iQ360XT

Operator’s Manual

888-274-7744

www.iqpowertools.com

USE THE PROPER EXTENSION CORD

If using an extension cord, make sure it is in good

condition first. When using an extension cord, be sure

to use one heavy enough to carry the current your

product will draw. An undersized cord will cause a

drop in line voltage that will result in a loss of power

and overheating.

WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties, rings,

bracelets, or other jewelry that may be caught in

moving parts. Non slip footwear is recommended.

Wear protective hair covering to contain long hair.

ALWAYS USE SAFETY GLASSES

Safety glasses should always be worn when working

around power tools. In addition, a face, dust mask

or respirator should be worn if a cutting operation

is dusty. Everyday eyeglasses only have impact

resistant lenses and may not prevent eye injury -they

are NOT safety glasses.

DO NOT OVERREACH

Keep proper footing and balance at all times by not

overreaching. Keep your hands free to operate a power

tool is safer.

CHECK FOR DAMAGED PARTS

Before using a power tool, check for damaged parts.

A guard or any other part that is damages should

be carefully checked to determine it would operate

properly and perform its intended function. Always

check moving parts for proper alignment or binding.

Check for broken parts and mountings and all other

conditions that may aect the operation if the power

tool. A guard, or any damaged part, should be properly

repaired or replaced.

DIRECTION OF FEED

Always feed work into the blade or cutter against the

direction of rotation. A blade or a cutter should always

be installed such that rotation is in the direction of the

arrow imprinted on the side of the blade or cutter.

NEVER LEAVE A TOOL RUNNING UNATTENDED—TURN

OFF POWER

Do not leave a tool until it comes to a complete stop.

Always turn a power tool OFF when leaving the work

area, or, when a cut is finished.

SAFETY MESSAGES

Sawing and drilling generates dust. Excessive airborne

particles may cause irritation to the eyes, skin, and

respiratory tract. To avoid breathing impairment,

always employ dust controls and protection suitable to

the material being sawed or drilled; See OSHA (29 CFR

Part 1910. 1200). Diamond Blades improperly used are

dangerous. Comply with American National Standards

Institute Safety Code, B7.1 and, Occupational Safety

and Health Act covering Speed, Safety Guards, Flanges,

Mounting procedures, General Operating Rules,

Handling, Storage and General Machine Conditions.

CALIFORNIA PROPISITION 65 MESSAGE:

Some dust created by power sanding, sawing, grinding,

drilling, and other construction activities contain

chemicals known [known to the State of California] to

cause cancer, birth defects or other reproductive harm.

Some examples of these chemicals are:

• Lead, from lead-based paint

• Crystalline silica, from bricks and cement

and other masonry products

• Arsenic and chromium, from chemically

treated lumber.

For Further information consult the following sources:

http://www.osha.gov/SLT/silicacrystalline/index.html

http://www.oehha.org/prop65/out_of_date/6022kLstA.html

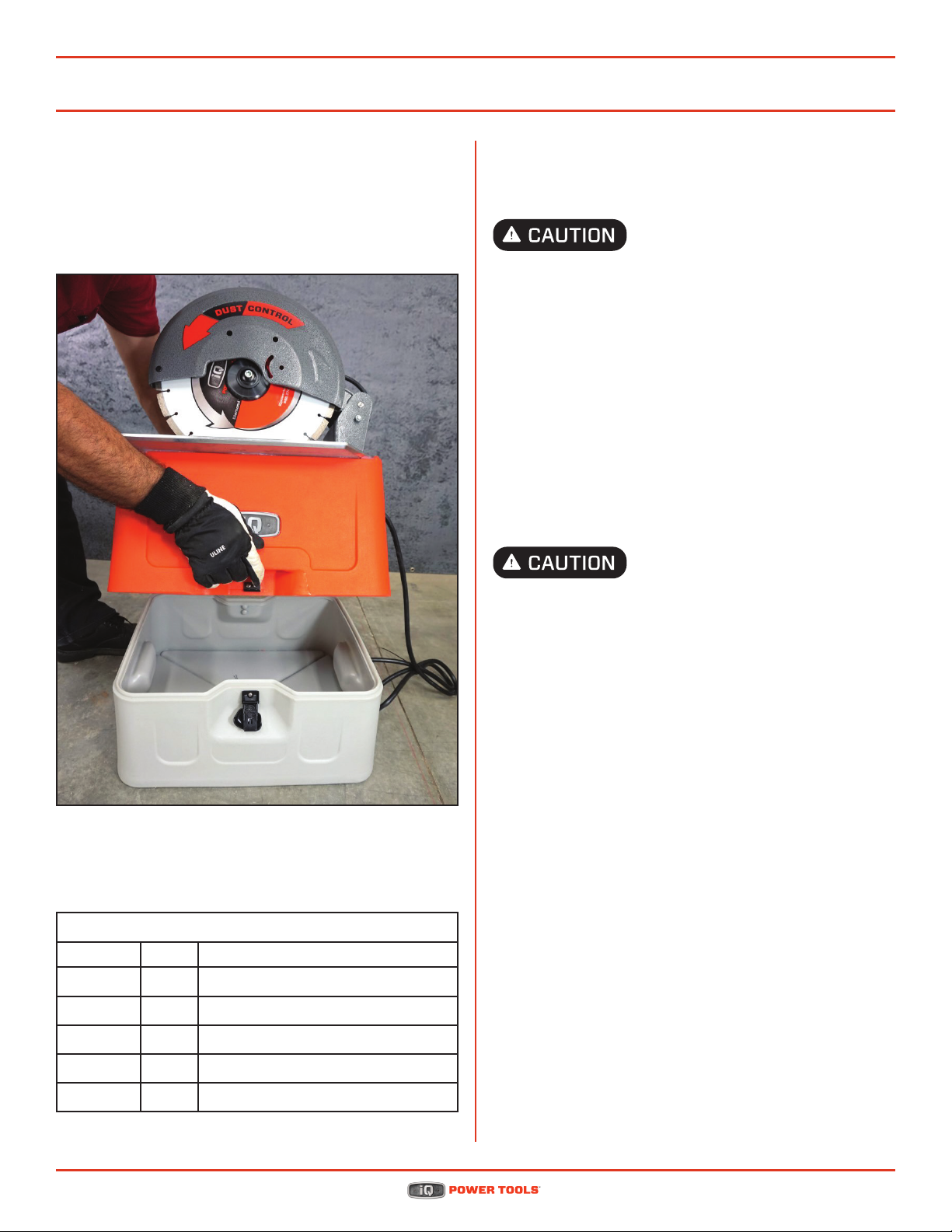

The iQ360XT® is very eective dust control saw but,

your risk from these exposures varies depending on

how often you do this type of work. To reduce your

exposure to these chemicals, work in a well-ventilated

area, and work with approved safety equipment, such

as dust masks that are specially designed to filter out

microscopic particles.

3.2