MANUAL •Subject to alteration! Version: June 2016

ipf electronic gmbh

•Rosmarter Allee 14 •58762 Altena

│

Tel +49 2351 9365-0 •Fax +49 2351 9365-19

│

INDEX

1. GENERAL INFORMATION......................................................................................1

1.1. General Description of the safety light curtains ........................................................3

1.1.1. Package contents.....................................................................................................4

1.2. How to choose the device ........................................................................................5

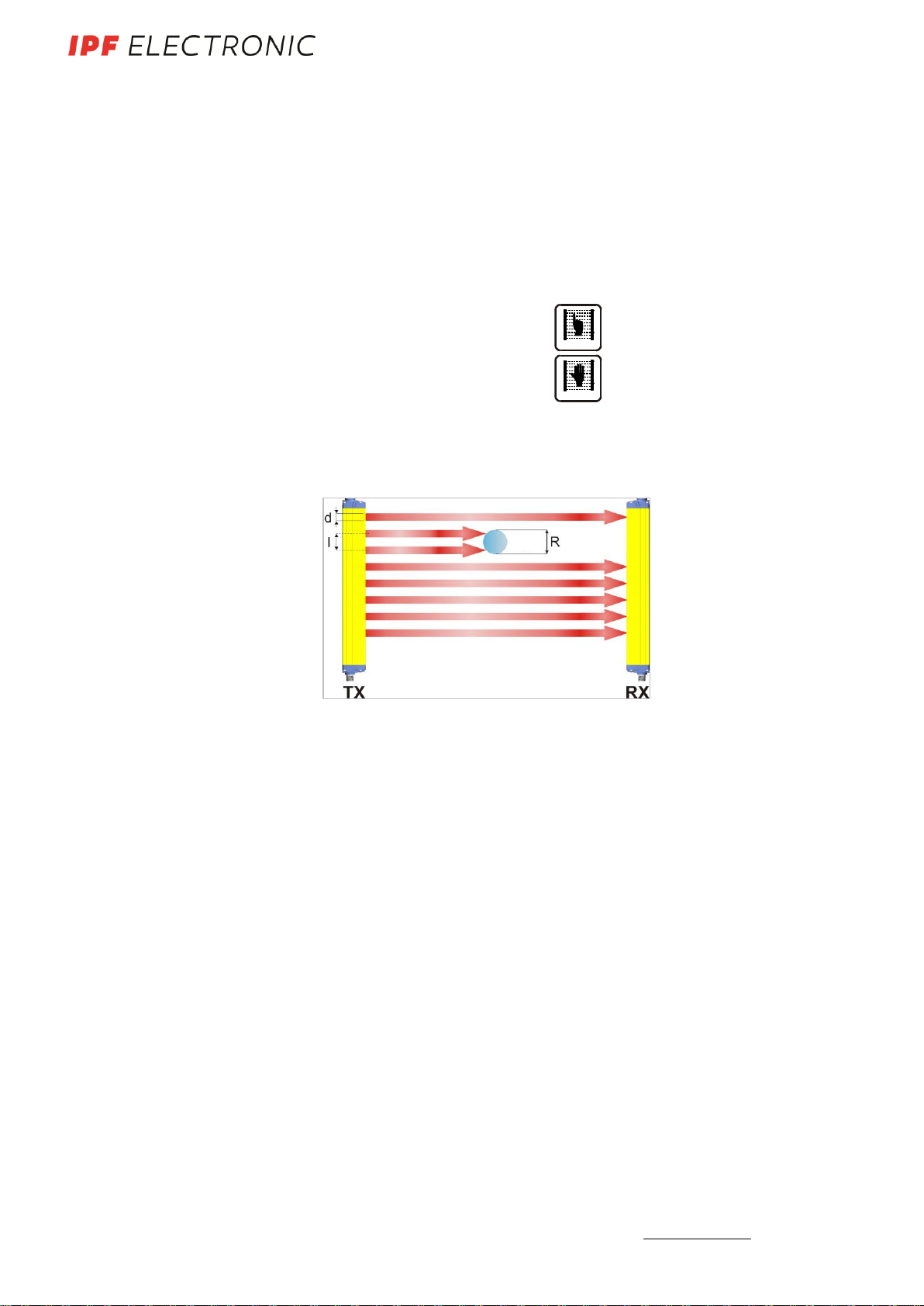

1.2.1. Resolution................................................................................................................5

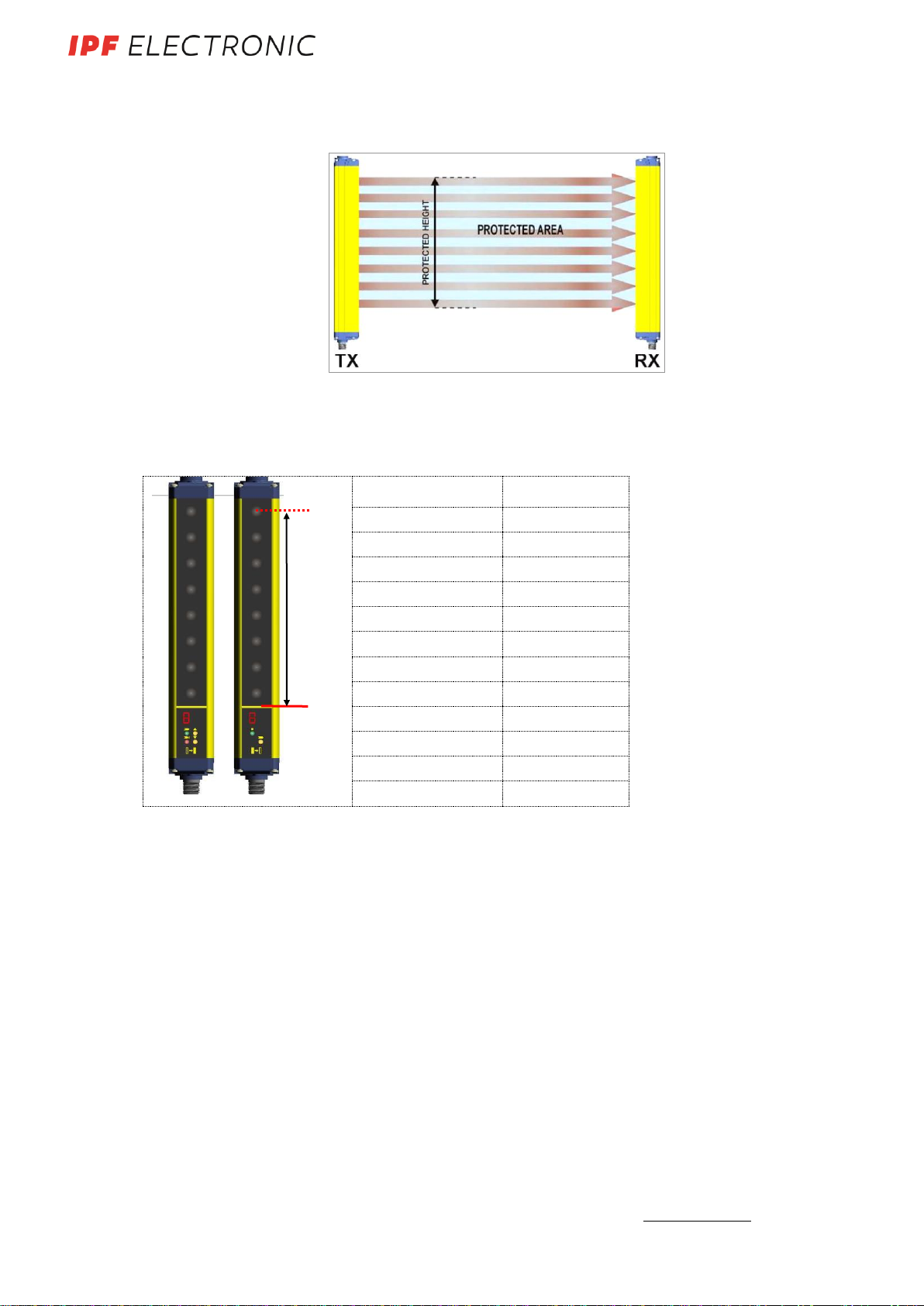

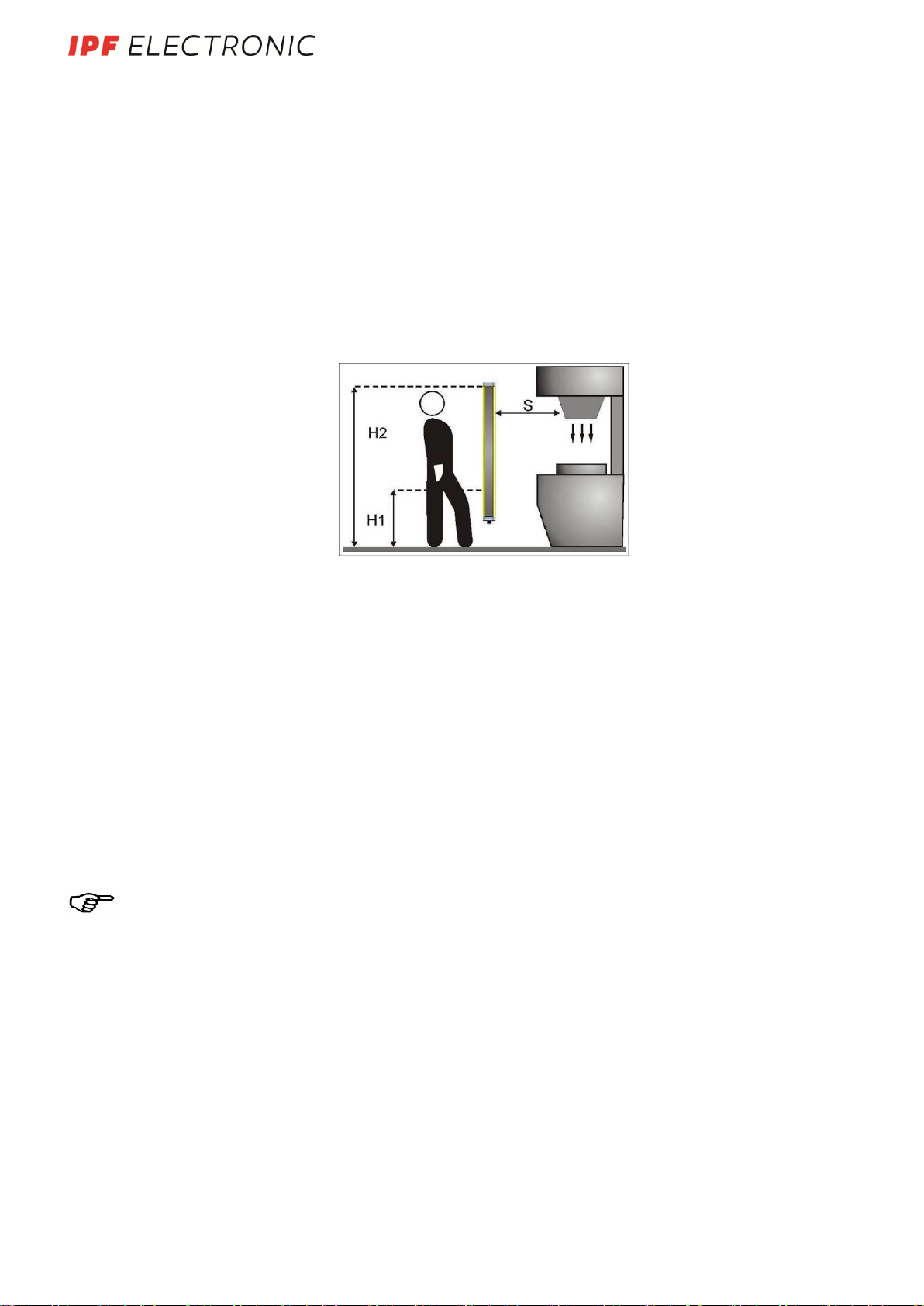

1.2.2. Controlled height......................................................................................................6

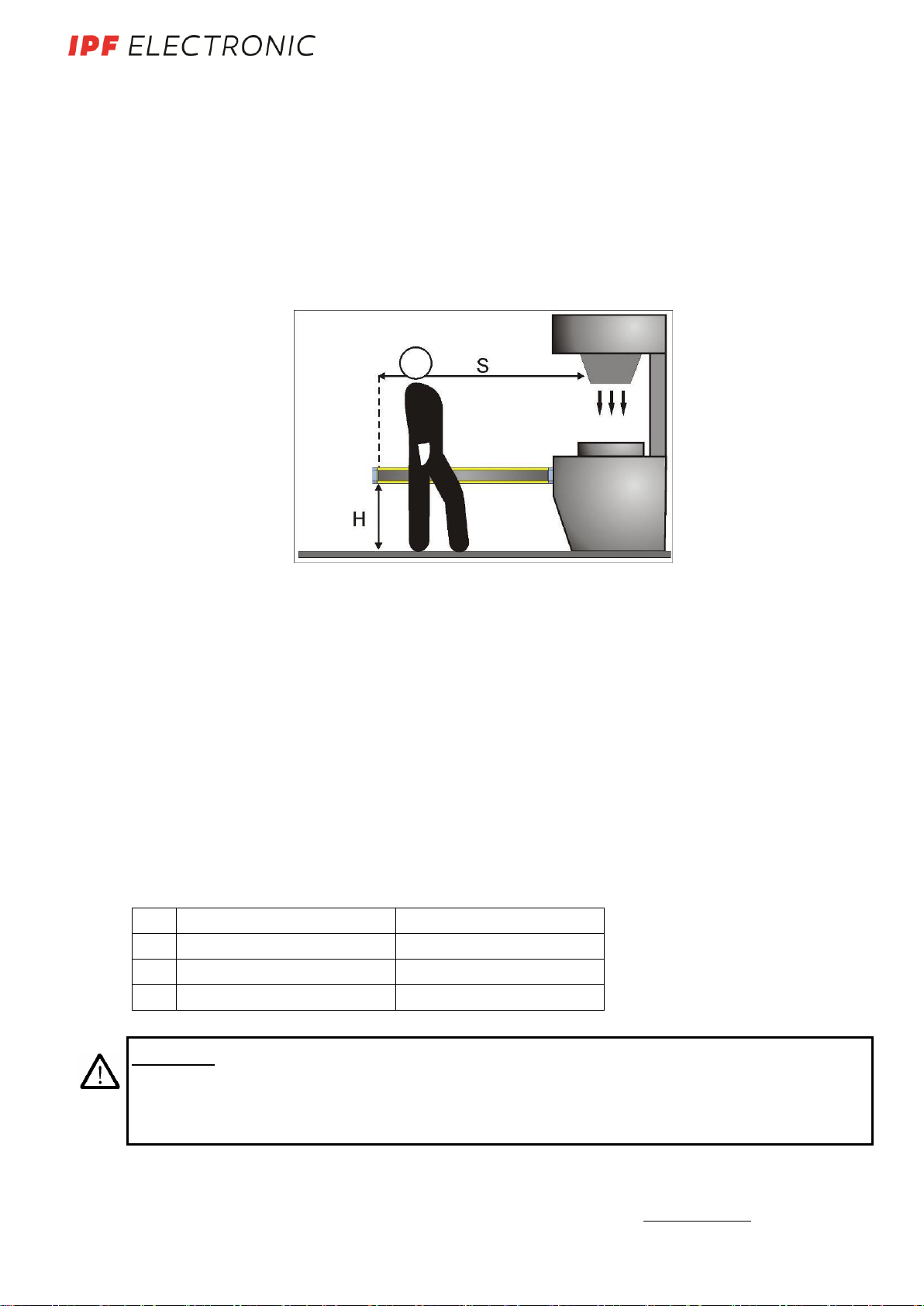

1.2.3. Minimum installation distance...................................................................................7

1.3. Typical applications..................................................................................................9

1.4. Serial Number ........................................................................................................11

1.5. Safety information ..................................................................................................11

2. INSTALLATION MODE............................................................................................9

2.1. Precautions to be observed for the choice and installation.......................................9

2.2. General information on device positioning..............................................................10

2.2.1. Minimum installation distance.................................................................................10

2.2.2. Minimum distance form reflecting surfaces ............................................................11

2.2.3. Distance between homologous devices..................................................................13

2.2.4. Emitter and receiver orientation..............................................................................19

2.2.5. Use of deviation mirrors .........................................................................................19

2.2.6. Controls after first installation.................................................................................21

3. MECHANICAL MOUNTING...................................................................................24

4. ELECTRICAL CONNECTIONS..............................................................................24

4.1. Notes on connections.............................................................................................25

4.2. Ground connection.................................................................................................27

5. ALIGNMENT PROCEDURE...................................................................................28

5.1. Correct alignment procedure..................................................................................29

6. FUNCTIONING MODE...........................................................................................31

6.1. Restart mode..........................................................................................................31

6.2. Test function...........................................................................................................32

6.3. Reset function........................................................................................................32

6.4. EDM-Function ........................................................................................................33

6.5. Alignment and function...........................................................................................34

7. DIAGNOSTIC FUNCTIONS ...................................................................................35

7.1. User interface.........................................................................................................35

7.2. Diagnostic messages.............................................................................................36

8. PERIODICAL CHECKS .........................................................................................39

8.1. General information and usefull data......................................................................39

8.2. Warranty ................................................................................................................40

9. DEVICE MAINTENANCE.......................................................................................41

9.1. Product disposal.....................................................................................................41

10. TECHNICAL DATA................................................................................................42

11. LIST OF AVAILABLE MODELS ............................................................................43

12. OVERALL DIMENSIONS.......................................................................................45

13. OUTFIT..................................................................................................................46

13.1. Angled fixing bracket mounting ..............................................................................47

13.2. Test pieces.............................................................................................................47

14. ACCESSOIRES .....................................................................................................48

15. GLOSSARY...........................................................................................................54

16. EC-DECLARATION OF CONFORMITY.................................................................57