2.8.3 Z-method Installation ----------------------------------------------------------------------16

2.8.4 W-method Installation ---------------------------------------------------------------------17

2.8.5 N-method Installation ----------------------------------------------------------------------17

2.9 Installation Checkup --------------------------------------------------------------------------17

2.9.1 Signal Strength -------------------------------------------------------------------------------17

2.9.2 Signal Quality ---------------------------------------------------------------------------------18

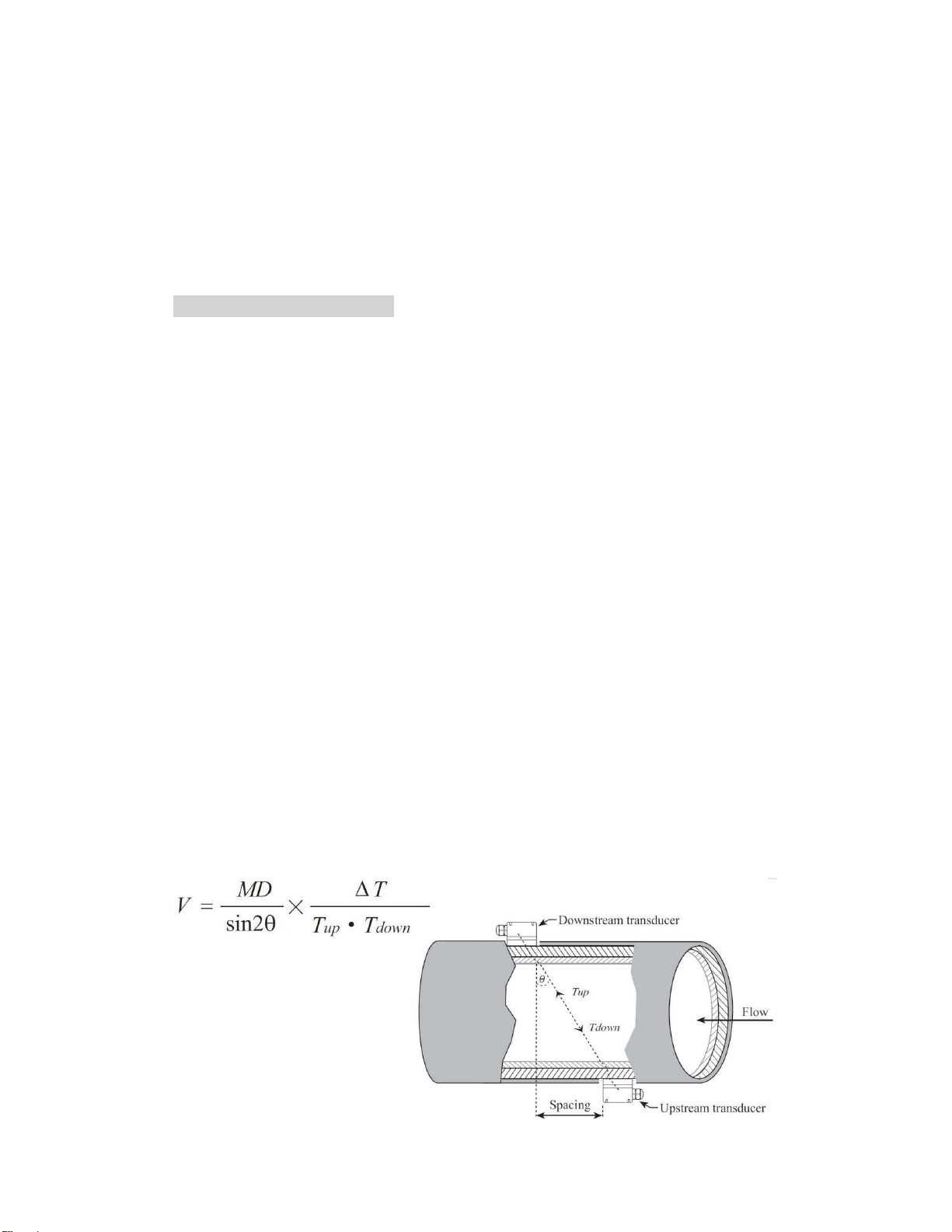

2.9.3 Total Transit Time and Delta Time -------------------------------------------------------18

2.9.4 Time Ratio between the Measured Total Transit Time and the Calculated Time

------------------------------------------------------------------------------------------------------------19

3. How To ----------------------------------------------------------------------------------------------19

3.1 How to judge if the instrument works properly ----------------------------------------19

3.2 How to judge the liquid flowing direction -----------------------------------------------19

3.3 How to change between measurement units-------------------------------------------19

3.4 How to select a required flow rate unit --------------------------------------------------20

3.5 How to use the totalizer multiplier --------------------------------------------------------20

3.6 How to open or shut the totalizers --------------------------------------------------------20

3.7 How to reset the totalizers ------------------------------------------------------------------20

3.8 How to restore the flow meter with default setups -----------------------------------20

3.9 How to use the damper ----------------------------------------------------------------------20

3.10 How to use the zero-cutoff function ----------------------------------------------------20

3.11 How to setup a zero point -----------------------------------------------------------------21

3.12 How to get a scale factor for calibration ------------------------------------------------21

3.13 How to use the operation locker ---------------------------------------------------------21

3.14 How to use the built-in data logger ------------------------------------------------------21

3.15 How to use the Frequency Output -------------------------------------------------------22

3.16 How to use the Totalizer Pulse Output --------------------------------------------------

22

3.17 How to produce an alarm signal ----------------------------------------------------------

23

3.18 How to use the built-in Buzzer ------------------------------------------------------------24