SERVICE MANUAL

AYXP12JHRN

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

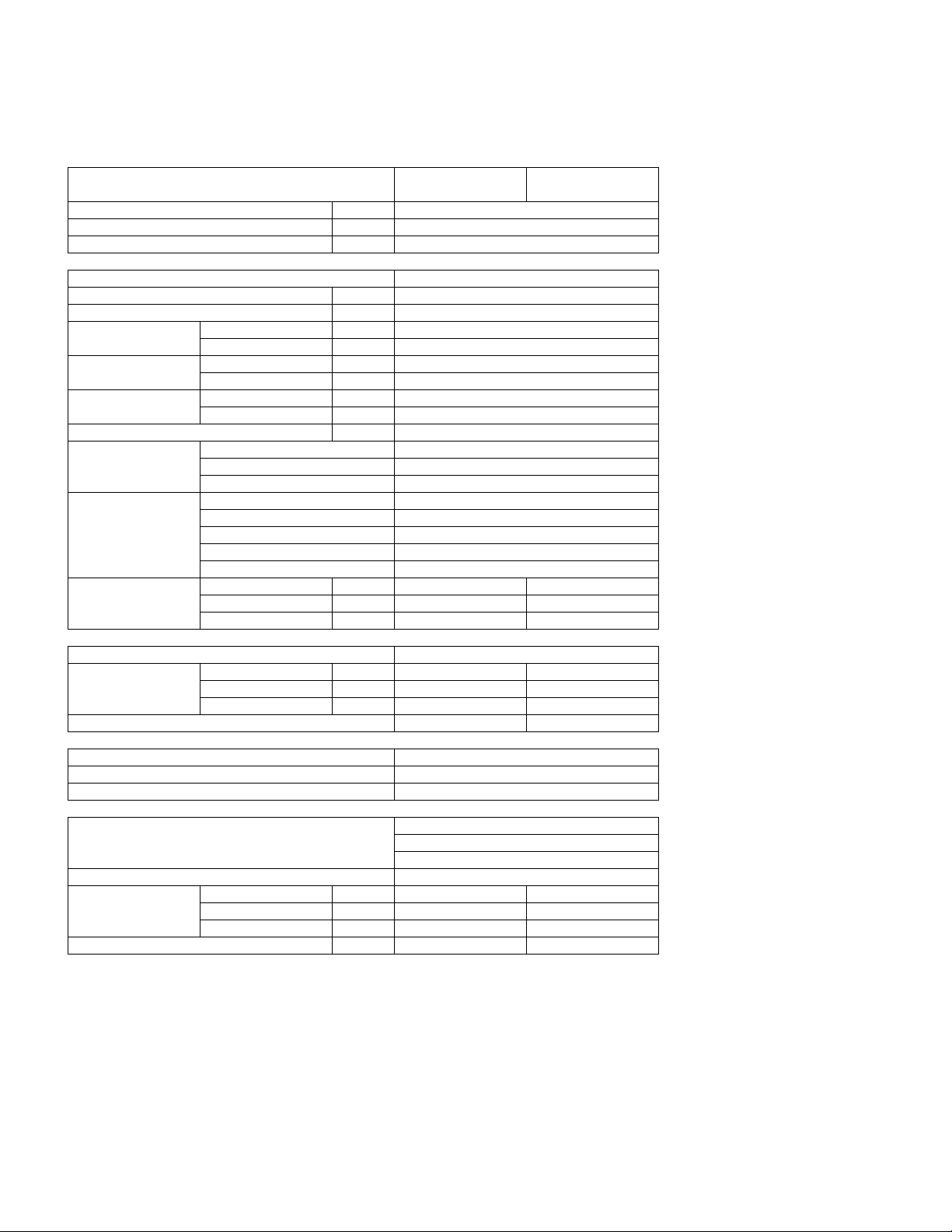

CHAPTER 1. SPECIFICATION

[1] SPECIFICATION............................................ 1-1

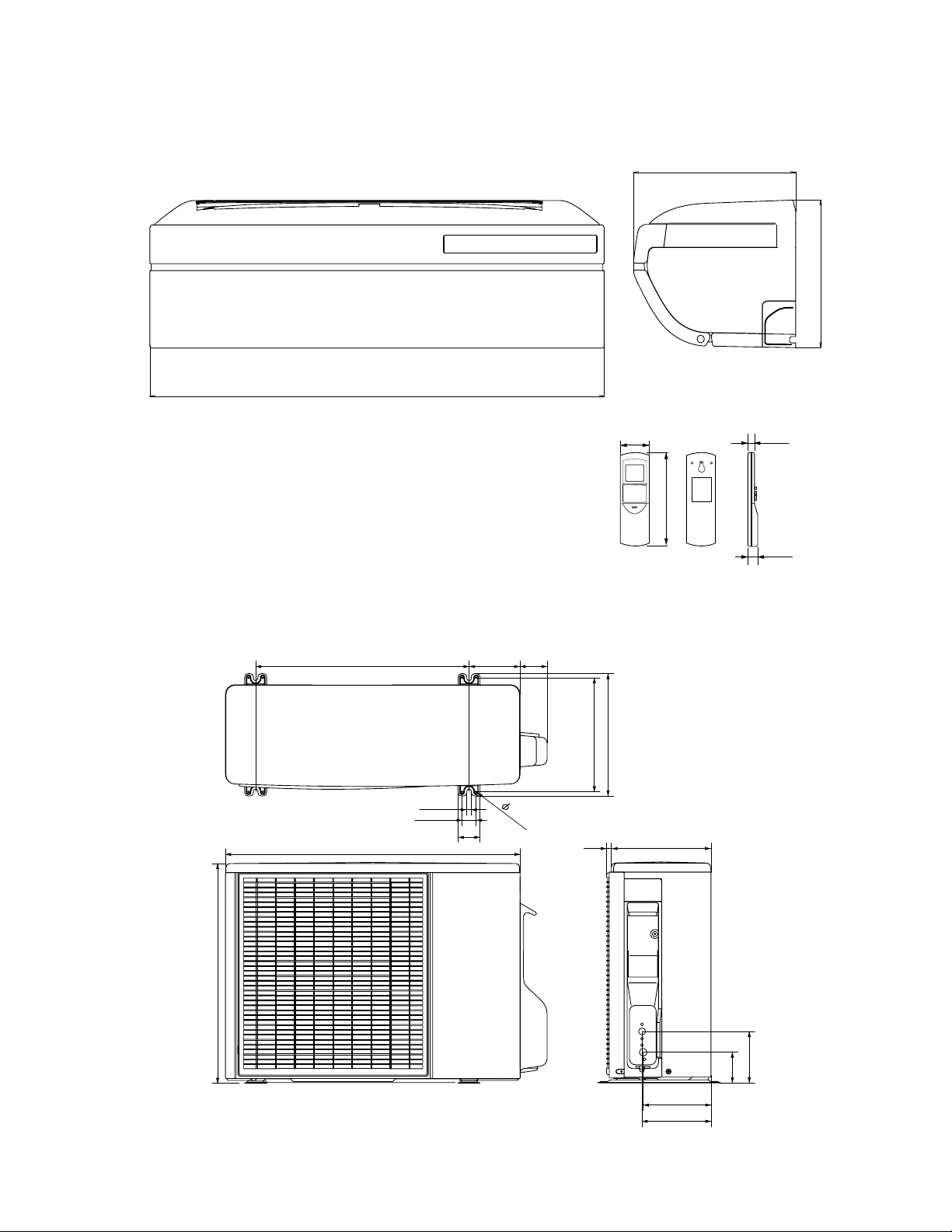

[2] EXTERNAL DIMENSION............................... 1-2

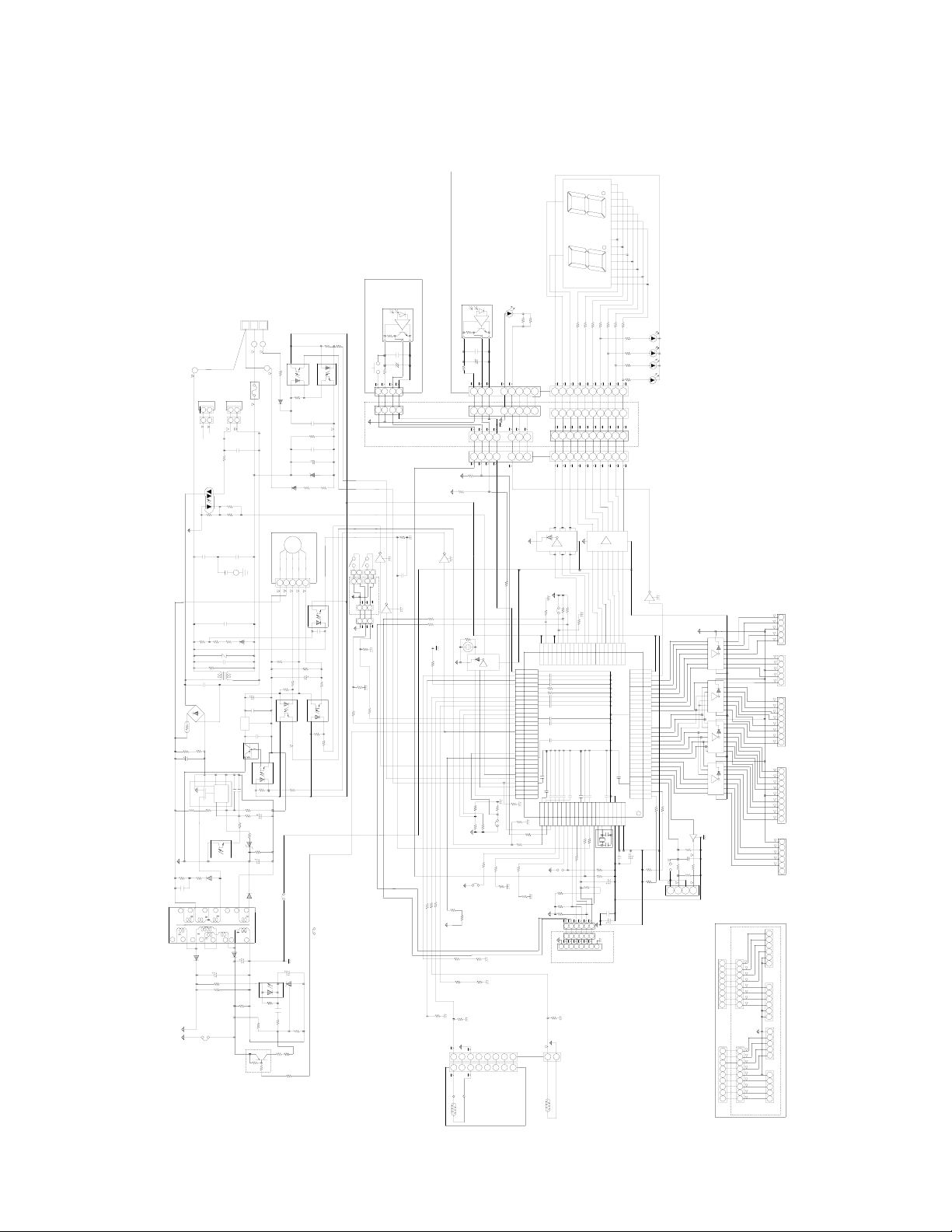

[3] WIRING DIAGRAM ........................................ 1-3

[4] ELECTRICAL PARTS .................................... 1-3

CHAPTER 2. EXPLAMATION OF CIRCUIT AND OP-

ERATION

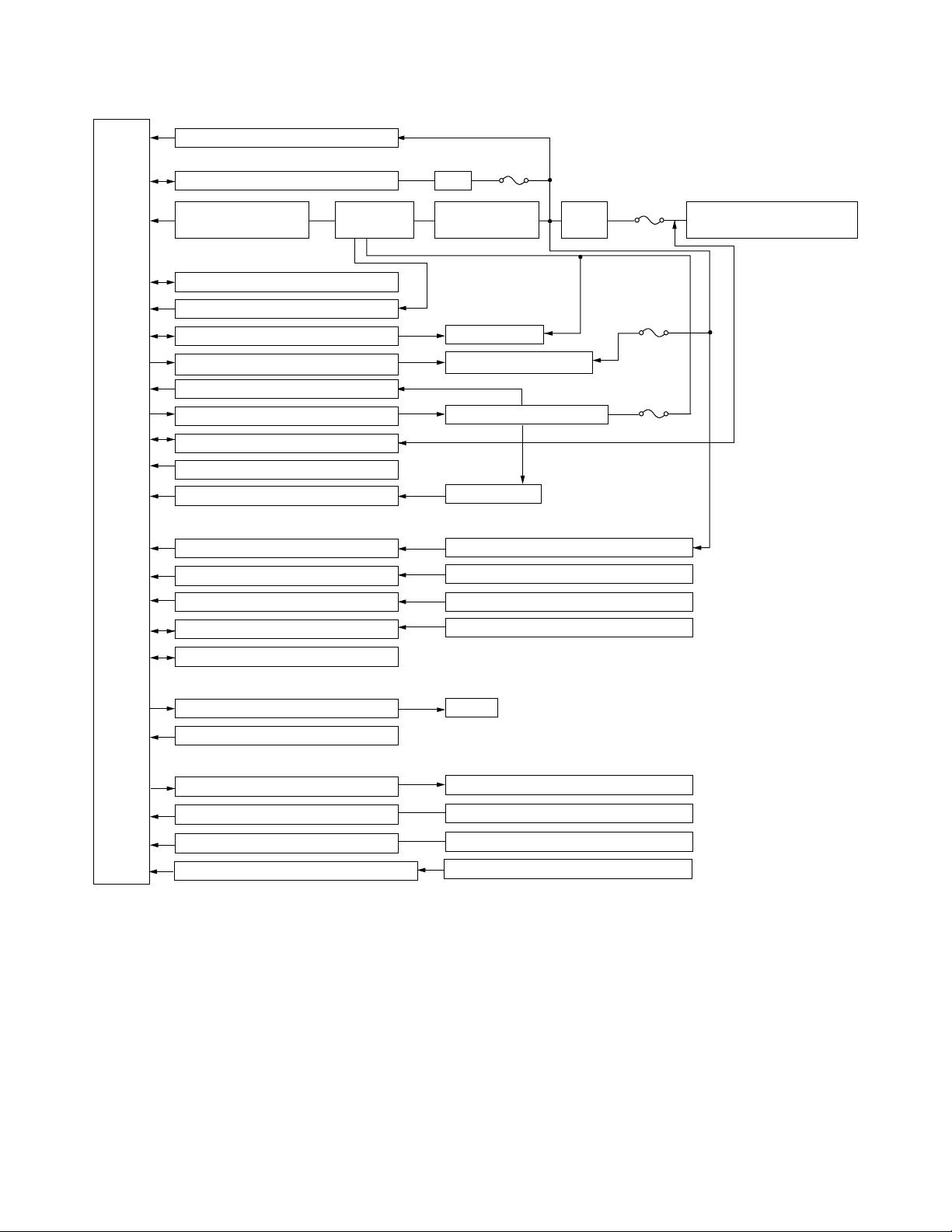

[1] BLOCK DIAGRAMS....................................... 2-1

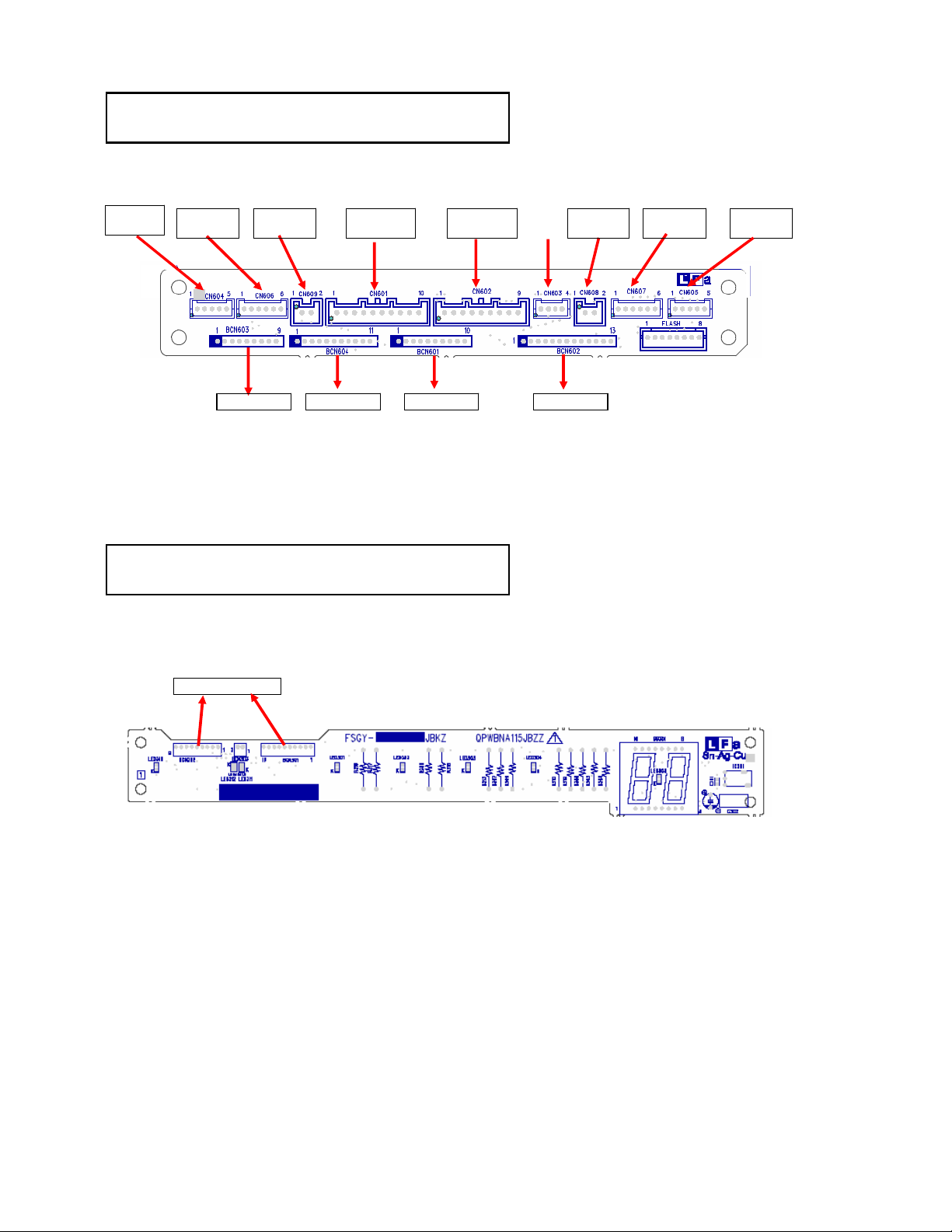

[2] MICROCOMPUTER CONTROL SYSTEM........ 2-3

[3] FUNCTION..................................................... 2-9

CHAPTER 3. FUNCTION AND OPERATION OF PRO-

TECTIVE PROCEDURES

[1] PROTECTION DEVICE FUNCTIONS AND

OPERATIONS................................................ 3-1

[2] AIR CONDITIONER OPERATION IN

THERMISTOR ERROR ................................. 3-3

[3] THERMISTOR TEMPERATURE CHAR-

ACTERISTICS ............................................... 3-5

[4] HOW TO OPERATE THE OUTDOOR

UNIT INDEPENDENTLY................................ 3-6

[5] GENERAL TROUBLESHOOTING CHART........3-6

[6] MALFUNCTION (PARTS) CHECK METH-

OD .................................................................3-8

[7] OUTDOOR UNIT CHECK METHOD...........3-10

[8] TROUBLESHOOTING GUIDE ....................3-13

CHAPTER 4. REFRIGERATION CYCLE

[1] FLOW FOW REFRIGERANT ........................4-1

[2] STANDARD CONDITION ..............................4-1

[3] TEMPERATURE AT EACH PART AND

PRESSURE IN 3-WAY VALVE ......................4-1

[4] PERFORMANCE CURVES...........................4-2

CHAPTER 5. DISASSEMBLING PROCEDURE

[1] DISASSEMBLY OF INDOOR UNIT...............5-1

[2] DISASSEMBLY OF OUTDOOR UNIT.........5-10

Parts Guide

TopPage

CONTENTS

SPLIT TYPE

ROOM AIR CONDITIONERS

OUTDOOR UNIT

AE-X12JR-N

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

INDOOR UNIT

AY-XP12JHR-N

MODELS