4

Contents

Abbreviations ................................................................................................................................ 3

Safety Information ....................................................................................................................... 5

Personal Protective Equipment / Installation Tools ........................................................... 6

Unboxing the Battery .................................................................................................................. 6

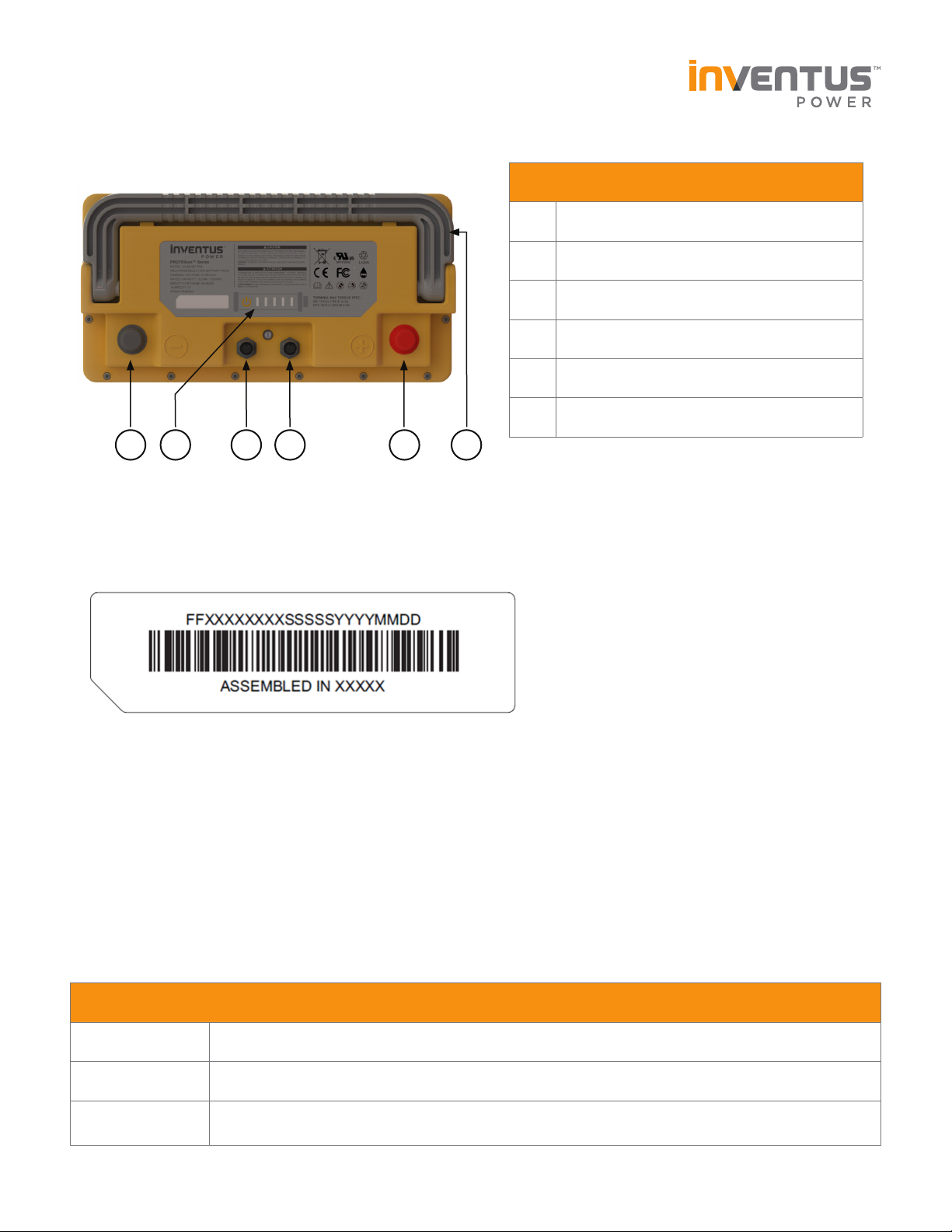

Mechanical Features .................................................................................................................... 7

Battery Serial Number Format ................................................................................................. 7

Product Dimensions .................................................................................................................... 7

Wake-Up & Ship Mode ................................................................................................................ 8

Selecting Power Cables .............................................................................................................. 9

Communication Cables ............................................................................................................... 9

Selecting a Battery Charger .................................................................................................... 10

Connecting the Battery ............................................................................................................. 11

Battery Terminal Torque Rating .............................................................................................. 11

Module Configuration ................................................................................................................ 12

Communications .......................................................................................................................... 13

Pin Definition ............................................................................................................................... 14

Battery Modes............................................................................................................................... 15

Battery State of Charge Indicator .......................................................................................... 16

Heater Operation ......................................................................................................................... 16

Disconnecting the Battery ........................................................................................................ 17

Battery Specifications ................................................................................................................ 17

Battery Performance Data ........................................................................................................ 18

Maintenance, Storage, and Disposal ..................................................................................... 20

Transporting Lithium-ion Batteries ........................................................................................ 21

Emergency and First Aid Procedures ................................................................................... 23

Troubleshooting ......................................................................................................................... 24

Serial Number Record ............................................................................................................... 25

Warranty Violations ................................................................................................................... 26

Recycling ...................................................................................................................................... 27

Technical Support ...................................................................................................................... 27