washing....................................................................................................................................... 40

8PROGRAMMING.................................................................................................................................. 40

8.1 General parameters..................................................................................................................... 41

8.2 Customised programs.................................................................................................................. 42

8.3 Change parameters..................................................................................................................... 44

9CALIBRATION...................................................................................................................................... 44

9.1 1st level milk calibration measurement (on each panel) .............................................................. 44

9.2 2nd level milk calibration measurement (on the total milked)....................................................... 46

9.3 Temperature calibration............................................................................................................... 46

10 GENERAL MAINTENANCE ............................................................................................................ 47

10.1 Component maintenance............................................................................................................. 47

10.1.1 LE30 and CV 30 pulsators................................................................................................... 47

10.1.2 DVC1000 Cylinder............................................................................................................... 48

10.1.3 SO valve .............................................................................................................................. 48

10.2 Periodic maintenance .................................................................................................................. 48

10.2.1 Daily..................................................................................................................................... 48

10.2.2 Weekly................................................................................................................................. 48

10.3 Extraordinary maintenance.......................................................................................................... 49

11 TROUBLESHOOTING..................................................................................................................... 50

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 5

12 DHM SOFTWARE........................................................................................................................... 52

12.1 Installation and initial use............................................................................................................. 52

12.1.1 Combifast mobile part electrical connections ...................................................................... 52

12.1.2 Combifast fixed washing part electrical connections........................................................... 53

12.1.3 Connector ............................................................................................................................ 54

12.1.4 iMilk401 parameters settings............................................................................................... 54

12.1.5 Software installation............................................................................................................. 55

12.1.6 Software settings ................................................................................................................. 55

12.2 Data Download ............................................................................................................................ 57

12.3 Software operation....................................................................................................................... 57

12.3.1 Initial screen......................................................................................................................... 57

12.3.2 Cow management screen.................................................................................................... 58

12.3.3 Graphs screen ..................................................................................................................... 58

12.3.4 Report screen ...................................................................................................................... 59

13 SPARE PARTS DIAGRAM.............................................................................................................. 60

13.1 PORTABLE iMILK401 ................................................................................................................. 60

13.2 DVC 1000 .................................................................................................................................... 60

13.3 CV30 & LE30............................................................................................................................... 61

13.4 S/O Valve..................................................................................................................................... 61

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 6

1 GENERAL INFORMATION

1.1 General information and safety warnings

1.1.1 Important warnings

To safeguard the operator and prevent any damage to the equipment, before carrying out any kind of

operation it is important to have read and fully understood the instruction manual.

1.1.2 Symbol used in this manual

The following symbols are used in this manual to highlight indications and warnings which are of particular

importance:

WARNING

This symbol indicates health and safety regulations designed to protect operators and/or any

exposed persons.

CAUTION

This symbol indicates that there is a risk of causing damage to the equipment and/or its

components.

NOTE

This symbol is used to highlight useful information.

1.1.3 Rules and regulations for the user

WARNING

Any failure to observe the warnings provided in this manual may lead to equipment

malfunctions or damage to the system.

1.1.4 Limitation of liability

InterPuls S.p.A. declines all liability for damage to persons, animals and/or things caused by incorrect use of

the equipment.

1.2 Prior using the product

1.2.1 Requirements and rules for personnel and Safety Rules

WARNING

Before using the device, the operator must carefully read the manual.

The person using the device must be of legal age and be trained and physically and mentally

fit. He or she must also have been provided with adequate information on how to operate the

device.

During the assembly and activation of the device, follow the instructions in the manual and

rules and regulations applying to health and safety at the workplace.

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 7

As the Portable ACR-SMART is an operator hand-held device, the operator must wear non-

slip safety shoes during use to prevent damage from accidental falls of the device

1.3 Disposal

1.3.1 General regulation

The appliances must be disposed of only and exclusively by specially authorized waste disposal companies

in accordance with all relative legislation and prescriptions.

The packaging must be consigned to the relative authorized companies to be recycled.

1.4 Fire prevention

1.4.1 Fire prevention

NOTE

The machine is not equipped with fire extinguishers.

The operator must make sure that the place in which the appliance is installed is equipped

with an adequate number of suitable fire extinguishers. The extinguishers must be positioned

where they are clearly visible and protected from damage and improper use.

1.4.2 Safety regulations

WARNING

It is strictly prohibited to extinguish fires involving electrical equipment with water!

1.4.3 Characteristic of extinguishers

Use powder, foam or halogen extinguishers which must be positioned next to the device.

Operating personnel must receive adequate instruction on how to use the extinguishers.

1.5 Normative references applied

Europe:

Directive no. 2006/42/EC Machinery Safety

Directive no. 2004/108/EC Electromagnetic Compatibility (EMC)

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 8

1.6 Marking

1.6.1 Dataplates affixed to the machine

1.7 Safety decals

WARNING

The removal or damaging of safety decals is strictly prohibited.

Generic danger

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 9

2 DESCRIPTION OF THE MACHINE

2.1 General features

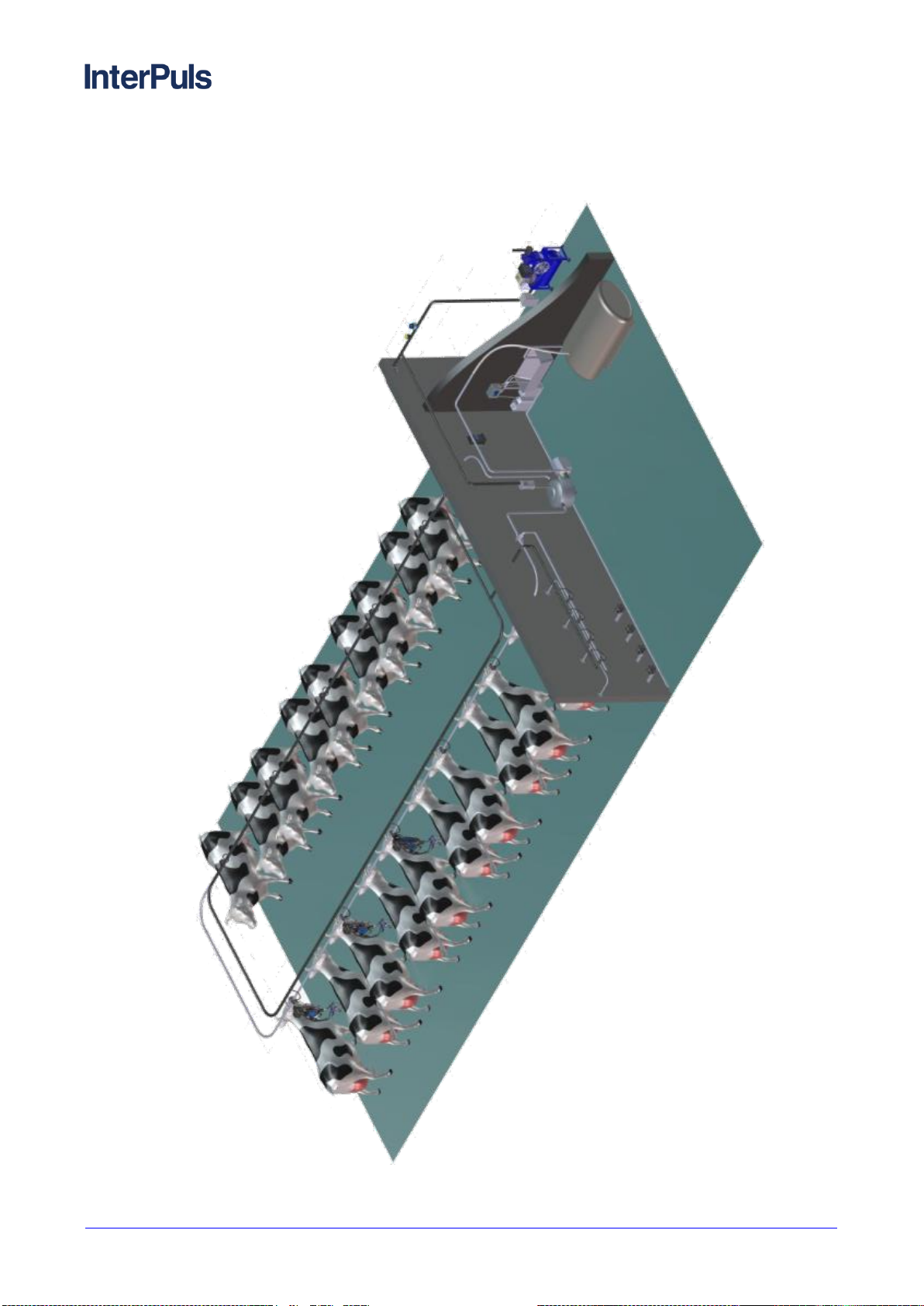

The Portable iMilk401 is a portable milking device with automatic shut-off, with pulse control, and

measurement of the quantity of milk that has been milked, designed for milk transport systems for tied

animals.

The package includes (already assembled):

- Plastic frame with built-in 1.5 lt (0.05 ft3). vacuum tank to have a constant vacuum reserve and in

order to reduce vacuum fluctuations (ref. 1)

- 1 iMilk401 Panel to manage milking and to view the quantity of milk that has been milked (ref.2)

- DVC 1000 Cylinder for automatic removal of the unit (ref.3)

- Shut Off Valve to close/open the vacuum to the unit (ref.4)

- 1 LE 30 control valve to control the Shut off valve and automatic shut off cylinder (ref.5)

- 1 LE 30 pulsator to generate the pulse signal (ref.6)

- Cover for the pulsators (ref.7)

- Indicator light to indicate end of the milking process (ref.8)

- Brackets to clamp the components (ref.9-10-12)

- Bracket with a terminal to fix the milk tube (ref.11)

- Direct passage sensor to measure the flow of milk that has been milked (ref.13)

- A piece of pipe with twin connection terminals (ref. 14)

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 10

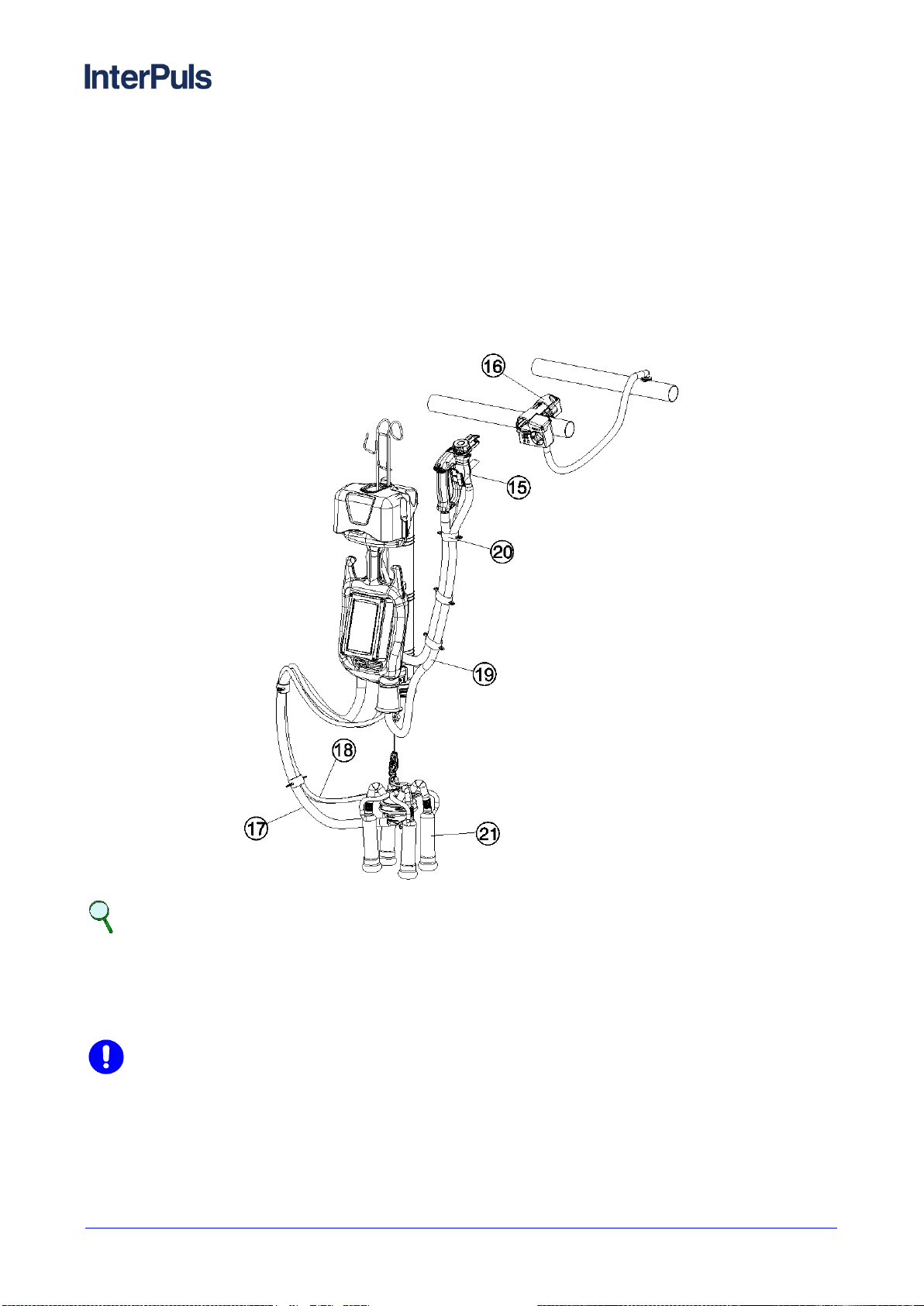

The package does not include the following components, which are supplied separately and which are

required for the final commissioning:

- Combifast mobile part (ref.15)

- Combifast fixed part (ref.16)

- Milk tube, twin tube, vacuum tube, retaining ring (ref.17,18,19,20)

- Milking cluster (ref. 21)

The following are the features of the pipes to be used:

1. Milk pipe 16x29 mm (0.63x1.14 in) (Preferably black)

2. Vacuum pipe 13x23 mm (0.51x0.9 in) (Preferably black)

3. Twin pipe 7.6x14.5 mm (0.3x0.57 in) (Preferably black)

NOTE

The individual iMilk401 panels can be connected to the network by means of a CAN-BUS

communication protocol, and it is possible to view the milking data via remote PC, which is

located in the farmer's office, which has a milking system management software installed

(DHM)

CAUTION

The Portable iMilk401 has been designed to work with InterPuls components to complete the

installation: the milking cluster design is composed of a Lunik 350 claw and IPL11 liner, and

the 3-way connection device is the Combifast. For any other installation with non InterPuls

material, the system engineer will be responsible for ensuring proper system commissioning.

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 11

CAUTION

The Portable iMilk401 has been designed to operate with the aforementioned pipe sizes. Do

not use different sized pipes as such use would compromise the operation of the system

CAUTION

All assembly diagrams and explanations in this manual refer to the use of InterPuls

components (Pulsators, Cylinder, Control Valve, Combifast and milking clusters with Lunik

350); InterPuls declines any liability for any malfunction, if the system engineer replaces

components not explicitly mentioned in this manual with competitive devices.

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 12

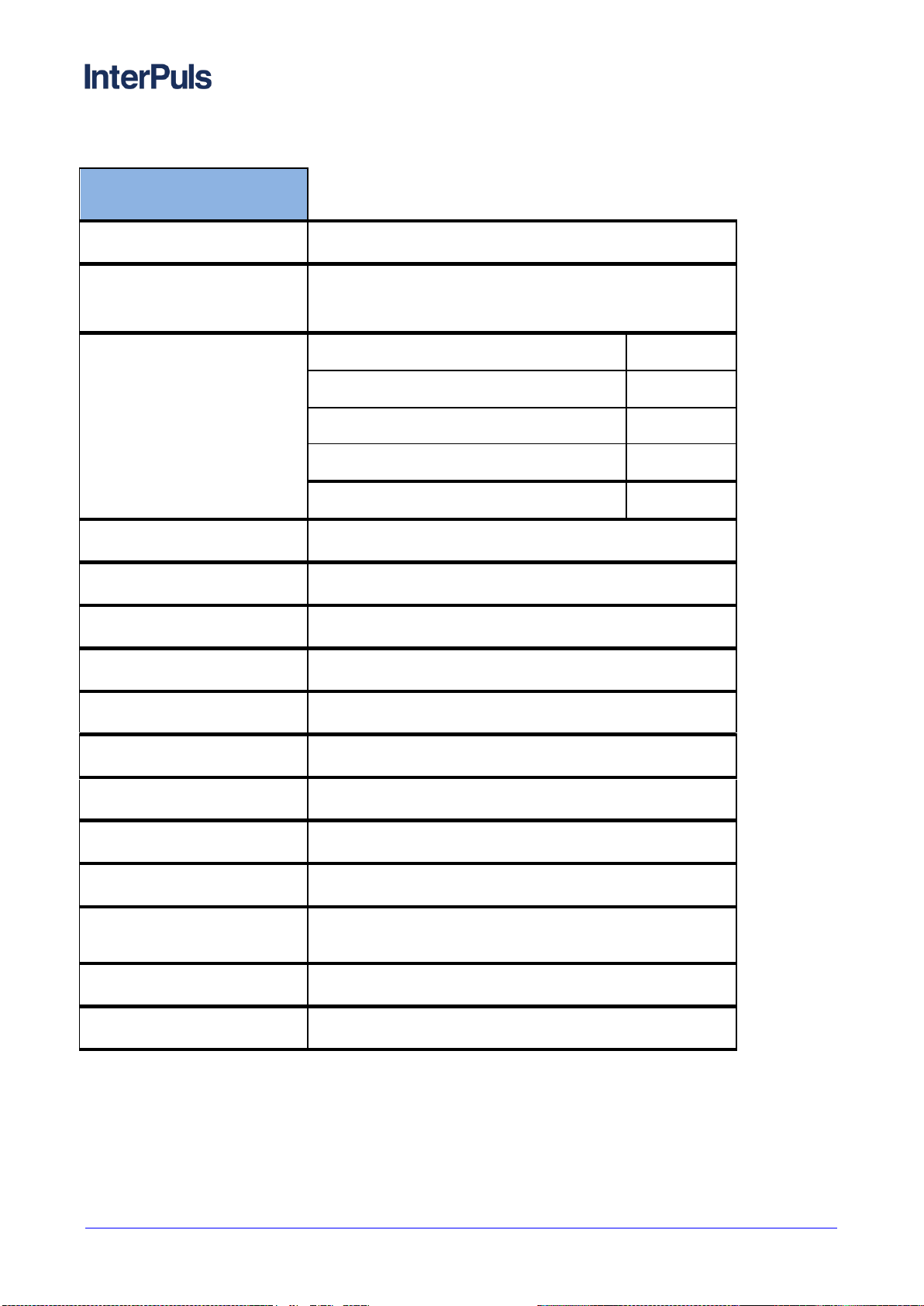

2.2 Technical characteristics

Technical

Specifications

Input voltage

24 VDC -5% / +20%

Protective devices

Inverse polarity protection

Inputs and outputs are protected from current overload

4A fuse at the power supply input

Power consumption

iMilk401 panel

100 mA

Indicator light to signal the end of the

milking process

30 mA

Control Valve CV 30

260 mA

LE 30 Pulsator

260 mA

TOTAL

650 mA

Accuracy when measuring

the amount of milk

±10%

Operating vacuum

between 36 and 60kPa (typically 50kPa)

between 10.63 and 17.72 “Hg (typically 14.76 “Hg)

Operating temperatures

(environment)

-5ºC ÷ +40ºC (23°F ÷ 104°F)

Transport/storage

temperatures

-20ºC ÷ +50ºC (-4°F ÷ 122°F)

Temperature of the washing

mixture

Min 60°C - Max 90°C (Min 140°F –Max 194°F)

Effective stroke of the

cylinder

1230 mm (48.42 in)

Protection class (cover and

cables installed correctly)

IP67

Dimensions (LxLxH)

960 x 230 x 240 mm (37.8 x 9.05 x 9.45 in)

Device weight

4.6 kg (10.14 lb)

Weight of the complete

device ready for milking

operations *

10 kg (22.05 lb)

Maximum weight admissible

by the milking clusters **

3.0kg (6.61 lb)

Sound pressure

< 70 dB

*: The weight of the device is considered to be set up with InterPuls unit (composed of Lunik 350 and IPL11

sheaths) and with the 3 way Combifast connecting device for which the system has been explicitly designed

**: should you wish to apply a unit supplied by the competition, weight refers to that of the claw, teat cup

shells and liners.

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 13

3 INTENDED AND NON-INTENDED USE

3.1 Intended use

The Portable iMilk401 is a portable milking device with automatic shut-off, with pulsation control and

measurement of the quantity of milk that has been milked, designed for milk transport systems for tied

animals (cows).

The device is moved by the operator from one milking location to another in 2 possible ways:

1. Hand transport

2. Track transport

WARNING

The Portable iMilk401 is a portable machine that must work under supervision.

WARNING

The machine must be used only for appropriately lit milk transport systems (at least 300 lux)

3.2 Non-intended use

The Portable iMilk401 is not intended for use in milking sheds.

Use of the Portable iMilk401 is not intended for milking animals other than cows.

No other handling of the machine is intended other than the aforementioned.

WARNING

Any use other than the one covered in this manual is considered improper use and is

therefore forbidden. InterPuls S.p.A. declines any liability associated with any use of the

machine other than the one covered in this manual.

4 RESIDUAL RISKS

WARNING - ELECTRICAL AND FIRE-PROTECTION SAFETY

The machine must be powered by 24VDC through SELV and PELV circuits in compliance with

applicable regulations.

The electrical system to which the machine is to be connected must have the following

protection:

For protection against indirect contact:

the machine must be supplied by means of an electrical system having a differential circuit

breaker connected to the earthed system according to the standards and laws in force.

For protection from machine overloads:

a suitable overload protection device is to be installed against overloads (circuit breaker),

which interrupts the circuits once the machine's nominal current has been exceeded.

WARNING - ACCIDENTAL IMPACTS

In the event of failure or sudden start during milking cluster detachment operations, the

operator may be involved in accidental impacts with the milking clusters.

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 14

In the event of a temporary blackout during milking, the machine is designed to start the

milking detachment procedures of the milking cluster; the operator may be involved in

accidental impacts with the milking clusters.

To overcome this residual risk, the operator must wear the P.P.E. indicated in this manual.

WARNING

HANDLING

During handling operations of the Portable iMilk401, the device may fall and accidentally hit

the operator.

To overcome this residual risk, the operator must wear the P.P.E. indicated in this manual.

WARNING

WASHING

During system washing, the operator may come into contact with the washing mixture that

can reach 90°C and with washing acids.

To overcome this residual risk, the operator must wear the P.P.E. indicated in this manual.

WARNING

MAINTENANCE

During pulsator and CV maintenance operations, the operator may come into contact with the

coils that can reach 80°C.

To overcome this residual risk, the operator must wear the P.P.E. indicated in this manual.

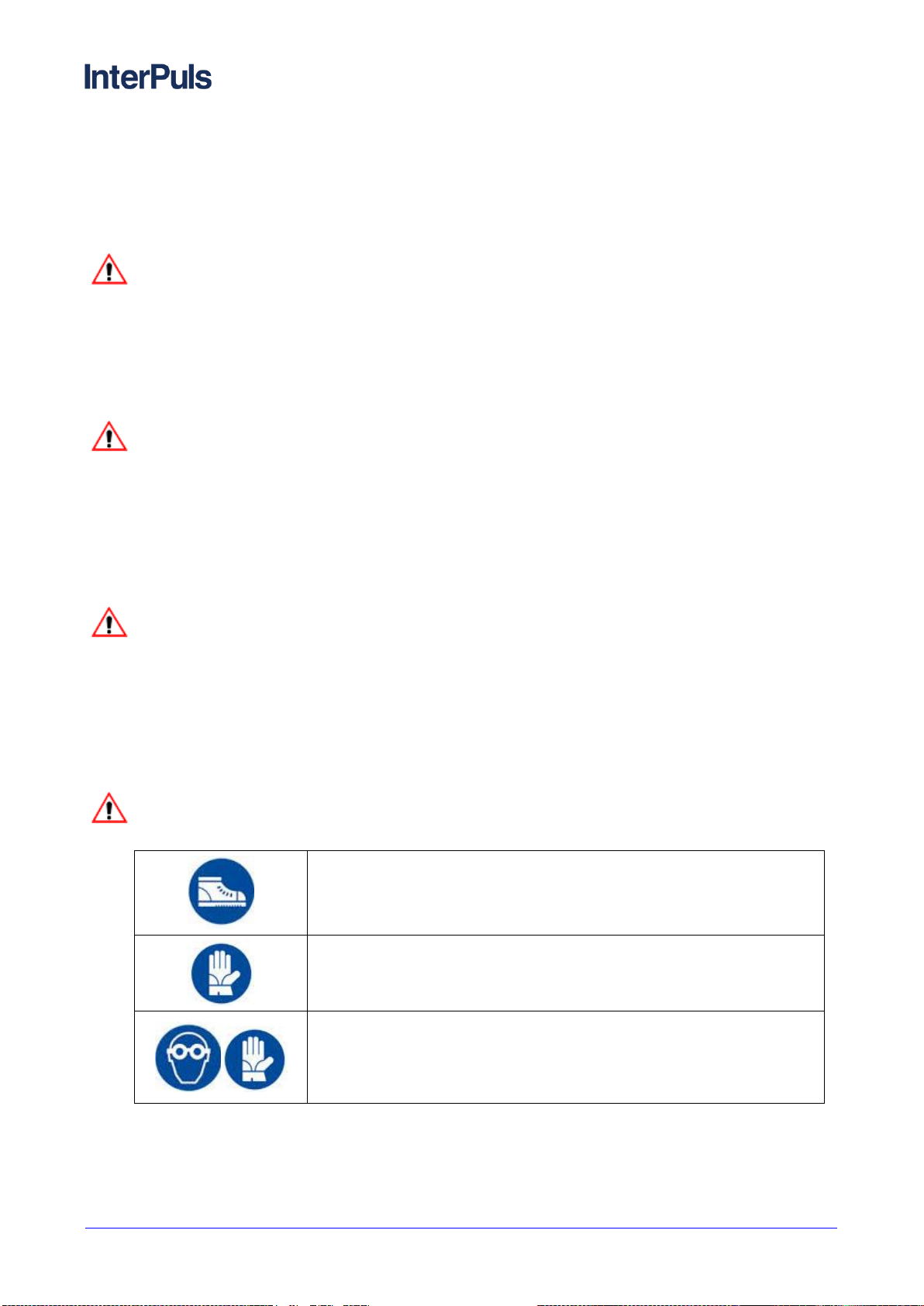

WARNING

PERSONAL PROTECTIVE EQUIPMENT

Use safety shoes for machine handling

Use gloves for safer handling of the machine and maintenance

operations

Use safety glasses and gloves during the washing phase, where it

is possible to come into contact with washing acids.

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 15

5 SYSTEM

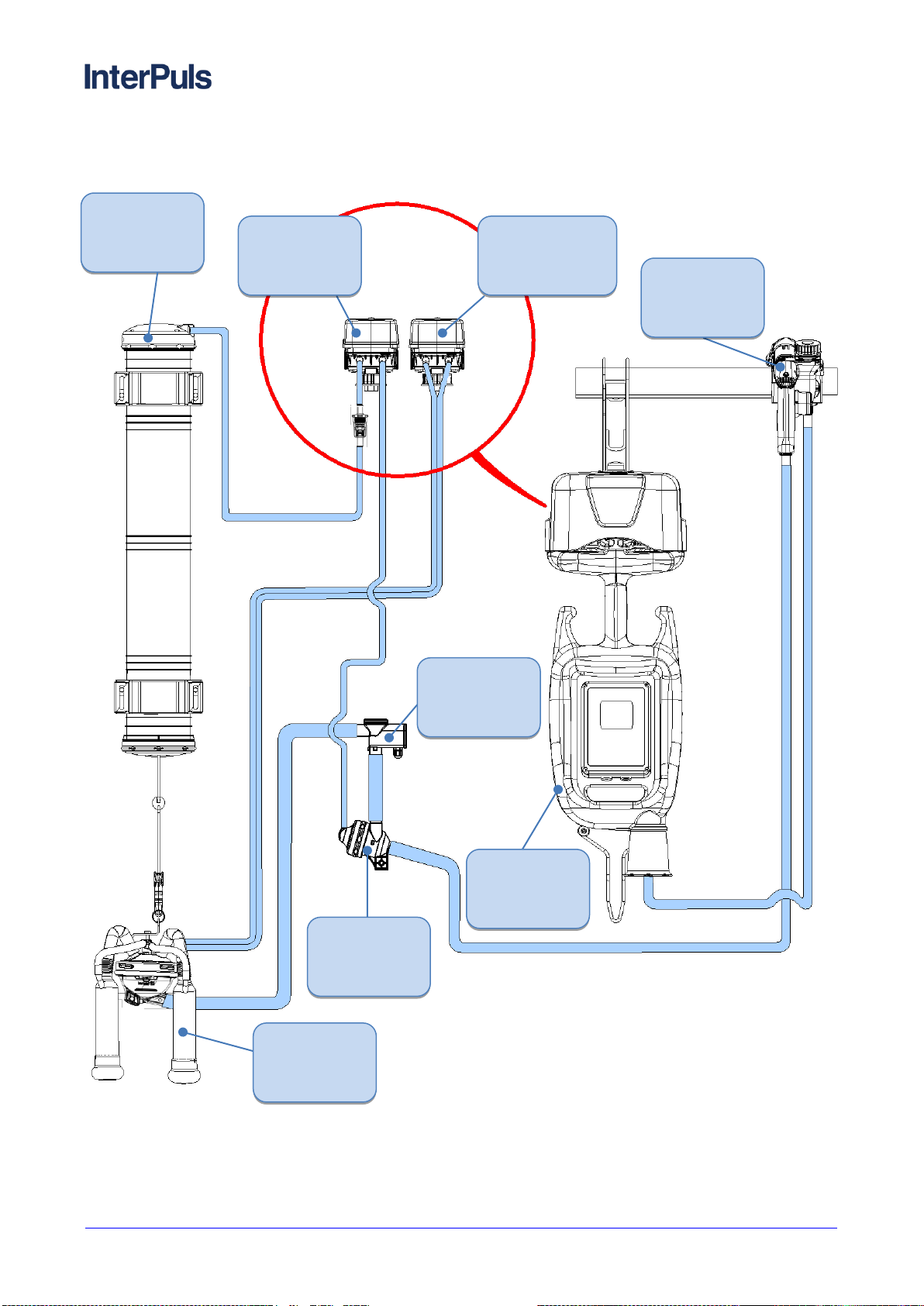

5.1 Washing mode

1

Washing plates

2

Portable iMilk401

3

Milk pump

4

Milk filter

5

Drainage valve

6

Water tank

7

Vacuum pump

8

Inverter (iDrive100)

9

Vacuum adjustment valve

(Stabilvac)

10

Sanivac

11

Vacuum gauge (DVG500)

12

Washing machine (Top Wash III)

13

Power unit (IUP)

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 16

5.2 Milking mode

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 17

6 FIRST USE OF THE MACHINE

6.1 General description

Before using the machine, you need to make some pneumatic and electrical connections and know the

correct uses of the Portable iMilk401.

This paragraph illustrates:

1. how to insert the tube retaining rings

2. how to carry out pneumatic connection between the Portable iMilk401 and the Combifast mobile

part

3. how to carry out pneumatic connection between the Portable iMilk401 and the milking clusters

4. the pneumatic connection diagram

5. the iMilk401 panel connection diagram

WARNING

Do not connect power supply before all cabling has been completed and the iMilk401 box has

been closed correctly.

Do not connect anything when the Portable iMilk401 is connected to the network.

NOTE

This manual only shows how to connect the Combifast mobile part to the iMilk401 and how to

make the electrical connection. For details on assembling the Combifast, refer to the specific

product manual.

NOTE

This manual shows how to connect the milking cluster correctly to the iMilk401. The

procedure for milking cluster assembly is left to the system engineer as it is not covered by

this manual.

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 18

6.2 Pneumatic Connections

The following is the assembly sequence of the Combifast mobile part, milking cluster, long milk pipe, vacuum

pipe and twin pipe.

1. Retaining ring insertion

2. Connection of the milk tube and vacuum tube between the Combifast and the Portable

Milk tube

Ø external 29mm

(1.14 in)

Ø internal 16mm

(0.63 in)

Vacuum tube

Ø external 23mm

(0.9 in)

Ø internal 13mm

(0.51 in)

Vacuum tube

Ø external 23mm

(0.9 in)

Ø internal 13mm

(0.51 in)

Milk tube

Ø external 29mm

(1.14 in)

Ø internal 16mm

(0.63 in)

Vacuum tube

Ø external 23mm

(0.9 in)

Ø internal 13mm

(0.51 in)

Milk tube

Ø external 29mm

(1.14 in)

Ø internal 16mm

(0.63 in)

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

5640015_07.17_EN

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 19

3. Sensor connection (already provided by InterPuls)

4. Connection between the milking cluster and the Portable

Twin tube

Ø external 2 x 14.5mm

(2 x 0.57 in)

Ø internal 7.6 mm

(0.3 in)

Milk tube

Ø external 29mm

(1.14 in)

Ø internal 16mm

(0.63 in)

Milk tube

Ø external 29mm

(1.14 in)

Ø internal 16mm

(0.63 in)

5640015_07.17_EN

PORTABLE IMILK401 - Instruction Manual, Operation and

Maintenance original instructions

THIS MANUAL IS THE PROPERTY OF - InterPuls S.p.A. - ANY COPYING, EVEN PARTIAL, IS STRICTLY PROHIBITED

MI - 20

5. Pneumatic connection diagram

DVC 1000

LE30

(CONTROL

VALVE)

LE30

(PULSATOR)

FLOW

SENSOR

S/O

Milking

Cluster

PORTABLE

IMILK 401

COMBIFAST

Table of contents

Other InterPuls Farm Equipment manuals

Popular Farm Equipment manuals by other brands

AGCO

AGCO LELY ATTIS PT 130 Operator's manual

K-Line

K-Line SPEEDTILLER 2900 Series operating manual

Hisarlar

Hisarlar SB1150 User and maintenance manual

HE-VA

HE-VA Top-Cutter Solo Operating Instructions, Spare parts list, Declaration of Conformity

MASSEY FERGUSON

MASSEY FERGUSON 9186 Service manual

Hagie

Hagie NTB 16-Row Operator's manual