TABLE OF CONTENTS

Overview .................................................................................................................... 2

Sequence of Operation ............................................................................................... 2

Design and Installation Guidelines .............................................................................. 2

ZP6-ESP-PRO Panel Layout .............................................................................................3

System Wiring .......................................................................................................... 4-8

Warning! ........................................................................................................... 4

Caution! ............................................................................................................ 4

System Power .................................................................................................... 4

HVAC System .................................................................................................... 4

Heat/Cool ............................................................................................... 4

Heat Pump .............................................................................................. 4

DS/BK Option .......................................................................................... 5

HUM Option ........................................................................................... 5

DHUM Option ......................................................................................... 5

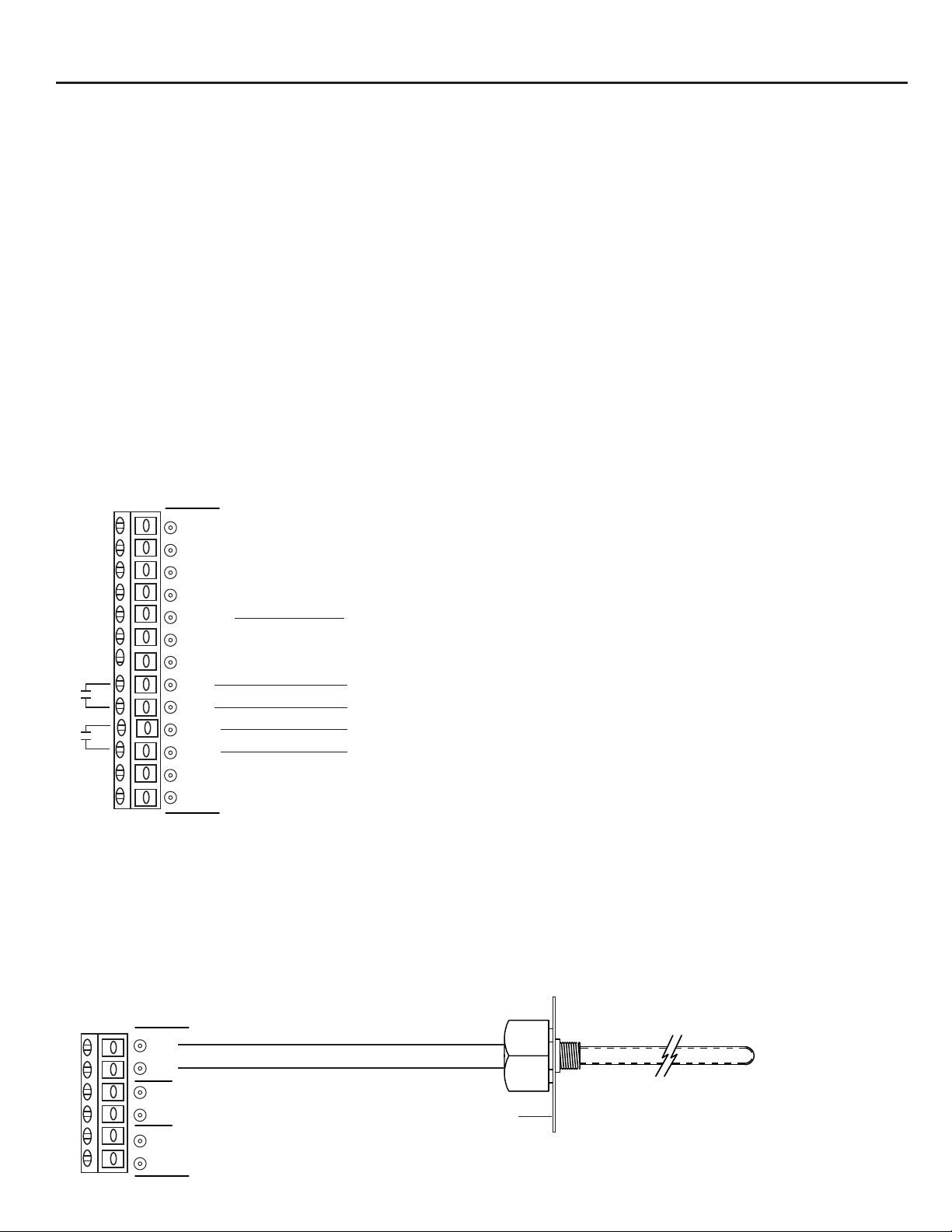

Sensors .......................................................................................................... 5-6

Discharge Air Sensor .............................................................................. 5

Return Air Sensor .................................................................................... 6

Outdoor Air Sensor ................................................................................. 6

Night Stat Option .............................................................................................. 6

Fault Terminals .................................................................................................. 7

Zone Thermostats ........................................................................................... 7-8

Heat/Cool ............................................................................................ 7

Heat Pump ........................................................................................... 7-8

Zone Dampers .......................................................................................... 8

SPS Terminals.............................................................................................9

How ESP Works................................................................................9

Adding 3-Zone Expansion Panels................................................................................ 10

Panel Setup ......................................................................................................... 11-12

Switch Congurations ...................................................................................... 11

System Conguration ............................................................................ 11

Capacity Control .................................................................................. 12

DS/BK Control ..................................................................................... 12

Graphic Display Module ........................................................... 12

Setting High Limit ........................................................................ 12

Setting Low Limit ......................................................................... 13

Setting High Balance Point .......................................................... 13

Setting Low Balance Point ........................................................... 14

Upstage Timer Option ................................................................. 14

Selecting ESP Zones .......................................................................15

Panel LED Denitions and Functions ........................................................... 16-17

Panel Time Delays ..................................................................................................... 17

Optional Night Stat Setup and Scheduling ............................................................ 18-19

Overview ...................................................................................................... 18

How It Works ................................................................................................... 18

Recommended Setup ....................................................................................... 18

System Switch Settings ..................................................................................... 18

Installer Setup Menu Changes ......................................................................... 18

Setting the Clock and Day of Week .................................................................. 19

Daylight Saving Time ....................................................................................... 19

Programming Events ................................................................................... 19-20

Typical 7-Day Schedule .................................................................................. 20

Notes ........................................................................................................................ 21

1