7

3

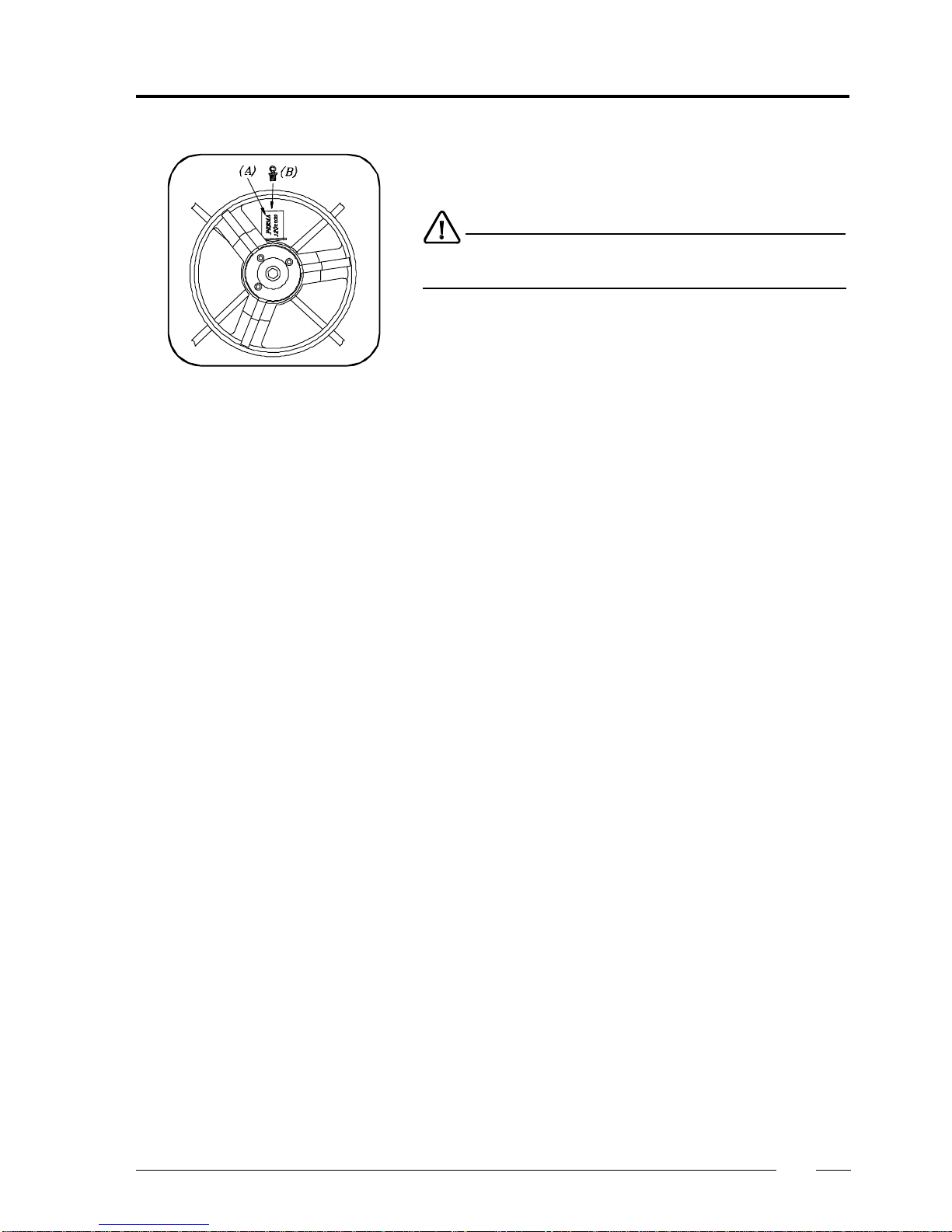

To prevent damage during transportation, the machine has been equipped with

fourredtransportbrackets(D)toeliminateeverypossiblemovementofthetub.

After the machine has been placed level, take off the service- and the back panel

to remove these transport brackets.

Important

The machine must never be activated before removing these transport

brackets.

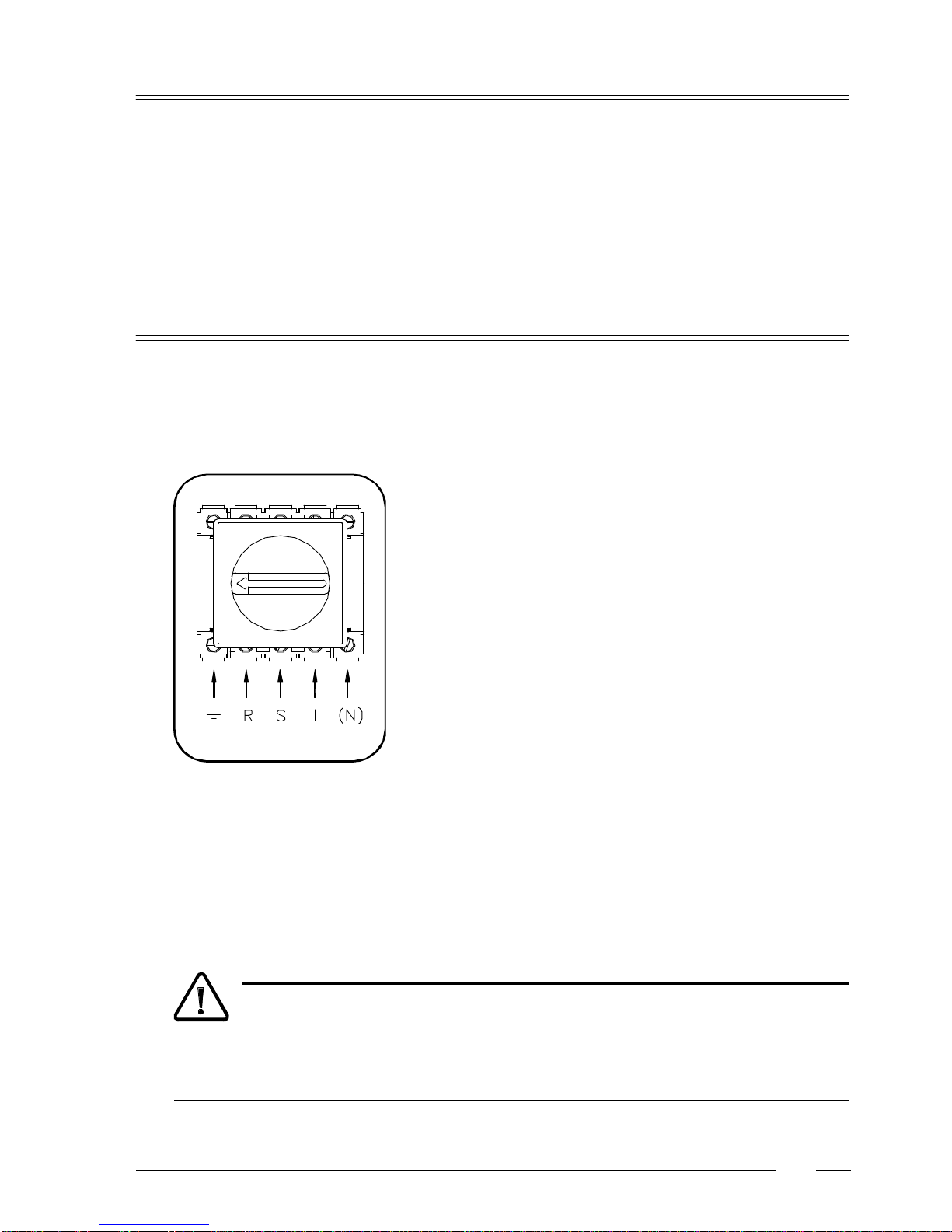

Installation and connection

Ground

Themachine mustbe placedon aflat, solidsurface (metalbase, concreteor solid

ground).Itisrecommendedthatthemachinebeanchored(M16)ontheprovided

places (A) in the base, especially in case of a plinth

(see Dimensions 2).

Themachine mustbeplacedentirelylevel. Foreasymaintenanceitisrecommen-

ded to keep a minimal distance of 600 mm between the wall and the back of the

machine.

If several machines are placed next to each another, there should be a minimal

distance of 30 mm between each machine.

The machine is delivered with hoses with 3/4" connections. These hoses fit the

water inlet valves of the machine and the main water inlet taps. To ensure the

optimal functioning of the water inlet valves, the water pressure on the inlet

shouldbebetween 0,5 and10kg/cm² (7and 145 psi).Ifthe pressure istoolow,

the cycle time will increase considerably.

Incaseofboilerfedmachines,aminimumofhotwaterof90°Cshouldbeavailable:

FortheHFP455:350l. HFP575:445l.

Water connection

Removing the transport brackets