2

INTRODUCTION ..................................................................................... 3

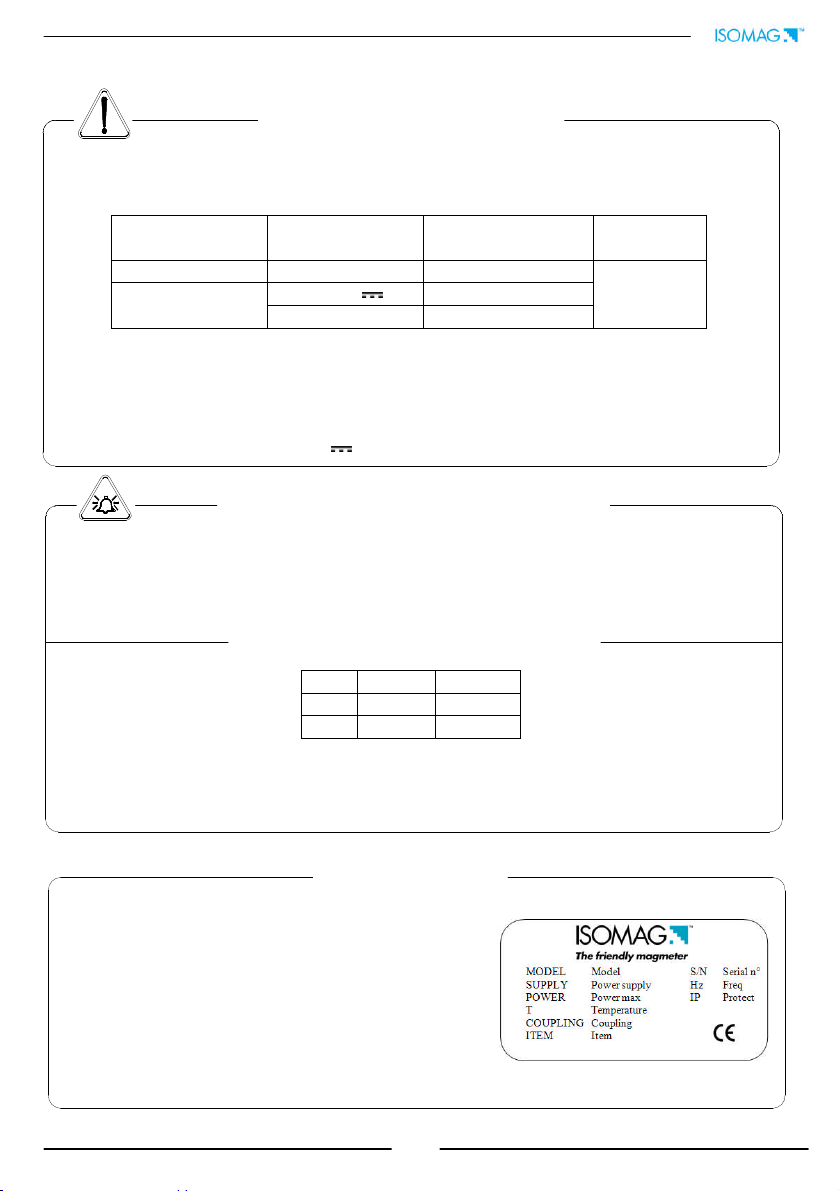

SAFETY INFORMATIONS........................................................................ 3

SAFETY CONVENTIONS .............................................................................. 4

TECHNICAL CHARACTERISTICS ............................................................ 5

ENVIRONMENTAL USE CONDITIONS........................................................... 5

AMBIENT TEMPERATURE............................................................................ 5

Data plate.................................................................................................. 5

ELECTRIC CHARACTERISTICS..................................................................... 5

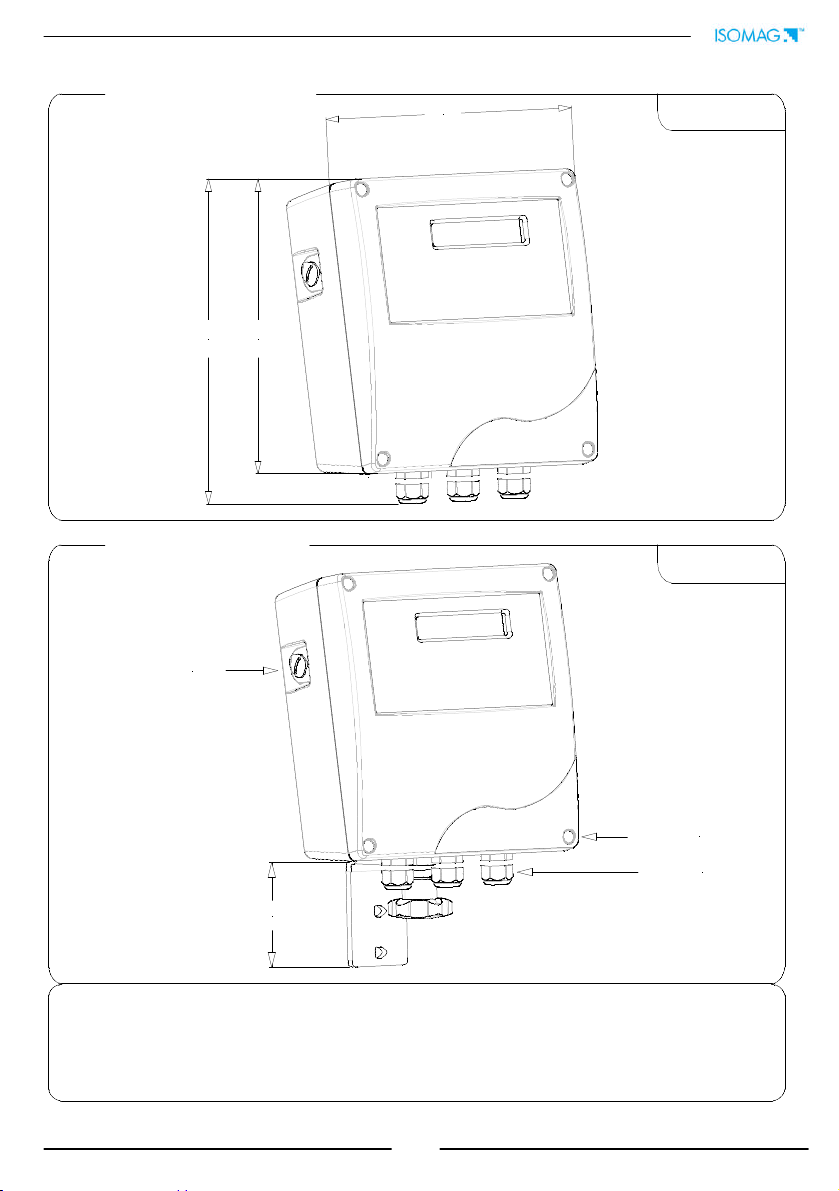

DIMENSIONS (PA6 HOUSING) .................................................................... 6

DIMENSIONS (ALUMINUM HOUSING) ......................................................... 7

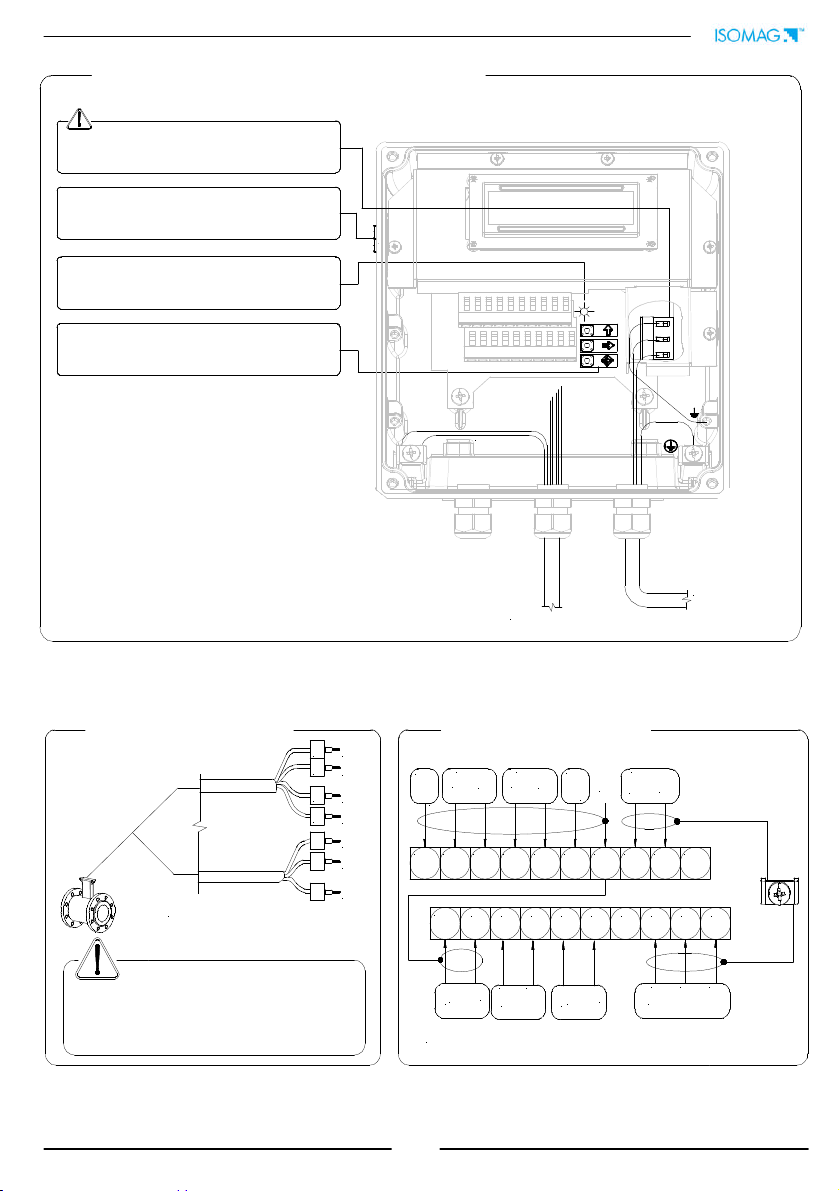

ELECTRICAL CONNECTIONS.................................................................. 8

GROUNDING INSTRUCTIONS ..................................................................... 8

CONVERTER POWER SUPPLY...................................................................... 8

PA6 CONVERTER INTERNAL VIEW .............................................................. 9

PA6 CONVERTER TO SENSOR ELECTRICAL CONNECTIONS .......................... 9

ALUMINUM CONVERTER INTERNAL VIEW ................................................. 10

ALUMINUM CONVERTER TO SENSOR, ELECTRICAL CONNECTIONS ............ 10

DIGITAL INPUT .................................................................................... 11

INPUT ON/OFF OPERATION...................................................................... 11

OUTPUT WIRINGS................................................................................ 12

DISPLAY FLAGS AND LED WARNING INTERPRETATION................... 13

CONVERTER ACCESS ............................................................................ 14

KEYPAD................................................................................................... 14

BLIND CONFIGURATION .......................................................................... 14

ACCESSING THE TRANSMITTER FUNCTIONS AT START-UP (Power On)...... 15

FLOW RATE VISUALIZATION............................................................... 16

ACCESS CODES ..................................................................................... 17

QUICK START MENU............................................................................. 18

ACCESS TO THE CONFIGURATION MENU ........................................... 19

EXAMPLE ................................................................................................. 20

FUNCTIONS MENU................................................................................ 22

FUNCTIONS DESCRIPTION ....................................................................... 25

ALARMS................................................................................................. 32

ISOMAG RETURN MATERIAL ............................................................... 33

CONFORMITY DECLARATION .............................................................. 35

ADDRESSES .......................................................................................... 36

INDEX