MACHINE SET UP AND OPERATION

Attention: always wear work gloves!!

1) Tractor towing bar (pict 15 pos 23):

To hook the machine up to a tractor or UTV, pull down on

the draw bar until it lines up with the hitch. The sprinkler

cart will hook onto the stop bar and lift off the ground.

When arrived at the right place, unhitch the towing bar

and

lift it up until the anchoring angle iron and sprinkler cart

are on the ground.

Attention: max transport speed is 6 mph on flat roads.

2) Set up to irrigate: Put the drum in the proper direction toward the irrigation strip in order to get it

aligned with the pull out direction of the pe hose. Stand behind the drum and use the draw bar to aim

the traveler in the correct direction.

3) Anchor: Be sure that the anchoring angle iron foot is secure to the ground. If the ground is very

hard you may need to use anchoring spikes.

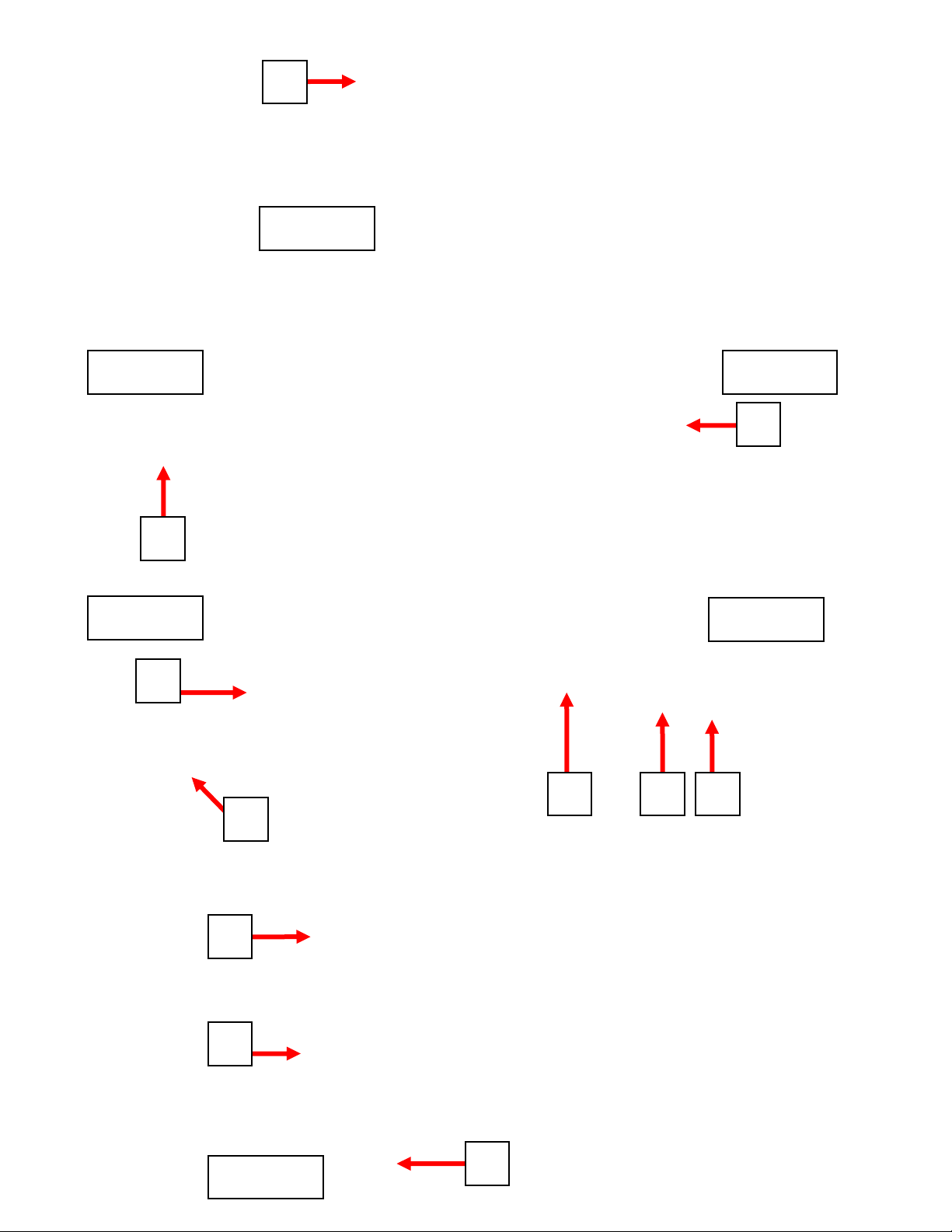

4) Disengage the gear box: Move the knob/lever (05) in the “pulling out” position as you see in

picture 01. In case it’s locked and won’t move, put the PTO hand wheel onto the PTO shaft, push it

and turn a bit counterclockwise, and push the gear box knob/lever (05) at the same time. Always keep

pushing the hand wheel when you use it and take it off the PTO after use and replace the protective

cover for safety.

Pay attention to the hand wheel: never leave it on the PTO shaft if you’re not using it as above

described! It’s very dangerous and can cause serious injuries!

5) Pull out the cart and PE hose: Hook the towing chain (20) of the sprinkler cart to the tractor

and pull out the cart along the field with the max speed of 2 mph (walking speed). Before you stop

reduce the speed smoothly to prevent the drum from free spooling. There is no alarm nor signal

about the pe hose length so be careful to don’t pull it out too much! Leave a couple wraps on the

drum or the hose might pull off of the drum! Check the sprinkler pattern is ok and adjust it.

Disconnect the tractor and drive back to the machine.

Important: Always leave at least one pe hose ring rolled on the drum and remember that for the first

use of the machine it is necessary to do a “full pull”, pulling out the complete PE hose not leaving

more than one or two rings on the drum : you’ll need to roll up all the pe hose while under pressure.

Failure to follow this procedure can lead to improper wrapping of the PE hose on the drum and

damage to the traveler!

PICT. 15

23

06

PICT. 01

01 05

02

03

Page 10