6

General Work Products LLC | 6000 Jefferson Hwy | Harahan, LA 70123 www.PalmerSafetyUS.com

•Fall Protection •Training •Netting •PPE

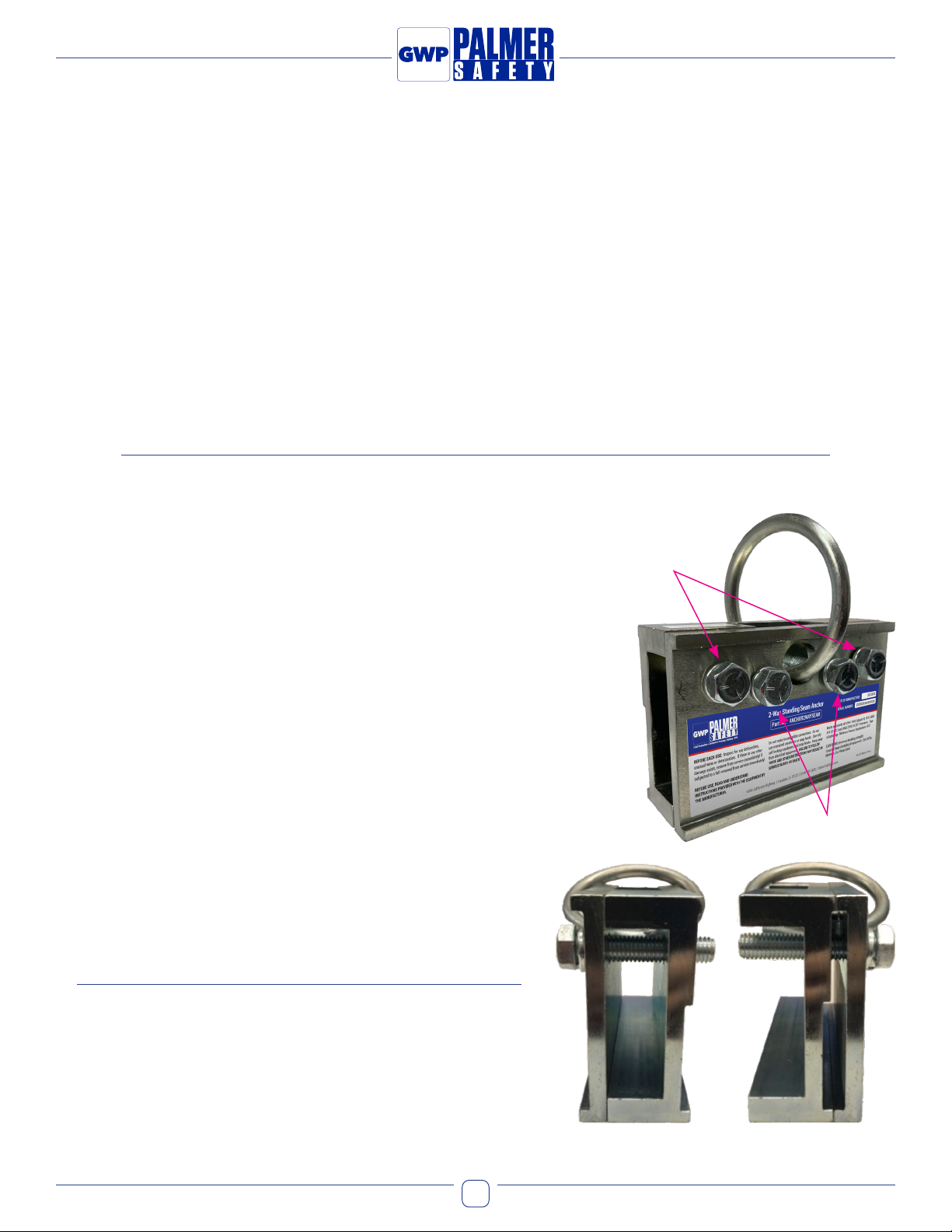

Product Components and Labels

A. Lock Washers, 4 pieces

B. O-Ring

C. Large Bracket

D. Narrow Bracket

E. Bolts, 4 pieces

6000 Jefferson Highway | Harahan, LA 70123 | (504) 733-1808 | PalmerSafetyUS.com

BEFORE EACH USE: Inspect for any deformities,

unusual wear or deterioration. If these or any other

damage exists, remove from service immediately! If

subjected to a fall removed from service immediately!

BEFORE USE, READ AND UNDERSTAND

INSTRUCTIONS PROVIDED WITH THE EQUIPMENT BY

THE MANUFACTURER.

Do not make incompatible connections. Do not

use oversized carabiners or snap hooks. Use only

self locking carabiners and snap hooks. Keep away

from electrical equipment. FAILURE TO FOLLOW

THESE AND OTHER INSTRUCTIONS MAY RESULT IN

SERIOUS INJURY OR DEATH.

Meets or exceeds all OSHA 1926 Subpart M, 1910, ANSI

A10.32-2012 and ANSI Z359.18-2017 standards. Type

A Anchorage. Minimum Service Temperature -30°F.

5,000 lb MBS (minimum breaking strength)

Capacity Range (including all equipment): 130-310 lbs.

Materials: Aluminum and Zinc Plated Steel

DATE OF MANUFACTURE:

SERIAL NUMBER:

2-Way Standing Seam Anchor

Part No.: ANCHORW2AYSEAMEX

Rev. B | Made in China

XX/XXXX

XXXXXXXXXXXXXXXX

6000 Jefferson Highway | Harahan, LA 70123 | (504) 733-1808 | PalmerSafetyUS.com

BEFORE EACH USE: Inspect for any deformities,

unusual wear or deterioration. If these or any other

damage exists, remove from service immediately! If

subjected to a fall removed from service immediately!

BEFORE USE, READ AND UNDERSTAND

INSTRUCTIONS PROVIDED WITH THE EQUIPMENT BY

THE MANUFACTURER.

Do not make incompatible connections. Do not

use oversized carabiners or snap hooks. Use only

self locking carabiners and snap hooks. Keep away

from electrical equipment. FAILURE TO FOLLOW

THESE AND OTHER INSTRUCTIONS MAY RESULT IN

SERIOUS INJURY OR DEATH.

Meets or exceeds all OSHA 1926 Subpart M, 1910, ANSI

A10.32-2012 and ANSI Z359.18-2017 standards. Type

A Anchorage. Minimum Service Temperature -30°F.

5,000 lb MBS (minimum breaking strength)

Capacity Range (including all equipment): 130-310 lbs.

Materials: Zinc Plated Steel.

DATE OF MANUFACTURE:

SERIAL NUMBER:

Rev. B | Made in China

2-Way Standing Seam Anchor

Part No.: ANCHOR2WAYSEAM

XX/XXXX

XXXXXXXXXXXXXXXX

Product Specications

Maximum 1 connection per anchor.

Worker Weight Range: 130-310 lbs. including all tools and equipment

Minimum Breaking Strength: 5,000 lbs.

Materials:

ANCHOR2WAYSEAM: Zinc Plated Steel

ANCHOR2WAYSEAMEX: Zinc Plated Steel and Aluminum

Weight: ANCHOR2WAYSEAM - 7 lbs. | ANCHOR2WAYSEAMEX - 3 lbs.

A

B

D

C

E