CANNON STANDARD page 1 of 20

ASSEMBLY AND WIRING INSTRUCTION

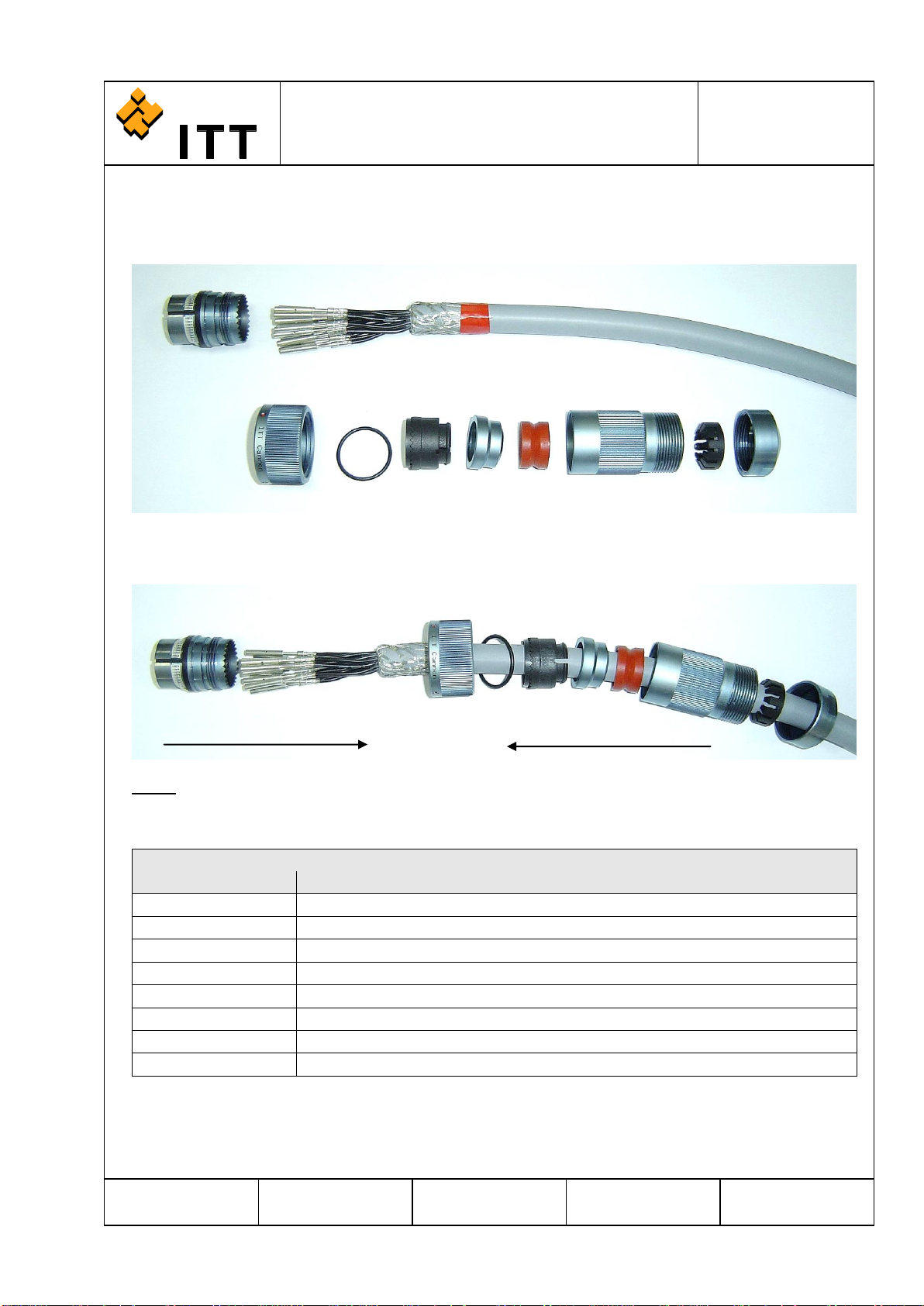

CA-BAYONET IP69K

Circular Connector with Protection Class IP69K

ITT Cannon GmbH, D-71384 Weinstadt

1General Information.......................................................................................2

1.1 Scope..........................................................................................................................2

1.2 Recommended Method of Mounting...........................................................................2

1.3 Cross Reference.........................................................................................................2

2Connector Components.................................................................................3

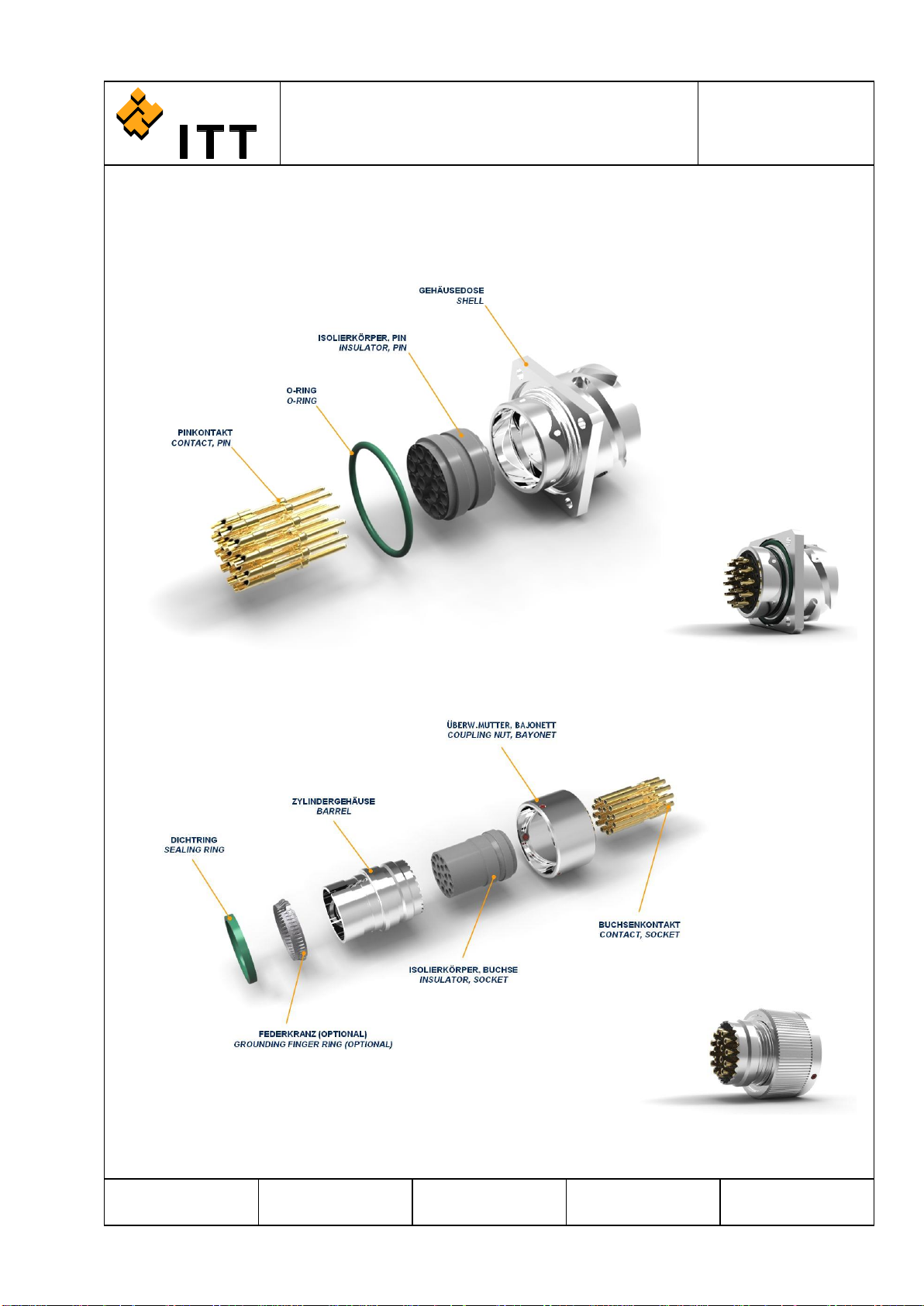

2.1 Explosion View Shell Assembly (Box Mounting Receptacle).....................................3

2.2 Explosion View Barrel Assembly (Straight Plug)........................................................3

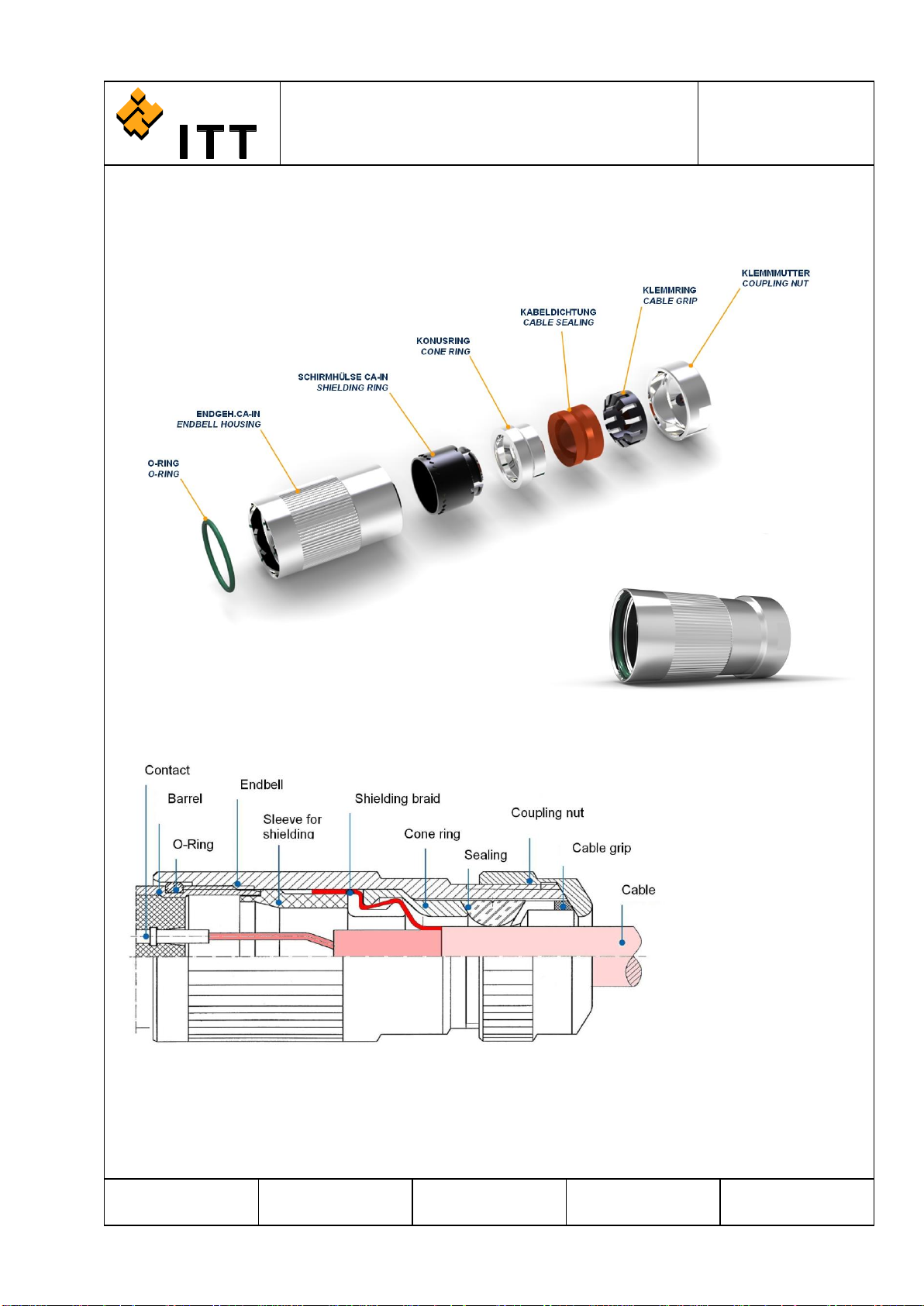

2.3 Explosion View of Universal Endbell / Concept of Shielding......................................4

3Contacts and Assembly Tools .......................................................................5

3.1 Standard Crimp Contacts ...........................................................................................5

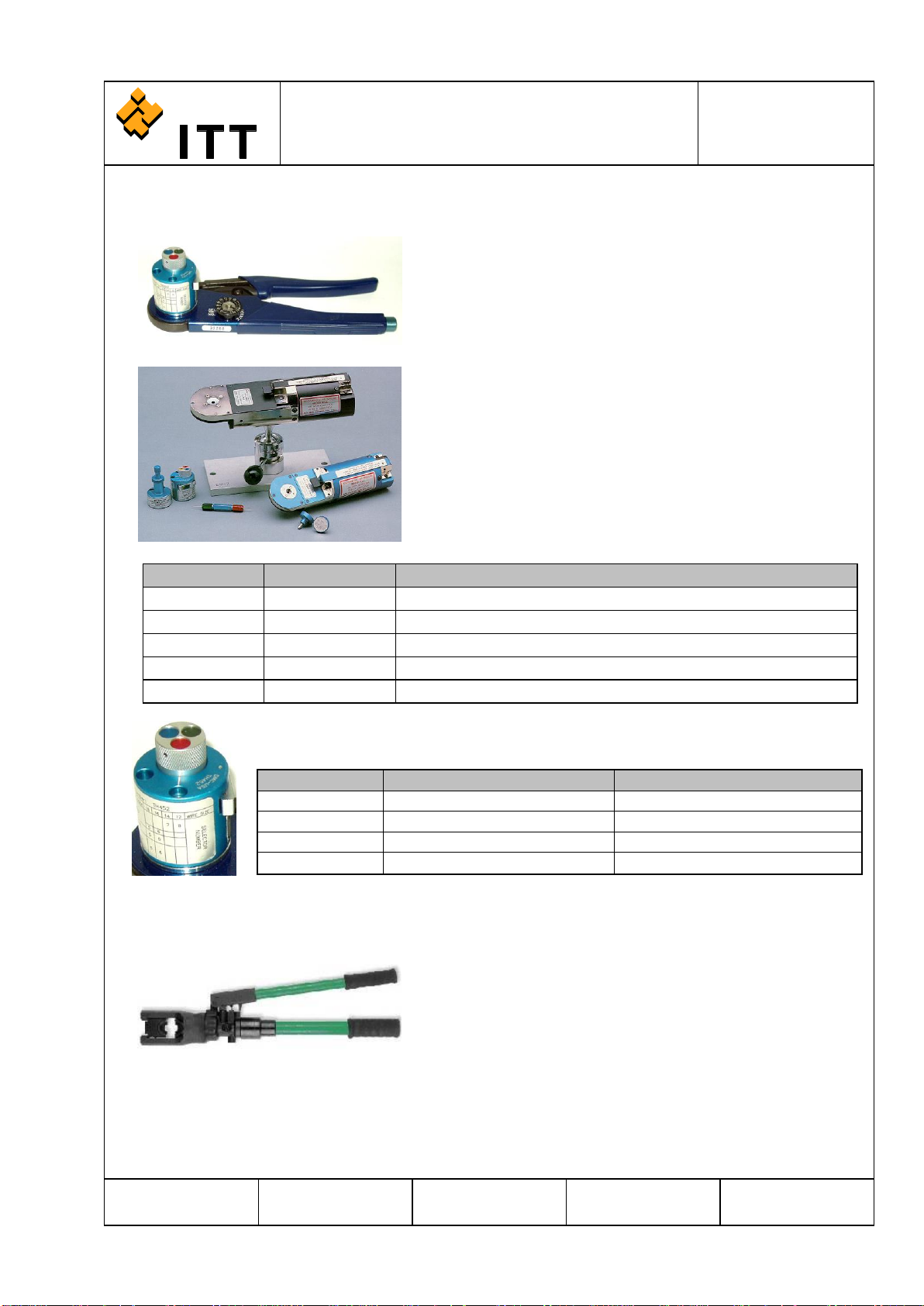

3.2 Crimping Tools............................................................................................................6

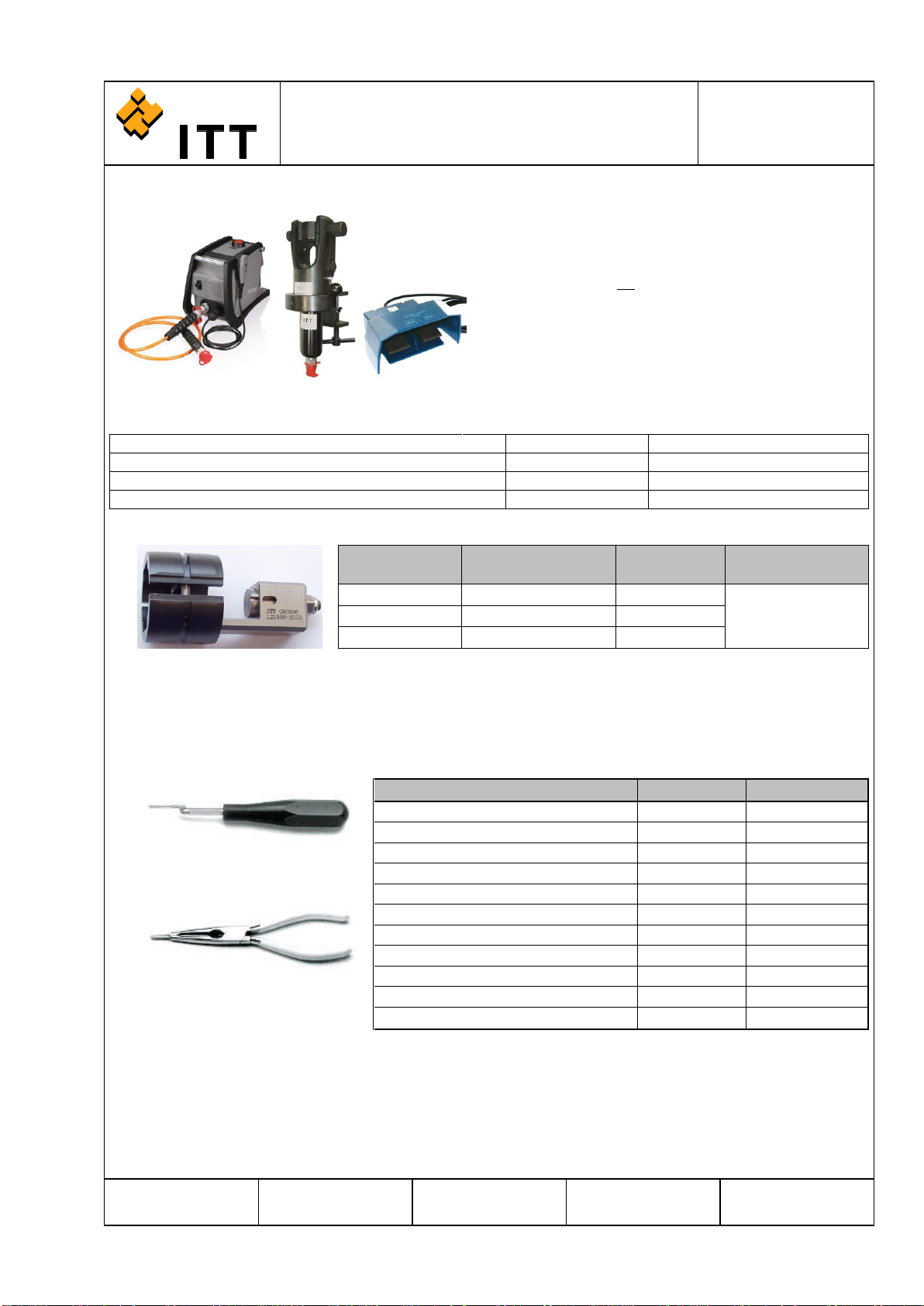

3.3 Insertion Tools ............................................................................................................7

3.4 Extraction Tools..........................................................................................................8

3.5 Pipe Wrench ...............................................................................................................8

3.6 Operating Instructions for Machined Contacts ...........................................................8

4Preparation....................................................................................................9

4.1 Dimensions for Single Conductor, Wire Stripping ......................................................9

4.2 Wire Stripping Length for System Cable ....................................................................9

4.3 Preparation of Shielded System Cable................Fehler! Textmarke nicht definiert.

5Assembly Instructions..................................................................................10

5.1 Overview and Configuration .....................................................................................10

5.2 Insertion of Contacts.................................................................................................11

5.3 Removal of Contacts ................................................................................................13

5.4 Assembly Instruction for the Universal Endbell ........................................................13

6Annex ..........................................................................................................16

6.1 Useful Hints...............................................................................................................16

6.2 Product Safety Information .......................................................................................17

7Brochure......................................................................................................18