User manual

AKKUTEC 2412 VdS

Document page 1 / 16

0812G01B02-160422.docx

J. Schneider Elektrotechnik GmbH

Helmholtzstraße13, 77652 Offenburg · Postfach 2327, 77613 Offenburg · Werner-von-Siemens-Straße 12, 77656 Offenburg

Tel

+49

(0)

781

206

0

·

Fax

+49

(0)

781

253

18

·

[email protected] · www.j-schneider.de · Amtsgericht Freiburg HRB 470458 Geschäftsführer: Dipl.-Betriebswirtin (BA) Bettina Schneider · Dipl.-Wirt,-Ing. (FH) Rolf Anti · UST-Ident-Nr. DE142532740

DC-USV

NBPA0812G01***

VdS-Nummer G209169

0786-CPD-20873

page

1. General......................................................................................................................2

1.1 General safety notes

1.2 Short description

2Transportation and storage.....................................................................................3

3Installation and connection.....................................................................................3

3.1 Installation

3.2 Connection

3.3 Connection lead accumulator

3.4 Connection of mains voltage

3.5 Connection load

3.6 Signal contacts

3.7 Circuit diagram

4Start-Up .....................................................................................................................9

4.1 Display and messages

5Operation ..................................................................................................................9

5.1 Mains operation

5.2 Back-up operation

5.3 Deep discharge protection

5.4 Accumulator circuit monitoring

5.5 Accumulator test

5.6 Temperature tracking (optional)

5.7 Shut-Down

5.8 Acoustic alarm transmitter (optional)

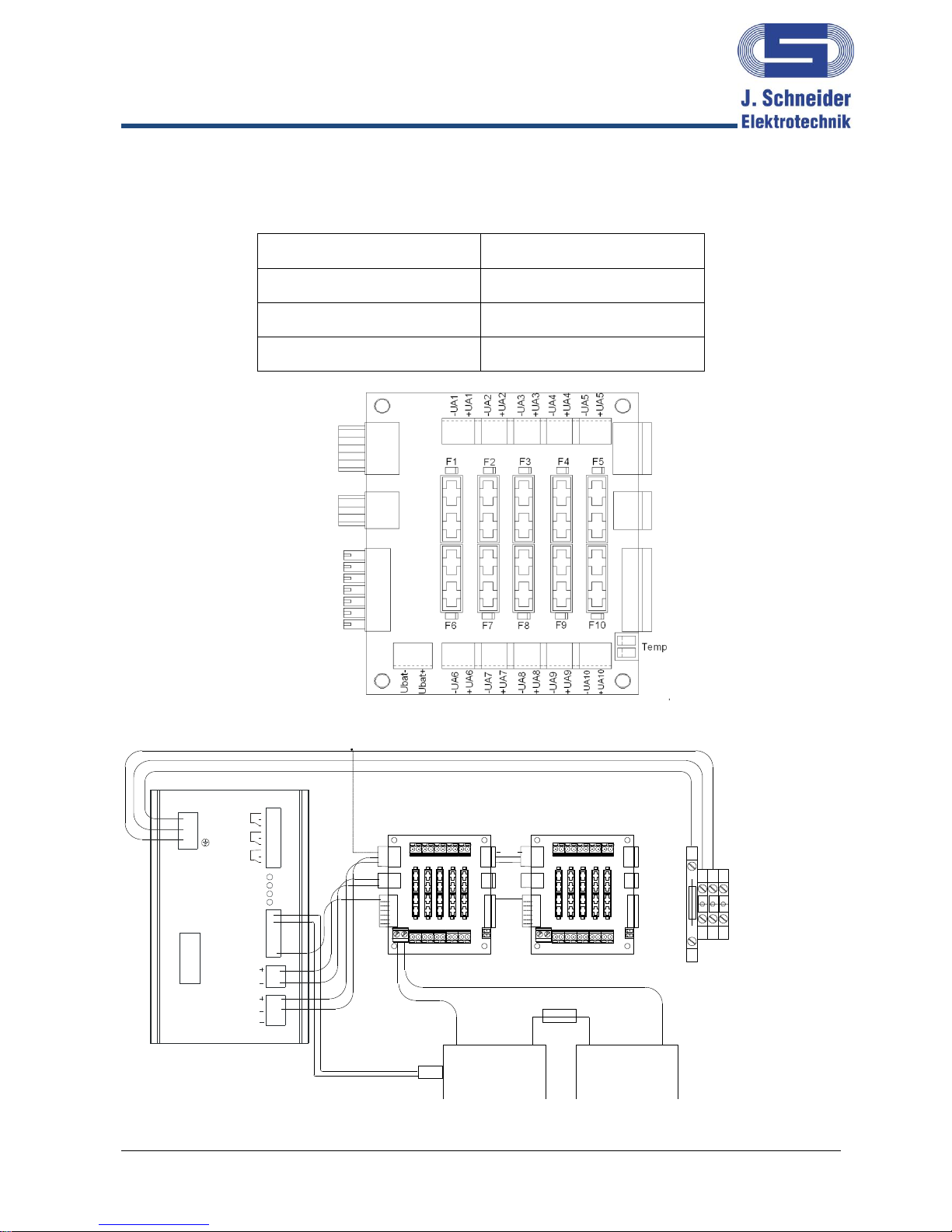

6Master/Slave-operation at parallel connection .....................................................11

6.1 Connection at Master/ Slave-operation

6.2 Signalisation at Master/Slave-operation:

6.3 Shutdown at Master/Slave-operation

6.4 Configuration Master/Slave

7Servicing ..................................................................................................................13

7.1 Testing the lead accumulators

7.2 Exchanging the lead accumulators

8Decommissioning....................................................................................................14

9Disposal ...................................................................................................................14

10 Norms and regulations ...........................................................................................14

11 Technical Data.........................................................................................................15

12 Accessories .............................................................................................................16