IonSense DART-Thermo LTQ User manual

DART-Thermo LTQ/Orbitrap Interface

Manual

For Thermo LTQ (Orbitrap) Velos, LTQ Orbitrap XL, LTQ

Ion Trap, Exactive High Performance, and all other

instruments that utilize the Ion Max Source

Version 20120423

IonSense Inc.

999 Broadway

Suite 404

Saugus, MA 01906

2

Thermo Ion Max—DART Interface Manual

Copyright © 2005-2010 by

IonSense Inc.

All rights reserved.

The information in this document has been carefully checked and is believed to be

reliable. However, no responsibility is assumed for inaccuracies. Statements in the

document not intended to create any warranty, expressed or implied. Specification and

performance characteristics of the hardware and software described in the manual may be

changed at any time without notice. IonSense Inc. reserves the right to make changes in

any product herein in order to improve reliability, design, or function. IonSense does not

assume any liability arising out of application or use of any product or circuit described

nor does it cover any license under its patent rights or the rights of others.

The apparatus and application of the apparatus described in this document is protected by

US Patent Number 6,949,741 and used under license; additional patents pending.

All trademarks are properties of their respective owners.

3

Thermo Ion Max—DART Interface Manual

This manual details the steps necessary to install a DART source on a Thermo LTQ Ion

Trap or Orbitrap Instrument.

Table of Contents

1. Diagram of the Thermo Source Region

2. Attaching the DART Flange to the Instrument

a. Adjusting the Exactive Side Brackets

3. Vacuum Issues

4. Optimal Parameters

4

Thermo Ion Max—DART Interface Manual

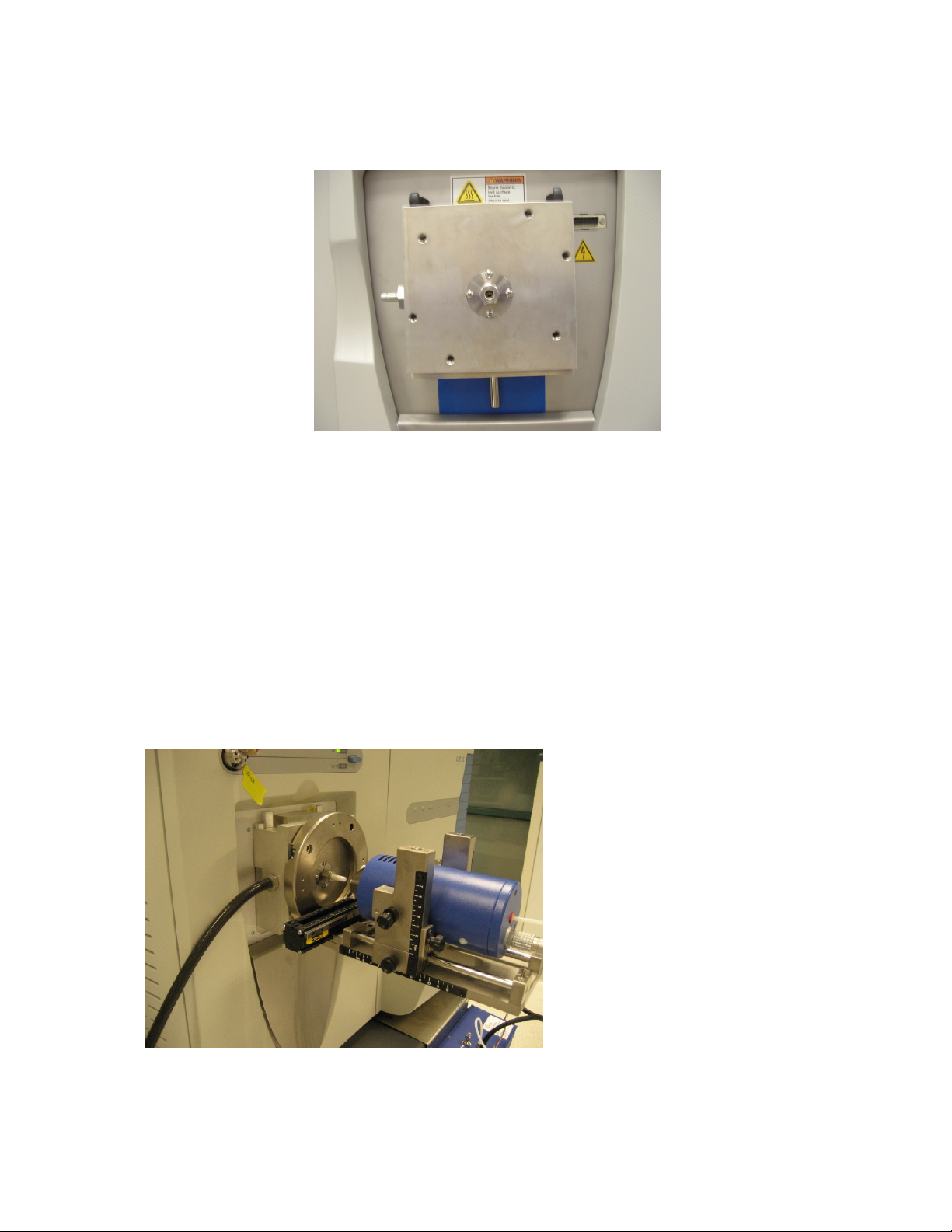

Diagram of the Thermo Source Region and Interface

Disconnect the waste hose from the

bottom of the Ion Max source, as well as

all gas, syringe, and voltage connections.

Carefully remove the Ion Max source

from the Mass Spectrometer interface

and place it aside in a safe place.

Remove the Thermo ion sweep cone as

shown in the photo above – this is the

removable spray shield that sits over the

capillary. Using a small flat-head screw

driver, loosen the set screws on the sides of

the spray shield. Caution: the shield may

be hot.

Pictured to the left is the source region with

the Thermo ion sweep cone removed.

5

Thermo Ion Max—DART Interface Manual

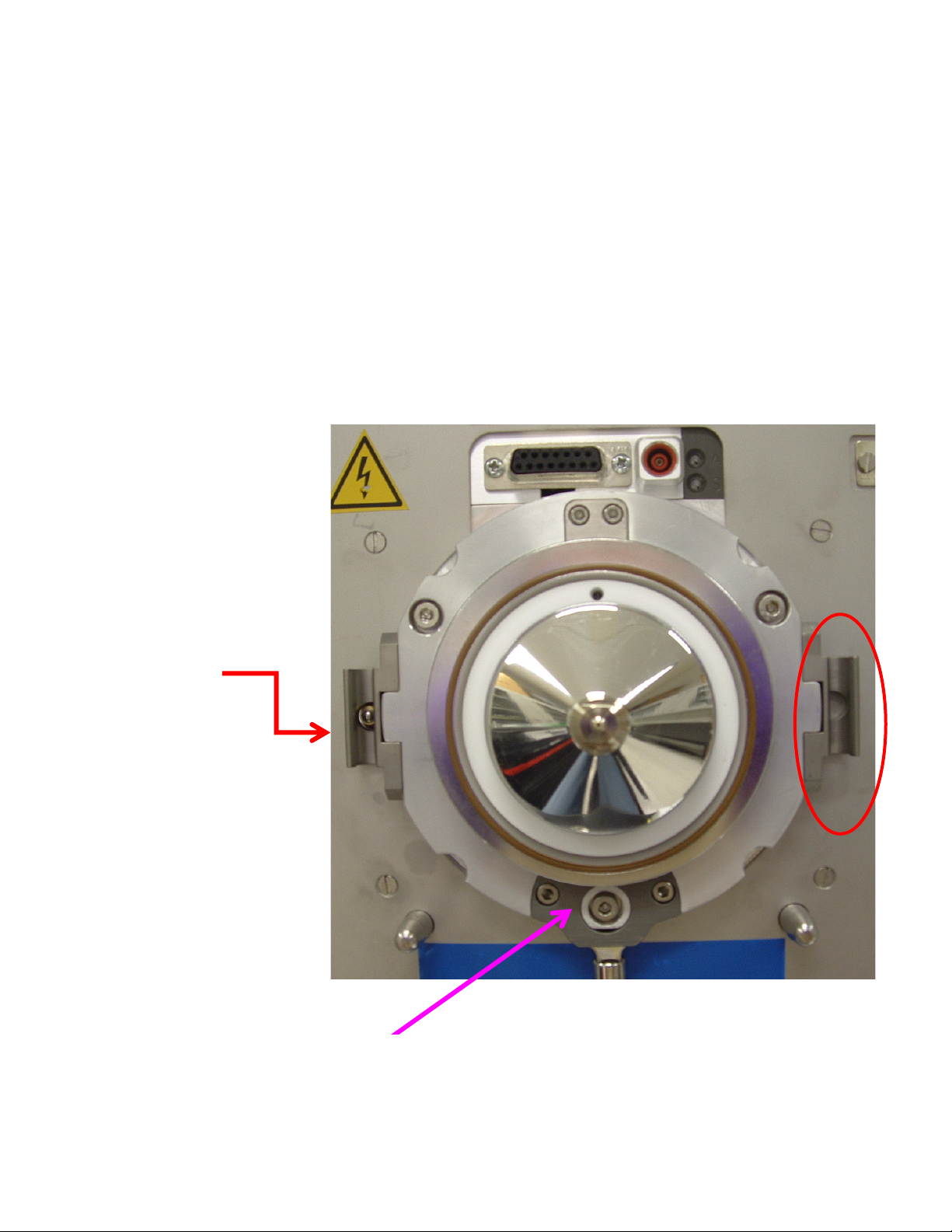

Adjusting the Side Brackets on the Thermo Exactive

Instrument

• The side brackets (circled in red in the picture below) need to be adjusted before

mounting the IonSense SI-140-GIST Vapur interface flange to an Exactive.

– The side brackets on the Exactive and LTQ need to be set 0.2 - 0.3 mm out

from the front metal surface around the API inlet.

• In general these brackets are set flush with the metal surface around the API inlet

as a default position.

• The Thermo ESI source will fit properly even with the changed positioning of the

side brackets.

• The side brackets on the

Exactive and LTQ need

to be adjusted so that

the front surface of the

brackets measures 0.2 –

0.3 mm from the front

metal surface around

the API inlet.

• The brackets are to be

moved away from the

mass spectrometer and

towards the installation

engineer.

Note: The Thermo spray shield is

also removed before mounting the

IonSense Vapur interface flange.

6

Thermo Ion Max—DART Interface Manual

Attaching the DART Flange to the Instrument

Attach the IonSense flange to the source by matching the lock bars with the slots on the

side and then locking them on the top by turning the knobs simultaneously until they are

facing at least 45 degrees from the side plane of the flange.

Insert the ceramic tube into the Swagelok nut on the end of the VAPUR attachment and

secure it with the graphite ferrule. Take care that there is a 2mm gap inside the VAPUR

between the end of the ceramic tube and the protruding end of the Agilent capillary.

This ensures that the excess helium gas will be evacuated and maintain proper vacuum in

the instrument.

Then, attach the DART either by 1) attaching the large front ring of the DART to the

holes on the front of the flange, or 2) by screwing the base of the DART into the two

holes on the bottom of the flange.

Attach the black silicone rubber

tubing to the port on the left side

of the flange.

Finally, attach the DART source

to the flange.

Figure: The DART is shown attached to the flange using the screws in the front ring.

7

Thermo Ion Max—DART Interface Manual

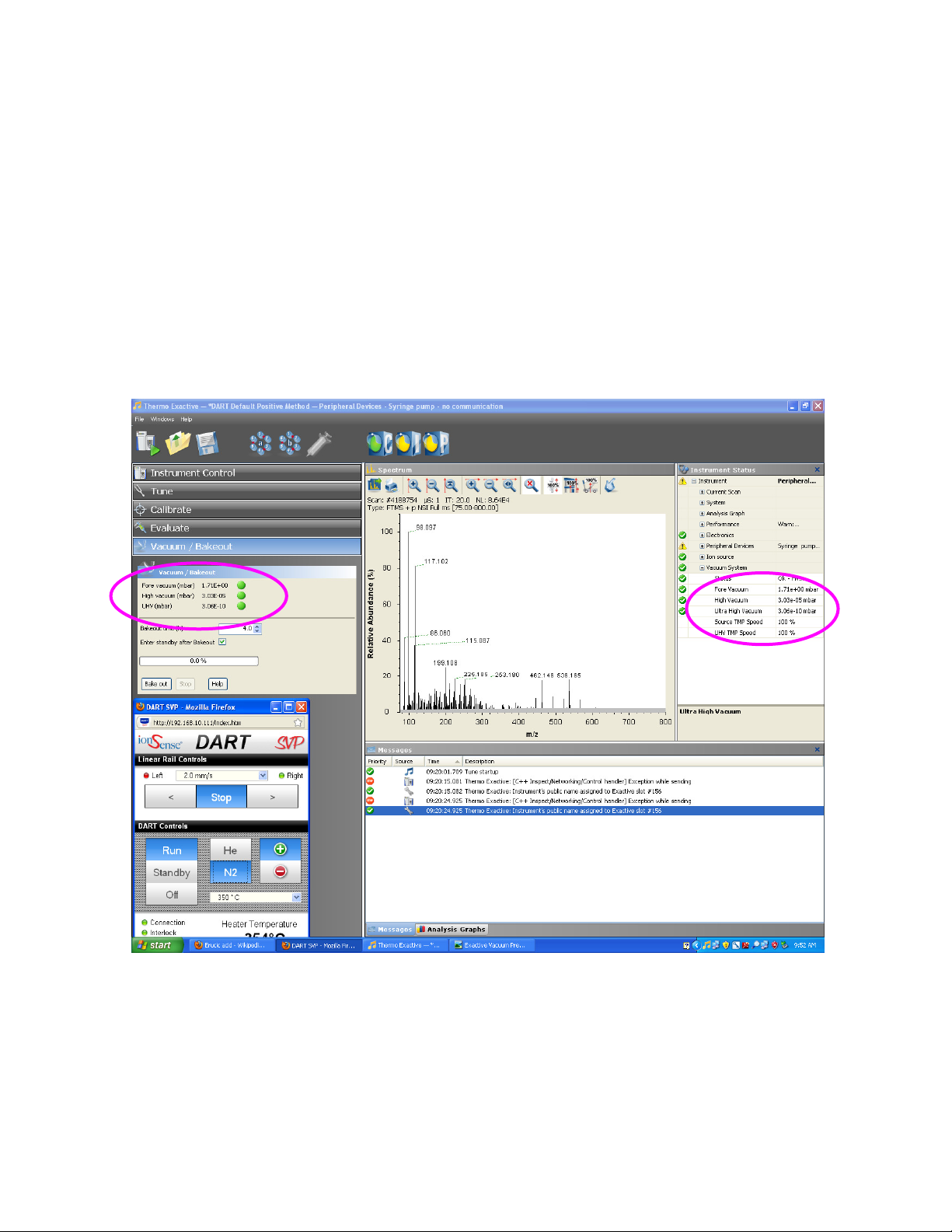

Monitoring Vacuum Levels

Use of the DART will increase the vacuum level in your instrument due to the amount of

helium being pushed into the instrument. It will not, however, harm the mass

spectrometer or cause it to function differently. Below is a printout showing what the

Thermo Exactive’s vacuum levels should be during operation. If your vacuum levels

exceed this amount, call IonSense and ask to speak with the Service Department.

Stable vacuum pressure read back values for the Exactive.

• N

2

is running through the DART source for this screen shot.

• UHV reading will rise to ~ 8-9 E-10 mbar when operating the DART with

He, but is still stable.

• The threshold where the UHV will fail is at 1.26 E-9 mbar.

8

Thermo Ion Max—DART Interface Manual

Optimal Parameters

IonSense recommends using the following operational settings:

• Scan Parameters:

• Scan Settings: 1 µ-scan by 250 ms max inject time

• AGC Target: Balanced (1e

6

)

• Inlet Parameters:

• Capillary Temp: 200° C 200° C

• Capillary Voltage: 25 V - 50 V

• Tube Lens Voltage: 120 V -120 V

• Skimmer Voltage: 26 V -25 V

• The following Source Parameters are set to zero:

• Sheath Gas Flow, Aux Gas Flow, Sweep Gas Flow.

• For all ID-CUBE experiments the Spray Voltage was set to 1 kV.

This manual suits for next models

1

Table of contents