SERVICE MANUAL

xxxxxxxxx

No. XXXXXXXXXXXXX

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining the

safety and performance of the set.

This document has been published to be used for

after sales service only.

The contents are subject to change without notice.

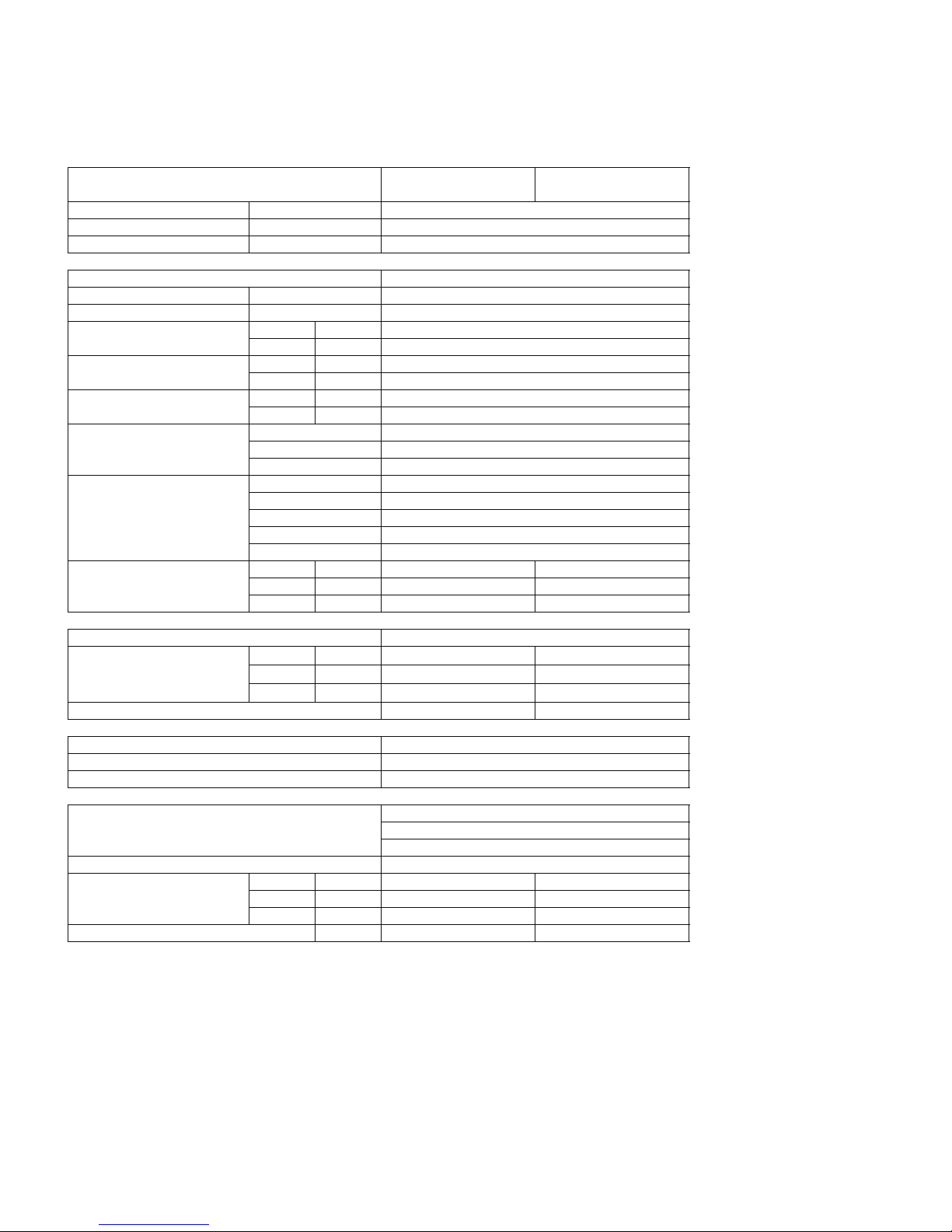

CHAPTER 1. SPECIFICATION

[1] SPECIFICATION............................................ 1-1

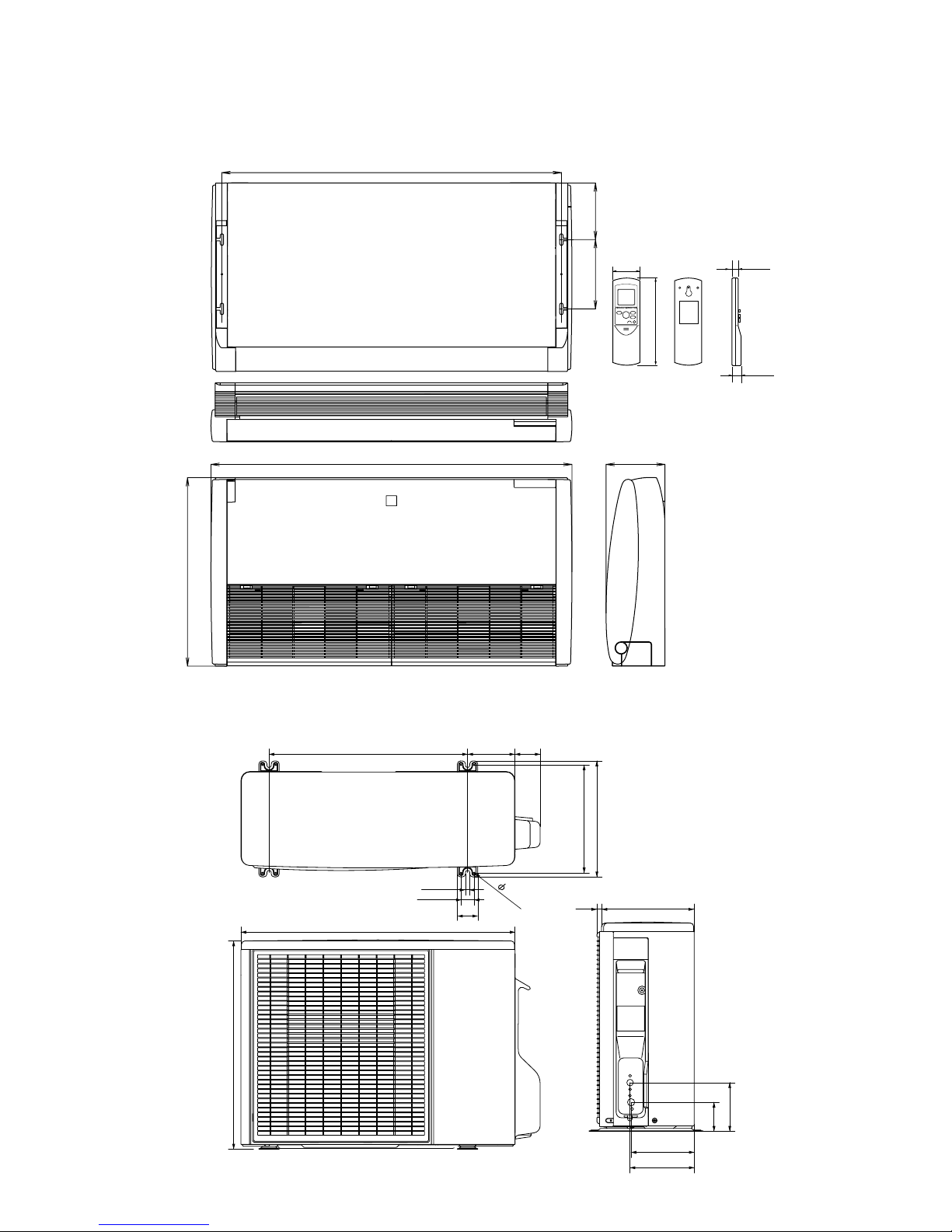

[2] EXTERNAL DIMENSION............................... 1-2

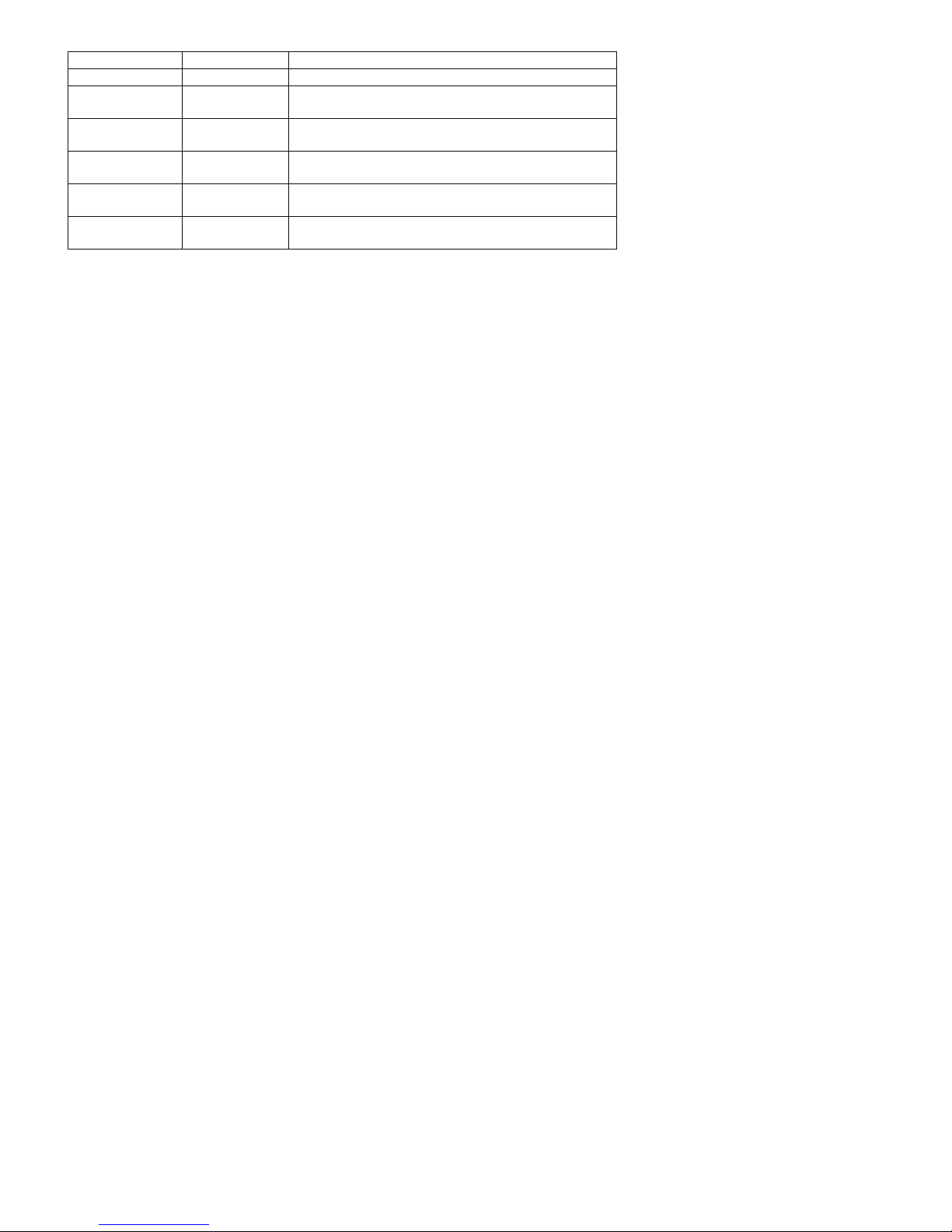

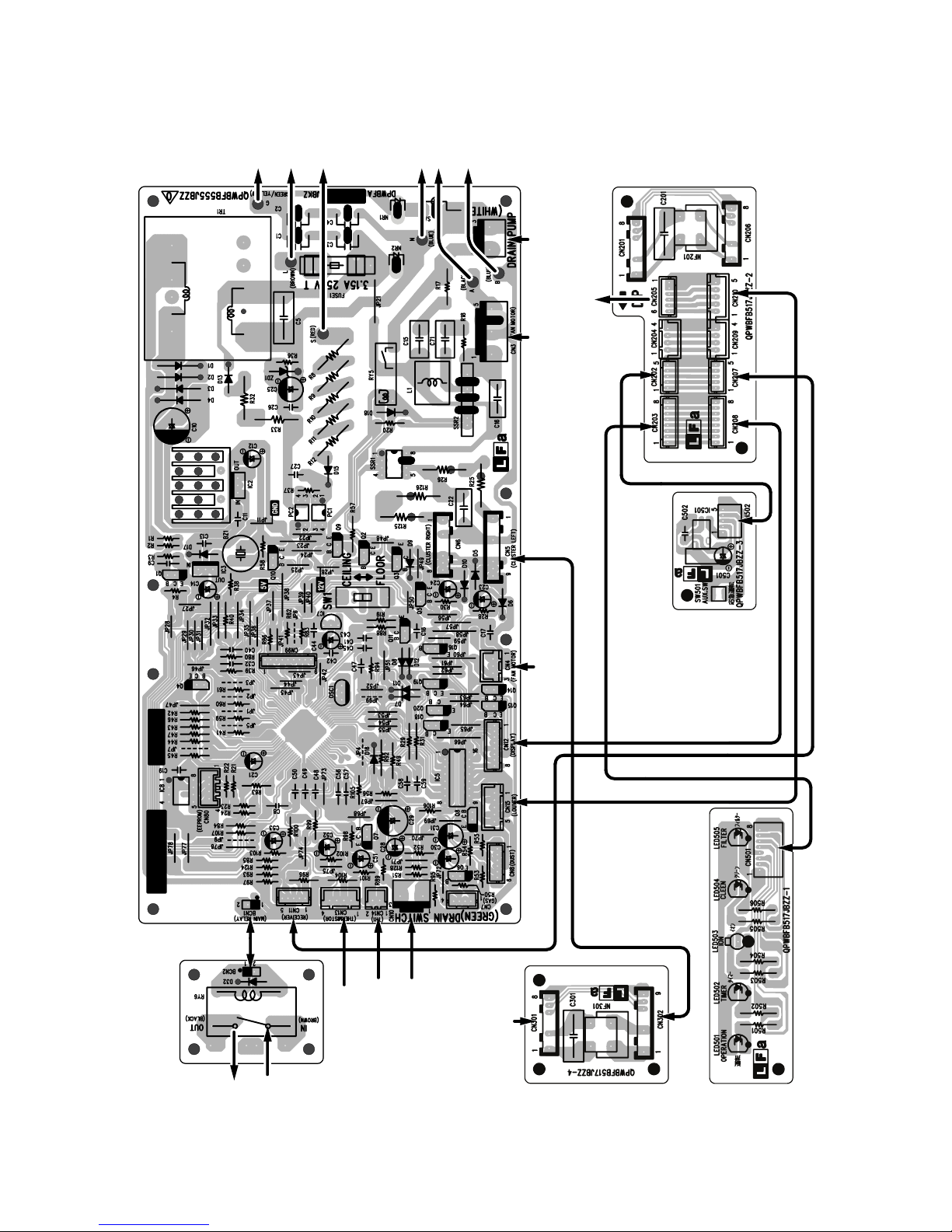

[3] WIRING DIAGRM .......................................... 1-4

[4] ELECTRICAL PARTS .................................... 1-4

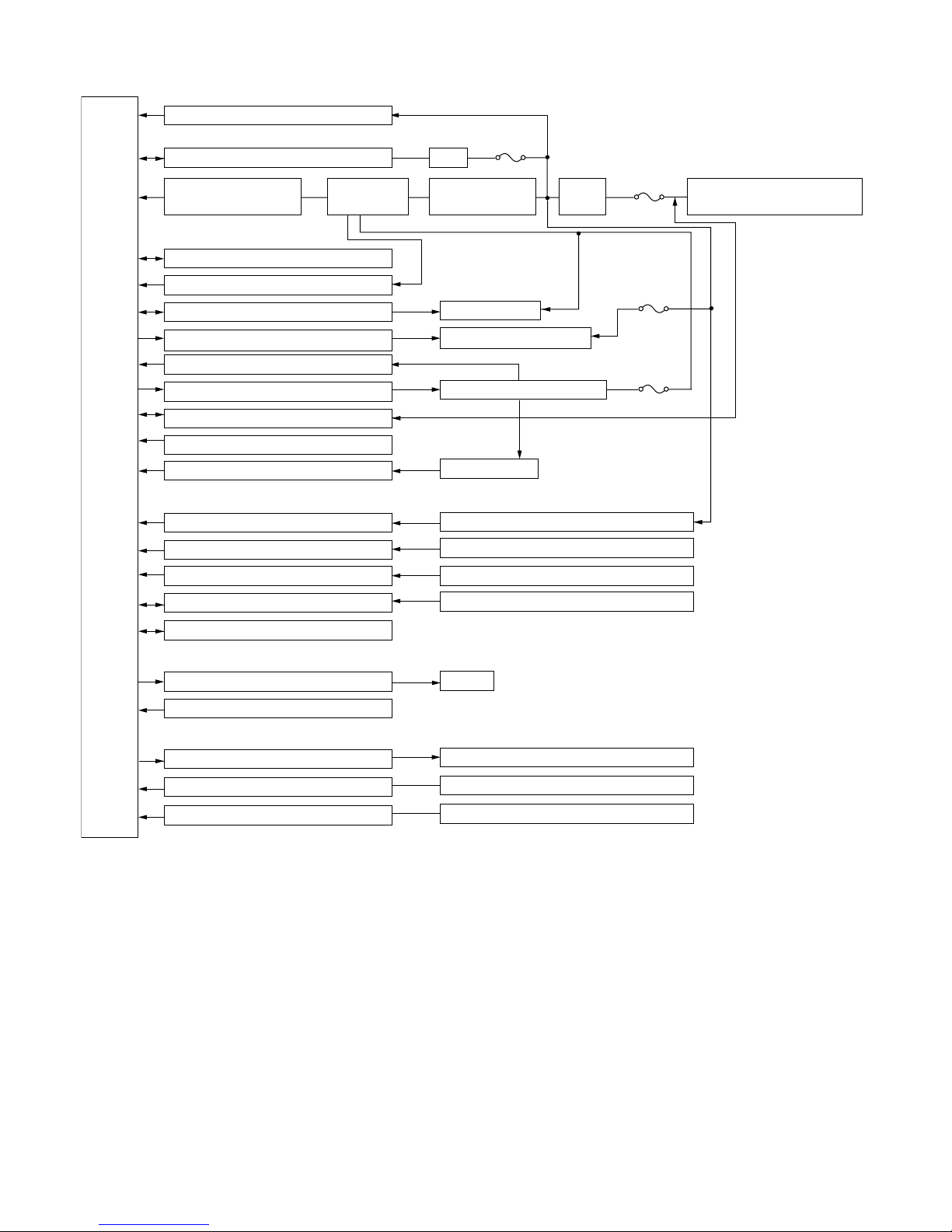

CHAPTER 2. EXPLANATION OF CIRCUIT AND OP-

ERATION

[1] BLOCK DIAGRAMS....................................... 2-1

[2] MICROCOMPUTER CONTROL SYSTEM........ 2-3

[3] FUNCTION..................................................... 2-7

CHAPTER 3. TROUBLESHOOTING

[1] TROUBLESHOOTING GUIDE....................... 3-1

[2] THERMISTOR TEMPERATURE CHAR-

ACTERISTICS ............................................... 3-5

[3] HOW TO OPERATE THE OUTDOOR

UNIT INDEPENDENTLY................................ 3-5

CHAPTER 4. REFRIGERATION CYCLE

[1] FLOW FOR REFRIGERANT.........................4-1

[2] STANDARD CONDITION ..............................4-1

[3] TEMPERATURE AT EACH PART AND

PRESSURE IN 3-WAY VALVE ......................4-1

[4] PERFORMANCE CURVES...........................4-1

CHAPTER 5. DISASSEMBLING PROCEDURE

[1] DISASSEMBLY OF INDOOR UNIT...............5-1

[2] DISASSEMBLY OF OUTDOOR UNIT.........5-13

Parts Guide

TopPage

CONTENTS

SPLIT TYPE

ROOM AIR CONDITIONERS

OUTDOOR UNIT

AE-X12FR-N

In the interests of user-safety (Required by safety regulations in some

countries) the set should be restored to its original condition and only

parts identical to those specified should be used.

INDOOR UNIT

GS-XP12HR-N

CEILING TYPE

FLOOR TYPE

MODELS