SkidWeigh ED2-SM Version 1500

Our policy is one of continuous improvement and the information in this document is subject to change without notice.

Check that software version displayed on the LED display is reflective of this manual.

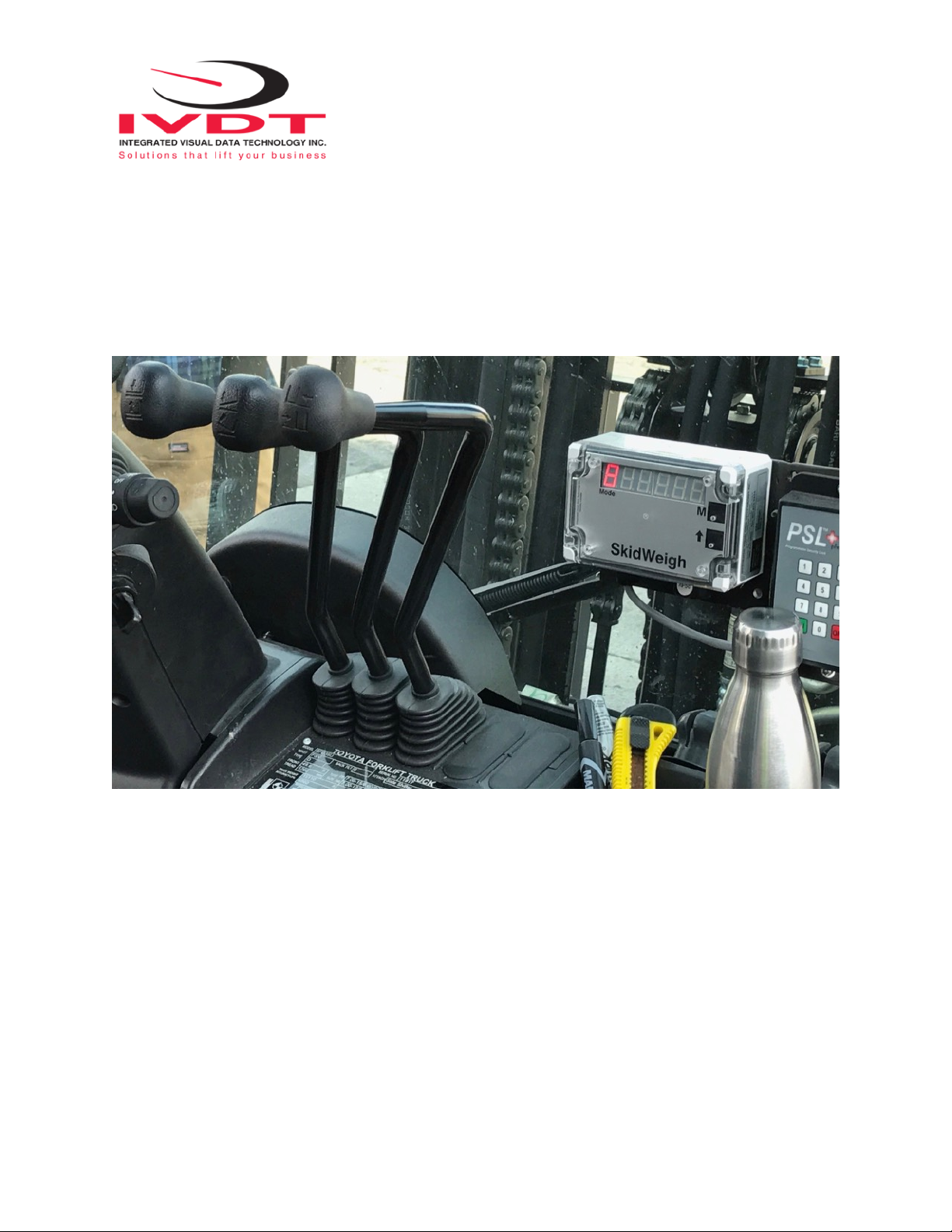

Overview of Components

The standard SkidWeigh ED2-SM check weighing system kit consist of two main components:

* Digital indicator with external overload audio warning, wiring harness and anti-vibration mounting bracket.

* Hydraulic pressure transducer with 3 wire connection cable.

* Installation & calibration manual as well as quick reference operator usage instructions.

Operational Principal

The SkidWeigh ED2 operational principal is based on

mounting a pressure transducer into the vehicles hydraulic

lifting circuit between the lift control valve and lifting cylinder(s).

Upon usage proprietary software will automatically activate

the “weighing cycle algorithm ” when a skid load is lifted just

above the ground. The increase in pressure is converted

through an electronic signal at the sample rate of 16000

readings per session which is then converted into a load

weight reading.

Installing the Pressure Transducer

The pressure transducer must be installed in the hydraulic lift

line between the lift control valve and lift cylinder(s). In

some cases you can install the pressure transducer in the flow

divider, drilling and tapping for 1/4”-18 NPT male in spare plug

or in the body of the flow divider. Also, you can drill and tap

on any “larger elbow” that might be available in the hydraulic

lift circuit found in vehicles with larger hoses to accommodate

larger vehicle lifting capacities.