Manual #50-14 Revised 3/05

C. 2002 I

1: Safety Instructions 1 - 1...........................................

About this Manual 1 - 1...........................................................

Proper Use of System 1 - 1........................................................

Manual Symbols 1 - 1............................................................

Authorized Use of System 1 - 1....................................................

Installation, Maintenance, Repair or Disposal of the System 1 - 1.......................

Modification to the System 1 - 2....................................................

Working with Cover Open 1 - 2....................................................

2: Product Description 2 - 1..........................................

General 2-1....................................................................

Technical Data 2-2..............................................................

Dimensions (Basic version) 2 - 4...................................................

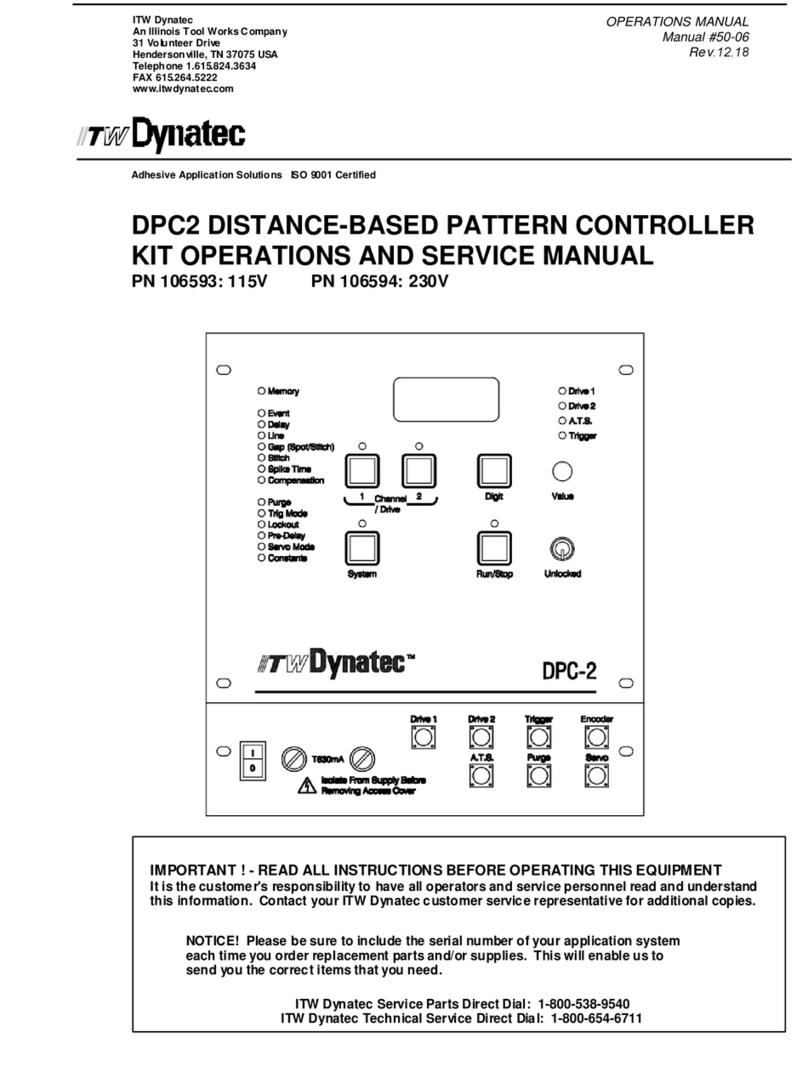

Operating and Connecting Elements (Basic version) 2 - 4.............................

3: Installation 3 - 1..................................................

Connectors and Pin Definitions 3 - 1................................................

Connecting the System 3 - 2......................................................

Locating an Optical Trigger (Sensor) 3 - 2...........................................

Connecting Optional Accessories 3 - 3..............................................

4: Operating 4 - 1...................................................

Operator’s Panel 4 - 1............................................................

Remote Purge Control 4 - 2.......................................................

Service Settings Menus 4 - 3......................................................

Production Setup Menu 4 - 4......................................................

Power On and Software Version 4 - 5...............................................

Service Settings 4-6.............................................................

Service Settings Menu 1 of 3 Overview 4 - 6..............................................

Service Settings Menu 2 of 3 Overview 4 - 8..............................................

Service Settings Menu 3 of 3 Overview 4 - 9..............................................

Factory Defaults 4-9..................................................................

Service Setting Programming Conventions 4 - 11.....................................

Display Contrast Adjustments 4 - 11.................................................

Service Settings Menu 1 4 - 12.....................................................

Select Language 4-12..................................................................

Load Program 4-13....................................................................

Trigger Assignment 4-14................................................................

Trigger Lock 4-15......................................................................

Encoder--Channel Assignment 4 - 15......................................................

Encoder Scaling (Encoder Type and Unit) 4 - 17............................................

Min/Max Speed Configuration 4 - 18.......................................................

Channel Mode Adjustment 4 - 19.........................................................

Change Security Lock 4 - 22.............................................................

Change Access Code 4 - 22.............................................................

Service Settings Menu 2 4 - 23.....................................................

Trigger Setup 4-23.....................................................................

Pressure Signaling 4-24................................................................

Pressure Assignment 4-25..............................................................

Pressure Curve Configuration 4 - 25.......................................................