2008

--------------------------------------------------------------- IPT Technologies AB --------------------------------------------------

HRV-601A Scaler/Chipper is very power ul but our advanced,

patented anti-vibration system has reduced vibrations to an

extremely low level. Much lower than other tools in its class assuming

the tools are operated under real world conditions. The low vibration

level makes it possible to use the tool for long periods and for precision

work. The noise level is also remarkably low!

Following these simple instructions will ensure a long life of excellent

operation. ote that this tool needs generous lubrication.

HRV-601A is equipped with a rubber grip

for comfort.

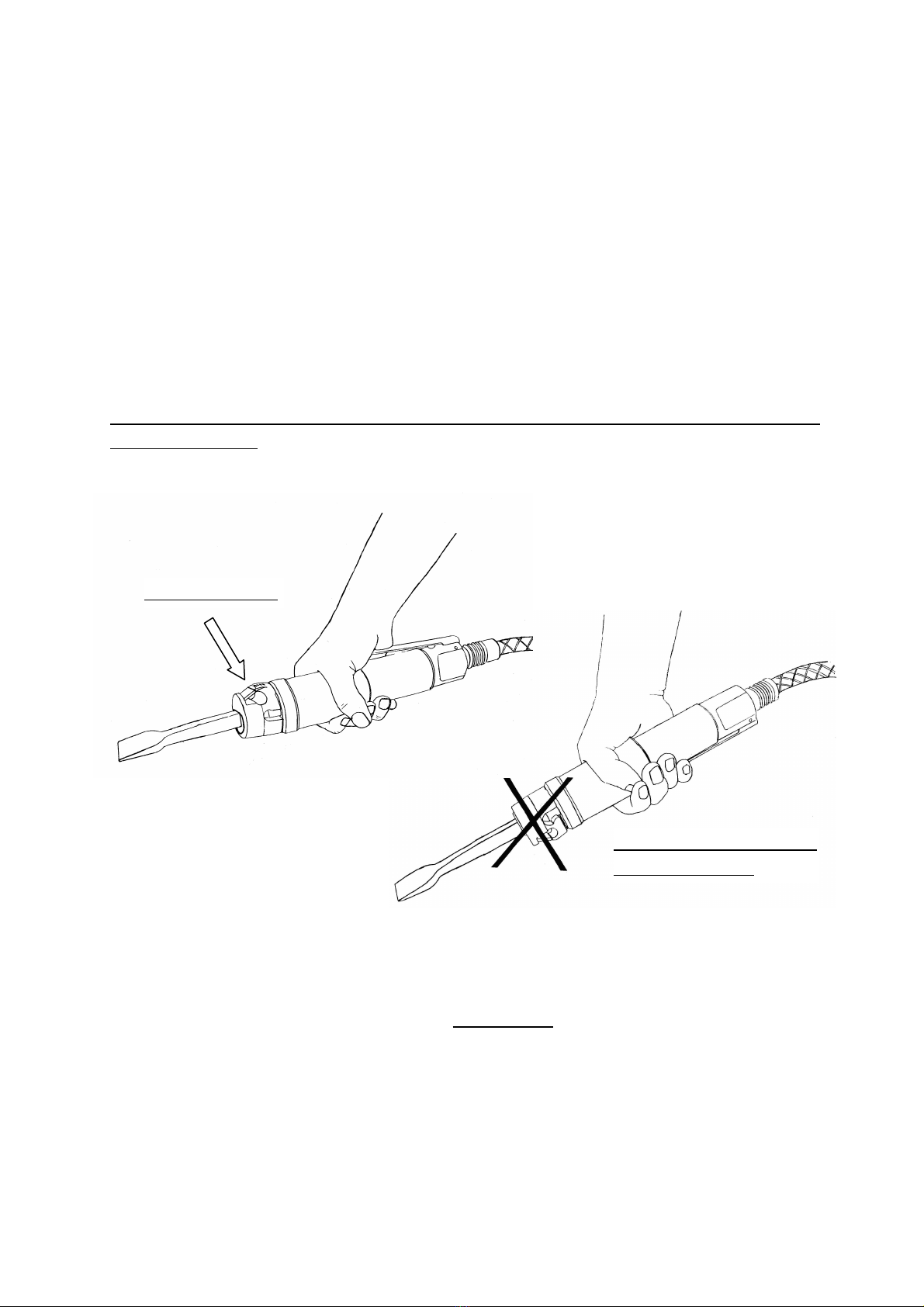

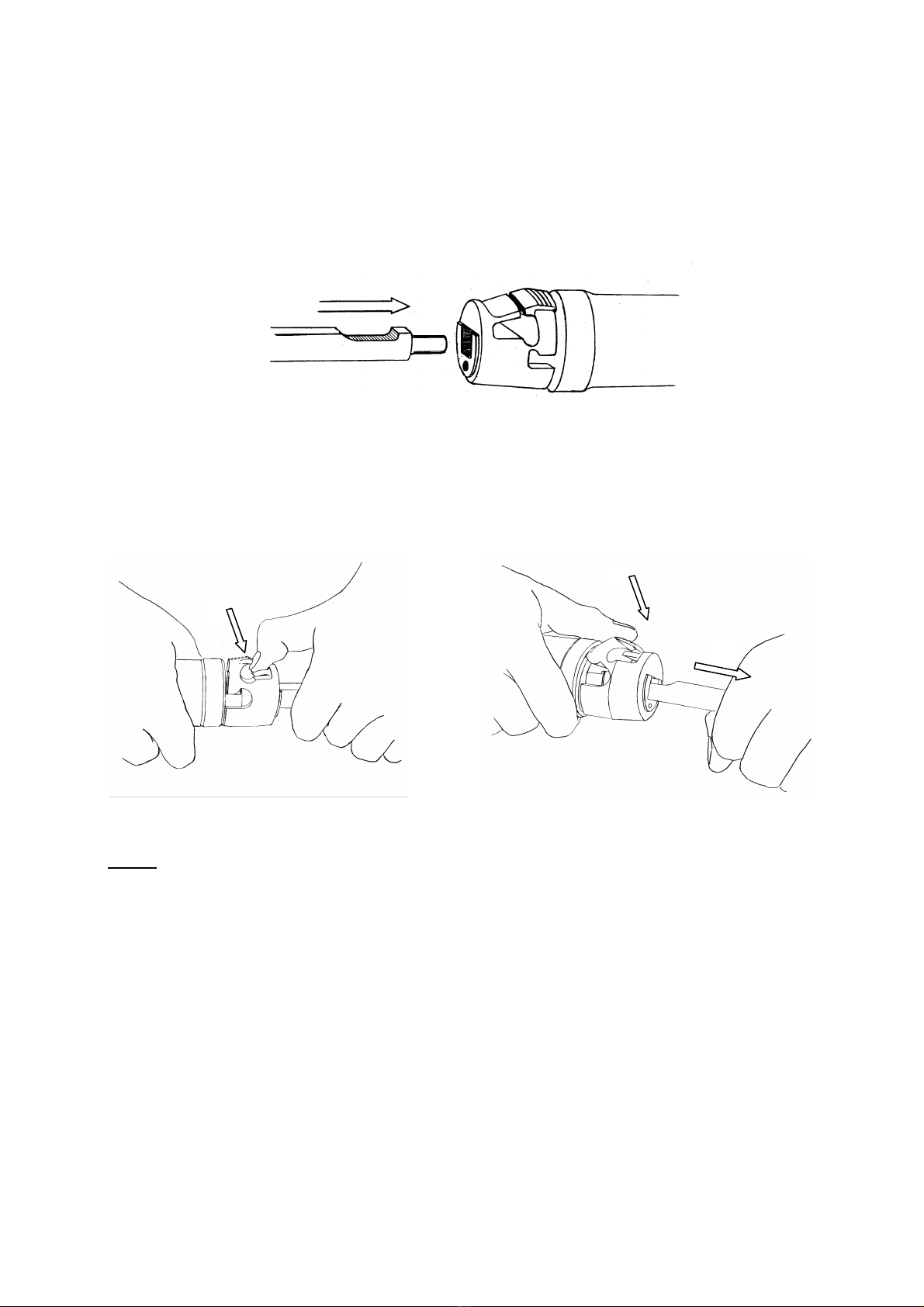

Chisel change is quic and easy.

General In ormation

The Scaler/Chipper is designed to operate at an air pressure of 6,5 to 7

bar, but will tolerate some variations without much change in

performance. Do not exceed 8 bar pressure (although normally the

excess pressure will discharge into the atmosphere). Connect to a 9 mm

or larger hose. Use a an air connection that will not interfere with the end

of the lever (17).

The compressed air should be dry and clean. A filter unit should always

be used. In line lubrication is recommended. Where this is not available,

apply a generous amount of oil at the inlet every 4 hours of operation.

See pages 5 and 7 for information about chisels and extension handles..

______________________________________________________________________________________________________

Address Telephone Tele ax Bankgiro Bank

Tegeluddsvägen 92 at 08-664 34 74 at 08-664 21 55 5799-4188 Handelsbanken

S-115 28 STOCKHOLM Int +46 8 664 34 74 Int +46 8 664 21 55 Lidingö