The manufacturer guarantees only English text available on our web site www.isoil.com

110_EN_IT_IS_R3_1.00.0

1 di 79

INDICE

SAFETY INFORMATION __________________________________________________ 3

INTRODUCTION________________________________________________________ 3

SAFETY CONVENTION ___________________________________________________ 4

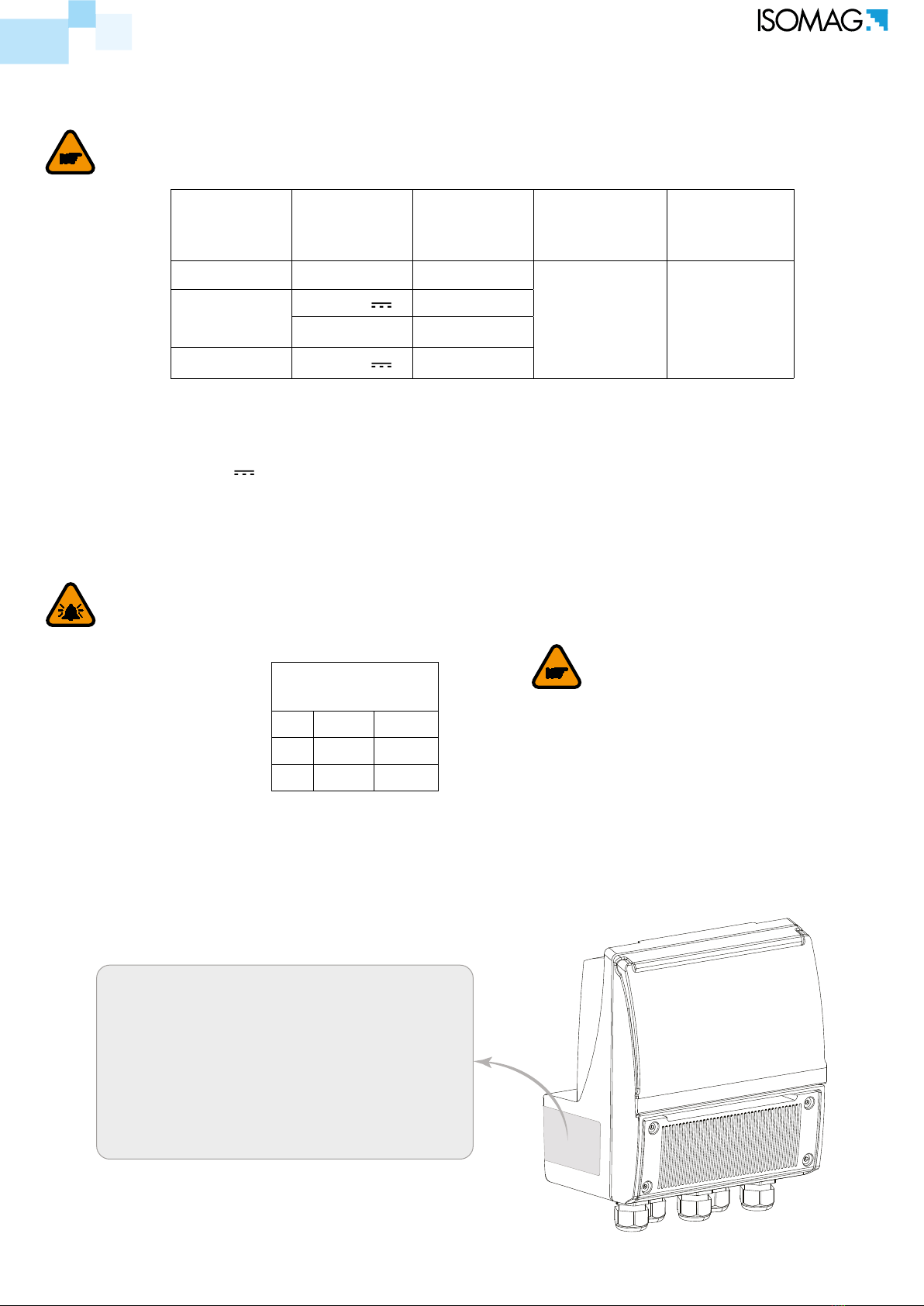

DATA PLATE ___________________________________________________________ 5

AMBIENT TEMPERATURE _________________________________________________ 5

TECHNICAL CHARACTERISTICS ___________________________________________ 5

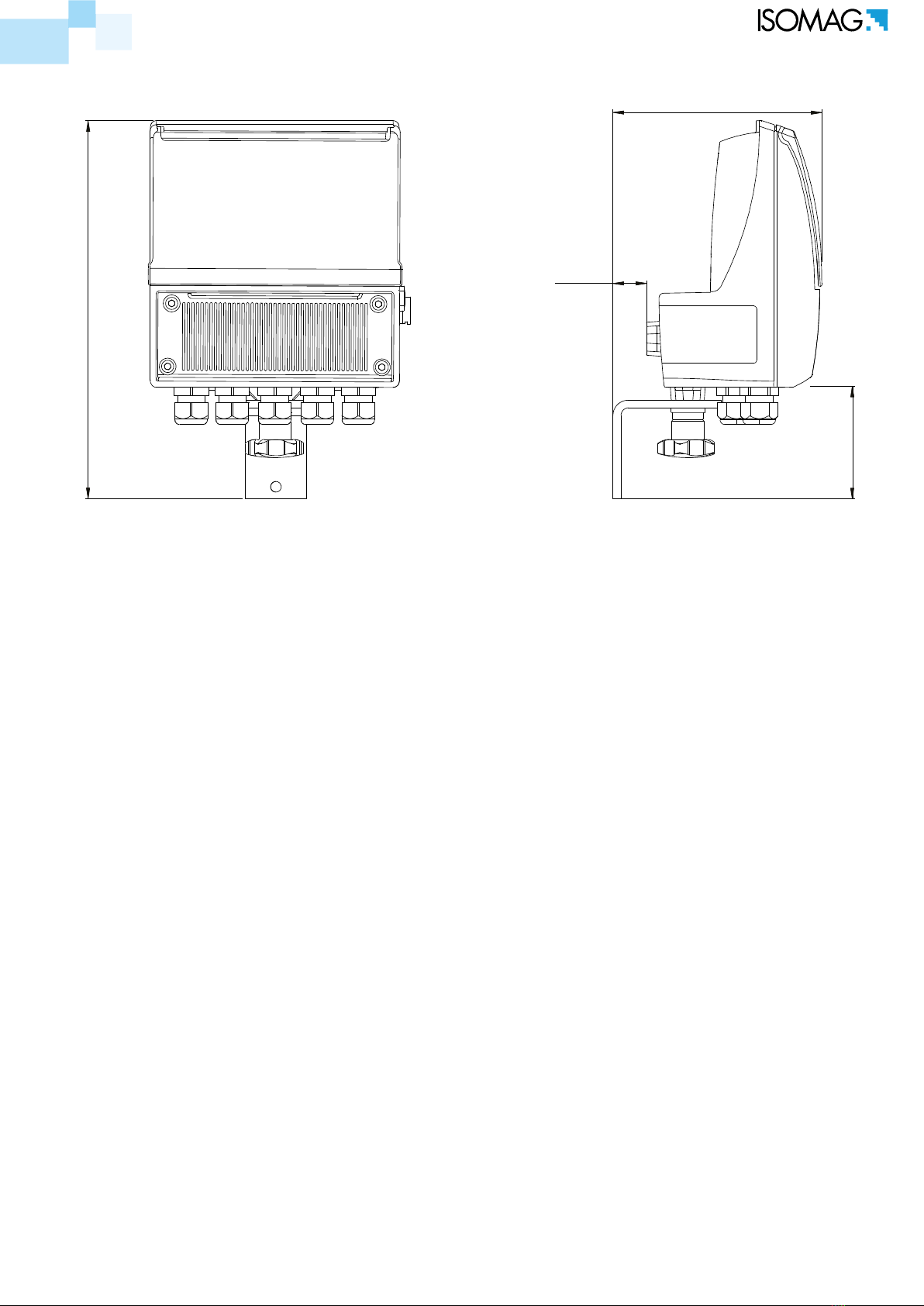

DIMENSIONS __________________________________________________________ 6

SEPARATE VERSION_____________________________________________________ 7

HORIZONTAL VERSION __________________________________________________ 8

VERTICAL VERSION _____________________________________________________ 8

MV110 CONSTRUCTION_________________________________________________ 10

INTERNAL LAYOUT ____________________________________________________ 11

ELECTRICAL CONNECTION AND GROUNDING INSTRUCTIONS ___________________ 12

DIGITAL INPUT ON/OFF OPERATION ______________________________________ 14

RS485 MODBUS MODULE (OPTIONAL) _____________________________________ 15

OUTPUTS WIRING _____________________________________________________ 15

DIGITAL OUTPUTS _____________________________________________________ 15

ANALOG OUTPUTS ____________________________________________________ 15

CONNECTORS MIL_____________________________________________________ 16

MEANING OF FLAGS____________________________________________________ 19

MEANING OF LED COLORS_______________________________________________ 19

ACCESS VIA KEYPAD ___________________________________________________ 20

ACCESS VIA MCP INTERFACE (VIRTUAL DISPLAY) ____________________________ 20

ACCESS TO THE CONFIGURATION MENU____________________________________ 20

FLOW RATE VISUALIZATION _____________________________________________ 21

FLOW RATE ALERT _____________________________________________________ 21

QUICK START MENU ___________________________________________________ 21

ACCESS CODE SET : MENU 13 SYSTEM______________________________________ 22

RESTRICTED ACCESS SET : MENU 13 SYSTEM _______________________________ 22