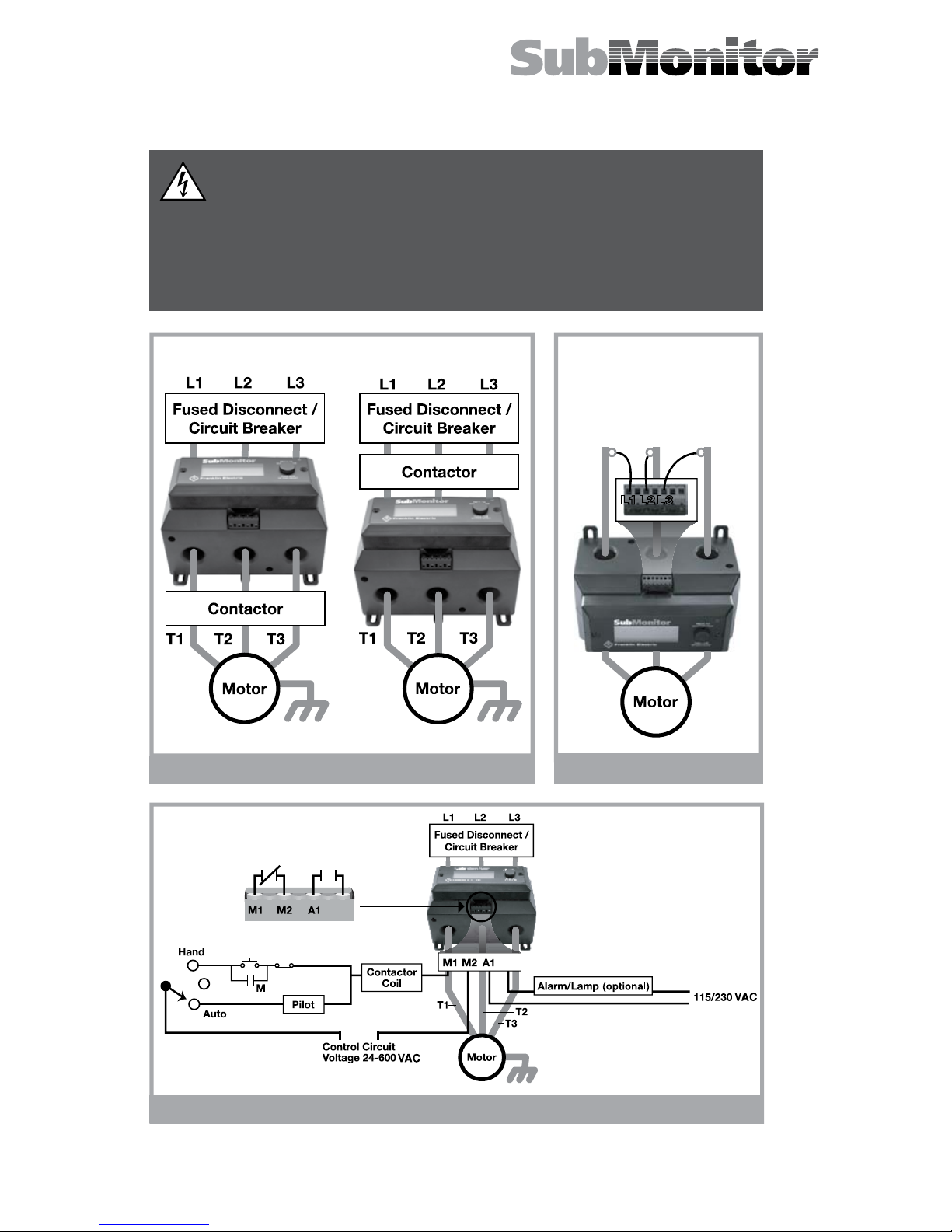

SubMonitor Wiring

1. Read this section of the manual thoroughly.

2. Disconnect power & verify that power is off before installing SubMonitor.

3. Install SubMonitor as illustrated in the wiring diagram in Figure 1.

SubMonitor may be mounted above or below the contactor as shown.

To use the DIN rail mount, rst attach the DIN rail clip to the bottom of

the base unit. Then secure the SubMonitor to the DIN rail. Attach the top

rail rst, then apply downward pressure until the bottom rail snaps into

place.

4. Connect three phase power leads to the plug-in connector L1, L2, and

L3 terminals as shown in Figure 2. Wire strip length is 5/16” (8mm).

The L1, L2, L3 connections must be made to the line side of the

contactor passing through the sensor coils as shown in Figure 2.

(This is because the overheat signal from the motor must rst pass

through the sensor coils, then into the L1, L2, and L3 terminals of

SubMonitor).

5. Connect the control circuit wires to the M1 and M2 plug-in connector

terminals, and signal circuit wires to the A1 and A2 plug-in connector

terminals (Figure 3). Tighten all terminals to 4.5 in-lbs and install the plug-

in connectors into SubMonitor (plugs are keyed to avoid misconnection).

6. Pass the T1, T2, and T3 motor power leads through the sensor coils in

the base unit.

7. NOTE: 6-lead Wye-Delta motors - for a 6-lead motor with a Wye-Delta

control panel, each sensor coil must encircle a pair of leads which connect

to the same line in the delta connection, such as T1-T6; T2-T4 or T3-T5.

8. As an option, the SubMonitor display unit is detachable and can be

mounted on the exterior of the panel door (requires a small punch-out

and two screw holes). Use the extension cable provided in the kit to

connect the base unit to the display unit.

Lightning Arrestor

1. Install the lightning arrestor and connect line leads to the line side of the

contactor as shown in Figure 4.

2. The lightning arrestor ground lead must be connected to water strata

ground to provide suitable surge protection. Connect metal-to-metal to

well casing, drop pipe, or to the

submersible motor with wire the

same size as drop cable wires.

NOTE: Refer to Franklin Electric

Submersible Motor Application,

Installation and Maintenance (AIM)

manual for further discussion of

lightning protection. FIGURE 4