GENERAL PUMP A member of the Interpump Group

R3LP/230

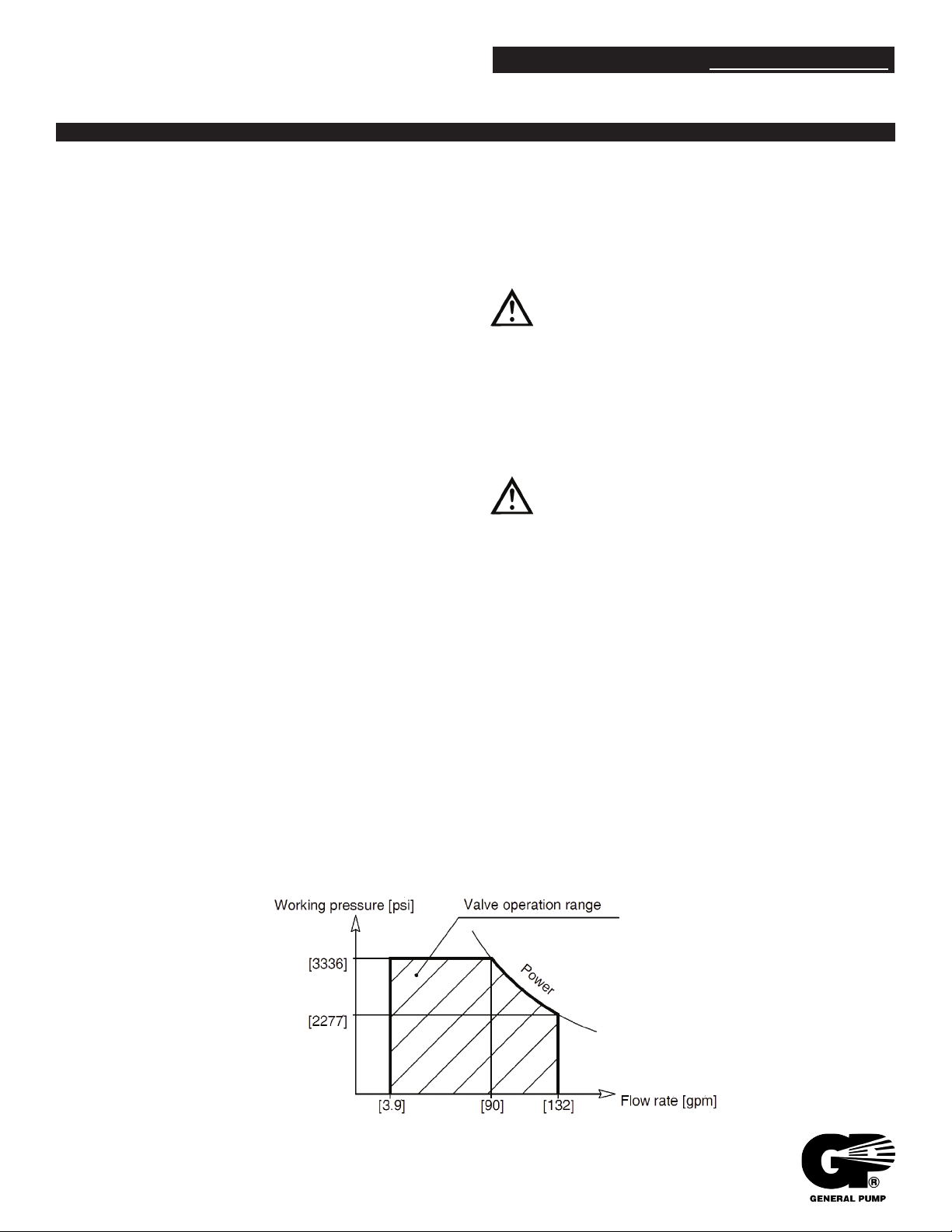

Pressure Regulating Valve

I STALLATIO A D I STRUCTIO S FOR USE

1. GE ERAL I FORMATIO

1.1 The R3LP/230 pressure regulator is a manually adjustable,

pressure operated devices, which, according to

its setting, limits the pumps/system pressure by conveying the

excess of water to the by-pass. oreover, when the outlet flow is

blocked, this device totally releases the flow, thus keeping the

pump/system at the adjusted pressure.

1.2 Since the R3LP/230 valve is used in conjunction with a high

pressure water pump/system, which shall be called

hereafter only “system”, installation and use must be suited to the

type of system used and comply with the safety regulations in

force in the country where the valve is used.

1.3 Before using the valve, make sure that the system to valve

is used with is certified to comply with the relevant directives

and/or regulations.

1.4 Before installing and using the valve for the first time, we

suggest you check that it is undamaged and make sure that the

rated features correspond to the required ones. If this is not the

case, do not use the valve and contact the Customer Service

Department.

1.5 In order to install the valve correctly, follow the instructions for

the water inlet, outlet and by-pass connections, as stated in

this manual and/or the valve itself.

2. I STRUCTIO S FOR PRESSURE SETTI G

2.1 In order to obtain a correct adjustment and consequently a

proper functioning of the valve, always make sure that, when

working at the maximum pressure, the valve by-pass keeps

releasing a quantity of water equal to 5% of the total flow rate.

In case the flow rate at the by-pass is close to zero or exceeds

15% of the maximum flow rate, this could cause failure, early

wear and result in situations of danger.

The positions mentioned in the following instructions refer to

those shown in the parts list on page 2.

2.2 Connect the valve to the water system and follow these

steps:

2.2.1 Loosen the nut (pos. 2).

2.2.2 Unscrew the nut (pos. 1) in order to completely release

the spring.

2.2.3 Open the gun or the water control device and start the

system. ake sure the air contained in it is fully ejected.

2.2.4 Keeping the gun or the water control device open, start

adjusting the pressure by screwing down the nut (pos. 1).

Alternate the adjusting operations with a few openings and

closings of the gun or of the control device. When the desired

pressure has been reached, open and close the gun/control device

a few times again in order to stabilize the various

components (seals, springs, etc.). Check the pressure valve

again and correct if necessary.

2.2.5 Screw down the lower nut (pos. 2) up to contact with the

body.

2.2.6 In order to obtain working pressures lower than the

maximum set pressure, unscrew the nut (pos. 1).

3. WAR I GS

3.1 The installation and the setting of the maximum pressure must

be made by qualified staff only, who must have the required skills

to handle high pressure systems and be informed of the

operating and safety instructions contained in this manual.

3.2 The installer must provide the ultimate consumer with the

proper instructions for the correct use of the system the valve is

used in connection with.

3.3 Use soft and filtered water only. In case of salt water and/or of

water containing solid particles of a size exceeding 360µm, the

internal components of the valve will be subject to quick wear;

furthermore, this might compromise the correct functioning of the

valve. Addition agents can be used in the water, provided that

they are biodegradable and always complying with the regulations

in force in the country where the valve is used.

3.4 In the systems for hot water production, the

temperature of the liquid that comes into contact with

the valve must always be lower than the value stated

in this instruction manual and/or indicated on the valve

itself. Avoid the formation of steam or overheated

water.

IMPORTA T: When the temperature of the liquid is

close to the maximum value, the outside temperature

of the valve body is only slightly lower. Therefore,

take care in case of contact with the hot surface.

Ref 300931 Rev. A

08-13