Interscan Corporation 4000 Series User manual

Other manuals for 4000 Series

2

Table of contents

Other Interscan Corporation Measuring Instrument manuals

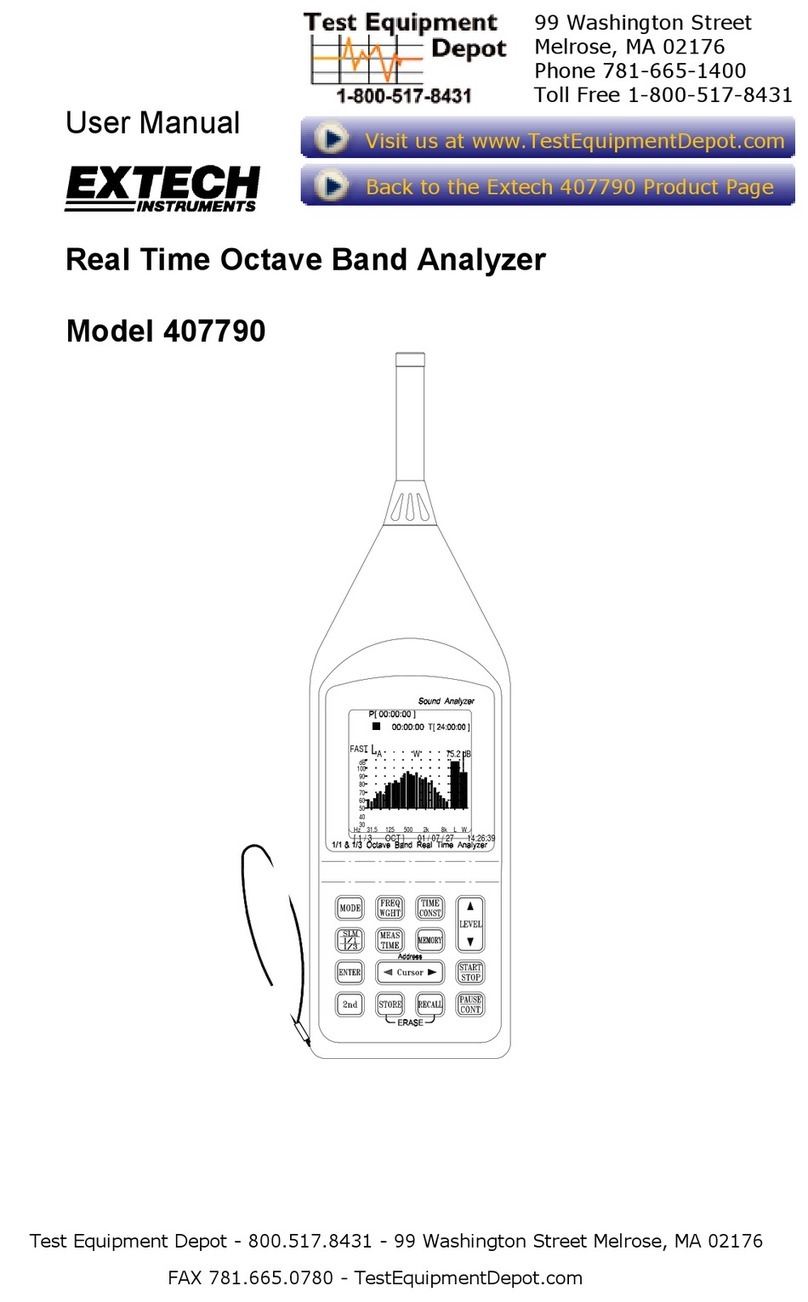

Interscan Corporation

Interscan Corporation 4000 Series User manual

Interscan Corporation

Interscan Corporation 4000 Series User manual

Interscan Corporation

Interscan Corporation GasD 8000 Series User manual

Interscan Corporation

Interscan Corporation GF1900 User manual

Interscan Corporation

Interscan Corporation GF1900 User manual

Popular Measuring Instrument manuals by other brands

Minipa

Minipa MLM-1011 instruction manual

QUANTACHROME INSTRUMENTS

QUANTACHROME INSTRUMENTS MVP-6DC operating manual

BNC

BNC RTSA 7500 Programmer's manual

Monacor

Monacor JTS SIEM-2/5 instruction manual

Circutor

Circutor DM45 V installation guide

Parker

Parker SensoControl ServiceJunior Series operating instructions

Agilent Technologies

Agilent Technologies N1911A Programming guide

Hanna Instruments

Hanna Instruments HI705 instruction manual

Milwaukee

Milwaukee PRO MI415 user manual

Lovibond

Lovibond Tintometer SensoDirect Con110 instruction manual

VOLTCRAFT

VOLTCRAFT MF-100 operating instructions

C-LOGIC

C-LOGIC 8900 user manual