J D Squared 4 Quick reference guide

Mo d e l 4 Tu b e be n d e r

Assembly & Operating Instructions

J D Squared Inc.

2244 Eddie Williams Rd. Johnson City, TN 37601

(423) 979-0309, FAX (423) 979-2426

Internet: www.jd2.com

© Copyright 2008 by J D Squared Inc.

Revision 4 (7/10/2008)

Unpacking & Parts List

The basic Model 4 bender is shipped in 2 packages. Package 1 contains the lower frame only. Package

2 contains all other parts needed for assembly, excluding the hydraulic cylinder, pump and hose. If these

items were also ordered with the bender, they will arrive in their own separate boxes. Upon receiving

both packages verify that neither package shows any signs of damage and that all parts are present. If

a package has been damaged and parts are either missing or damaged, you must immediately contact

our sales ofce.

PACKAGE 1 CONTENTS:

1 Lower frame

PACKAGE 2 CONTENTS:

1 Instruction manual

------------------------------

1 Upper frame

11 3/4" S.A.E. washers

3 3/4" x 2" at head screws

3 3/4" nuts

3 1 1/2" diameter frame sleeves

3 1" x 8" bolts

6 1" S.A.E. washers

3 1" nuts

1 1" x 8" diameter frame pin

2 7/8" x 8" frame link pins

------------------------------

1 7/8" x 6 1/4" drive link pins

1 Drive link - Lower

1 Drive link - Upper

1 3/4"-16 x 5" long bolt (Outside drive link bolt)

1 3/4"-16 x 4 1/2" long bolt (Inside drive link bolt)

2 1" diameter drive link sleeves

1 Hydraulic swivel block

------------------------------

1 Pusher block with 1" diameter ange bolt welded in place

1 Pusher block handle

1 3/16" x 1 1/4" long roll pin

1 1 1/2" diameter pushrod (screws into hydraulic cylinder)

1 Bronze pivot block

2 1/2" diameter shoulder bolts

1 3/8" nylock nut

1 Anti-Springback lever

1 1/2"-20 x 1" long bolt

1 1/2" S.A.E. washer

1 3/4" diameter x 3/8" long sleeve (for anti-springback lever)

1 1/2" threaded spring pin

1 1/2"-20 ne thread nut (will be installed on spring pin)

1 spring

1 1/4" x 1 1/2" long socket head bolt

2 1/4" nuts

- 1 -

Assembly

1) The bender may be mounted to anything rigid enough not to twist or move

during the bending operation. To mount the bender, drill three 3/4" holes through

your mounting surface. You can use the frame holes as a guide. Place two 3/4"

washers on the top of each drilled hole. These washers will act as spacers to insure

that the bender pins, when installed, will be completely pass through the lower

frame holes. If you purchased the optional pedestal, position the washers over the

slots as shown in gure 1.

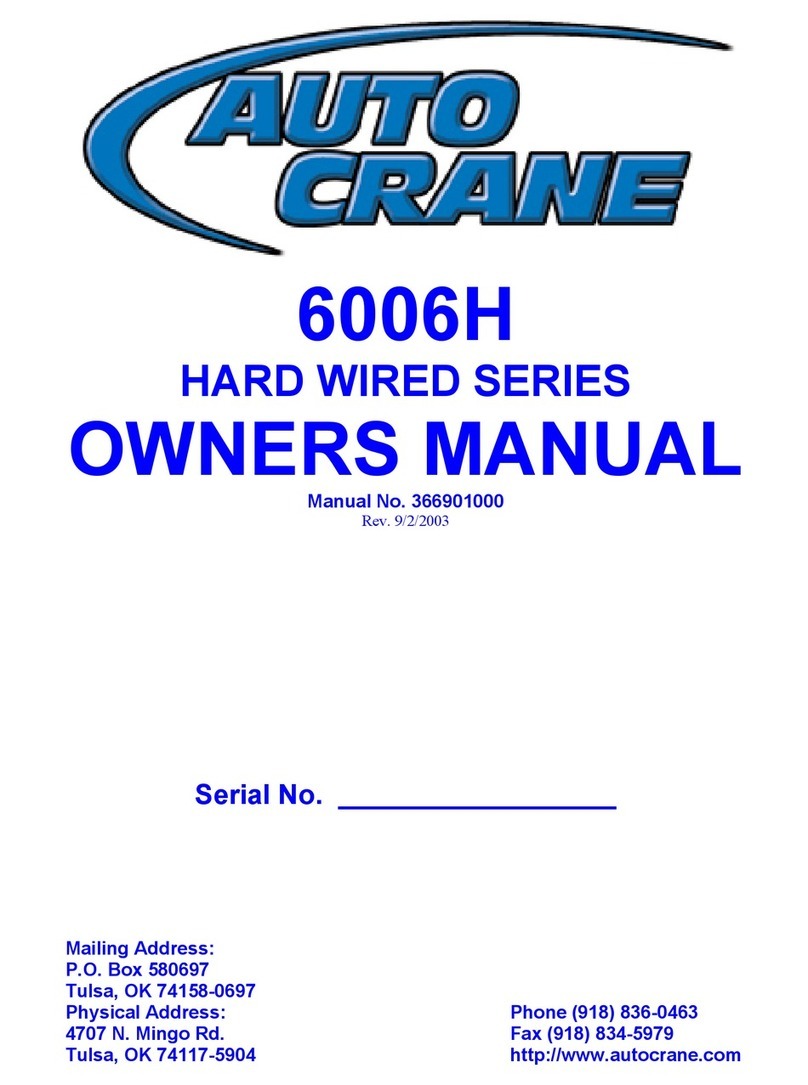

3) Remove the 1" frame pin. Locate the lower drive link. It will

have two 3/4" tapped holes in it and a recess milled out of its

bottom side's center. Place it on the lower frame with its inside 1"

hole over the lower frame's 1" center hole and its milled recess

facing down. Replace the 1" frame pin. Locate the hydraulic

cylinder's swivel block. Examining the swivel block you will see

the word 'TOP' stamped into it. Insert the swivel block into the

lower drive link's remaining 1" hole. Your Model 4 should now

look like gure 3.

2) Refer to gure 2. Using three 3/4" x 2" long at head

bolts, three 3/4" nuts and three 3/4" washers, tightly

securetheframetoyourmountingsurface/pedestal. Using

three 1 1/2" diameter frame sleeves, three 1" diameter

x 8" long bolts, six 1" washers and three 1" nuts, install

the upper frame onto the lower frame. Lightly tighten the

bolts. Next install the 1" frame pin as shown in gure 2.

Using a small square placed against the 1" pin, move

the upper frame around until the frame pin is perfectly

vertical. Tighten all three 1" bolts.

4) Refer to gure 4 for this step. Remove the 1" frame pin. Locate the

upper drive link. Place it in the bender so that it aligns with the lower

drive link and engages the swivel block's upper shaft. Reinstall the 1"

frame pin. Place the two 1" diameter drive link sleeves between the two

drive links aligned with the 3/4" holes. Place a 3/4" washer onto the

3/4"-20 x 5" long bolt. Install it into the outside 3/4" sleeve and lightly

tighten. Place a 3/4" washer onto the 3/4"-20 x 4 1/2" long bolt. Install

it into the inside 3/4" sleeve and tighten securely. Remove the whole

drive link assembly and turn upside down. Look on the bottom side

of the lower link and verify that the inside 3/4" bolt threads do NOT

protrude out of the link. If it does, it will severely scratch the frame's

machined surface. Also the bender's links will not ride properly on the

lower frame. The only way this should be able to occur would be if the

longer 5" bolt was installed where the 4 1/2" bolt should be.

- 2 -

Figure 3

Figure 1

Figure 2 - Upper frame installed

Figure 4 - Drive links installed

Upper Frame Link

Lower Drive Link

Hydraulic

Swivel

Block

5) Invert the drive link assembly as shown in gure 7.

Locate the parts listed below:

1 Anti-Springback lever

1 1/2"-20 x 1" long bolt

1 1/2" S.A.E. washer

1 3/4" diameter x 3/8" long sleeve

1 1/2" threaded spring pin

1 1/2"-20 ne thread nut

1 1/4" x 2" long socket head bolt

2 1/4" nuts

1 Spring

Place the 1/2" washer onto the 1/2"-20 x 1" long bolt.

Next place the 3/4" diameter sleeve onto the bolt also. This

sleeve acts as a spacer. Study gures 5 and 7 carefully and

then position the anti-springback lever as shown. Install the

bolt, washer and sleeve through the anti-springback lever

and into the lower drive link. Tighten securely. Verify that

the lever rotates freely.

Install the 1/2"-20 ne thread nut onto the spring pin

about half way up. Install the spring onto the spring pin as

shown in gure 6. Screw the spring pin into the lower link

until it starts to protrude out the other side of the drive link.

Back it off 1 to 2 turns, to make sure it doesn't protrude,

and tighten the 1/2" nut.

Install a 1/4" nut onto the 1/4" x 2" long socket head

bolt. Adjust the 1/4" nut so that when the bolt is installed in

the anti-springback lever, the 1/4" nut on the other side of

the anti-springback lever can be completely installed with

only 1 thread visible. This will put the bolt's head roughly

even with the spring pin's head. Remove the 1/4" bolt. Being

careful not to turn the 1/4" nut already installed, insert the

bolt's head through the open loop of the spring. Holding

the bolt, stretch the spring and insert the bolt back into the

1/4" hole in the anti-springback lever. Install the other 1/4"

nut onto the bolt from the top side of the anti-springback

lever and tighten. Remember that only one thread of the 1/4"

bolt should be visible from the top side of the anti-springback lever. Figures 6 and 7 show the complete

assembly correctly installed. Note that the outside 3/4" bolt protrudes out of the bottom of the lower drive

link and that the inside 3/4" bolt does NOT.

Install the completed drive link assembly into the bender. The easiest way to do this is from the rear of the

bender. Insert the drive link assembly with

the open 1" holes between the 1" holes in the

frame.Insertthe1"framepin.Nowrotatethe

drive link assembly counterclockwise until it

rest on the machined upper surface of the

frame. If it does lay at, the upper frame link

will need to be loosened and repositioned

until the 1" frame pin is perfectly vertical.

Rotate assembly until the degree scale

reads 30 to 60 degrees on the right side

of the lower drive link.

- 3 -

Figure 5 - Anti-springback lever

Figure 6 - Spring installation

Figure 8

Figure 7 - Lever system installed

Spring Pin1/4" Bolt

Anti-Springback

lever

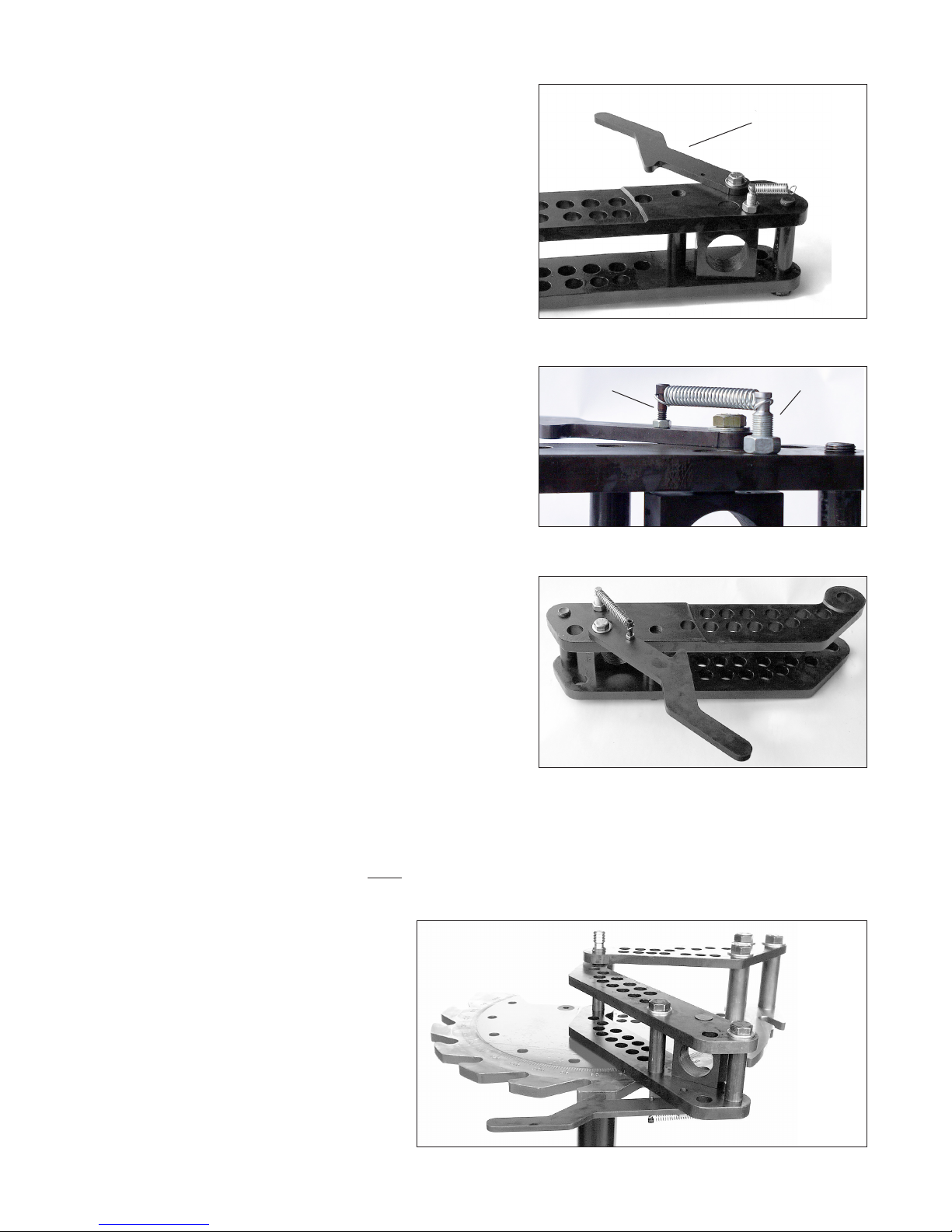

6) Locate the parts shown in gure 9 and listed

below:

1 Pusher Block

1 Pusher Block Handle

1 Bronze Pivot Block

1 Pushrod (1 1/2" diameter)

2 1/2" x 2 1/2" long shoulder bolts

1 3/16" roll pin

1 3/8" nylock nut

1 1" diameter welded ange bolt

NOTE: This bolt is shown as a seperate

itemingure9foreasieridentication.

However,Ithasalreadybeenweldedinto

thePusherBlock.

Examine the bronze pivot block.You will notice

that the 1/2" hole has been offset drilled to one

side as shown in gure 10. The distance from

the hole's edge to the pivot block's side will be

less than the other three sides. This is the pivot

block's upper side. Now examine the pusher

block. You will see a 1 1/2" slot milled completely

through its top surface and on its bottom you will

see a smaller recess milled into it's front edge.

Note: The pusher block shown in gure 9 is bottom side up so that

the milled recess can be clearly seen. This recessed area is where

the bronze pivot block is installed. Hold the pusher block so that the

engraving on its side is right side up and facing you. Position the

bronze pivot block into the lower recess so that its upper surface is

facing up (the hole is offset to the top). From the engraved side of

the pusher block, insert one of the two 1/2" shoulder bolt and secure

tightly with the 3/8" nylock nut. When completed it should look like

gure 11. The pivot block must also be protruding out of the bottom

of the pusher block approximately 1/16" as shown in gure 12. If it's

not, it's installed wrong and must be reinstalled.

As shown in gure 13, position the pushrod into the pusher block's

upper slot. The 1/2" hole in the pushrod nearest to the end should be

lined up with the 1/2" hole in the pusher block. Insert a 1/2" shoulder

bolt into the pusher block from the side opposite the engraving. Install

the pusher block handle onto this shoulder bolt and tighten. Lay the

pusher block down on the side opposite the engraving. Slightly rotate

the pushrod so that the 1/2" hole in its middle is under the 3/16" hole

drilled into the engraved side of the pusher block. Being careful not to

mar the engraved face of the pusher block, hammer in the 3/16" roll

pin until it is ush with the pusher block's surface. Figure 11 shows

this step completed.

- 4 -

Figure 9 - Pusher assembly

Figure 10

Figure 12

Figure 11 - Pusher block

Figure 13

Pusher assembly complete

Bronze Pivot

Block Upper Side

Pushrod

1" Welded

Flange Bolt

Pusher Block Handle

Pusher Block

Bronze Pivot Block

7) Screw the hydraulic cylinder completely into the hydraulic

swivel block. If when tightened the cylinder's quick disconnect

hose tting is not facing in the downward direction, loosen

the cylinder until it does face in the downward direction. The

cylinder will have a little play in its threads. This is normal and

will not cause any problems.

Screw the completed pusher block assembly into the

cylinder. You may need to rotate the drive links to the rear

of the bender in order for the handle to clear the main frame

as the pusher block is screwed into the cylinder. Rotate the

pusher block so that the handle is facing toward you. Rotate

the drive links until the pusher block is positioned approximately

as shown in gure 14.

Using the handle, move the 1" welded ange bolt into

one of the lower frame's teeth. When the bender is under load, the rear of the pusher blockshould rise

approximatley 1/16" above the face milled at of the lower frame. With the bronze pivot block protruding

out of the bottom of the pusher block 1/16", this should make the pusher block ride at when bending.

This will eliminate any side loads on the hydraulic cylinder, therefore preventing any unnecessary wear

in the cylinder.

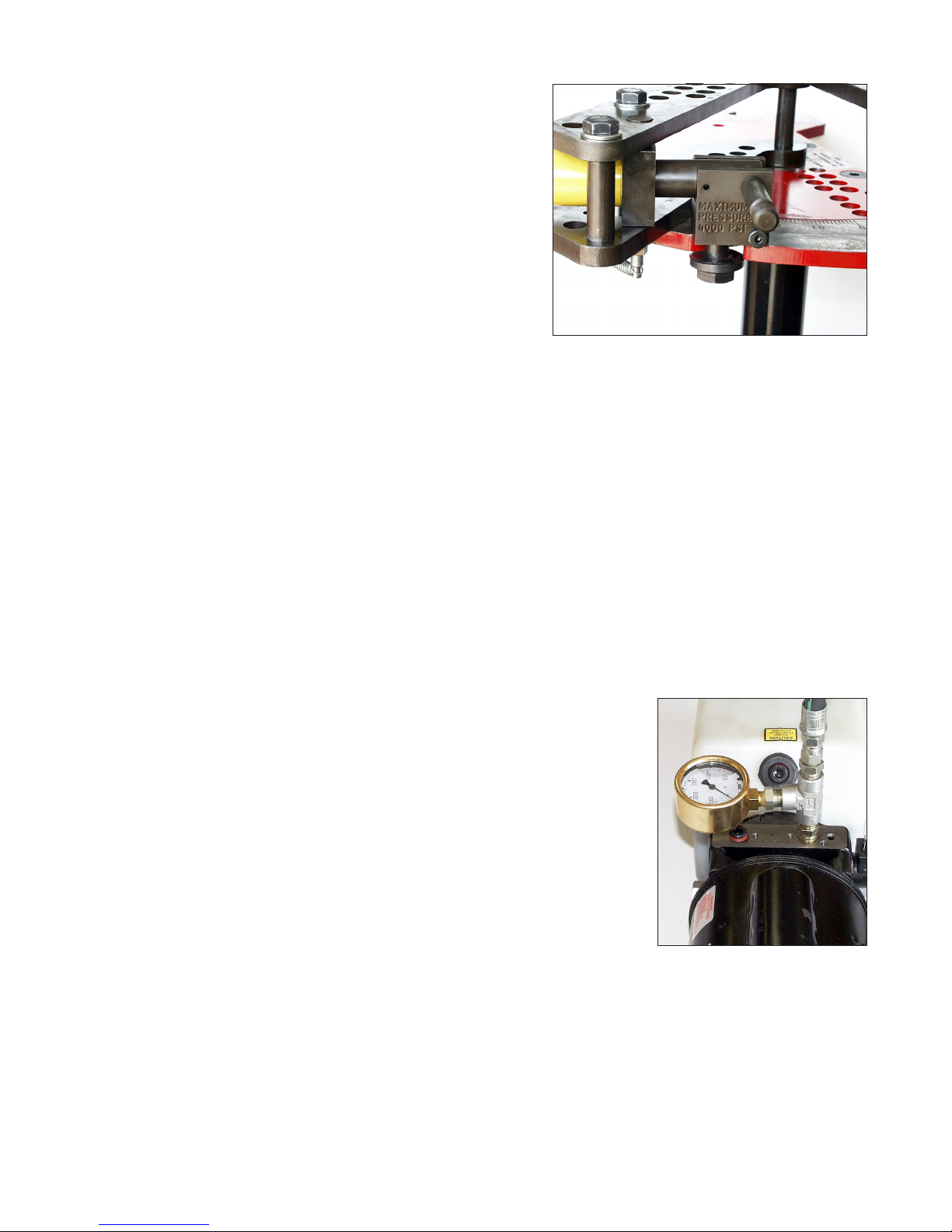

8) Next attach the hose to the pump in its correct port. If you have your own pump or purchased a

pump with your bender and it wasn't the 2 HP model, follow the directions included with the pump. If you

purchased the preferred 2 HP pump as shown in gure 15, you can look at the photo as a reference. Wrap

2 to 3 layers of teon tape around the male threads on the hydraulic hose. Looking at the bender from

the electric motor side, screw the hose into the right side upper port. Wrap 2 to 3 layers of teon tape

around the 1/2" pipe plug and screw it into the left side upper port. Make sure both are tightened snugly.

Attach the hose to the cylinder's quick disconnect tting and hand tighten only. Plug the pump into the

proper electrical outlet. Note: Upon start up, if the pump acts like it's not getting enough current, take these

steps to x the problem. First use a heavy gauge (12 gauge or heavier),

short electrical extension cord. The shorter the better. If using 110 volts,

make sure the electrical circuit breaker is rated at least 30 amps. As a

general rule, if when the bender is operating, the electrical extension cord

feels hot, it's too small. Also if the electrical relay operates erratically when

pressed, it's probably a sign of an electrical supply problem.

Pressing the pump control buttons will extend the cylinder under

pressure or release the pressure, thereby retracting the cylinder using its

internal spring return. If neither button is pressed the cylinder will hold its

position. The 2 HP pump is relatively fast. It's easy to overshoot the desired

bend angle. To prevent this from happening, follow this procedure: Press

the cylinder extend button and hold down until the bender is 3-5 degrees

before the desired angle. Now quickly tap the button on and off until the

bender edges up to the proper degree. With practice you should easily be

able to advance the cylinder as little as 1/5 of a degree. Note the 5000 p.s.i.

pressure gauge shown in gure 15. This gauge is not included with the pump, but is highly recommended.

A good quality gauge can be purchased at any hydraulic supply business. Simply tee it into the pressure

hose as shown in gure 15.

- 5 -

Figure 14 - Pusher block engaged

Figure 15

- 6 -

Installing Die Sets

The Model 4 bender comes with 4 pins. Locate the pins listed below:

1 1" Diameter x 8" Frame Pin

2 7/8" Diameter x 8" Long Frame Pins (Long Pin)

1 7/8" Diameter x 6 1/4" Long Drive Pin (Short Pin)

A Die Set consists of the 3 parts listed below:

1 Forming Die (Circular in shape, usually with a groove)

1 Pressure Die (The part that slides along the workpiece)

1 U-Block (A small square block that retains the workpiece, also usually has a groove)

STEP 1 - INSTALL THE FORMING DIE

Forming Die Installation

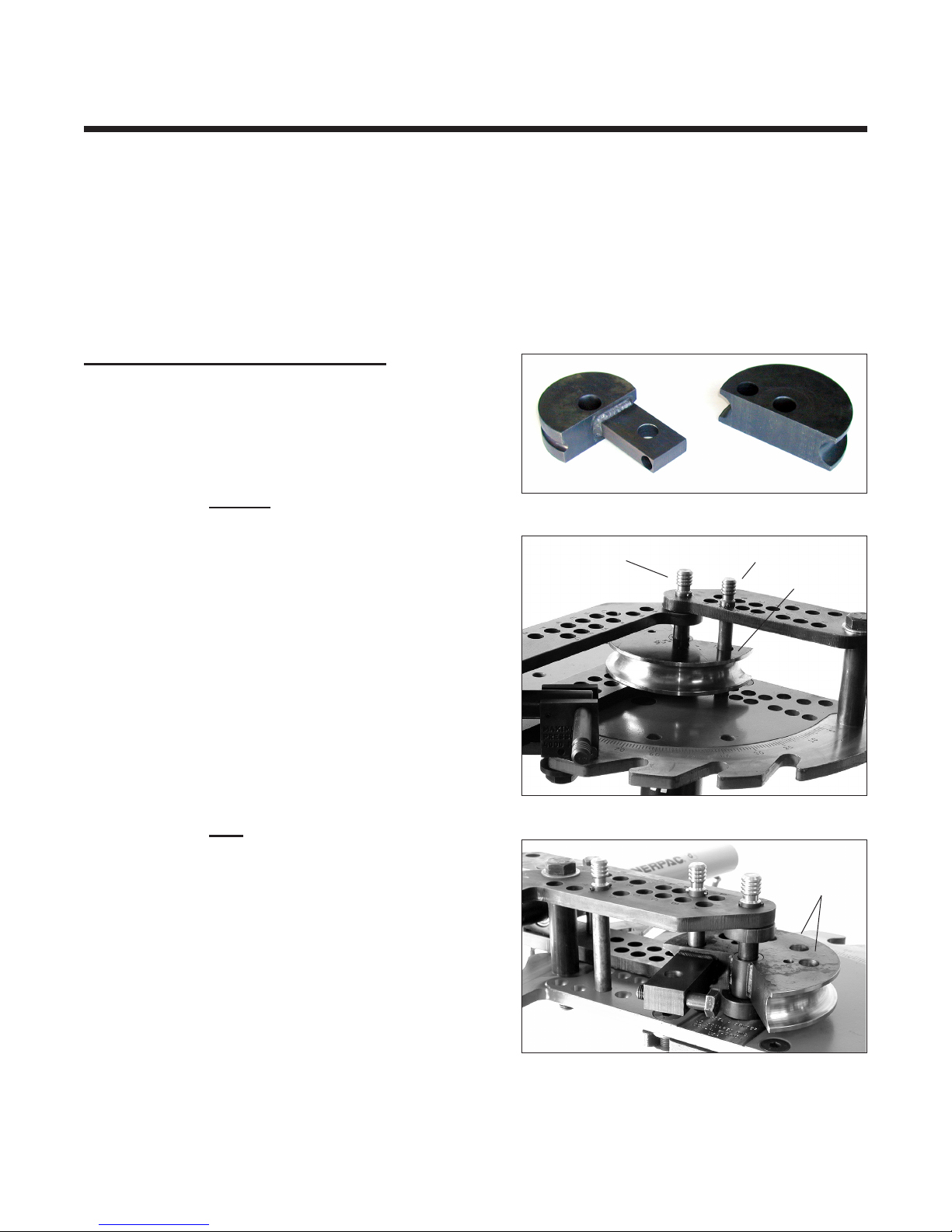

There are two styles of forming dies. One has a

square block welded to its backside as shown in left side

of gure 17. The other doesn't as shown in right side of

gure 17. The method of die installation depends on what

style you have.

Installing a Die without a welded block:

Using the 1" frame pin, place the forming die into the

bender with its rounded side forward as shown in gure

18. The forming die will normally only have one other hole

drilled through it, as shown on the right side of gure 17.

This hole is very close to the die's edge, usually within

a 1/8"-1/4". If there is more than one hole, use the hole

closest to the die's edge. Model 1, 2 and 3 die sets will

work in the Model 4, however they usually will have 3 to 5

holes drilled through them. So with those dies you would

only use the hole closest to the at side of the die.

Rotate the die until the hole in the die lines up with

one of the NUMBERED holes 1 - 4 in the frame (not the

lettered holes). Insert one of the two long 7/8" frame pins

through the frame and die. This pin will prevent the die

from rotating when the bender is operating.

Installing a Die with the welded block:

Using the 1" frame pin, place the forming die into the

bender as shown in gure 19 with the welded block closest

to the frame bolts. The die shown has multiple drive holes

drilled in it. Only the one closest to the die's at side (it

will be the one nearest to the welded block) needs to be

used. A long 7/8" frame pin has been installed in the hole

closest to the dies welded block. Installed this way the

welded block serves no function. This would be the case

if a Model 3 die set was being used in the Model 4.

If the forming die does NOT have any drive holes,

only a welded block, then install the die as shown but

do not use a 7/8" pin. In this case, when the bender is

operating, the welded block on the die will rotate clockwise and contact the workpiece, thus preventing

the die from rotating. Note that if the die has a welded block and drilled drive holes you can use either the

welded block or the rst drive hole.

Drive Holes

Figure 16 - Die styles

Forming Die

1" Frame Pin 7/8" Frame Pin

Figure 17 - Die installed

Figure 18 - Die with welded block

Figure 20 - Top view drawing

Angled Groove

Straight Groove

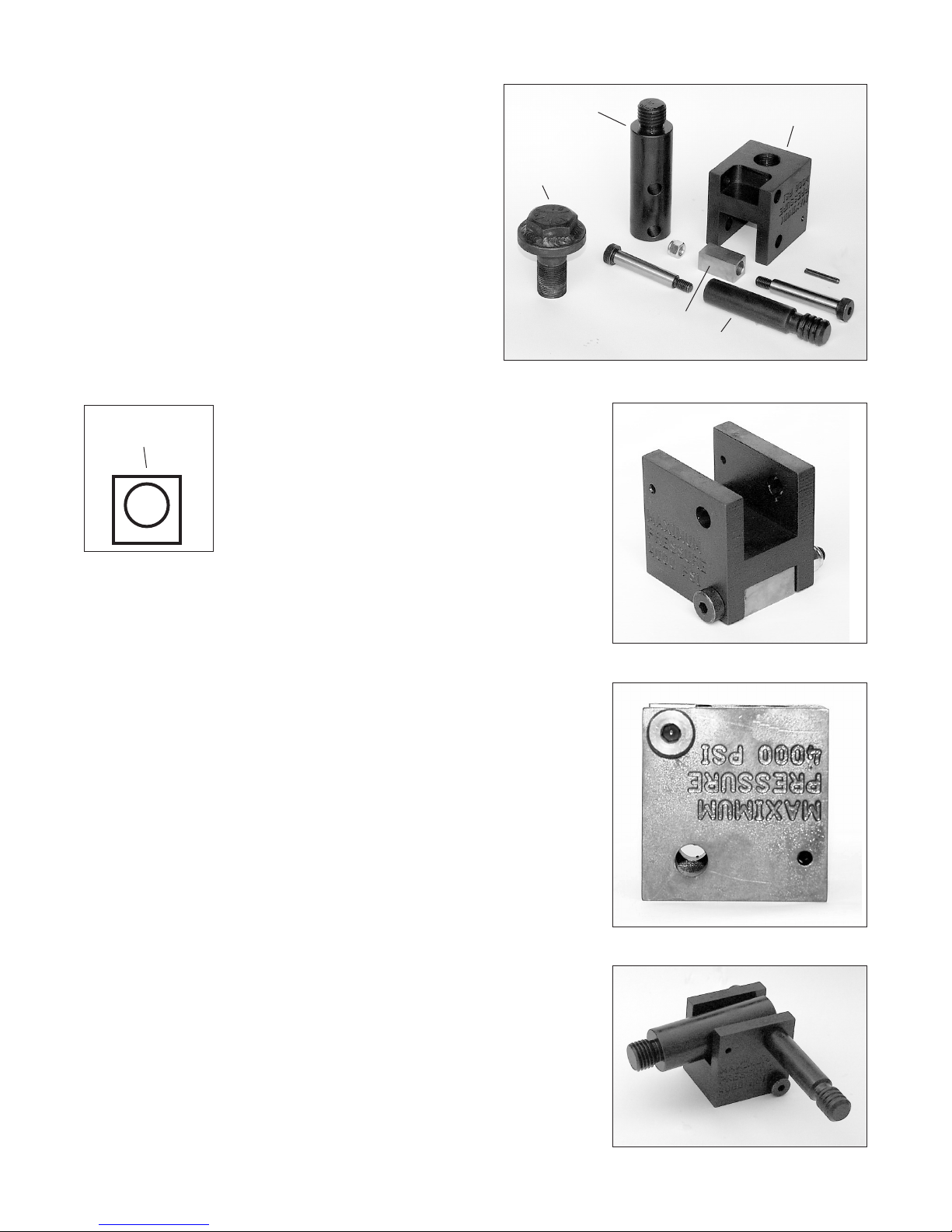

STEP 2 - INSTALL THE PRESSURE DIE

Pressure Die Installation

Pressure dies are machined to exacting standards and must be installed in the proper orientation.

Depending on whether the die set is for pipe, round or square tubing follow the appropriate directions

below.

ROUND TUBING OR PIPE

The pressure die is shown in gure 19. For round tubing and pipe, the pressure die will have two circular

grooves machined on each end, a leading and a trailing groove. The trailing side groove is machined at

an angle. This angled groove provides better control of the workpiece than a straight groove, resulting

in a better bend quality. However, the pressure die MUST be installed in the bender's drive links with the

angled groove closest to the forming die. If the pressure die is installed upside down, that is with the angled

groove forward, it will try to dig into the workpiece and bend quality will suffer.

Engraved into the pressure die will be the O.D. size of the tubing or pipe and the correct hole number

that it should be installed into the drive links with.

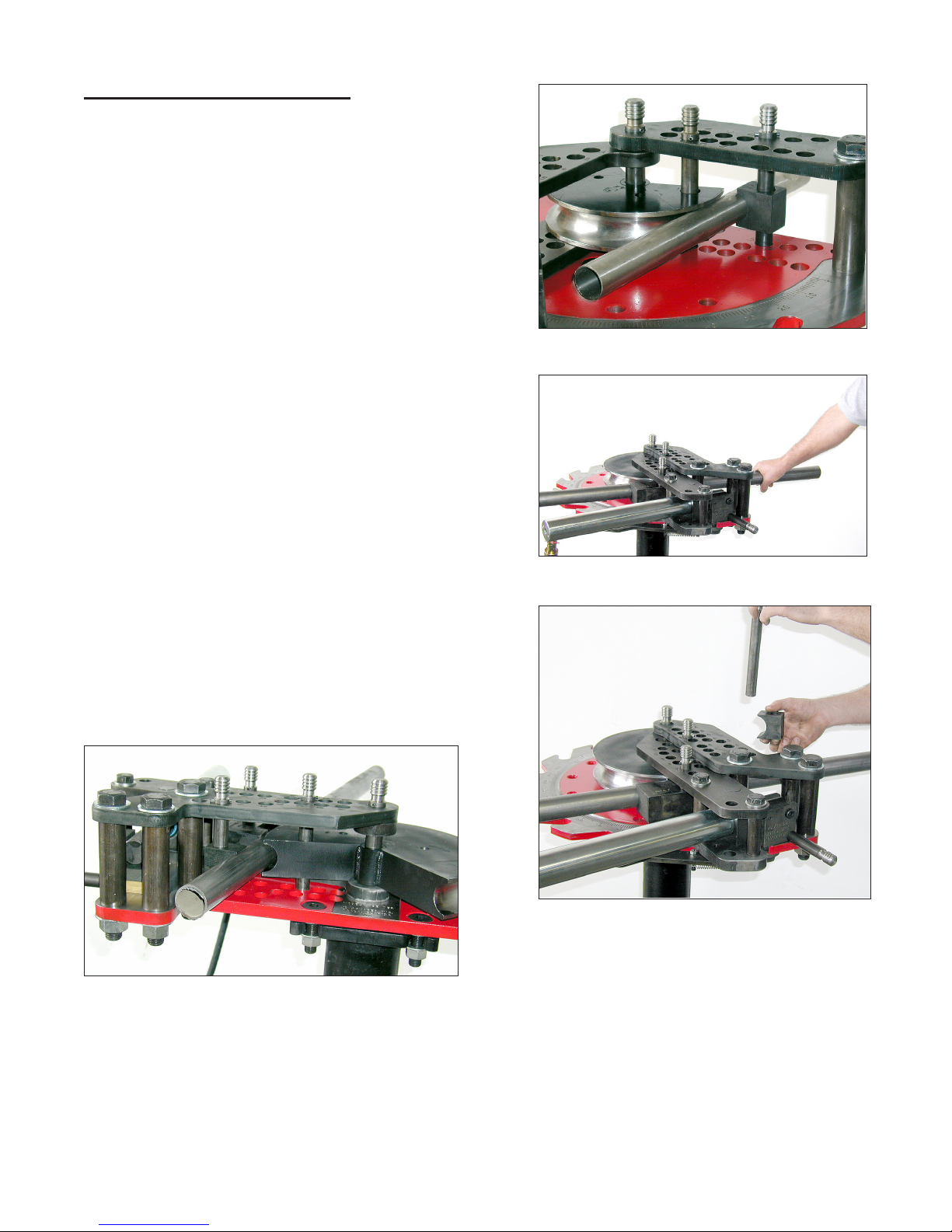

Referring to gures 21 and 22. After the forming die

has been installed, rotate the drive links counter-clockwise

until they are parallel with the upper frame link. Place the

tubing or pipe to be bent through the middle of the drive

links as shown. Next place the pressure die between the

drive links with the angled groove closest to the forming

die. The angled groove should now be towards the rear of

the bender and on your right side. Insert a short 7/8" pin

through the drive links and the pressure die in the exact

hole number engraved into the pressure die.

NOTE:Theangledgroovesupportsthetubeduringthe

bending process, thereby preventing it from excessively

attening on the outside. Never install the pressure die

upside-downwiththeangledgroovenotatthepointofbend

(closesttotheformingdie).Itcandamagethepressuredie

andseverelygougeyourtubeorpipe.Also,ifthepressure

dieisplacedinahole#otherthantheonemarkedonit,

bendqualitywillsuffer.Ifthetubeorpipeisatteningalarge

amountontheoutside,checktomakesurethepressure

dieisinstalledinthecorrectdrivelinkhole.

- 7 -

Figure 19 - Tube or pipe Pressure Die

Figure 22 - Pressure Die installed - back

Figure 21 - Pressure Die installed - front

Straight Groove Angled Groove

Angled Groove towards

back of bender

Straight Groove

STEP 3 - INSTALL THE U-BLOCK

Shown in gure 23 is the U-Block installed in the bender.

Normally the pressure die would have already been installed,

but for a clearer view of the u-block it has been removed.

Looking at the top of the upper frame you will see two

rows of 7/8" holes with letters or numbers beside them. The

front seven row holes (1,2,3,4,E,F,G) are in a straight line

and the back seven holes (A,B,C,D,5,6,7) are staggered.

The back side holes are the ones where the U-Block pin is

normally installed as shown in gure 23.

PROCEDURE:

The forming die, pressure die and workpiece (tube

or pipe) have already been installed in the bender in the

previous two steps.

Position the workpiece where you want it bent. Referring

to gure 24, push the workpiece away from you rmly. This

will seat the workpiece in between the forming die and

pressure die, removing any play.

- 8 -

Install the u-block and long 7/8" frame pin into one of the

7/8" back side holes AS CLOSE TO THE 1" FRAME PINAS

POSSIBLE. This is why you had to push the workpiece away

from you. Figure 26 shows the complete die set installed

as seen from the back side of the bender.

SQUARE TUBING

Square tube die sets are installed in the same way as round tube die sets with the exception of the

pressure die. Square tube pressure dies do not have an angled groove, just one long straight groove.

Therefore, all you need to do is install it in the correct hole# as marked on it.

Figure 23 - U-block installed

Figure 24 - Pushing workpiece

Figure 25 - Installing pin in back hole

Figure 26 - Die set installed as seen from back

side of bender

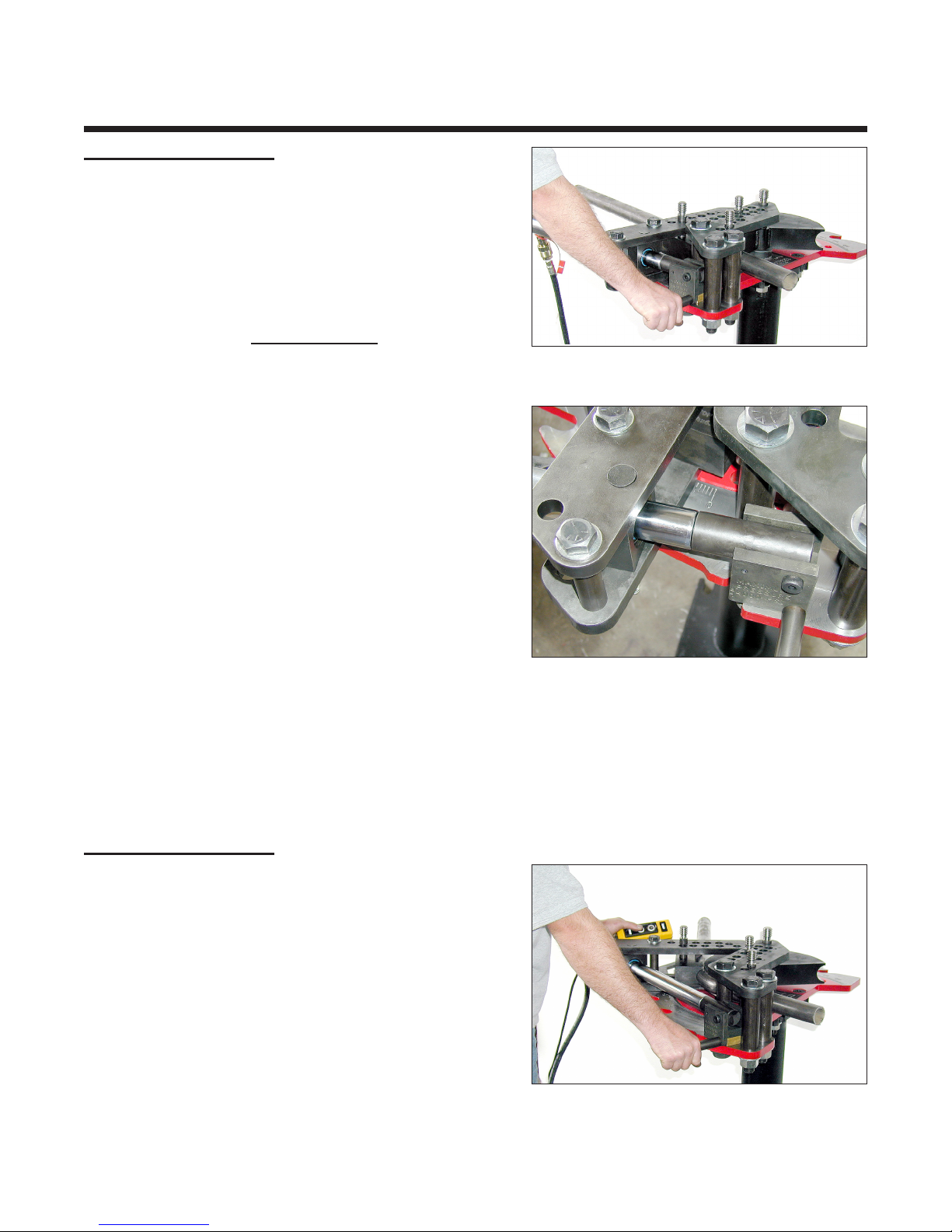

Operation

STEP 1 - Figure 27 & 28

Using your hands, rotate the drive links clockwise until

the workpiece is rmly seated in the die set with no play.

With the cylinder fully retracted, extend the cylinder while

guiding the pusher block into the rst ratchet tooth on the

frame. DO NOT PLACE YOUR HANDS ANYWHERE ON

THE PUSHER BLOCK EXCEPT ON THE HANDLE. THIS

WILLPREVENTANYPOSSIBLE PINCH POINT.ALWAYS

KEEP YOUR HANDS OUTBOARD OF THE BENDER

WHEN OPERATING. BE CAREFUL!!!

Extend the cylinder lightly until the workpiece is securely

seated in the die set but has NOT started to bend. Look

on the lower rightside of the lower drive link and note the

degree reading as shown in gure 28. Two to eight degrees

is normal, but may vary. This initial degree reading is called

the lead-in angle. You need to add 3 angles together in

order to obtain a correct bend angle.

1) The lead-in angle. This accounts for the bender

and die set clearances.

2) The desired bend angle. This is the actual angle

of bend you want the nished bend to be.

3) Thespringbackangle.Allworkpieceswillspringback

when pressure is removed after bending. Usually

on the order of 2-8 degrees, depending on the

yield strength of the workpiece and the amount

of bend. A tube that springs back 3 degrees at 90

degrees of bend may spring back 5-6 degrees at

180 degrees of bend. The only way to determine

springback values is by trial and error. Once you know the correct values for a specic workpiece

(material, wall thickness, angle of bend) write it down so you can use the same value next time.

Lead-In+Desiredbendangle+Springbackangle=Degreereadingonbenderwhennished

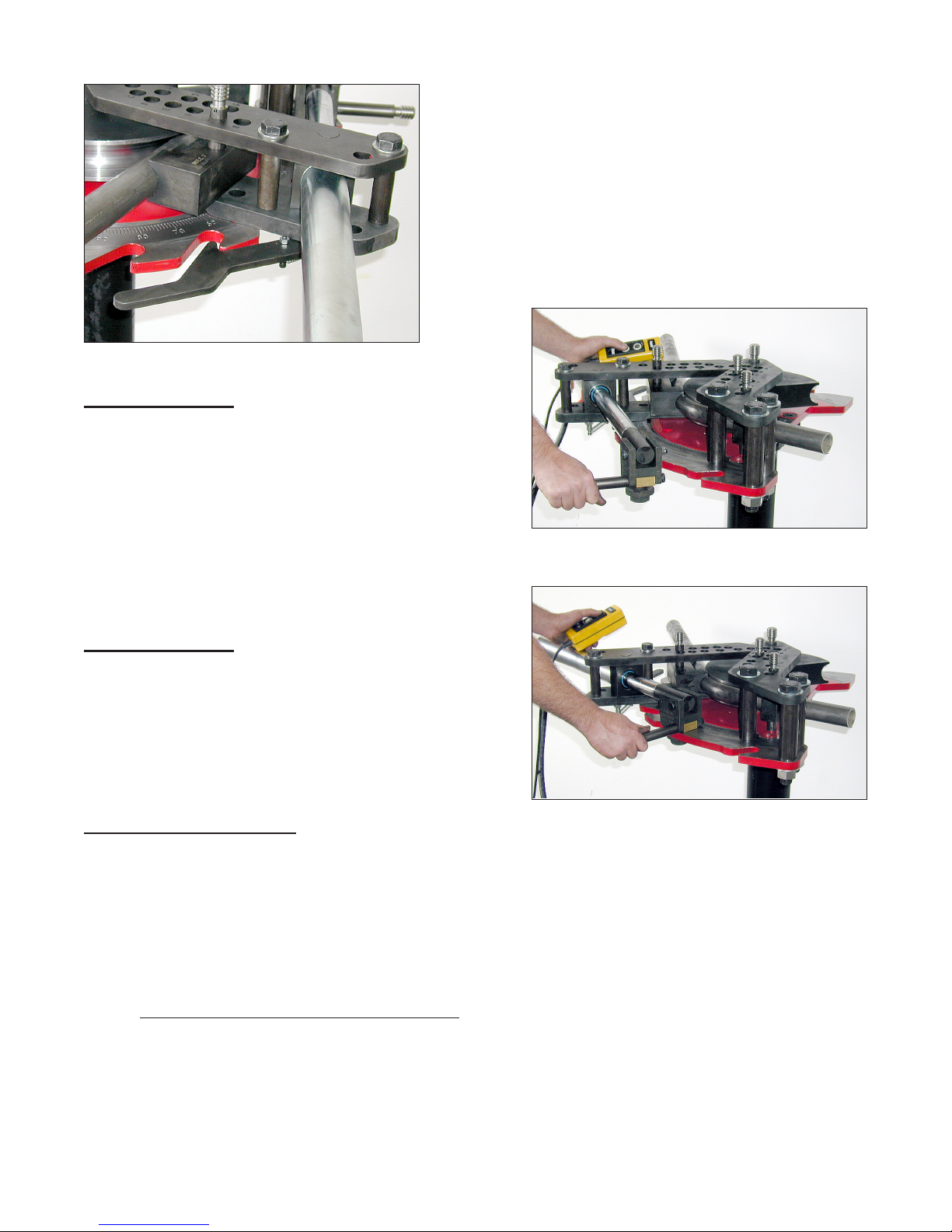

STEP 2 - Figure 29 & 30

Engage the anti-springback lever by pushing it in

towards the frame teeth. While watching the degree

markings on the bender start extending the cylinder. If

making a bend over 55 degrees go ahead and quickly stroke

out the cylinder until around 50 degrees or so. Just before

the anti-springback lever engages the frame's ratchet teeth

stop the cylinder. Try to stop it as close as you can without

the anti-springback lever actually clicking into the frame

tooth. Now rapidly tap the cylinder extend button until the

anti-springback lever engages the frame tooth. You do not

want to go too far, because that would defeat the purpose

of the lever. You want to be able to retract the ram with as

little springback as possible. Refer to gure 30.

-9-

Figure 27 - Engaging 1st ratchet tooth

Figure 29 - Ram extended

Figure 28 - Lead-in degree reading

A QUICK EXAMPLE BEND

As an example, let's say you want to bend a piece of 1 1/4" schedule 40 pipe 90 degrees. Place a

mark on the pipe where you want the bend to start. Install the pipe and the die set into the bender. Position

the mark on the pipe at the point on the forming die where the bend will start. Engage the rst tooth and

preload the pipe by lightly extending the ram. As shown in gure 28, note the lead-in angle. Let's say it

shows 4 degrees. For this size pipe, a springback angle of 3-4 degrees is normal is average. So let's use

3 1/2 degrees. Now add up the 3 degree values.

4 degrees of lead-in angle

90 degrees of desired bend angle

3 1/2 degrees of springback

97 1/2 Degrees total

Extend the ram out until the degree reading is over 50 degrees and just before the lever engages stop

the ram. Quickly tap the ram extend button until the anti-springback lever fully engages, but just barely.

Retract and reengage the ram as shown in gure 32. Continue bending until around 95-96 degrees and

stop. Quickly tap the button until the degree reading is 97 1/2. Disengage the lever and remove the nished

pipe.

STEP 3 - Figure 31

Fully retract the hydraulic ram as shown in gure 31.

STEP 4 - Figure 32

Engage the next tooth and continue.The second stroke

of the ram will take the bend to over 90 degrees. Bends of

120 - 130 degrees will generally require another stroke.

- 10 -

Figure 30 - Lever engaged

Figure 31 - Retracting cylinder

Figure 32 - Engaging next tooth

Learning the operation of a bender is fairly easy. The real challenge is accurately placing the tubing

into the bender so that the bend comes out in the right position. This short tutorial explains the simple

process of template bending.

Make a sample bend called the Template as shown in Figure 33. A permanent mark scribed on the

template allows you to measure and visualize where the bend should be placed in the tubing. Once bent

the tubing will spring out to a larger radius than the forming

die’s size indicates. The larger the O.D. or the stronger

the tubing, the greater the springback. For instance,

chromemoly tubing will springback roughly twice as far

as the exact same size and wall thickness of welded seam

mild steel tubing. By using a template bend with the same

kind of tubing you are going to bend, you do not have to

worry about this springback because the template has

already sprung out to its n ished size.

You may ask if buying bending software is a good

idea. I believe bending software can only jus tied for two

reasons:Creatingpartdrawingsifthesoftwaresupportsthat

function and for setting up a fully automatic CNC bender

for the initial test of a part with multiple bends. Even using

the software the bend locations usually need to be hand

tweaked for accuracy before going into production. Most

professional fabricators use a method similar to what is

described here. It is extremely easy, accurate and fast.

However, what if you need to bend 500 pieces. How would

you use this process? Don’t worry, it’s a simple technique

that I will explain later but rst let’s just complete a single

piece job. To do this I’m going to go through the whole

process that I use to make a four bend rollbar for a racecar

as shown in Figure 34. This is a great example because it’s

a common request, there are no simple 90 de gree bends,

and it is generally a one-off piece. So hold on to your lug

nuts, here we go.

- 11 -

First, you need to make a template. For our example,

we are going to use 1 1/2” o.d. x .120” wall welded seam

mild steel tubing. As shown in Figure 15, the template is a

piece of tubing bent to 90 degrees with approximately 6”

of straight tubing on each side of the bend. Cut a piece of

tubing roughly 30” long. Next, scribe an accurate line all

the way around this tubing 6” from the end. An accurate

and easy way to do this is to use an inexpensive pipe

cutter. Your local home supply store should carry them in

the plumbing department. A small lathe with a sharp cutter

also does a good job. Scribe the line deep enough, roughly

.015”, so that when you paint the template, the line is still

clearly visible. Hand scribing this line is dif cult and not rec-

ommended. The tube should now resemble Figure 35.

Bending Method #1 - Using Template Bends

The Easy Way To Position Bends

Figure 33 - Sample Template Bend

Let’s Make A Bend Template...

Figure 34

Sample Rollbar

Figure 35

Template Line

Load this tube into your bender as shown in

Figure 36. Note that only the die set and tubing

are visible in the gure. The actual bender and

the die set’s u-strap are not shown so that you

can see what we’re trying to achieve. Place the

scribed line at the at edge of the forming die.

Never use the followbar as a reference. If the

forming die has a lock bolt on it, use it to securely

tighten the tubing in place. It’s very important

that this mark stays in line with the die’s at

edge during the bending process or template

will not give you accurate results later.

Figure 36 - Tube positioned

in forming die Template Line

Followbar

Forming Die

Figure 37

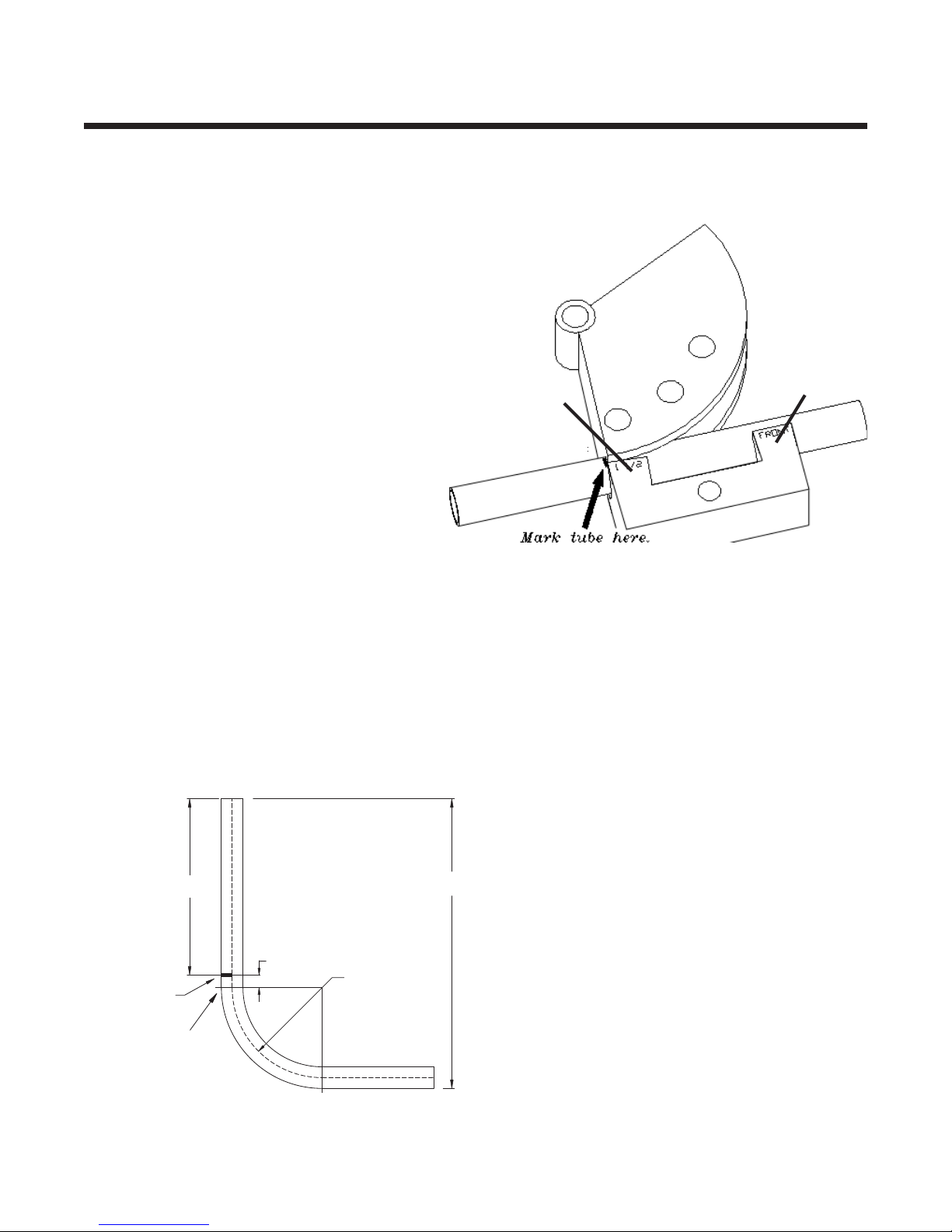

As shown in Figure 38, the rollbar will be 40” tall from the oor to its UPPER side. It will be 62” wide

outside to outside. The top two bends are 70oeach and the two lower bends are 20oeach. I recommend

that you purchase an adjustable carpenter's protractor to help determine the degree of bend for your

specic job. They are made of clear plastic and have legs approximately 12” long.

To determine the total length of

tubing needed, you could sit down

and calculate it. This is described in

the next section "Bending Method #2"

which presents a more mathematical

method to bend tubing. However, for

this application, I think it’s a waste of

time.Timeusuallycostmore thantubing,

so here’s the fast way: Take the total

width of the rollbar (62”) and add it to

twice the height (40”) which gives us a

length of 142” (62” + 40” + 40”). This is

slightly too long, maybe a foot are so,

but there’s a popular rule in fabricating:

It is easier to remove material then to

add it.Through experience you will learn

how much extra tubing you must leave

to complete the part.

Bend the tube to a nished bend of exactly 90 degrees. On this

example, I had to bend to 94 degrees to achieve a true 90 degree

bend after the tubing relaxed. Cut the straight length of tubing that

is not scribed to 6” long so that it matches the scribed side. This is

not really necessary but it does look nice. Debur both ends and then

paint the template an easily visible color. Why does it need paint?

It doesn’t. But after losing this thing a few times you’ll get the idea.

The template is nished.

If you work with different types of tubing that are of the same

size but differ in the amount of springback they produce, possibly

because of a different material or wall thickness, you may need to

make a separate template for each one. You can decide later if this

necessary depending on the accuracy that you require.

Figure 37 shows a nished template bend still in the die. Note

the position of the scribed line on the tube.

62"

40"

20°

70°

50"

Figure 38

Time To Start Bending...

- 12 -

An important rule of bending is to, if possible, always make the bends closest to the center rst and

work your way out. This allows you to make measurement corrections between bends. Based on this rule,

place a mark at the center of the rollbar tube. This is shown Figure 39.

BEND 1:

The rst bend will be the

upper right side bend. Referring

toFigure38,theupperdimension

of the rollbar is 50”. From the

centeroftherollbartotheoutside

of the bend is 25” (50” divided by

2). Lay the tubing to be bent on

the oor and hold the template

with the scribed side parallel

to the rollbar tubing and directly above it, as shown in Figure 39 . The scribed side of the template will

always face towards the center of the tubing being bent. Using a tape measure, slide the template left or

right until it is 25” from its outside edge, shown by the right arrow in Figure 39, to the rollbar’s center mark.

Using a marker, draw a small line on the rollbar directly below the scribed line. Take note of what side

of this mark the bend needs to be and draw an ‘X’ there so that when you load the tube into the bender

you’ll be bending on the correct side. Since the desired bend is only 70o and the template is 90o, you

will have to use your best judgement of when the template is 25” out. This gets easier with experience.

Now, load the tube into the bender and make the rst bend. Don’t forget to over bend a little to account

for tube springback. For this material 3 to 4 degrees should be sufcient. Since all J D Squared benders

are equipped with degree of bend indicators this is easily accomplished. Once you know the correct over

bend required, you may want to record it for future reference.

BEND 2:

Place the template above

the rollbar tube with the template

line facing bend 1 as shown in

gure 40. Using a tape measure,

position it for the desired 50”

outside to outside of the two

top rollbar bends. DO NOT

use the tube’s center mark

as a reference and place the

template 25” left of center. The

reason for this is that if the rst

bend was not made at the exact right spot to achieve 25” from center you can correct for the error in the

second bend’s position. Once again, since the bend will be 70o and the template is 90oyou must use your

judgement as to where to position the template. Place a mark on the rollbar tube exactly underneath the

template line. Load the tube in the bender so that the bend will be made on the CORRECT side of the

tube and make the 70obend.

Erase the center mark on the rollbar tube. Using the tape measure, place a new center mark exactly

midway between the outside of the two bends. Why? Let’s say your measurement shows the two top

bends are really 50 1/4” wide instead of the desired 50”. In that case, your old center mark could be off by

as much as a 1/4”. The NEW center mark corrects this error. That’s the cool part about template bending.

Your errors can generally be xed with the next bend. Also note that if you had not started your bending

from the center of the rollbar you would not have been able to make the correction. Every bend adds a

little more error and you end up with a rollbar that does not t.

25”

50”

Figure 39 - Template positioned for 1st bend.

Figure 40 - 2nd bend position

Tube’s

Center Mark

Template Line

Template Line

- 13 -

31”

62”

Figure 41 - 3rd bend position

Figure 42 - 4th bend position

BEND 3:

At this step you may want to use

a large 90osquare to help position the

template. Position the template above

the rollbar tube with the template line

facing up towards the top of the rollbar

as shown in gure 41. Slide the template

up or down the rollbar tube until its

outside is 31” from the rollbar’s center.

Mark your tube and make the bend.

BEND 4:

Position the template with the

template line facing up towards the

top of the rollbar as shown in gure

42. Slide the template up or down the

rollbar tube until its outside is 62” from

the outside of the 3rd bend.Also, verify

the bend is the same distance down

the tube from the top of the rollbar. If

all is correct mark the tube and make

the bend.

Lastly, cut the ends of the tube

to make the rollbar 40” tall and your

done.

Finished!

PROCEDURE FOR SETTING UP A PRODUCTION BENDER USING THE TEMPLATE METHOD

As I stated earlier, this method can be used for production bending. The idea of making the bends

from the center out doesn’t usually work well in production. Most production bending is done by feeding

the tube through the bender and making each bend as needed, thereby eliminating the need to remove

the tube from the bender and ip it around. For this you would want a setup sheet with the locations of

where to place the marks on the tubing for each bend location. The problem with template bending is that

the template has the tube stretch and springback already in it. Since the tubing will grow in length as you

make bends in it, how can you measure it accurately once it’s bent? Unfortunately, you can’t. What you

must do is place marks down the tube, for example 10” apart, starting at the one end before you start

bending. Now whenever you transfer the mark from the template to the tube being bent you can easily

measure the distance from one of the 10” marks to determine where the mark would of been placed on

an unbent piece of tube.

- 14 -

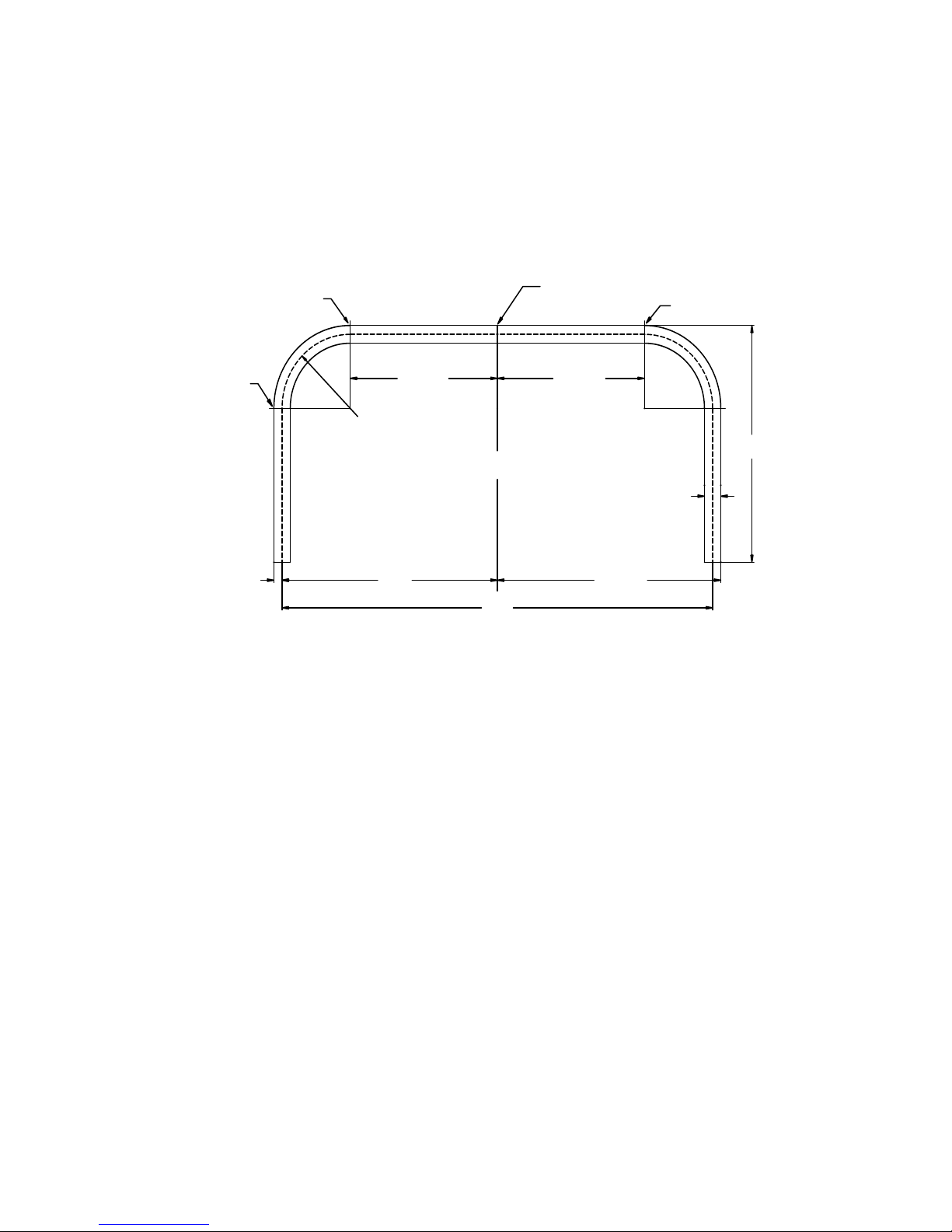

The rst thing you need to do is to determine the actual starting location of a bend produced by the Bending Die you installed

in the bender. This can vary between die sets and must be checked for every die set purchased. In the below example we are

using 1 1/2" O.D. tubing and a Bending Die with a Center Line Radius of 6 1/2".

Here's the procedure:

A) Place a piece of tubing (app. 2 1/2' long) into the

bender so that exactly 12" extends out from the

edge of the die to the end of the tubing when

the tubing is fully seated in the Bending Die's

groove. Place a little bending pressure on the

tube so as to seat the tubing in the Bending

Die. Not enough to start bending the tubing just

enough to seat it in the groove. NOTE:Ifyou

layasmalllengthoftubinginthegrooveofa

BendingDieyouwillnoticethetubingdoesnot

seattothebottomofthegroove.TheBending

Dies are deliberately machined this way so

thatduringthebendingoperationasideforce

isdevelopedinthetubing.Thishelpstoreduce

atspottingandwrinkles.

B) Using a Black Magic Marker mark a line on

the tubing precisely at the edge of the die. See

gure 43.

C) Bend the tube to an exact 90 degrees. Use a

carpenters square to check the angle. You will

have to over bend the tube a little to account for

springback. How much to over bend will come

with practice. If you over bend the tube a little don't worry. Because cold worked steel has memory, you can place the

tube in a vise or anything else that will retain it, and simply unbend it. Obviously this only works for small amounts of

over bend. If the tubing is under bent, it will be necessary to put it back into the bender.

D) With the tube bent correctly to 90 degrees locate the actual start of the bend. To do this, measure from the end of the

tube to the far end of the 90 degree bend. In the example in gure 44 this came out at 20 1/4". Subtract 6 1/2" for the

centerline radius (CLR) of the Bending Die, another 3/4" for the radius of the tubing not seated in the die, and 1/8" for

springback. (Substitute the CLR and tube radius to match your die set). The 1/8" gure for springback is an approxi-

mation, not an exact gure. However it is usually very close to the real thing and may be used without worry to determine

the actual starting location of the bend. So:

201/4"-61/2"-3/4"-1/8"=127/8"

Now subtract from the 12 7/8" the original 12" we had

marked earlier and you nd that the bend will actually

start 7/8" in from the edge of the bending die. Now we

know for example, if we want 40" from the end of the

tubing to the start of the bend, we must subtract 7/8"

from 40" and set the tubing 39 1/8" from the edge of

the Bending Die.

Another example, you want 36" from the bottom to the

top of a rollbar. Tube size is 1 3/4" and you have an

actual bend start 1/2" inside of the Bending Die's edge.

The CLR of the Bending Die is 7 1/2". So: 36" - 1/2"

(Actual Bend start) - 7 1/2" (CLR of die) - 7/8" (Half

of the tubing diameter) - 1/8" (Springback) = 27". Set

the tube 27" from the edge of the Bending Die and

make the bend.

Bending Method #2 - Using Math Formulas

- 15-

Figure 43

Figure 44

Angledgroove

closesttothe

formingdie

Straight

groove

Actual start

of bend

6 1/2" CLR

7/8"

20 1/4"

12"

Mark

6 1/2" CLR

3/4"

20"

20 3/4"

20"

40"

13 1/2" 13 1/2"

1 1/2"

Start of 2nd bend

Center mark on tube

End of 1st bend

Start of 1st bend

C

L

- 16 -

Example hoop :

Preparation is the key to making accurate bends. To make multiple bends in one section of tubing you will need a universal

protractor. The protractor is then clamped, using a machinist v-block and a radiator hose clamp, to the tube. Make sure the pointer

indicates '0' before making your rst bend. Also using a carpenter's level, make sure the tube is entering the bender level. On

the second bend if you turn the tube so that the pointer again reads '0' and the carpenter's level indicates the tube is level, both

bends will be on the same plane with no noticeable twist.

First step is to draw a sketch of the intended shape and all measurements. Figure 45 below is the desired hoop. The Bending

Die has a centerline radius (CLR) of 6 1/2". The tube O.D. is 1 1/2". We determined earlier that the Bend Start measurement is

3/4" behind the edge of this particular Bending Die set.

1) Determine the total length of tubing needed. Using a calculator and the formula below let's add it all up.

61/2"(CLRofbend)x90(Numberofdegreesofbend)x.0175=Length of tubing used in a bend.

Using the formula above we get 6 1/2" (CLR of bend) x 90 (Degrees of bend) x .0175 = 10.2375. Let's round this off to 10 1/4"

inches (10.250"). This is the amount of tubing used in the bend. We have two bends so we double this and get 20 1/2". Add to

this the straight sections and we get 20 1/2" (tubing in bends) + 27 (the center section) + 13 1/2" for the left upright + 13 1/2" for

the right upright = 74 1/2" of tubing needed. It's usually a good idea to leave a couple of inches extra on the end. Remember,

it's easier to remove tubing then to add it. So let's add 2" to 74 1/2".

2) We cut our tube to 76 1/2". It's generally easier to work from the center out when making two bends in a tube. Divide 74 1/2"

by 2 and our center point is 37 1/4" from the end of the tube. Place a mark on the tubing 37 1/4" in from one edge and mark the

tubing so you will know which side is the 37 1/4 side and which side is 39 1/4". Notice we didn't use the 76 1/2" measurement

that we cut our tubing to. This way we only have to cut 2" off one end of the nished tube instead of 1" off each end. The rst

bend is made on the short 37 1/4" side.

3) Using the method described on page 11 we determine that the tube should extend 12 5/8" from the edge of the Bending Die.

Below is the equation from page 4.

20"(Heightofhoop)-61/2"(CLRofdie)-3/4"(1/2oftube'sdiameter)-1/8"(Springback)-3/4"(BendStart)=117/8".

After making the bend we have half our hoop completed. The top of the bend is 20" from the bottom of the tube.

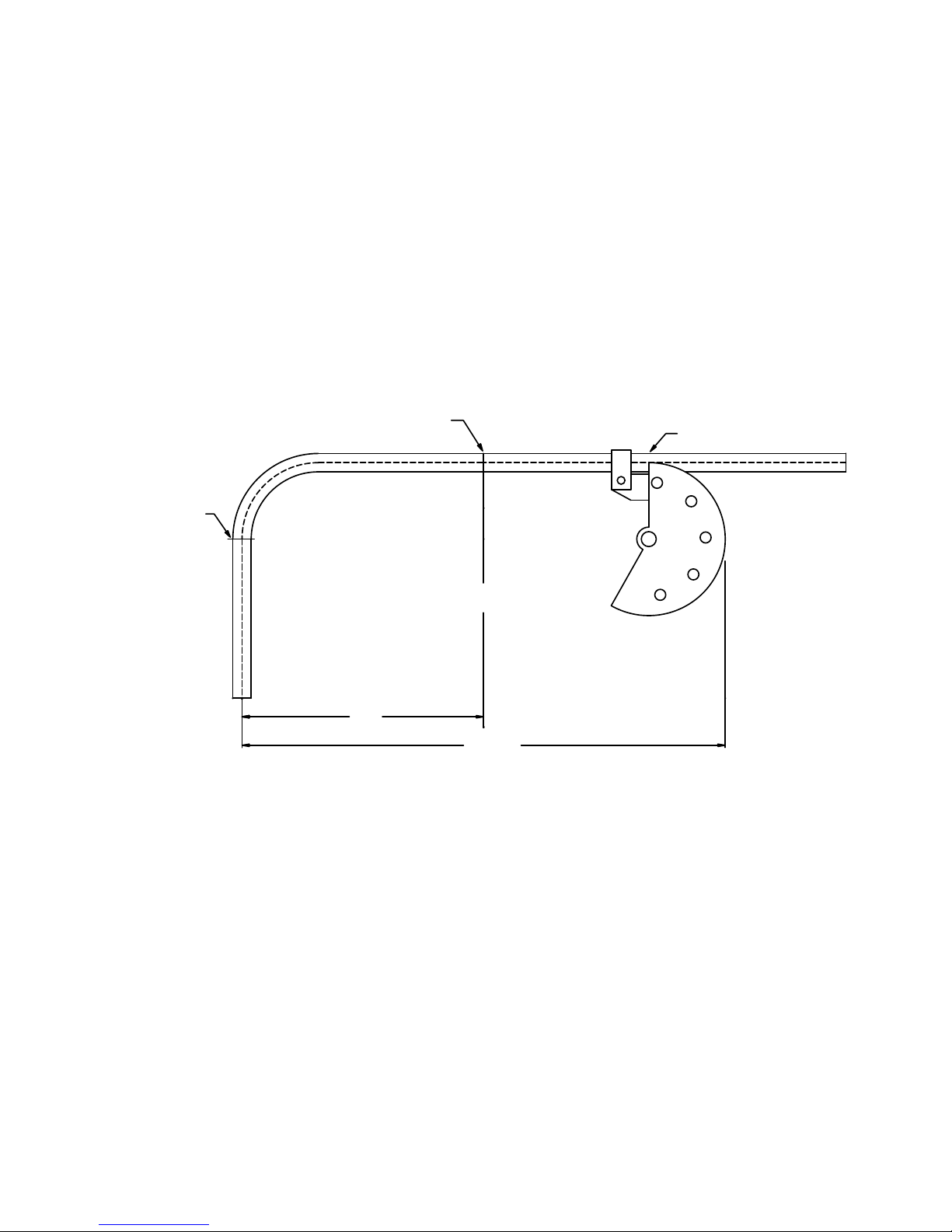

4) Now for the other bend. First we need to determine how much the tube stretched in the bend area. From gure 9 we see that

the tube should be 20 3/4" from the outside edge to our 37 1/4" center mark. However after measuring from our center mark to

the outside edge of the bend we now have 21" and not the planned 20 3/4". This 1/4" increase is due to springback and the tube

stretching in the area of the bend.

Figure 45- Example hoop.

If we now repeated the second bend, using the same 12 5/8" from the end of the tubing + 2" for the extra tubing we allowed,

we would end up with a hoop 1/2" too wide. This is because the 1/4" stretch developed in the rst bend will also be developed in

the second bend, giving us 1/2" total increase in width. Not a good deal if you only want a 40" wide hoop. So what's the solution.

Actually there is two ways to do it.

FIRST METHOD:

Look at gure 45 and notice the second bend starts at the top of the hoop and not at the top of the upright as the rst bend did.

Also the start of the second bend is drawn as 13 1/2" from the center mark. If you take the 13 1/2" measurement and subtract

the 1/4" of growth that was developed in the rst bend and another 1/4" to compensate for the second bend's growth you end up

with 13". Subtract another 3/4" to account for the 3/4" Bend Start location on the Bending Die set and we have a nal setting of 12

1/4". Notice we did not subtract an 1/8" for springback. This is accounted for already in the 1/4" we added for the second bend's

growth. Set the tube so that the Bending Dies edge is exactly 12 1/4" from the center mark. Make sure the universal protractor

reads '0' and the carpenter's level is centered. As one nal check you can also measure from the far side of the completed bend

to the edge of the bending die. See gure 46. This measurement should read:

40"(widthofhoop)-3/4"(radiusoftubenotinbendingdie)-1/8"(springbackallowance)=391/8"

Make the second bend. Measure the height of the second upright and cut off the extra tubing we allowed for earlier.

SECOND METHOD:

The second method is basically the opposite of the rst method. The second bend will start at the bottom of the upright and NOT

at the top of the hoop as in the rst method and as shown in gure 46. We use the same method as used to bend the rst bend

with a few exceptions. First calculate the starting point for the second bend as shown below:

20"(totalheightofhoop)-61/2"(CLRofbendingdie)-3/4"(BendStart)=123/4"

Add 2" to account for the extra tubing we allowed earlier. Also add the 1/4" growth developed in the rst bend and another 1/4" for

the second bend. DO NOT ADD 1/8" SPRINGBACK. Once again this is already accounted for in the 1/4" growth of the second

bend. We end up with:

123/4"+2"(extratubing)+1/2"(growthforbothbends)=151/4"

Set the tube's end at 15 1/4" from the Bending Die's edge. Make sure the universal protractor reads '0' and the carpenter's level is

centered. Make the second bend. Measure the height of the second upright and cut off the extra tubing we allowed for earlier.

Thank you for purchasing the Model 4 Bender. Any further questions please call.

- 17 -

Figure 46

21"

39 1/8"

Start of 2nd bend

Center mark on tube

Start of 1st bend

C

L

Table of contents

Other J D Squared Construction Equipment manuals

Popular Construction Equipment manuals by other brands

Rittal

Rittal 4050.200 Assembly and operating instructions

Roper Whitney

Roper Whitney MBB 4181 MAGNABEND Operation, parts & maintenance manual

Weber mt

Weber mt MC 85 Operating and maintenance manual

Tadano

Tadano TR-150XL-4 Service manual

Sealey

Sealey FDT3.V2 instructions

Labounty

Labounty MHP 350 Operating and maintenance manual