4Contents

Air line piping .............................................................................................................................................. 21

Supply air port I.D. .............................................................................................................................. 21

Air line piping diagram..............................................................................................................................22

Composite effective cross-sectional area................................................................................................ 24

Effective cross-sectional area............................................................................................................. 24

Preventive measures against condensation ....................................................................................... 24

Electric wiring .............................................................................................................................................25

Installation ................................................................................................................................................25

Lead wires........................................................................................................................................... 25

Extension of leak sensor wires ........................................................................................................... 25

Installation of proximity switch wires ................................................................................................... 25

Extension of proximity switch wires .................................................................................................... 25

Wiring diagram .........................................................................................................................................26

Operation................................................................................. 27

Before operation ......................................................................................................................................... 27

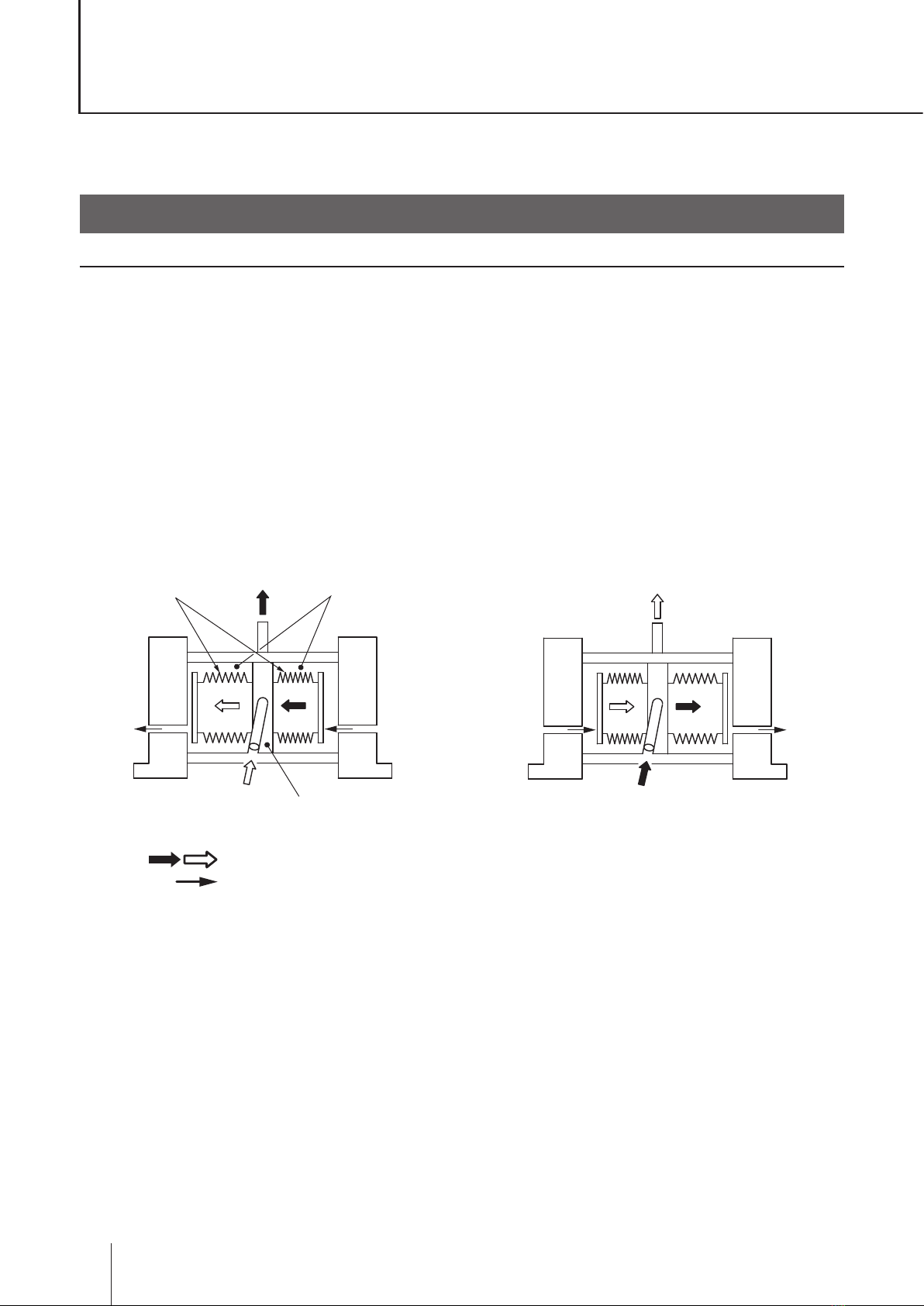

Pump operation...........................................................................................................................................28

Starting the pump..................................................................................................................................... 28

Flow rate adjustment ................................................................................................................................29

Stoppage..................................................................................................................................................29

Maintenance............................................................................ 30

Troubleshooting ..........................................................................................................................................30

Inspection ....................................................................................................................................................33

Daily inspection ........................................................................................................................................33

Periodic inspection...................................................................................................................................33

Wear part list ............................................................................................................................................34

Specication/Outer dimension..................................................................................................................35

Specication.............................................................................................................................................35

FS-15 H T 1 or 2..................................................................................................................................35

FS-30 H T 1 or 2 .................................................................................................................................36

FS-60 H T 1 or 2 .................................................................................................................................36

Outer dimension....................................................................................................................................... 37

FS-15 H T 1......................................................................................................................................... 37

FS-15 H T 2......................................................................................................................................... 37

FS-30 H T 1 ........................................................................................................................................38

FS-30 H T 2 ........................................................................................................................................38

FS-60 H T 1 ........................................................................................................................................39

FS-60 H T 2 ........................................................................................................................................39

Part names...............................................................................................................................................40

FS-15 H T 1.........................................................................................................................................40

FS-15 H T 2......................................................................................................................................... 41

FS-30 H T 1 ........................................................................................................................................ 42

FS-30 H T 2 ........................................................................................................................................43

FS-60 H T 1 ........................................................................................................................................44

FS-60 H T 2 ........................................................................................................................................45

EC DECLARATION OF CONFORMITY .................................................................................................. 46