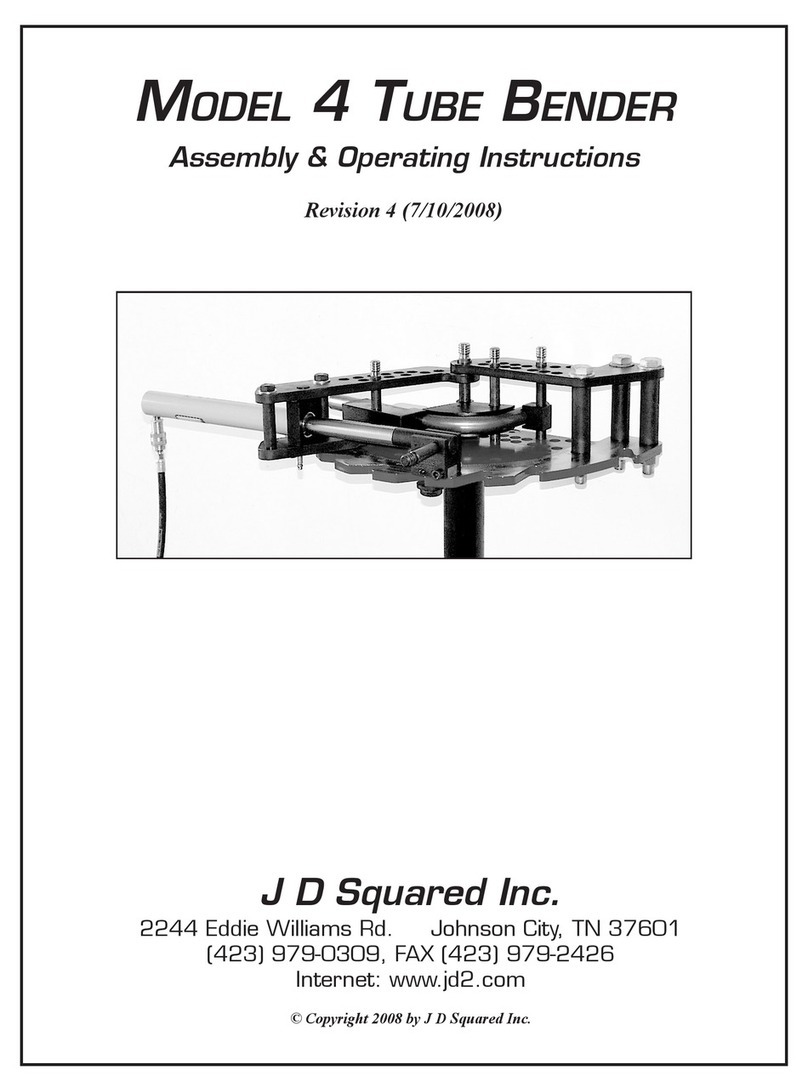

J D Squared 3 Quick reference guide

Mo d e l 3 Tu b e be n d e r

Assembly & Operating Instructions

J D Squared Inc.

2244 Eddie Williams Rd. Johnson City, TN 37601

(423) 979-0309, FAX (423) 979-2426

http://www.jd2.com

© Copyright 2009 by J D Squared Inc.

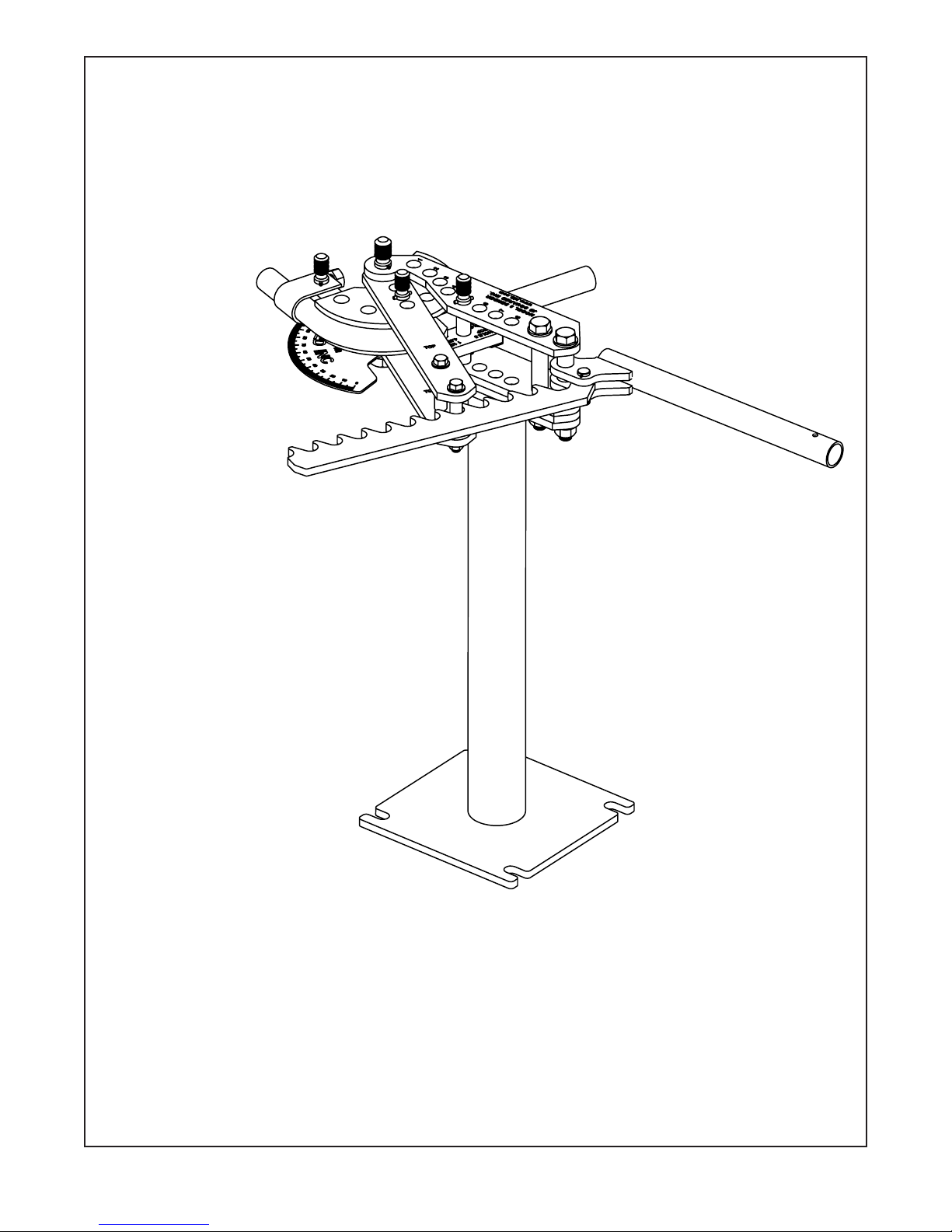

ASSEMBLY

- 1 -

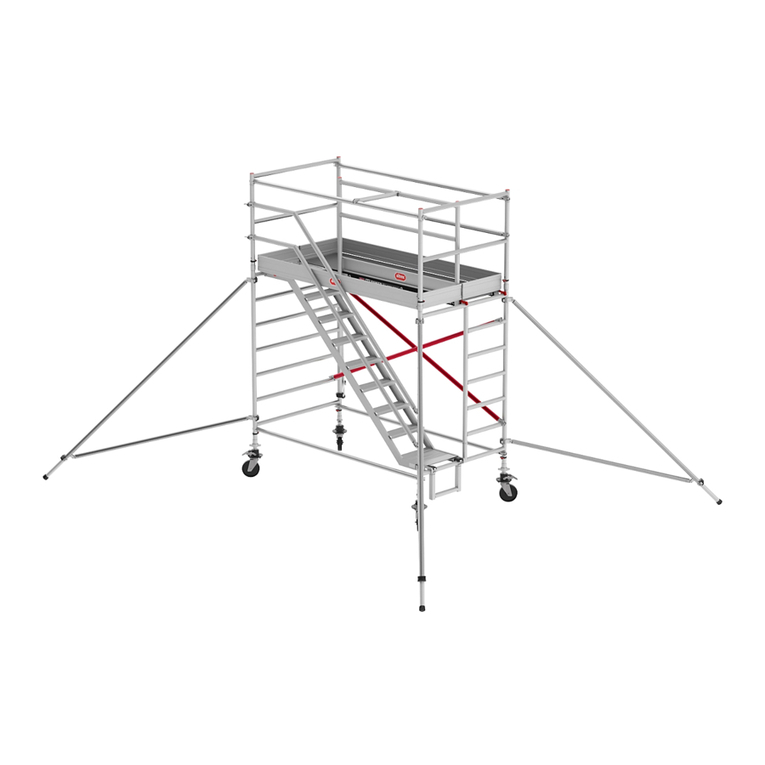

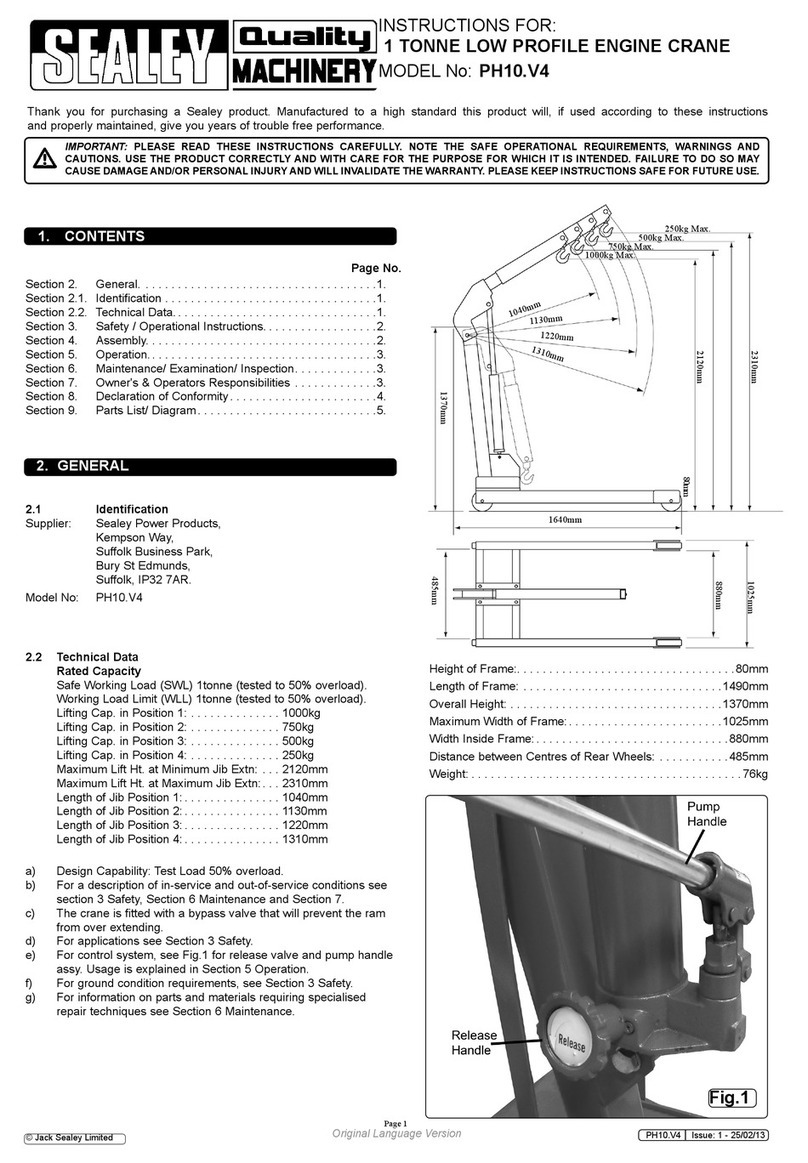

1) The bender may be mounted to anything rigid enough not to twist or move during the bending operation. To mount the bender

drill two 3/4" holes 2" inches apart through the mounting surface. The front cover shows the bender mounted on the optional

pedestal. NOTE: You can use the Frame Base to help position the holes the correct distance apart for drilling.

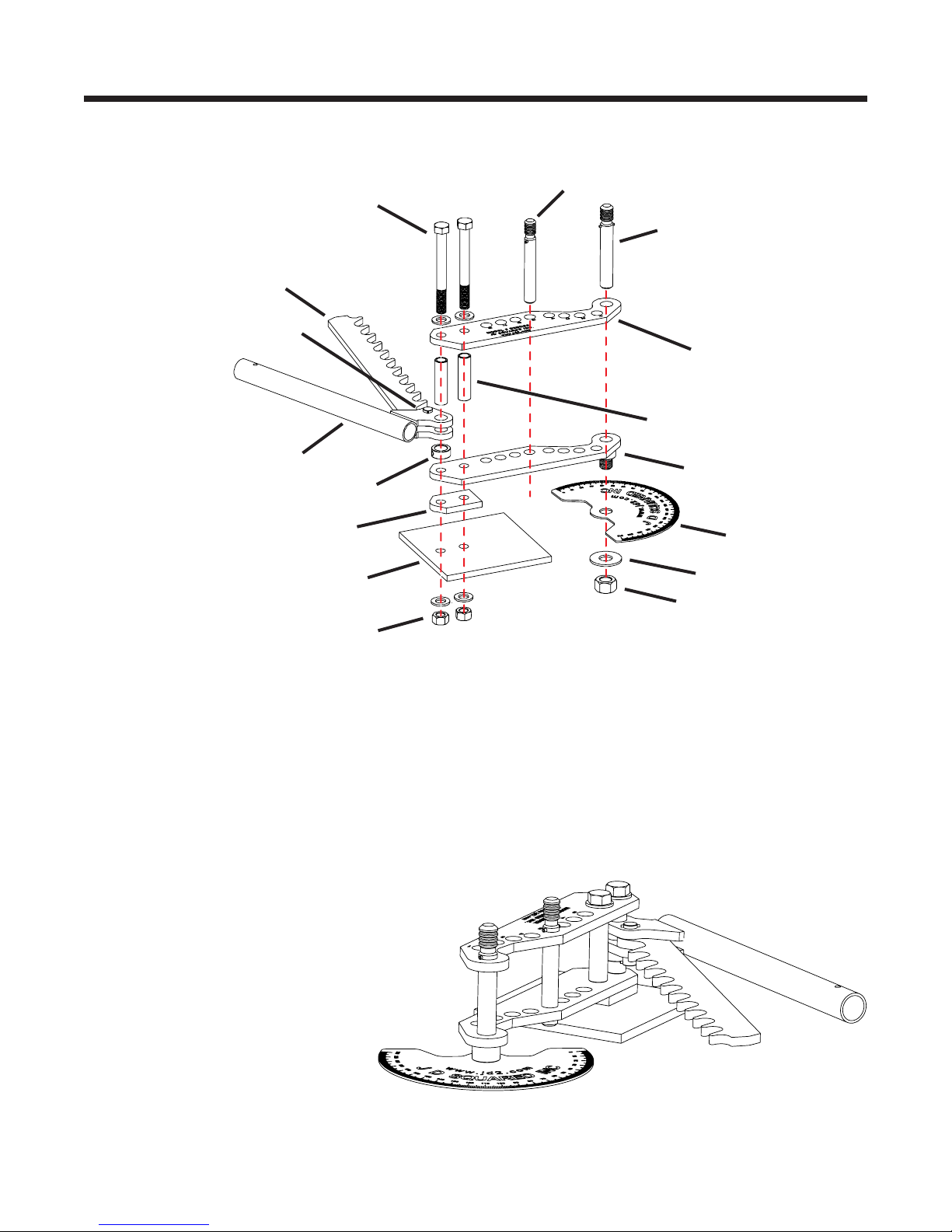

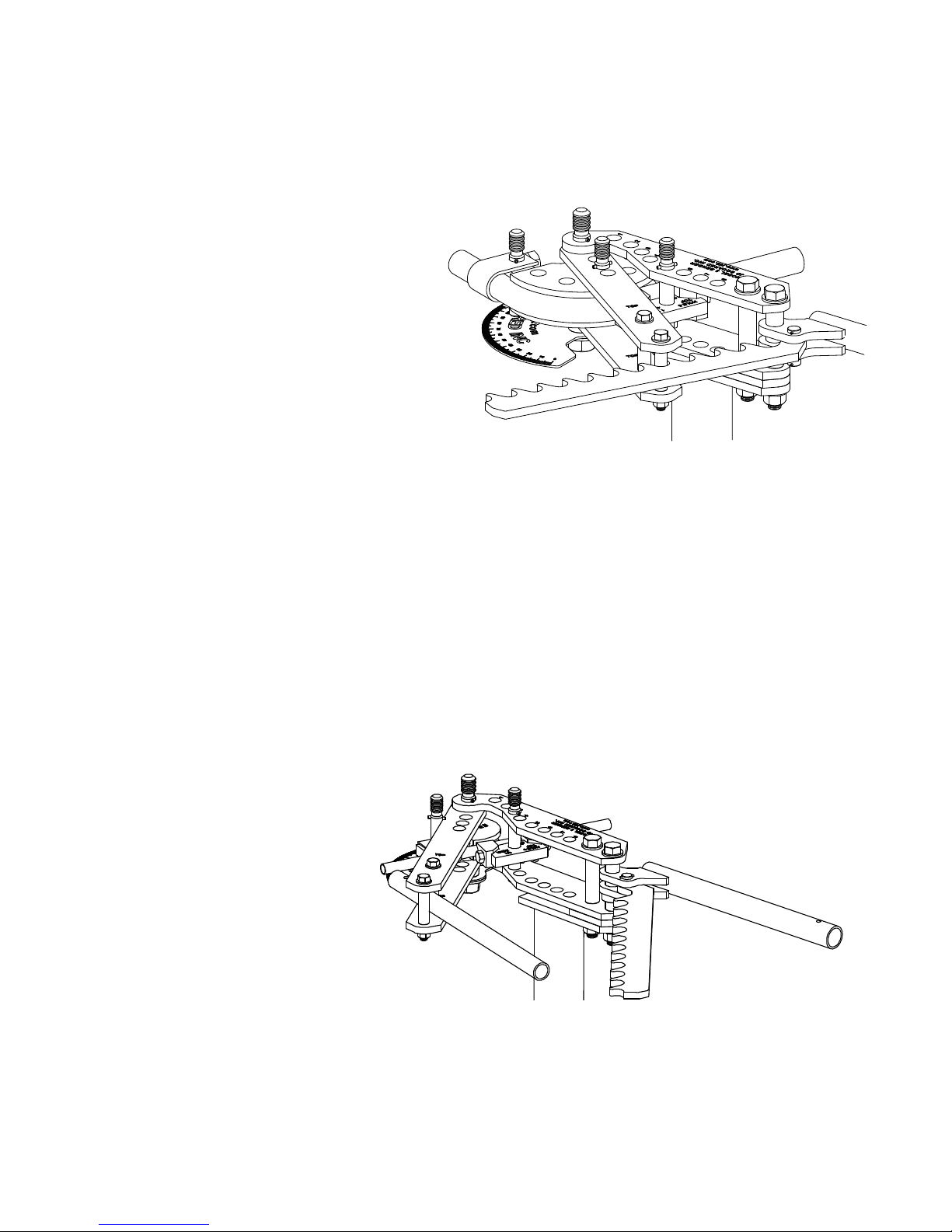

2) Assemble the bender's frame assembly as shown below.

A) Place the Frame Base on your mounting surface aligned with your drilled 3/4" holes.

B) Place the Lower Frame Link with the notched side to the left on top of the Frame Base aligned with the two 3/4"

holes.

C) AssembletheRatchetandRatchetLeverasshowningures1,2&4 using the 3/4" pin and two 1/8" spring pins. For

hydraulic adapter installation see page 3.

D) Place the Ratchet Lever and the 1" Collar on one of the two Spacer Tubes (1" OD tubes). Do not tighten collar.

E) InstalltheUpperFrameLink,Ratchetassemblyand1"SpacerTubesasshownabove.Handtightenthebolts.

F) Insert the 1" Frame Pin into the 1" Frame Link hole. Slide the 7/8" Frame Pin into hole #5. Tighten the 3/4" nuts as tightly

aspossible,whileinsuringthetwopinsareperfectlyverticalandslideeasilythroughtheirrespectiveholes.

G) Raise the Ratchet Lever to the middle

of the Tube Spacer and lock into

position with the 1" Collar.

H) InstallDegreePlateasshown.Use

only your hand to snug down the nut.

This nut is never wrench tightened.

This allows you to easily adjust the

Degree Plate while bending.

3/4"Bolts&Washers

Ratchet

Upper Frame Link

1" Frame Pin

1" OD Frame Spacer Tubes

Ratchet Lever

1" Collar

Frame Base

Your Mounting Surface

Figure 1 - Exploded view of the Frame Assembly with Degree Plate

Ratchet Pin

Lower Frame Link

Degree Plate

1"Washer

1"HexNut

3/4"NutsandWashers

7/8" Frame Pin

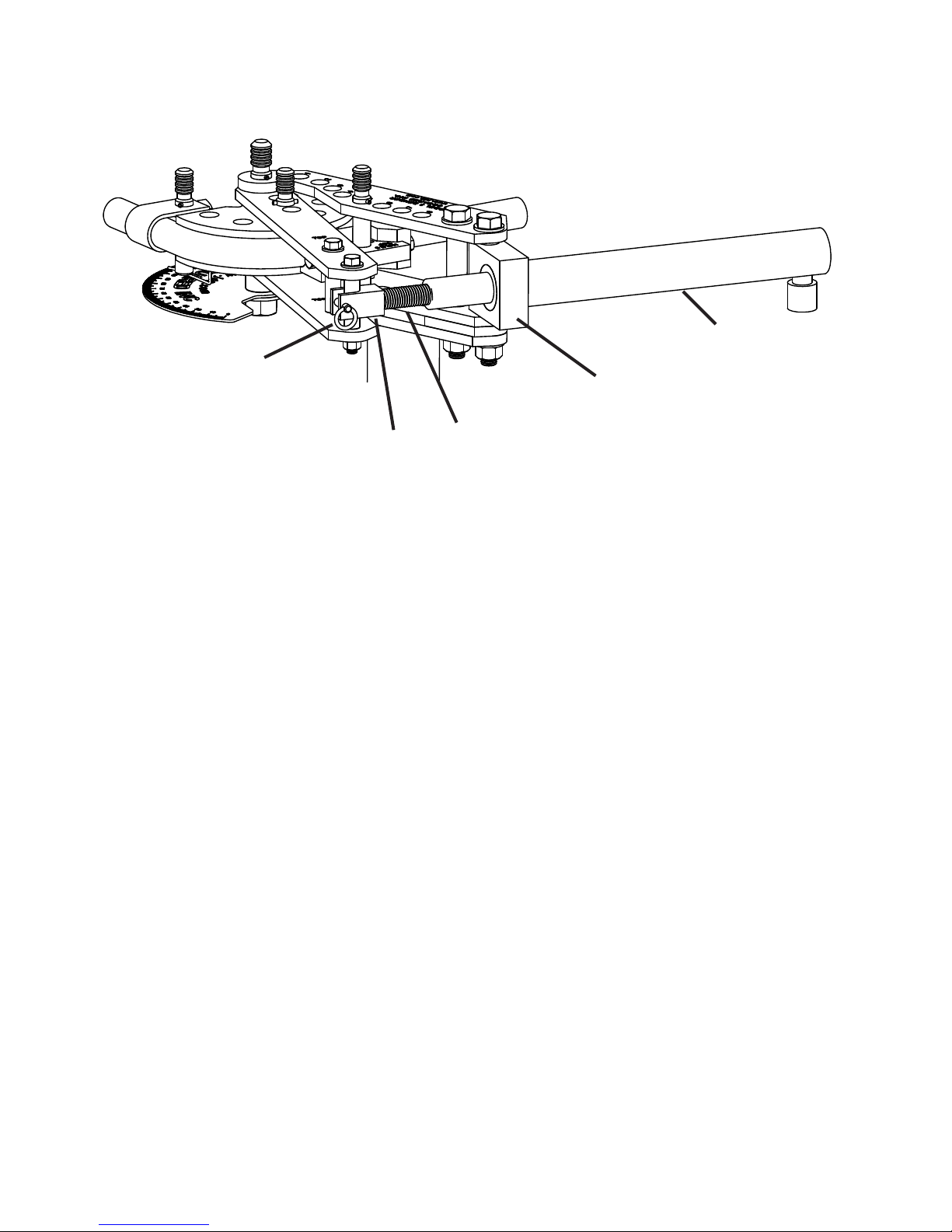

Figure 2 - Completed Frame Assembly with Degree Plate

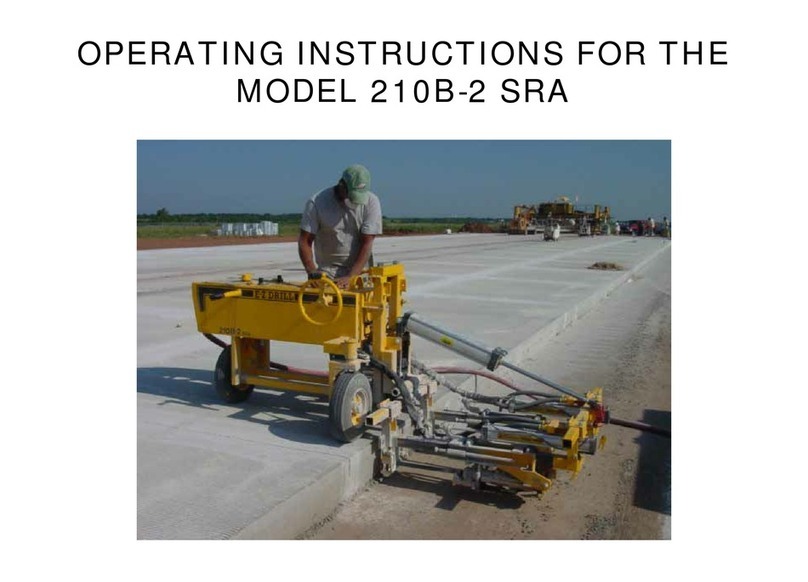

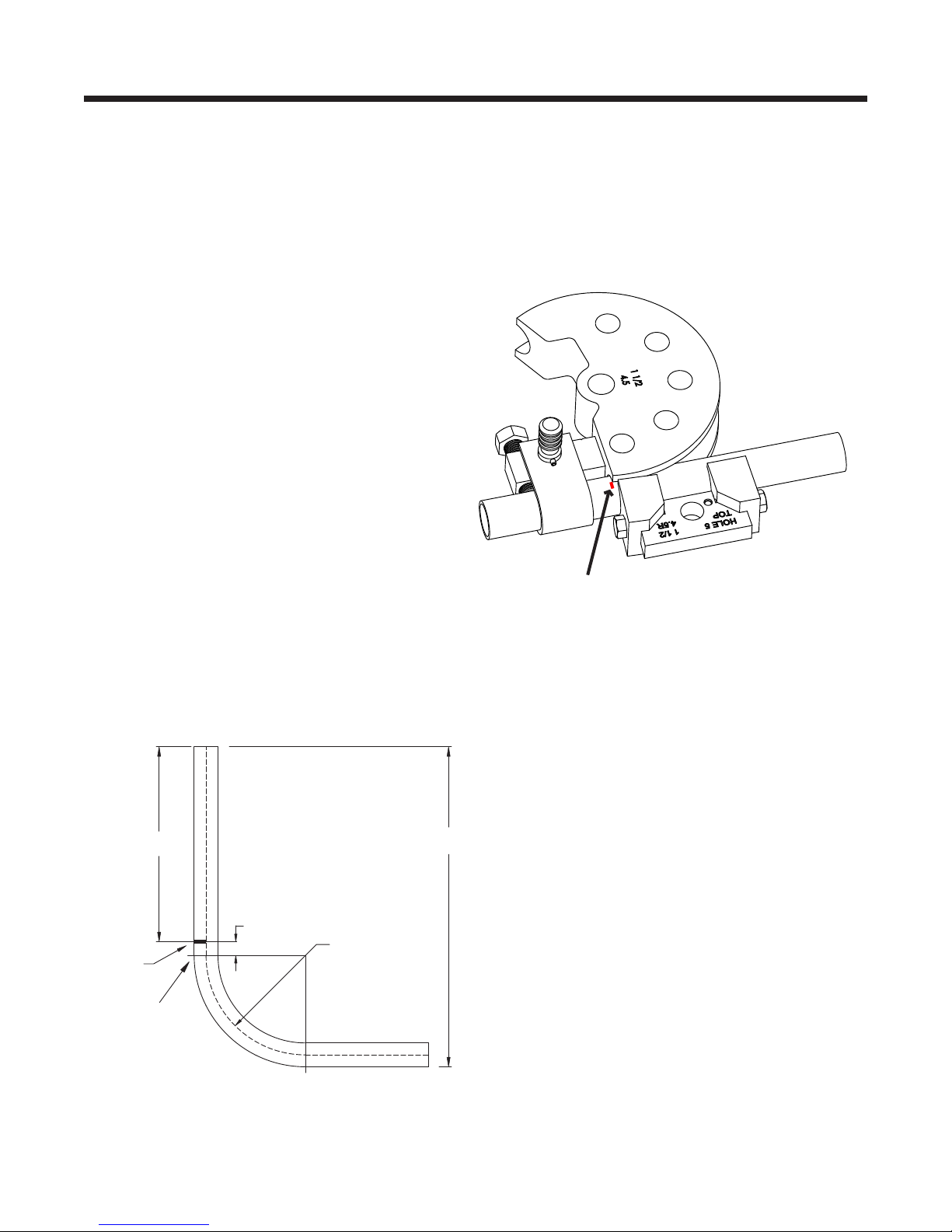

4)RemoveallpinsfromtheDriveLinkassembly.Withtheword'TOP'facingup,InstalltheDriveLinkassemblyintotheFrame

assemblyusingthe1"FramePin.Seegure4.Thebenderisnowassembledandreadyforthediesettobeinstalled.

NOTE:A19"extensionhandleisprovidedwiththebender.Slideitintotheratchetleverandusingthesupplied3/8"pullpin,

secureinplace.Thecombinedhandlewillbeapproximately36"long.Thisshouldallowtheaverageusertobend13/4"x.095"

wallmildsteeltubingusingjustonehand.Ifbendingchromemoly,DOMorlargertubingandndyoudesiremoreleverageto

reducethebendingeffortrequired,simplyobtainalengthof1"pipe(1.315"o.d.)andcutittothedesiredlength.Youalsoneed

todrilla7/16"holenearoneendsothepullpinmaybeinstalled.

3)ThetwoDriveLinksareassemblednext.Usingthe

two3/4"ODDriveLinkSpacerTubes,two1/2"bolts,

four 1/2" washers and two 1/2" nuts, assemble the

twoDriveLinksasshowningure3.Theword'TOP'

must be face up on both links. This is very important

because the three 7/8" drive holes are offset to the

right.Handtightenonly.Insertthetwopinsintotheir

respective holes to help alignment. Lay the assembly

on its side to further help alignment and wrench tighten

securely.

- 2 -

Figure 3 - Drive Link assembly

1" Frame Pin

7/8" Drive Pin

1/2"Bolts&Washers

3/4" OD Drive Link Spacer Tubes

1/2"NutsandWashers

Drive Link

Drive Link

Figure 4 - Completed bender without die set installed

- 3 -

Model 3 Bender Hydraulic Adapter Assembly

Adapter Components: Excludingthehydraulics:

Hydraulic Swivel Block

Yoke

Threaded Extension Rod

Clevis Pin

Recommended Cylinder:

EnerpacRC1014ortheO.T.C.(PowerTeam)Part#C1014Coranequivalentcylinder.Theseporta-powercylindersarerated

at10tonsandhavea14"stroke.Onthefrontofthecylinderisa21/4"x14TPIthread.

Recommended Power Unit:

WeofferseveralhydraulicpumpssuitablefortheModel3Bender.However,anypowerunitmaybeusedthathasanoutput

ofatleast1500-2500PSI.Theaveragebendingpressurewillgenerallybebelow1300PSI.Testedexamples:13/4"x.095"

mildsteel-800PSI,15/8"x.083"4130chromemoly-1300PSI,11/2"solidroundbarstock-3100PSI.Notethattheair-

over-hydraulic10,000PSIpumpsdeliverlessvolumeandthereforebendslowerthantheair-over-hydraulic3,000PSIpumps.

Apressuregaugeishighlyrecommended.Ifthebenderisoperatedatapressurehigherthan2500PSIthefollowbarpinmay

bend. This pin has been designed to be the bender’s weak link and therefore acts as a warning indicator of over loading. In other

words,ifyoubendthefollowbarpin,STOPBENDINGIMMEDIATELY.Forsafereliableoperationdonotoperatethebenderat

pressuresabove2500PSI.

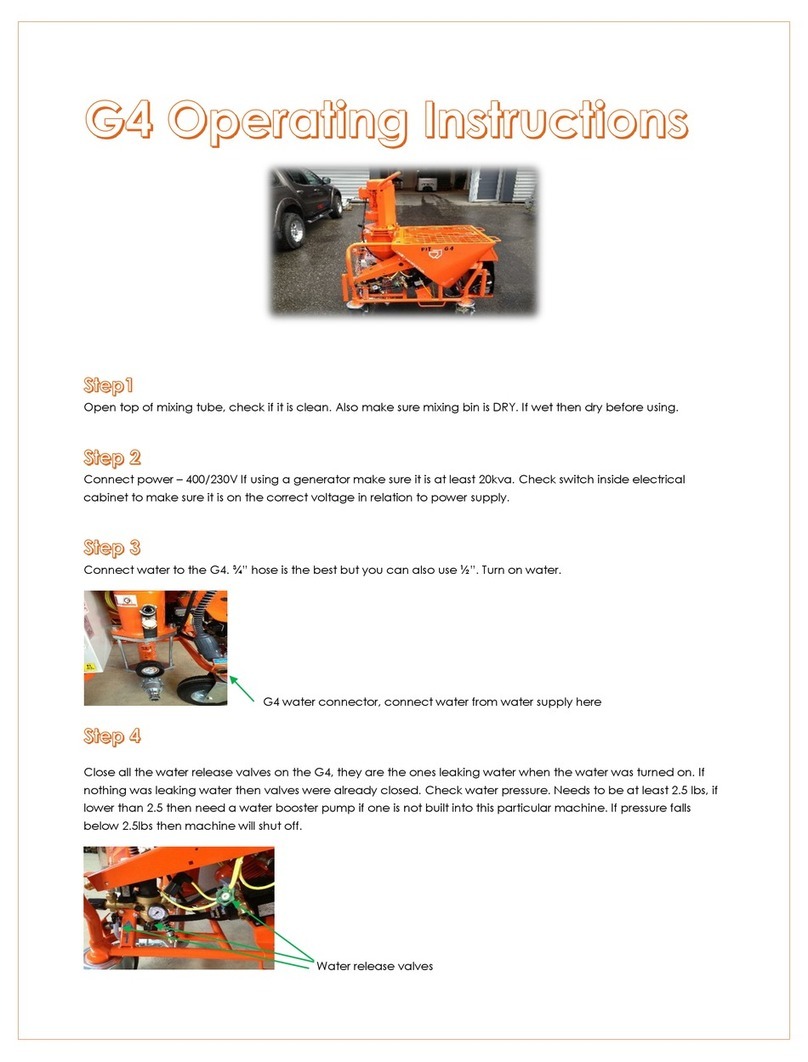

Assembly:

Removetheouter3/4"bolt,sleeveandratchetassemblyfromthebender’sframe.Noticethatthroughthehydraulicswivel

blockismachineda21/4"x14TPIthreadandaslightshoulder.Theshouldershouldfaceawayfromthedrivelinkstowardsthe

rearofthecylinder.Thiswillallowthecylindertobescrewedallthewayushwiththeswivelblock'sfront.Placethepreviously

removed1"ODsleeveintothecylinderswivelblock.Usingthe3/4"bolt,nutandwashers,installtheSwivelblockintothebender

asshownabove.Screwthehydrauliccylinderintotheblockasfarasitwillgooruntilitsfrontsurfaceisushwiththeswivel

block'sfrontsurface.Thequickdisconnectttingontherearofthecylindershouldpointdowntowardsthegroundtorelieve

stressonthehose.Ifitdoesnot,unscrewthecylinderoutoftheswivelblockuntilitdoes,butnofurther.

Ifthecylinderhasastudinstalledintotheendofitsram,itmustberemoved.Thiswillexposeathreadedholeintheendof

theram.ScrewtheThreadedExtensionRodintothecylinder'sramuntilitbottomsout.Now,screwtheYokeontothethreaded

rod until it bottoms out. Rotate the swivel clockwise (to prevent it from unscrewing off the threaded rod) until it may be slid onto

theouter3/4"drivelinksleeveasshownaboveingure5.InstalltheClevisPinthroughtheYoke.

Hookupthepumpandhose.Extendandretractthecylinderseveraltimestopurgeairfromthesystem.

Figure 5 - Bender with hydraulics installed.

10TonHydraulic

Cylinder

HydraulicSwivelBlock

Clevis Pin

Yoke ThreadedExtensionRod

Die Set Components

A Die Set refers to the components that are used in the bender to hold the tubing or pipe during the bending operation.

This section does not describe the operation of the bender. This section's purpose is to simply familiarize you with the different

components that make up a 'Die Set'. Knowing how the different die set parts interact with each other is essential in operating

thebendercorrectly.Thediesetmustmatchthesizeofthetubingorpipebeingbent.Forexample,neverbend11/2"tubingin

a 1 5/8" die set. This may damage the followbar's inserts.

First,let'sexplainthedifferencebetweentubing and pipe.Tubingisspeciedbyitsoutsidediameterandawallthickness.

Forexample,11/2"x.095"tubinghasanoutsidediameterof11/2"andawallthicknessof.095".Ontheotherhand,pipe is

speciedlooselyonitsinsidediameter.Wesaylooselybecausethepipe'ssizemaynotactuallybeitsinsidediameter.Confused

yet?Justrememberpipeiscommonlyusedforthepurposeoftransportinguids.Fluidowisonlyconcernedwiththeinside

areaofthepipeandtheoutsidemakesnodifferencewhatsoever.Pipewallthicknessisspeciedasaschedulenumberandis

obtainedfromapipechart.Anotherexample,11/2"schedule40pipehasanoutsidediameterof1.900"(largerthan17/8")and

awallthicknessof.145"andaninsidediameterof1.610"(near15/8").So,whenorderingdiesetsbecarefultospecifywhether

it's a tube or pipe size die set.

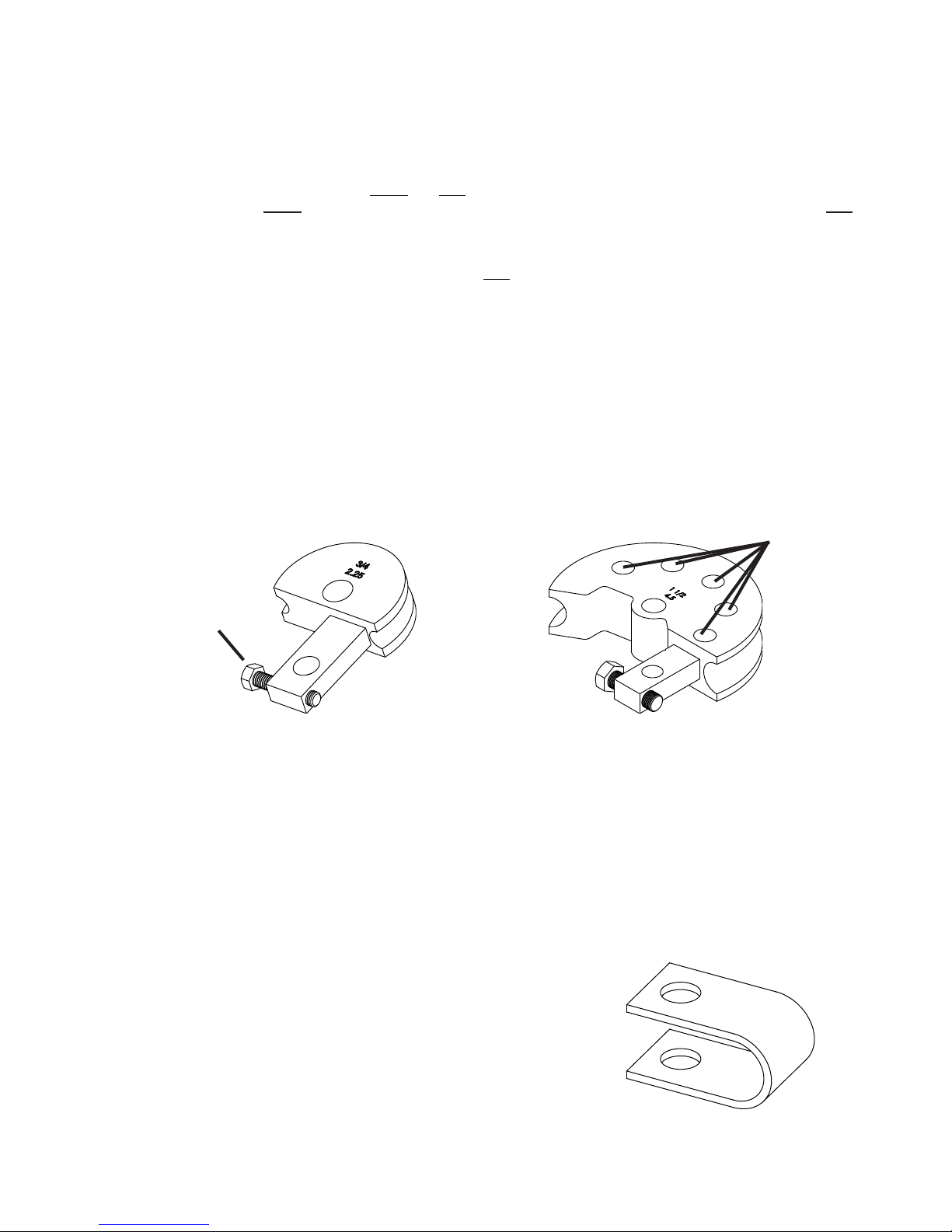

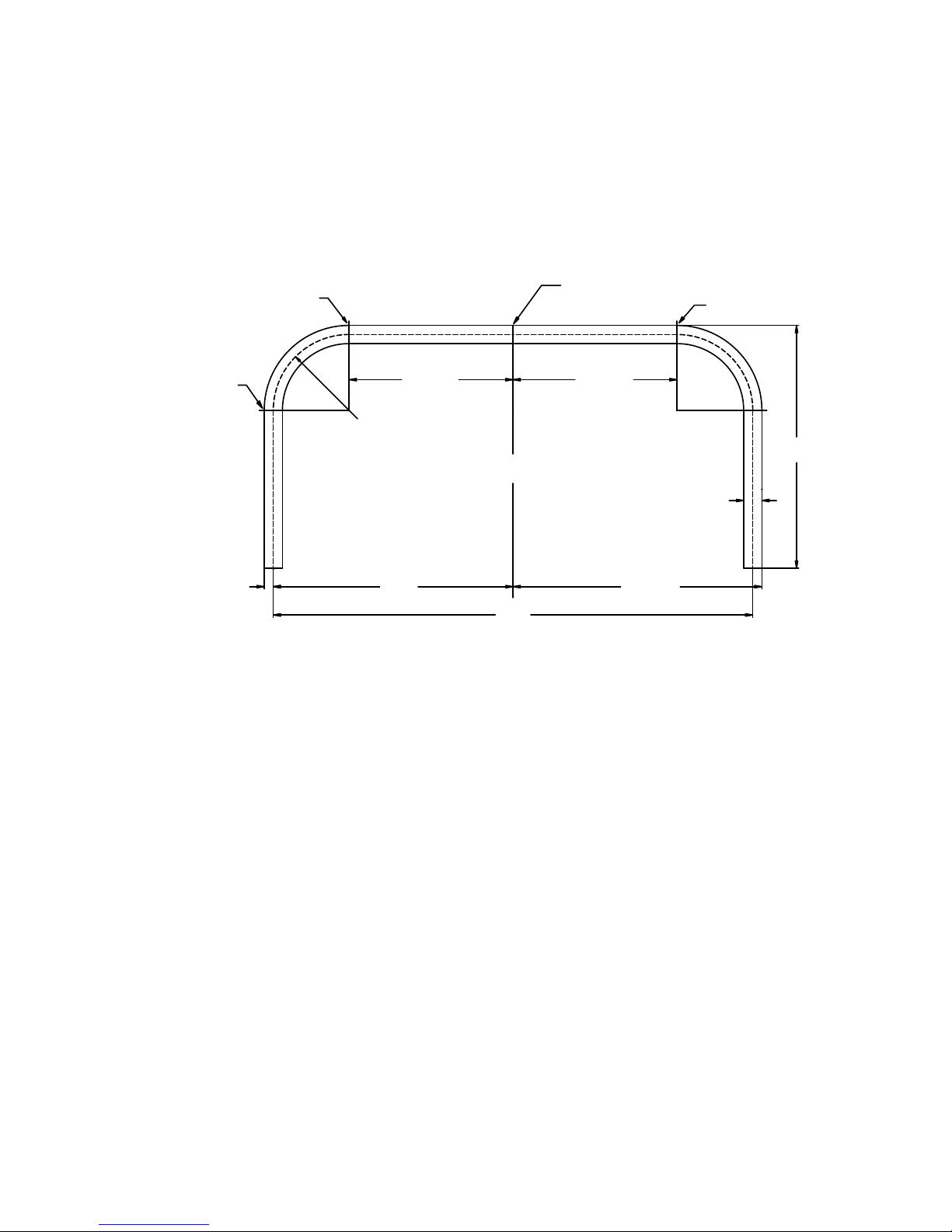

ROUND GROOVE DIES:

ARoundgroovediesetconsistsofthreemainelements:

1) Forming Die

This is the part that the tube or pipe actually bends around. It has a circular groove machined around its circumference.

Pleasenotethatthisgrooveismachinedwithaspeciallydesignedproletohelpinreducingatteningofthebend'soutside.

IfyoulayasectionoftubingintotheformingdieyouwillnoticethatitwillNOTcompletelyseatintothedie'sgroove.Thisis

normalfortubesizediesandbecomesveryimportantasthetube'swallthicknessgetsthinner.However,formingdiesthat

aremachinedfor'Pipe'insteadoftubingaregenerallynotmanufacturedwiththisproleandthepipemaycompletelyseat

in the groove. Pipe is much more forgiving when it comes to bending it because of its thicker wall. Stamped into the top is

the Outside diameter of the tube or pipe and the centerline radius (CLR) of the forming die. Above is pictured a 3/4" die with

a 2 1/4" CLR and a 1 1/2" die with a 4 1/2" CLR.

Driveholesaredrilledintomostdieswitharadiusof3"orlarger.Whenthe7/8"drivepinisinsertedintothedrivelinks,it

will pass through these holes. This is how the drive links rotate the forming die. The 1" drive holes are drilled oversize to

permit easy insertion of the 7/8" drive pin.

Diesetswitharadiussmallerthan3"willgenerallynothavedriveholesbecausethereisnoroomtodrillthem.Asexplained

inthefollowingsectiononhowtooperatethebender,thediameterofthetubingorpipeissosmallthebendercanbeoperated

without the use of the ratchet mechanism.

2) U-Strap

U-straps are sized to the OD of the pipe or tubing being bent. The size

is stamped onto them.

- 4 -

Figure 6 - Forming Die without drive holes Figure 7 - Forming Die with drive holes

U-StrapBolt

DriveHoles

Figure 8 - U-Strap for round groove dies

3) Followbar (Also referred to as the Pressure Die)

The Followbar is the component that presses the tubing into the forming die to create the bend. Shown in the illustration

below,itconsistsofthreemainparts:abackingblockandtwoinserts.Thismultipartdesignallowstheinserts,ifdamagedor

wornout,tobeinexpensivelyreplacedwithouthavingtopurchaseawholefollowbarassembly.TheInsertsarepermanent

moldcastfromaspecialbearinggradeanti-gallingmaterialtoprotectthetubingfromscratchingduringthebendingprocess

andthenCNCmachinedtosize.TheyaresilverishincolorbutareNOTaluminum.

Notice that one insert is slightly angled. This angle is

calculatedandmachinedintothebackingblockto1/1000

of a degree from theoretically perfect for the tube size

and bend radius. This angle helps to support the tube or

pipeafter thepoint ofbend, greatlyreducing attening.

Whenbending,theangledinsertwillalwaysbecloserto

theformingdie,andtheU-strapforthatmatter,thanthe

straight insert.

A5/16"diameterrollpinisinstalledtoholdthefollowbar

in position while loading. When the followbar is in the

bender, theinsert groovesmust rideslightly lowerthan

the forming die's groove. This allows the followbar to RISE

underpressure.Ifthepinextendedtoofar,thefollowbar

would bind under pressure.

COMPLETEROUNDGROOVEDIESET

Below is pictured all of the components which make up a complete die set for round tubing or pipe. You can see two red

linesdrawnat90degreesapart.Theselinesaremarkedas1and2.Line1runsfromthecenteroftheformingdie'scenter

holetoapproximatelythemiddleoftheangledrearinsert.Line2runsfromthatpointparalleltothetubing.Thisillustrates

the basic principle of how the components relate to each other. It is vital that when bending the rear insert is positioned as

shown.Forexample,supposethefollowbarinengravedwithhole6asshown,butyouinstallitinhole7.Therearinsertwill

be shifted to the right of line 1 and the angle machined into it will have no effect during bending. This will generally cause

atteningofthetubing'soutersideandmayalsocausewrinkling.Ifyouexperiencethisproblemandyouhavethefollowbar

installedinthecorrecthole,therearinsert'sbendingpositioncanbeeasilychecked.Simplyplaceashortpieceoftubinginto

the bender as if your were actually going to bent it. Apply enough bending force to remove any play but not actually bend the

tubing.Nowholda90degreecarpenter'ssquareabovethebendersothatitsoutsideedgesarepositionedsimilartothered

lines shown. The center of the angled rear insert should be roughly at the corner of the square. I say roughly because some

diesaredesignedtoshifttheinsertslightlytotheleftorrightofcentertoimprovebendquality.However,thiswillgenerally

belessthan1/4".Ifasintheexampleabove,youplacedthefollowbarinthewronghole,theinsertwillbeverynoticablyoff

center and almost always to the right of red line 1.

Followbar

Drive holes (5)

U-StrapPin

U-StrapBolt Tube

Angled Insert

Straight Insert

Figure 10 - Die set components

U-Strap

1

2

Forming Die

- 5 -

Figure 9 - 1 1/2" OD Followbar Assembly

Rear

Angled

Insert

Front Straight

Insert

Backing

Block

1/2"

Locking

Bolts

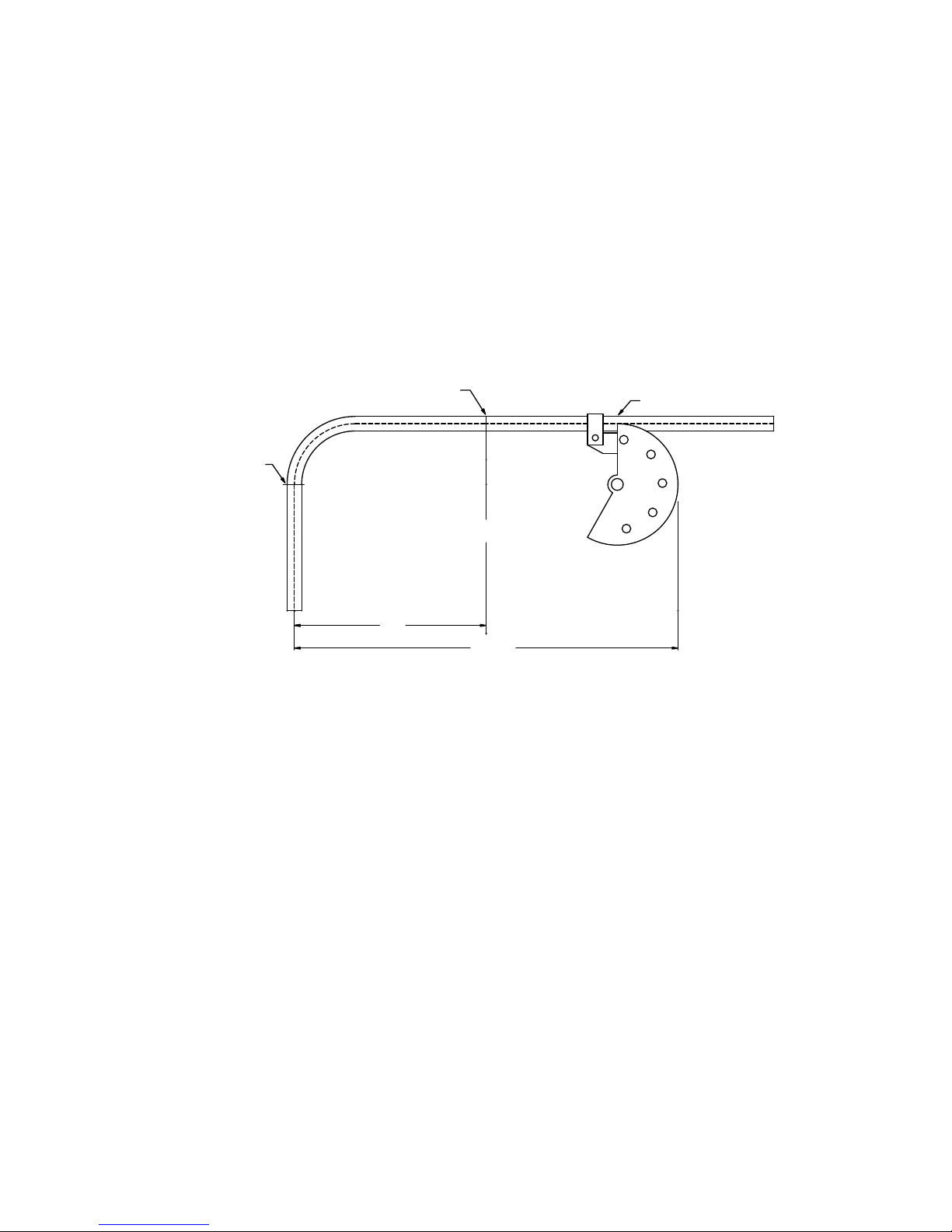

DEGREE POINTER INSTALLATION

Current production forming dies are made to accept a degree pointer. This is supplied as a straight piece of 3/32" copper coated

steelrod.Theillustrationbelowshowsthepointerinstalledontheformingdie.Youwillneedpliersandawirecuttertotthepointer.

Firstinstallthediesetintothebender,preferablywithalengthoftubinginstalledalso.Onthebacksideoftheformingdie'sdieblock,

youwillseeathingroovewithawasherandboltinstallednexttoit.Usingtheillustrationbelowasaguide,bendthewirepointer

tot,makingsureitclearstheU-strapanddrivelinks.Allowapproximately1/16"clearanceabovethedegreemarkings.Notice

we've placed a small bend in the pointer's lower end so that it aligns with the degree markings. This makes it easier to read when

bending.Whenyouarehappywiththet,tightenthepointerlockbolttosecurethepointerontotheformingdie.Thepointershould

beleftonthedieevenafterthedieisremovedfromthebender.Whenstoringthediesetbecarefulnottobendupthepointer.

However, this is just common 3/32"

copper coated TIG welding rod, so if

you do manage to mangle, damage,

decimate, disgure, batter, hurt, mutilate,

warp, destroy, lose, smash, wreck,

maim,ravage,sabotage,trash, demolish,

vandalize, incapacitate, ruin, obliterate,

cripple, (... deep breath ...) spoil, break,

annihilate, brutalize, make inoperable, or

otherwise extinguish its very existence,

just visit your local welding supply to get

a new one.

Pointer

Die Block

Figure 12 - Pointer installed on the backside of the Die Block

- 6 -

SQUARE AND RECTANGULAR GROOVE DIES:

Squaregroovediesoperatesimilartotheroundgroovediesexplainedearlierwiththeseexceptions:

1) The bottom of the groove has a raised crown machined into it. This starts the depression in the bottom side of the

tubingduringbendingtopreventthetubefromkinkingandhelpskeepthesidesreasonablystraight.Notethat

square tubing will always sink in on the outside and inside of the bend.

2) TheU-strapclampusesabolttotightlysecurethetubingtothedieblock.ThisboltpressesagainstaHshaped

steel plate to prevent the bolt from marring the tubing. To the right is an illustration of the tubing installed in the

forming die.

3) The followbar does not utilize inserts. It is

machined from one solid piece.

4) You must lubricate both the outside of the

tubing and the COMPLETE groove in the

forming die before bending. Square tubing

tends to wedge itself into the forming die

while bending and generally requires

a large rubber mallet to tap it out when

nished.Thebiggerthetubing,theworse

theproblem.Withoutlubricantitcanbe

very difcult to remove the tubing from

the die. This problem is not specic to

theModel3Bender,buttoALLbenders

utilizing a one piece die.

Pointer Lock Bolt

HPLate

Followbar

Figure 11 - Square die set components

U-Strap

Die Set Installation and Bending Procedure

There are two types of forming dies provided for the Model 3 Bender. Those with drive holes and those without. The drive holes

aretheve1"holesdrilledinacircularpatternaroundtheformingdie'scenterhole.A7/8"diameterpininsertsthroughthedrive

links and through the forming die's drive holes when in operation. The drive holes are drilled 1/8" oversize to provide easier pin

installation.Toprepareforbending,followthestepsbelowdependingonthetypeofdieset.

WITH DRIVE HOLES:

Place the forming die into the bender using the 1"

framepin.Ifbendingsquaretubing,thoroughlylubricate

theformingdie'sgroove.However,ifbendingroundtubing

orpipe,NEVERlubricatetheformingdie'sgroove.Ifyou

do,thetubewilltendtoslipbackwardsinthediewhile

bending,whichinturncausesthetubingtokinkorwrinkle.

PlacethetubeintotheformingDie.InstalltheU-Strap

withtheshorter7/8"U-strappin.Ifnecessary,tightenthe

U-strapbolttopreventthetubefromslippingthroughthe

die will bending. It's a good idea to cut a slice out of a

bigger piece of tubing place it between the bolt and tubing

to prevent the bolt from dimpling the tubing. If bending

thinwalltubing(.065"orthinner)youmustalwaysuse

theU-strapbolt.

Next,usingthe7/8"FollowbarPin,placetheFollowbar

into the bender. See page 5 for the correct way to install

the Followbar. Lightly spray some lubricant on the outside

of the tubing so that the tubing will slide through the Followbar easily. Any spray lubricant works well. If you are bending tubing

withawallthicknessof.065"orthinneryoumaywanttoskipthelubeentirely.Thiswillhelpthefollowbarsticktothetubingduring

ratchet repositioning and generally helps prevent wrinkling. Make sure all pins are completely seated in their holes. Failure

to do this may cause damage to the bender links or worse yet the operator may slip and fall.

RotatetheRatchetLeverfullycounter-clockwise.EngagetheRatchetontotheouter3/4"drivelinkspacertube.Lightlypull

onthehandletopreloadthetubing.Donotpullhardenoughtoactuallybendthetubing.Usingafreehand,loosenthedegree

platenut.Rotatethedegreeplateuntilthedie'spointerisat0degreesandthenhandtightenthenuttosecureitintoposition.

Nowyou'rereadytobend.PullonthehandleinaclockwisedirectionuntiltheRatchetLevercannotrotateanyfurther.Returnthe

Ratchet Lever to the starting position. Initially release the Ratchet easily so as not to move the tubing and minimize spring back.

Reengagetheratchetandpullagain.WhenthelastRatchettoothisreached,returntheRatchetLevertoitsstartingposition.

Removethe7/8"DrivePinandrotatetheDriveLinkscounter-clockwiseuntiltheDrivePinmaybereinstalledthroughanother

holeintheBendingDie.Becarefulnottomovethetube.Nowrepeattheabovebendingsequenceuntilthedesireddegreeof

bendisobtained.Toreleasethetubingfromthebender,removethehandlefromtheRatchetLever.Insertitdiagonallythrough

the3/4"drivelinkspacertubesandpullcounter-clockwise.TheFollowbarwillreleaseitsgripandthetubingmayberemoved.

WITHOUT DRIVE HOLES:

These dies typically have a center line

radius of less than 3". Because the radius of

thedieissosmall,driveholescannotbedrilled

into the die. This does not present a problem

as the tube sizes for these dies is of relatively

small diameter and is easily bent. The ratchet

is not used.

Die installation procedure:

Swing the ratchet assembly out of the

way as shown below. Place the forming die

into the bender. Place the tubing to be bent

in the bender and using the 5 1/4" long drive

pin(nottheshorterU-Strappinthatisusually

used)installtheU-strap.Ifdesired,tightenthe

U-strapbolt tosecure thetubingto thedie.

This is not mandatory and may be omitted if

the tubing shows no signs of slipping through

thediewhilebending.Nowinstallthefollowbarbeingsuretheword'TOP'isfacingup.Rotatethedrivelinksuntiltheirfrontedge

pushesdirectlyontheU-strappinasshowningure6.Placethehandlediagonallythroughthedrivelinks'two3/4"spacertubes.

Lightlypullonthehandletopreloadthetubing.Donotpullhardenoughtoactuallybendthetubing.Usingafreehand,loosen

thedegreeplatenut.Rotatethedegreeplateuntilthedie'spointerisat0degreesandthenhandtightenthenuttosecureitinto

position.Now,simplypullthehandleandobservethepointeruntilthedesireddegreeisreached.

- 7 -

Figure 14 - Handle installed and ready to bend without drive holes

Figure 13 - Bending with drive holes and ratchet

- 8 -

First,youneedtomakeatemplate.Forourexample,

wearegoingtouse11/2”o.d.x.120”wallweldedseam

mildsteeltubing.AsshowninFigure15,thetemplateisa

pieceoftubingbentto90degreeswithapproximately6”

of straight tubing on each side of the bend. Cut a piece of

tubingroughly30”long.Next,scribeanaccuratelineall

thewayaroundthistubing6”fromtheend.Anaccurate

and easy way to do this is to use an inexpensive pipe

cutter. Your local home supply store should carry them in

the plumbing department. A small lathe with a sharp cutter

alsodoesagoodjob.Scribethelinedeepenough,roughly

.015”,sothatwhenyoupaintthetemplate,thelineisstill

clearlyvisible.Handscribingthislineisdifcultandnotrec-

ommended. The tube should now resemble Figure 17.

Learning the operation of a bender is fairly easy. The real challenge is accurately placing the tubing

intothebendersothatthebendcomesoutintherightposition.Thisshorttutorialexplainsthesimple

process of template bending.

Make a sample bend called the Template as shown in Figure 15. A permanent mark scribed on the

template allows you to measure and visualize where the bend should be placed in the tubing. Once bent

the tubing will spring out to a larger radius than the forming

die’s size indicates. The larger the O.D. or the stronger

the tubing, the greater the springback. For instance,

chromemoly tubing will springback roughly twice as far

astheexactsamesizeandwallthicknessofweldedseam

mild steel tubing. By using a template bend with the same

kindoftubingyouaregoingtobend,youdonothaveto

worry about this springback because the template has

alreadysprungouttoitsnishedsize.

You may ask if buying bending software is a good

idea.Ibelievebendingsoftwarecanonlyjustiedfortwo

reasons:Creatingpartdrawingsifthesoftwaresupportsthat

functionandforsettingupafullyautomaticCNCbender

for the initial test of a part with multiple bends. Even using

the software the bend locations usually need to be hand

tweaked for accuracy before going into production. Most

professional fabricators use a method similar to what is

describedhere.Itisextremelyeasy,accurateandfast.

However,whatifyouneedtobend500pieces.Howwould

youusethisprocess?Don’tworry,it’sasimpletechnique

thatIwillexplainlaterbutrstlet’sjustcompleteasingle

piece job. To do this I’m going to go through the whole

process that I use to make a four bend rollbar for a racecar

asshowninFigure16.Thisisagreatexamplebecauseit’s

acommonrequest,therearenosimple90degreebends,

anditisgenerallyaone-offpiece.Soholdontoyourlug

nuts,herewego.

Bending Method #1 - Using Template Bends

The Easy Way To Position Bends

Figure 15 - Sample Template Bend

Let’s Make A Bend Template...

Figure 16

Sample Rollbar

Figure 17

Template Line

Load this tube into your bender as shown in

Figure18.Notethatonlythediesetandtubing

arevisibleinthegure.Theactualbenderand

thedieset’su-straparenotshownsothatyou

can see what we’re trying to achieve. Place the

scribedlineattheatedgeoftheformingdie.

Neverusethefollowbarasareference. Ifthe

formingdiehasalockboltonit,useittosecurely

tighten the tubing in place. It’s very important that

thismark stays in linewiththedie’satedge

during the bending process or template will not

give you accurate results later. Figure 18 - Tube positioned

in forming die

Template Line

Followbar

Forming Die

Figure 19

AsshowninFigure20,therollbarwillbe40”tallfromtheoortoitsUPPERside.Itwillbe62”wide

outsidetooutside.Thetoptwobendsare70oeachandthetwolowerbendsare20oeach. I recommend

that you purchase an adjustable carpenter's protractor to help determine the degree of bend for your

specicjob.Theyaremadeofclearplasticandhavelegsapproximately12”long.

To determine the total length of

tubing needed, you could sit down

and calculate it. This is described in

thenextsection"BendingMethod#2"

which presents a more mathematical

method to bend tubing. However, for

thisapplication,Ithinkit’sawasteof

time.Timeusuallycostmorethantubing,

sohere’sthefastway:Take thetotal

widthoftherollbar(62”)andadditto

twicetheheight(40”)whichgivesusa

lengthof142”(62”+40”+40”).Thisis

slightlytoolong,maybeafootareso,

butthere’sapopularruleinfabricating:

It is easier to remove material then to

addit.Throughexperienceyouwilllearn

howmuchextratubingyoumustleave

to complete the part.

Bendthetubetoanishedbendofexactly90degrees.Onthis

example,Ihadtobendto94degreestoachieveatrue90degree

bendafterthetubingrelaxed.Cutthestraightlengthoftubingthat

isnotscribedto6”longsothatitmatchesthescribedside.Thisis

not really necessary but it does look nice. Debur both ends and then

paintthetemplateaneasilyvisiblecolor.Whydoesitneedpaint?

It doesn’t. But after losing this thing a few times you’ll get the idea.

Thetemplateisnished.

If you work with different types of tubing that are of the same

sizebutdifferintheamountofspringbacktheyproduce,possibly

becauseofadifferentmaterialorwallthickness,youmayneedto

make a separate template for each one. You can decide later if this

necessary depending on the accuracy that you require.

Figure19showsanishedtemplatebendstillinthedie.Note

the position of the scribed line on the tube.

62"

40"

20°

70°

50"

Figure 20

Time To Start Bending...

- 9 -

Animportantruleofbendingisto,ifpossible,alwaysmakethebendsclosesttothecenterrstand

workyourwayout.Thisallowsyoutomakemeasurementcorrectionsbetweenbends.Basedonthisrule,

place a mark at the center of the rollbar tube. This is shown Figure 21.

BEND 1:

The rst bend will be the

upper right side bend. Referring

toFigure20,theupperdimension

of the rollbar is 50”. From the

center oftherollbartotheoutside

ofthebendis25”(50”dividedby

2). Lay the tubing to be bent on

theoorandholdthetemplate

with the scribed side parallel

totherollbartubinganddirectlyaboveit,asshowninFigure21.Thescribedsideofthetemplatewill

alwaysfacetowardsthecenterofthetubingbeingbent.Usingatapemeasure,slidethetemplateleftor

rightuntilitis25”fromitsoutsideedge,shownbytherightarrowinFigure21,totherollbar’scentermark.

Usingamarker,drawasmalllineontherollbardirectlybelowthescribedline.Takenoteofwhatside

of this mark the bend needs to be and draw an ‘X’ there so that when you load the tube into the bender

you’llbebendingonthecorrectside.Sincethedesiredbendisonly70oandthetemplateis90o,you

willhavetouseyourbestjudgementofwhenthetemplateis25”out.Thisgetseasierwithexperience.

Now,loadthetubeintothebenderandmaketherstbend.Don’tforgettooverbendalittletoaccount

fortubespringback.Forthismaterial3to4degreesshouldbesufcient.SinceallJDSquaredbenders

are equipped with degree of bend indicators this is easily accomplished. Once you know the correct over

bendrequired,youmaywanttorecorditforfuturereference.

BEND 2:

Place the template above

the rollbar tube with thetemplate

line facing bend 1 as shown in

gure22.Usingatapemeasure,

position it for the desired 50”

outside to outside of the two

top rollbar bends. DO NOT

use the tube’s center mark

as a reference and place the

template 25” left of center. The

reasonforthisisthatiftherst

bendwasnotmadeattheexactrightspottoachieve25”fromcenteryoucancorrectfortheerrorinthe

secondbend’sposition.Onceagain,sincethebendwillbe70oandthetemplateis90oyou must use your

judgementastowheretopositionthetemplate.Placeamarkontherollbartubeexactlyunderneaththe

template line. Load the tube in the bender so that the bend will be made on the CORRECT side of the

tubeandmakethe70obend.

Erasethecentermarkontherollbartube.Usingthetapemeasure,placeanewcentermarkexactly

midwaybetweentheoutsideofthetwobends.Why?Let’ssayyourmeasurementshowsthetwotop

bendsarereally501/4”wideinsteadofthedesired50”.Inthatcase,youroldcentermarkcouldbeoffby

asmuchasa1/4”.TheNEWcentermarkcorrectsthiserror.That’sthecoolpartabouttemplatebending.

Yourerrorscangenerallybexedwiththenextbend.Alsonotethatifyouhadnotstartedyourbending

from the center of the rollbar you would not have been able to make the correction. Every bend adds a

littlemoreerrorandyouendupwitharollbarthatdoesnott.

25”

50”

Figure 21 - Template positioned for 1st bend.

Figure 22 - 2nd bend position

Tube’s

Center Mark

Template Line

Template Line

- 10 -

31”

62”

Figure 23 - 3rd bend position

Figure 24 - 4th bend position

BEND 3:

At this step you may want to use

alarge90osquare to help position the

template. Position the template above

the rollbar tube with the template line

facing up towards the top of the rollbar

asshowningure23.Slidethetemplate

up or down the rollbar tube until its

outside is 31” from the rollbar’s center.

Mark your tube and make the bend.

BEND 4:

Position the template with the

template line facing up towards the

top of the rollbar as shown in gure

24. Slide the template up or down the

rollbartubeuntilitsoutsideis62”from

theoutsideofthe3rdbend.Also,verify

the bend is the same distance down

the tube from the top of the rollbar. If

all is correct mark the tube and make

the bend.

Lastly, cut the ends of the tube

tomaketherollbar40”talland your

done.

Finished!

PROCEDURE FOR SETTING UP A PRODUCTION BENDER USING THE TEMPLATE METHOD

AsIstatedearlier,thismethodcanbeusedforproductionbending.Theideaofmakingthebends

from the center out doesn’t usually work well in production. Most production bending is done by feeding

thetubethroughthebenderandmakingeachbendasneeded,therebyeliminatingtheneedtoremove

thetubefromthebenderandipitaround.Forthisyouwouldwantasetupsheetwiththelocationsof

where to place the marks on the tubing for each bend location. The problem with template bending is that

the template has the tube stretch and springback already in it. Since the tubing will grow in length as you

makebendsinit,howcanyoumeasureitaccuratelyonceit’sbent?Unfortunately,youcan’t.Whatyou

mustdoisplacemarksdownthetube,forexample10”apart,startingattheoneendbeforeyoustart

bending.Nowwheneveryoutransferthemarkfromthetemplatetothetubebeingbentyoucaneasily

measurethedistancefromoneofthe10”markstodeterminewherethemarkwouldofbeenplacedon

an unbent piece of tube.

- 11 -

TherstthingyouneedtodoistodeterminetheactualstartinglocationofabendproducedbytheBendingDieyouinstalled

inthebender.Thiscanvarybetweendiesetsandmustbecheckedforeverydiesetpurchased.Inthebelowexampleweare

using11/2"O.D.tubingandaBendingDiewithaCenterLineRadiusof61/2".

Here'stheprocedure:

A) Placeapieceoftubing(app.21/2'long)intothebendersothatexactly12"extendsoutfromtheedgeofthedietothe

end of the tubing when the tubing is fully seated in the Bending Die's groove. Place a little bending pressure on the tube

soastoseatthetubingintheBendingDie.Notenoughtostartbendingthetubingjustenoughtoseatitinthegroove.

NOTE: If you lay a small length of tubing in the groove of a Bending Die you will notice the tubing does not seat to the

bottom of the groove. The Bending Dies are deliberately machined this way so that during the bending operation a

side force is developed in the tubing. This helps to reduce at spotting and

wrinkles.

B) Using a Black Magic Marker mark a line on the

tubingpreciselyattheedgeofthedie.Seegure

25.

C) Bend the tube to an exact 90 degrees. Use a

carpenters square to check the angle. You will

have to overbend the tube a little to account for

springback.Howmuchtooverbendwillcomewith

practice. If you overbend the tube a little don't worry.

Becausecoldworkedsteelhasmemory,youcan

place the tube in a vise or anything else that will

retainit,andsimplyunbendit.Obviouslythisonly

works for small amounts of overbend. If the tubing

isunderbent,itwillbenecessarytoputitbackinto

the bender.

D) Withthetubebentcorrectlyto90degreeslocate

theactualstartofthebend.Todothis,measure

fromtheendofthetubetothefarendofthe90

degreebend.Intheexampleingure26thiscame

outat20 1/4".Subtract61/2"forthecenterline

radius(CLR)oftheBendingDie,another3/4"for

theradiusofthetubingnotseatedinthedie,and1/8"forspringback.(SubstitutetheCLRandtuberadiustomatchyour

dieset).The1/8"gureforspringbackisanapproximation,notanexactgure.Howeveritisusuallyveryclosetothe

realthingandmaybeusedwithoutworrytodeterminetheactualstartinglocationofthebend.So:

20 1/4" - 6 1/2" - 3/4" - 1/8" = 12 7/8"

Nowsubtractfromthe127/8"theoriginal12"wehad

markedearlierandyoundthatthebendwillactually

start7/8"infromtheedgeofthebendingdie.Nowwe

knowforexample,ifwewant40"fromtheendofthe

tubingtothestartofthebend,wemustsubtract7/8"

from40"andsetthetubing391/8"fromtheedgeof

the Bending Die.

Anotherexample,youwant36"fromthebottomtothe

top of a rollbar. Tube size is 1 3/4" and you have an

actual bend start 1/2" inside of the Bending Die's edge.

TheCLRoftheBendingDieis71/2".So:36"-1/2"

(ActualBendstart)-71/2"(CLRofdie)-7/8"(Half

ofthetubingdiameter)-1/8"(Springback)=27".Set

the tube 27" from the edge of the Bending Die and

make the bend.

Bending Method #2 - Using Math Formulas

Figure 25

Actual start

of bend

6 1/2" CLR

7/8"

20 1/4"

12"

Mark

Figure 26

Mark here at the saw cut edge of

die (not at the followbar's insert)

- 12 -

- 13 -

Example hoop :

Preparation is the key to making accurate bends. To make multiple bends in one section of tubing you will need a universal

protractor.Theprotractoristhenclamped,usingamachinistv-blockandaradiatorhoseclamp,tothetube.Makesurethepointer

indicates'0'beforemakingyourrstbend.Alsousingacarpenter'slevel,makesurethetubeisenteringthebenderlevel.On

thesecondbendifyouturnthetubesothatthepointeragainreads'0'andthecarpenter'slevelindicatesthetubeislevel,both

bends will be on the same plane with no noticeable twist.

First step is to draw a sketch of the intended shape and all measurements. Figure 27 below is the desired hoop. The Bending

Diehasacenterlineradius(CLR)of61/2".ThetubeO.D.is11/2".Wedeterminedearlier,usingthemethoddescribedonpage

4,thattheBendStartmeasurementis3/4"behindtheedgeofthisparticularBendingDieset.

1) Determine the total length of tubing needed. Using a calculator and the formula below let's add it all up.

6 1/2" (CLR of bend) x 90 (Number of degrees of bend) x .0175 = Length of tubing used in a bend.

Usingtheformulaaboveweget61/2"(CLRofbend)x90(Degreesofbend)x.0175=10.2375.Let'sroundthisoffto101/4"

inches(10.250").Thisistheamountoftubingusedinthebend.Wehavetwobendssowedoublethisandget201/2".Addto

thisthestraightsectionsandweget201/2"(tubinginbends)+27(thecentersection)+131/2"fortheleftupright+131/2"for

therightupright=741/2"oftubingneeded.It'susuallyagoodideatoleaveacoupleofinchesextraontheend.Remember,

it's easier to remove tubing then to add it. So let's add 2" to 74 1/2".

2)Wecutourtubeto761/2".It'sgenerallyeasiertoworkfromthecenteroutwhenmakingtwobendsinatube.Divide741/2"

by 2 and our center point is 37 1/4" from the end of the tube. Place a mark on the tubing 37 1/4" in from one edge and mark the

tubingsoyouwillknowwhichsideisthe371/4sideandwhichsideis391/4".Noticewedidn'tusethe761/2"measurement

thatwecutourtubingto.Thiswayweonlyhavetocut2"offoneendofthenishedtubeinsteadof1"offeachend.Therst

bend is made on the short 37 1/4" side.

3)Usingthemethoddescribedonpage4wedeterminethatthetubeshouldextend125/8"fromtheedgeoftheBendingDie.

Below is the equation from page 4.

20" (Height of hoop) - 6 1/2" (CLR of die) - 3/4" (1/2 of tube's dia.) - 1/8" (Springback) - 3/4" (Bend Start) = 11 7/8".

Aftermakingthebendwehavehalfourhoopcompleted.Thetopofthebendis20"fromthebottomofthetube.

4)Nowfortheotherbend.Firstweneedtodeterminehowmuchthetubestretchedinthebendarea.Fromgure9weseethat

thetubeshouldbe203/4"fromtheoutsideedgetoour371/4"centermark.Howeveraftermeasuringfromourcentermarkto

theoutsideedgeofthebendwenowhave21"andnottheplanned203/4".This1/4"increaseisduetospringbackandthetube

stretching in the area of the bend.

Figure 27- Example hoop.

6 1/2" CLR

3/4"

20"

20 3/4"

20"

40"

13 1/2" 13 1/2"

1 1/2"

Start of 2nd bend

Center mark on tube

End of 1st bend

Start of 1st bend

C

L

- 14 -

Ifwenowrepeatedthesecondbend,usingthesame125/8"fromtheendofthetubing+2"fortheextratubingweallowed,

wewouldendupwithahoop1/2"toowide.Thisisbecausethe1/4"stretchdevelopedintherstbendwillalsobedevelopedin

thesecondbend,givingus1/2"totalincreaseinwidth.Notagooddealifyouonlywanta40"widehoop.Sowhat'sthesolution.

Actually there is two ways to do it.

FIRSTMETHOD:

Lookatgure27andnoticethesecondbendstartsatthetopofthehoopandnotatthetopoftheuprightastherstbenddid.

Also the start of the second bend is drawn as 13 1/2" from the center mark. If you take the 13 1/2" measurement and subtract

the1/4"ofgrowththatwasdevelopedintherstbendandanother1/4"tocompensateforthesecondbend'sgrowthyouendup

with13".Subtractanother3/4"toaccountforthe3/4"BendStartlocationontheBendingDiesetandwehaveanalsettingof12

1/4".Noticewedidnotsubtractan1/8"forspringback.Thisisaccountedforalreadyinthe1/4"weaddedforthesecondbend's

growth.SetthetubesothattheBendingDiesedgeisexactly121/4"fromthecentermark.Makesuretheuniversalprotractor

reads'0'andthecarpenter'sleveliscentered.Asonenalcheckyoucanalsomeasurefromthefarsideofthecompletedbend

totheedgeofthebendingdie.Seegure28.Thismeasurementshouldread:

40" (width of hoop) - 3/4" (radius of tube not in bending die) - 1/8" (springback allowance) = 39 1/8"

Makethesecondbend.Measuretheheightoftheseconduprightandcutofftheextratubingweallowedforearlier.

SECONDMETHOD:

Thesecondmethodisbasicallytheoppositeoftherstmethod.ThesecondbendwillstartatthebottomoftheuprightandNOT

atthetopofthehoopasintherstmethodandasshowningure28.Weusethesamemethodasusedtobendtherstbend

withafewexceptions.Firstcalculatethestartingpointforthesecondbendasshownbelow:

20" (total height of hoop) - 6 1/2" (CLR of bending die) - 3/4" (Bend Start) = 12 3/4"

Add2"toaccountfortheextratubingweallowedearlier.Alsoaddthe1/4"growthdevelopedintherstbendandanother1/4"for

thesecondbend.DONOTADD1/8"SPRINGBACK.Onceagainthisisalreadyaccountedforinthe1/4"growthofthesecond

bend.Weendupwith:

12 3/4" + 2" (extra tubing) + 1/2" (growth for both bends) = 15 1/4"

Setthetube'sendat151/4"fromtheBendingDie'sedge.Makesuretheuniversalprotractorreads'0'andthecarpenter'slevelis

centered.Makethesecondbend.Measuretheheightoftheseconduprightandcutofftheextratubingweallowedforearlier.

Thank you for purchasing a JD Squared bender. Any further questions please contact us.

21"

39 1/8"

Start of 2nd bend

Center mark on tube

Start of 1st bend

C

L

Figure 28

Table of contents

Other J D Squared Construction Equipment manuals