Intertek T-HP212 User manual

1

COUNTERTOP RANGE

Installation and Operation Instructions

Models: T-HP212, T-HP424, T-HP636

IMPORTANT FOR FUTURE REFERENCE

Please complete this information and retain this manual for the life of the equipment. For

Warranty Service and/or parts, this information is required.

Model Number Serial Number Date Purchased

WARNING: For your safety, do not store or use gasoline or other flammable

vapours or liquids in the vicinity of this or any other appliances. Keep the area

free and clear of combustible. (SeeANSI Z83. 14B, 1991).

WARNING: Improper installation, adjustment, alteration, service, or maintenance

can cause property damage, injury, or death. Read the installation operating and

maintenance instructions thoroughly before installing or servicing this equipment.

WARNING: Instructions must be posted in a prominent location. All safety

precautions must be taken in the event the user smells gas. Safety information

can be obtained from your local gas supplier.

CAUTION: These models are designed, built, and sold for commercial use only. If these

models are positioned so the general public can use the equipment, make sure that

cautions, warnings, and operating instructions are clearly posted near each unit so that

anyone using the equipment will use it correctly and not injure themselves or damage

the equipment.

GAS PRESSURE

The appliance and its individual shutoff valve (to be supplied by the user) must be

disconnected from the gas supply piping system during any pressure testing of that system at

test pressures in excess of ½ psi (3.45 kPa).

The appliance must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.45 kPa).

WARNING: A factory-authorized agent should handle all maintenance and repairs.

Before doing any maintenance or repairs, contact your authorized service

representative.

2

TABLE OF CONTENTS

Congratulations on your purchase of Eurodib commercial cooking equipment. Eurodib takes

pride in the design and quality of our products. When used as intended and with proper care

and maintenance, you will experience years of reliable operation from this equipment. To

ensure best results, it is important that you read and follow the instructions in this manual

carefully.

LOCATION OF DATA PLATE

The data plate is located on the side panel.

IMMEDIATELY INSPECT FOR SHIPPING DAMAGE

All containers should be examined for damage before and during unloading. The freight

carrier has assumed responsibility for its safe transit and delivery. If equipment is received

damaged, either apparent or concealed, a claim must be made with the delivering carrier.

1. Apparent damage or loss must be noted on the freight bill at the time of delivery. It

must then be signed by the carrier representative (Driver). If this is not done, the

carrier may refuse the claim. The carrier can supply the necessary forms.

2. Concealed damage or loss if not apparent until after equipment is uncrated, a request

for inspection must be made to the carrier within 15 days. The carrier should arrange

an inspection. Be certain to hold all contents and packaging material.

A qualified installer who thoroughly read, understands and follows these instructions should

perform installation and maintenance.

If you have questions concerning the installation, operation, maintenance, or service of this

product, write to Eurodib.

ITEM

PAGE

ITEM

PAGE

Safety precautions

4

Cleaning & Maintenance

11

General Installation Instructions

5

Service/Repair

12

Specifications & Dimensions

6

Explosion View Drawing

13

Conversion

6

Spare Part List

14

Lighting Instructions

10

Limited Warranty

16

3

SAFETY PRECAUTIONS

DANGER: This symbol warns of imminent hazard, which could result in serious

injury or death.

WARNING: This symbol refers to a potential hazard or unsafe practice, which

could result in serious injury or death.

CAUTION: This symbol refers to a potential hazard or unsafe practice, which

could result in minor or moderate injury or product or property damage.

NOTICE: This symbol refers to information that needs special attention or must be

fully understood even though not dangerous.

NOTICE: This product is intended for commercial use only. Not for household use.

NOTICE: Local codes regarding installation vary greatly from one area to another. The

National Fire Protection Association, Inc., states in its NFPA96 latest edition that

local codes are “Authority Having Jurisdiction” when it comes to requirement for

the installation of equipment. Therefore, the installation should comply with all local

codes.

4

GENERAL INSTALLATION INSTRUCTIONS

Ensure that the gas supply and gas type, as shown on unit nameplate, agree.

Unit installation must conform with the National Fuel Gas Code, ANSI Z223.1/NFPA 54, the

National Gas Installation Code, CSA-B149.1, or the Propane Installation Code, CSA-B149.2

as applicable and in accordance with local codes.

Screw the legs into the permanently fastened nuts on the four corners of the unit and tighten

by hand. Level the unit by turning the adjustment screw at the bottom of each leg. Do not

slide the unit with legs mounted, lift if necessary to move unit.

Pipe threading compound must be resistant to the action of liquefied petroleum gases.

CAUTION: DO NOT use an open flame to check for leaks. Check all the gas piping for leaks

with a soap-and-water solution before operating the unit.

THESE UNITS ARE SUITABLE FOR INSTALLATION ON NON-COMBUSTIBLE

SURFACES ONLY.

Combustible clearances:

6" sides (152 mm) 6" rear (152 mm) 4" floor (102 mm)

Non-combustible clearances:

0" sides (0 mm) 0" rear (0 mm) 4" floor (102 mm)

Do not obstruct the flow of combustion and ventilation air, under the unit by the legs or behind

the unit by the flue. Adequate clearance for air openings into the combustion chamber is

required. Do not place objects between the bottom of the unit and the counter top. There

must be adequate clearance for removal of the front panel. All major parts, except the

burners, are removable through the front if the gas line is disconnected.

5

SPECIFICATION AND DIMENSIONS

MODEL

WIDTH

IN. (MM)

DEPTH

IN. (MM)

HEIGHT

IN. (MM)

# OF

BURNERS

BTU/PER

NAT/LP

TOTAL

BTU/ Hr

W.C.

IN.

T-HP212

12(305)

29.2(741)

18.7(475)

2

30,000

60,000

6/10

T-HP424

24(610)

29.2(741)

18.7(475)

4

30,000

120,000

6/10

T-HP636

36(915)

29.2(741)

18.7(475)

6

30,000

180,000

6/10

Note: Depth direction includes the regulator’s size.

CONVERSION

These instructions are for the conversion from Natural Gas to Propane (L.P.) on all models.

The conversion should be done before connecting the unit to the gas supply.

Units are shipped from the factory equipped for use on natural gas. Orifices necessary for

Propane (L.P.) are provided in a bag of the manual.

1. Shut off the main isolation gas valve and follow the lock-out/tag-out procedure.

6

2. Remove the tray and trivets.

3. Remove the bolt and all the cast burners.

Trivet

Tray

Cast Burner

Bolt

7

4. Remove the orifice and replace it. Use a 1/2” spanner. See the list of orifice numbers

for the appropriate gas type.

Orifice

Use for Propane (L.P.)

Use for Natural

gas

8

5. Converting the gas regulator.

a. Remove the converter cover from the regulator. Use a 7/8” spanner.

b. Pull out the converter from the cover.

c. Position of the converter when using propane (L.P.).

d. Install the converter cover to the regulator.

Note: The arrow in the regulator indicates the flow direction of the gas.

9

6. Reinstall the U burners.

7. Check leakage and reinstall the other parts.

8. Ignite the pilot burner and check flame state.

9. Turn the knobs to “High”.

If the U burner does not ignite, open the pilot valve more.

If the pilot flame appears larger than necessary, turn it down and reset burner ignition.

The pilot flame should be as small as possible but large enough to guarantee a

reliable ignition of the burners when the knobs are turned to “ON.

Note: Please check leakage before reinstalling the control-panel.

LIGHTING INSTRUCTIONS

Lighting the Pilot

The pilot light on the appliance has been set at the factory. A screwdriver maybe required for

the first lighting to adjust the flame for your elevation.

1. Turn off the manual valve and wait 5 minutes to clear the air gas.

2. Turn all knobs to the "OFF" position.

3. Hold an ignition source (match) at the pilot. When the flame is established, remove the

ignition source.

4. Turn the burner knobs to "ON". If the burner does not ignite, promptly open the pilot

valve more. If the pilot flame appears larger than necessary, turn it down and reset

burner ignition. The pilot flame should be as small as possible but large enough to

guarantee a reliable ignition of the burners when the knobs are turned to "ON".

Lighting the Main Burner

To light burner, turn the knob to “ON.” Then back off to the desired flame level. The range of

adjustment is virtually infinite between “ON” and “OFF”.

Main burner air supply:

For efficient burner operation, a proper balance of the gas volume and primary air supply

must be maintained, which will result in a complete combustion. Insufficient air supply results

in a yellow streaming flame. The primary air supply is controlled by an air shutter on the front

of the burner.

Loosen the screws on the front of the burner and adjust the air shutter to just eliminate the

yellow tips of the burner flame. Lock the air shutter in place by tightening the screws.

10

CAUTION: Never attempt to move a grill section while cooking. An unexpected flare could

cause severe injury. Turn off the unit, let it cool and use potholders and/or gloves to

reposition or remove. The space between the legs at the bottom admits combustion air. DO

NOT BLOCK THIS SPACE.

All burners are lit from constantly burning pilots. Turning the valve to the desired flame height

is all that is required to put the unit in service.

Do not permit fans to blow directly at the unit. Wherever possible, avoid open windows next

to the unit’s sides or back. Avoid wall-type fans, which create air crosscurrents within a room.

It is also necessary that sufficient air should be allowed to enter the room to compensate for

the amount of air removed by any ventilating system. Otherwise, a subnormal atmospheric

pressure will occur, affecting operation and causing undesirable working conditions.

A properly designed and installed hood will act as the heart of the ventilating system for the

room or area in which the unit is installed, and will leave the unit independent of changing

draft conditions.

All valves must be checked and lubricated periodically. This must be done by an authorized

service representative in your area.

11

CLEANING & MAINTENANCE

CAUTION: Use only non-abrasive cleaners. Abrasive cleaners could scratch the

finish of your unit, marring its appearance and making it susceptible to dirt

accumulation. Do not use steel wool, other abrasive cleaners or cleaners/sanitizers

containing chlorine, iodine, ammonia orbromine chemicals as these will

deteriorate the stainless steel and glass material and shorten the life of the unit.

Daily Cleaning

1. Thoroughly clean the back, sides, top, and front of the unit.

2. Clean the trivets daily.

Weekly Cleaning

1. Clean the unit thoroughly. Clean stainless steel or chromed surfaces with a damp cloth

and polish with a soft, dry cloth. A detergent may be used for cleaning. To remove

discolorations, use a non-abrasive cleaner.

2. To clean the drip pan, remove the drip pan by grabbing the handle and pulling it out of the

opening in the front panel. To replace the pan, perform this procedure in reverse order.

3. Burner air shutter openings must be kept clean. The main burner ports must be kept

clean. To clean the burners, boil them in a strong solution of lye water for 15-20 minutes.

Then either brush with a wire brush or clean the gas ports with a sharp-pointed metal

instrument to ensure open ports.

CAUTION: Clean the regulator at least once a month. Make sure the vent opening

is open and not blocked in any way. Failure to do so will cause variations in

pressure. Your unit will not function as well and it could shorten the life of the

product.

SERVICE /REPAIR

NOTE: This appliance must only be serviced by an authorized agent.

NOTE: Parts protected by the manufacturer or his agent are not to be adjusted by the

installer unless the installer is an authorized service agent.

If you have any questions or problems, contact your nearest service representative.

12

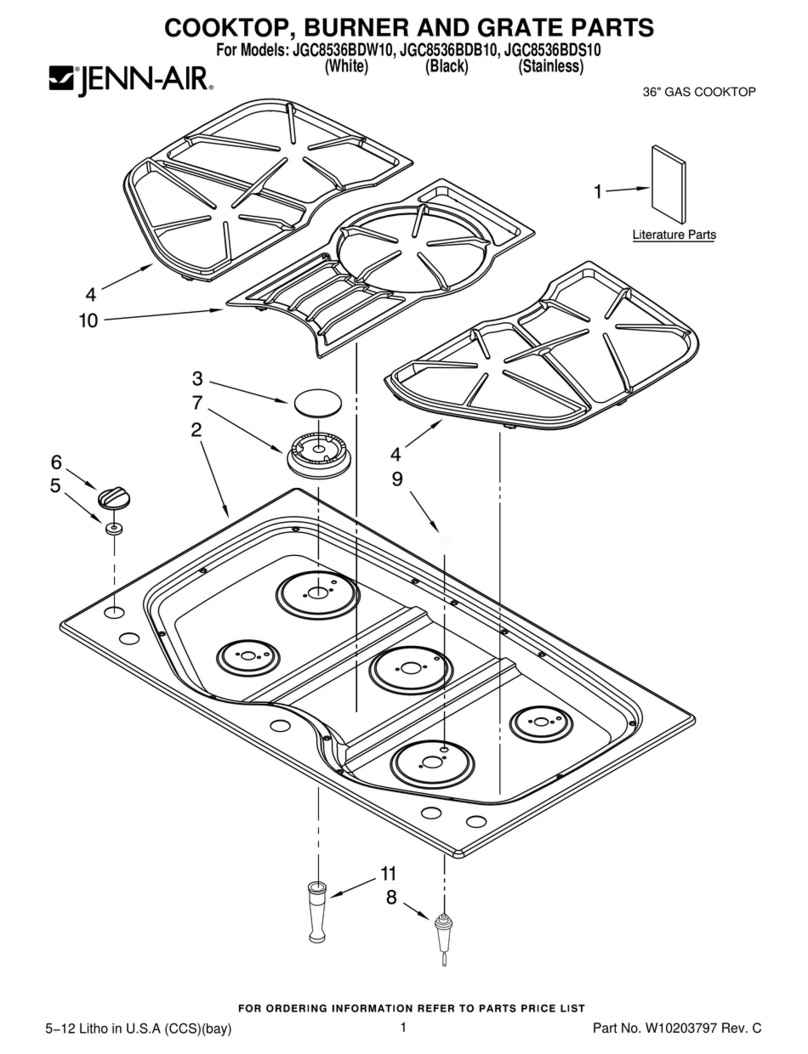

EXPLOSION VIEW DRAWING

MODEL: T-HP636

13

Spare Parts List

NO.

DESCRIPTION

MODEL

CODE

QTY

1

Trivet

HP212M

HP424M

HP636M

01.03.1015043

2

4

6

2

Burner

HP212M

HP424M

HP636M

06.05.1472521

2

4

6

3

Orifice

HP212M-NAT

HP424M-NAT

HP636M-NAT

01.20.1068643

2

4

6

HP212M-LPG

HP424M-LPG

HP636M-LPG

01.20.1068652

2

4

6

4

Regulator

HP212M

HP424M

HP636M

01.22.1069501

1

5

Foot

HP212M

HP424M

HP636M

01.02.1005165

4

6

Tray

HP212M

HP424M

HP636M

01.05.1029410

01.05.1029318

01.05.1029365

1

7

Dial

HP212M

HP424M

HP636M

06.05.1472430

2

4

6

8

Brand

HP212M

HP424M

HP636M

01.02.1005449

1

9

Pilot valve

HP212M

HP424M

HP636M

01.20.1068508

1

2

3

10

Valve

HP212M

HP424M

HP636M

01.20.1068502

2

4

6

11

Main pipe assy.-Rear

HP212M

HP424M

HP636M

06.05.1472523

1

2

3

12

Pilot pipe assy.-Front

HP212M

HP424M

HP636M

06.05.1472180

1

2

3

13

Main pipe assy.-Front

HP212M

HP424M

HP636M

06.05.1472522

1

2

3

14

Pilot pipe assy.-Rear

HP212M

HP424M

HP636M

06.05.1472179

1

2

3

14

For service or inquiry, please

Call Eurodib (toll free) at:

1 888 956 6866

Limited Warranty

Eurodib Cooking Equipment Models:

Griddles: T-G15, T-G24, T-G36, T-G48

Char Broilers: T-CBL15, T-CBL24, T-CBL36, T-CBL48, T-CBR15, T-CBR24,

T-CBR36, T-CBR48

Countertop Range: T-HP212, T-HP424, T-HP636

Fryer: T-CF15, T-CF30

All new Eurodib griddles, char broilers, and hot plates used for commercial purposes are

warranted against defects in materials and workmanship under normal use and maintenance.

The warranty runs for one year from the date of the original installation and is for the benefit

of the original purchaser only. All other warranties, expressed or implied, statutory or

otherwise, including without limitation any implied warranty of merchantability for fitness for

purposes, are excluded. The seller shall in no event be liable for direct, indirect, or

consequential damages in connection with Eurodib commercial products.

Exclusions

The following conditions are not covered by warranty:

Equipment damage or equipment failure occurs because of accident, carelessness,

lack of proper set-up, supervision when required, or if the equipment is installed or

operated in any manner contrary to the installation and operating instructions.

Equipment damage or equipment failure due to improper installation, improper utility

connection or supply, and problems due to ventilation.

Equipment that has not been used appropriately, or has been subject to misuse,

neglect, abuse, accident, alteration, negligence, damage during transit, delivery or

installation, fire, flood, or act of God.

Equipment that has the model number or serial number removed or altered.

Equipment that has been changed, altered, or modified or repaired by other than an

Authorized Service Agency.

Eurodib shall not be held liable for any damages to any person or property, which may result

from the use of the equipment thereafter.

This warranty does not apply to, and Eurodib is not responsible for any warranty claims on

15

products sold or used outside of the contiguous United States.

This equipment is intended for commercial use only. The warranty is void if equipment is

installed for other than commercial applications.

16

PLAQUE DE CUISSON

Instructions d'installation et d'utilisation

Modèles : T-HP212, T-HP424, T-HP636

IMPORTANT

POUR CONSULTATION FUTURE

Prière de fournir ces renseignements et de conserver ce manuel pendant toute la durée de

vie de l'appareil. Pour le service ou les pièces sous garantie, ces renseignements sont

requis.

Numéro de modèle Numéro de série Date de l'achat

AVERTISSEMENT : Pour votre sécurité, ne jamais ranger ni utiliser d'essence, ou

d'autres vapeurs ou liquides inflammables, à proximité de cet appareil ou de tout

autre appareil. Tenir les matières combustibles loin de la zone. (voir la norme

ANSI Z83. 14B, 1991).

AVERTISSEMENT : Toute installation, modification, réparation, tout réglage ou

entretien inapproprié peut occasionner des dommages matériels, des blessures

graves ou la mort. Lire les instructions d'installation, d'utilisation et d'entretien

attentivement avant d'installer ou de réparer cet appareil.

AVERTISSEMENT : Les instructions doivent être affichées dans un endroit bien en vue.

Toutes les mesures de sécurité doivent être prises dans l'éventualité où

l'utilisateur détecte une odeur de gaz. L'information de sécurité peut être obtenue

auprès de votre fournisseur de gaz local.

ATTENTION : Ces modèles sont conçus, fabriqués et vendus pour un usage

commercial seulement. Si ces modèles sont mis à la disposition du grand public,

s'assurer que les mises en garde, les avertissements et les instructions

d'utilisation sont clairement affichés, près de chaque appareil, de sorte que tout

utilisateur de l'appareil l'utilise correctement et ne se blesse pas ou n'endommage pas

l'appareil.

AVERTISSEMENT : Les instructions doivent être affichées dans un endroit bien

en vue. Toutes les mesures de sécurité doivent être prises dans l'éventualité où

l'utilisateur détecte une odeur de gaz. L'information de sécurité peut être obtenue

auprès de votre fournisseur de gaz local.

17

PRESSION DE GAZ

L'appareil et sa vanne d'arrêt individuelle (à être fournie par l'utilisateur) doivent être

débranchés de la canalisation d'approvisionnement en gaz durant toute pression d'essai du

système dont la pression d'essai est égale ou supérieure à 0,5 psi (3,45 kPa).

L'appareil doit être isolé du système de canalisation d'alimentation en gaz par la fermeture de

la vanne d'arrêt manuelle individuelle durant toute pression d'essai du système de

canalisation d'approvisionnement en gaz dont la pression d'essai est égale ou inférieure à

0,5 psi (3,45 kPa).

AVERTISSEMENT : L'entretien et les réparations devraient être effectués par un

représentant autorisé par l'usine.Avant de procéder à tout entretien ou réparation,

contactez votre représentant du service autorisé.

18

TABLE DES MATIÈRES

Félicitations pour l'achat de votre appareil de cuisson commercial Eurodib. Eurodib est fière

de la conception et de la qualité de ses produits. Cet appareil vous procurera une fiabilité

d'utilisation pendant de nombreuses années, à condition de l'utiliser comme prévu, d'en

prendre bien soin et d'en faire l'entretien. Pour obtenir de meilleurs résultats, il est important

de bien lire et suivre les instructions dans ce manuel.

EMPLACEMENT DE LA PLAQUE SIGNALÉTIQUE

La plaque signalétique est située sur le panneau latéral.

VÉRIFIER IMMÉDIATEMENT S'IL Y A DOMMAGES DUS AU TRANSPORT

Tous les contenants devraient être examinés pour déceler des dommages avant et pendant

le déchargement. Le transporteur de marchandises a assumé la responsabilité du transit et

de la livraison indemnes. Dans l'éventualité où l'appareil livré est endommagé (apparent ou

caché), une réclamation doit être effectuée avec le transporteur de marchandises.

1. Un dommage apparent ou une perte doit être indiqué sur la facture de transport au

moment de la livraison. Celle-ci doit être ensuite signée par le représentant du

transporteur (le chauffeur). À défaut de quoi le transporteur peut refuser la

réclamation. Le transporteur peut fournir les formulaires requis.

2. Un dommage caché ou une perte qui n'était pas apparent jusqu'au moment de

déballer l'appareil doit faire l'objet d'une requête d'inspection à soumettre au

transporteur dans un délai de 15 jours. Le transporteur devrait organiser une

inspection. Assurez-vous de conserver tout le contenu et le matériel d'emballage.

L'installation et l'entretien devraient être effectués par un installateur qualifié qui a lu,

comprend et suit attentivement ces instructions.

Si vous avez des questions au sujet de l'installation, de l'utilisation, de l'entretien ou du

service de ce produit, veuillez écrire à Eurodib.

ARTICLE

PAGE

ARTICLE

PAGE

Mesures de sécurité

4

Nettoyage et entretien

11

Instructions d'installation générales

5

Service/Réparation

12

Spécifications et dimensions

6

Vue éclatée

13

Conversion

6

Liste des pièces de rechange

14

Instructions d'allumage

10

Garantie limitée

16

19

MESURES DE SÉCURITÉ

DANGER : Ce symbole signale un danger imminent pouvant entraîner des

blessures graves ou la mort.

AVERTISSEMENT : Ce symbole désigne un risque potentiel ou une pratique

dangereuse pouvant entraîner des blessures graves ou la mort.

ATTENTION : Ce symbole désigne un risque potentiel ou une pratique

dangereuse pouvant entraîner des blessures mineures ou modérées, ou des

dommages au produit ou à la propriété.

AVIS : Ce symbole désigne l'information nécessitant une attention particulière ou

devant être entièrement comprise, malgré l'absence de danger.

AVIS : Ce produit est destiné à un usage commercial seulement. Ce produit n'est

pas destiné à un usage domestique.

AVIS : Les normes locales concernant l'installation changent considérablement

d'un secteur à l'autre. National Fire Protection Association, Inc., déclare dans sa

dernière édition NFPA96 que les normes locales relèvent des « autorités

compétentes » en ce qui a trait aux conditions d'installation d’appareils. Par conséquent,

l'installation doit être conforme à toutes les normes locales.

INSTRUCTIONS D'INSTALLATION GÉNÉRALES

Assurez-vous que l'approvisionnement en gaz et le type de gaz concordent, comme l'indique

la plaque signalétique de l'appareil.

L'installation de l'appareil doit être conforme au National Fuel Gas Code, ANSI Z223.1/NFPA

54, au National Gas Installation Code, CSA-B149.1 ou au Propane Installation Code,

CSA-B149.2, selon le cas et conformément aux normes locales.

Visser les pattes dans les écrous fixes se trouvant aux quatre coins de l'appareil et serrer à la

main. Niveler l'appareil en tournant la vis de réglage au bas de chaque patte. Ne pas glisser

l'appareil avec les pattes fixées; soulever pour déplacer l'appareil au besoin.

Le composé pour filetage doit résister à l'action des gaz de pétrole liquéfiés.

ATTENTION : NE JAMAIS employer une flamme nue pour déceler des fuites. Examiner

toutes les conduites de gaz pour déceler des fuites avec une solution de savon et d'eau

avant d'utiliser l'appareil.

20

CES APPAREILS DOIVENT ÊTRE INSTALLÉS UNIQUEMENT SUR DES SURFACES NON

COMBUSTIBLES.

Espaces de dégagement pour les matières combustibles :

6 po des côtés (152 mm) 6 po de l'arrière (152 mm) 4 po du sol (102 mm)

Espaces de dégagement pour les matières non combustibles :

0 po des côtés (0 mm) 0 po de l'arrière (0 mm) 4 po du sol (102 mm)

Ne pas obstruer le débit de l'air de combustion ou de ventilation sous l'appareil près des

pattes, ou derrière l'appareil près du conduit d'air.

Un espace de dégagement adéquat est requis pour les ouvertures d'aération dans la

chambre de combustion. Ne pas placer d'objets entre le bas de l'appareil et le plan de travail.

Un espace de dégagement adéquat est requis pour retirer le panneau frontal. Toutes les

pièces principales (sauf les brûleurs) sont amovibles par la partie frontale si la conduite de

gaz est déconnectée.

SPÉCIFICATIONS ET DIMENSIONS

MODÈLE

LARGEUR

EN PO

(MM)

PROFONDEUR

EN PO (MM)

HAUTEUR

EN PO

(MM)

NBRE DE

BRÛLEURS

BTU/PAR

GN/PL

TOTA

L

BTU/

h

CE

PO

T-HP212

12 (305)

29,2 (741)

18,7 (475)

1

30 000

60 000

6/10

T-HP424

24 (610)

29,2 (741)

18,7 (475)

2

30 000

120 000

6/10

T-HP636

36 (915)

29,2 (741)

18,7 (475)

3

30 000

180 000

6/10

Remarque : Le sens de la profondeur comprend la dimension du régulateur.

This manual suits for next models

2

Table of contents

Languages:

Popular Cooktop manuals by other brands

IKEA

IKEA w10297312b Use & care guide

Miele

Miele KM 5820 Operating and installation instructions

Capital

Capital Precision Series GSCR486Q Specifications

Falcon

Falcon Elise 100 Induction G5 User's guide & installation instructions

Kenmore

Kenmore C970 Series Use & care guide

Bestron

Bestron AHP212D instruction manual