J3 Competition Inc. – Kosmic Owner’s Knowledge Packet 5 | P a g e

2. Front Track Adjustment

Nearly all Post-2005 Kosmic Racing Karts are sold with HST front stub axle, which has a

25mm stub in order increase the chassis front-end grip or effectiveness.

The recommended front width is to use 3-5mm spacers on the inside of the hub (Standard

90mm HST Hub). If the track has less grip a narrow front track will improve the chassis

initial reaction, however, this may cause the chassis to lose performance on longer

corners. A track with medium to high grip often times requires a wider front track width

in order to increase the chassis weight transfer. This also helps the chassis to be more

effective on longer corners when more driver input is often times required to keep the

speed up.

3. Rear Track Adjustment

We recommend always starting with the standard OTK 92mm rear hubs. Typically we

will start the rear track at the maximum.

- For the senior divisions this will be 55” and for the junior divisions this will be 53 ½”.

(Measured form outside rear wheel to outside rear wheel). From this point the only real

movement is to narrow the rear track.

- By narrowing the rear track of the chassis while leaving the front track untouched the

chassis will become more effective at releasing the inside rear tires during cornering.

This can initially improve the chassis performance as well as through the entire corner.

However, as grip levels change a narrow rear track can also create too much ‘Side Bite’

thus, giving the chassis too much grip in the middle of the corner and decreasing its

effectiveness. It is also recommended when the grip levels are low to test the rear track

width narrower due the potential increase in ‘Side Bite’ from the tire. Rear width can

sometimes be complicated in regards to the effects it has on the chassis performance,

therefore, make minuet changes when adjusting. And one of the major factors with rear

width is chassis balance ‘Feel’. Some drivers do not like to drive on a chassis with a

narrower rear track width, so know your driver.

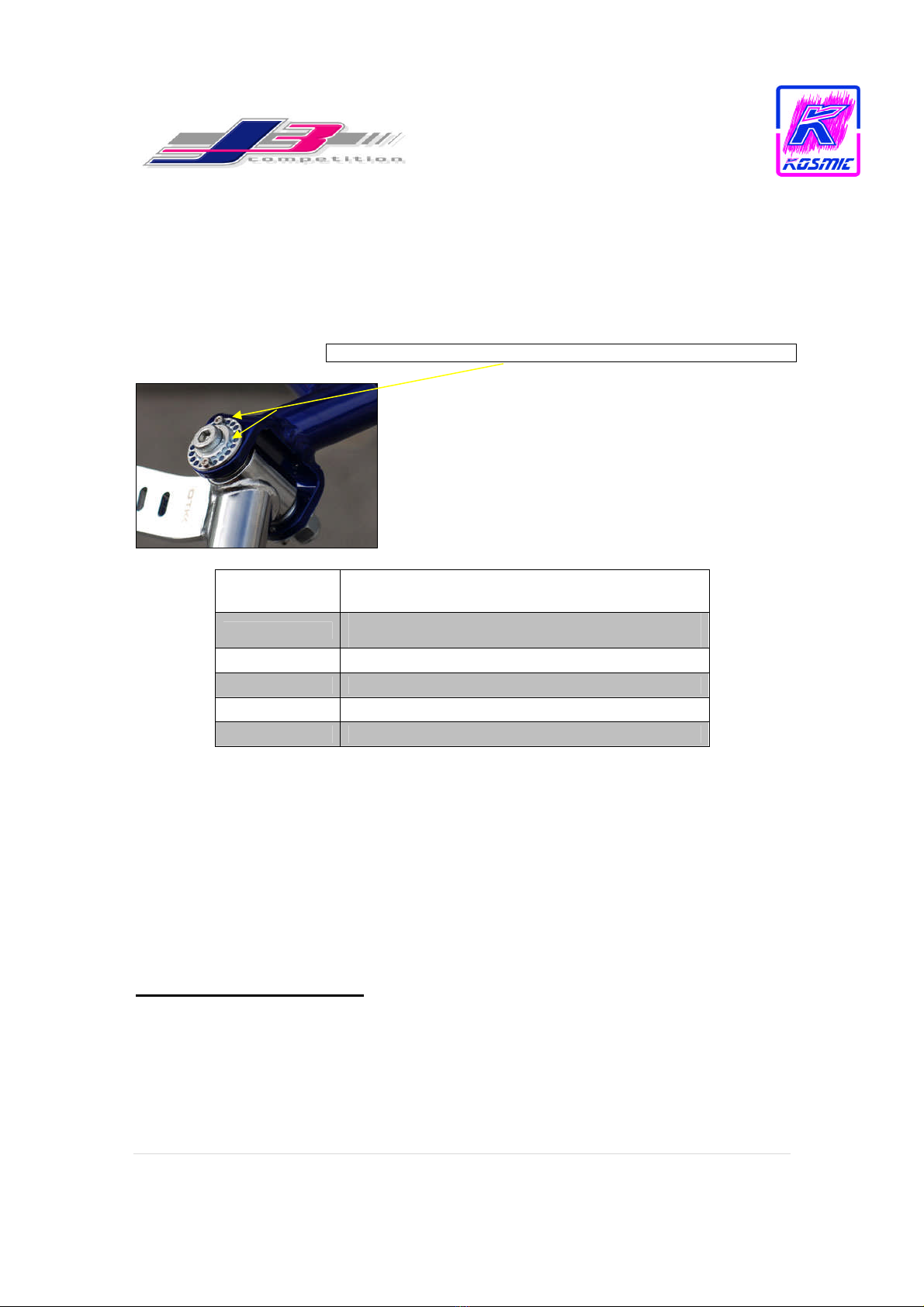

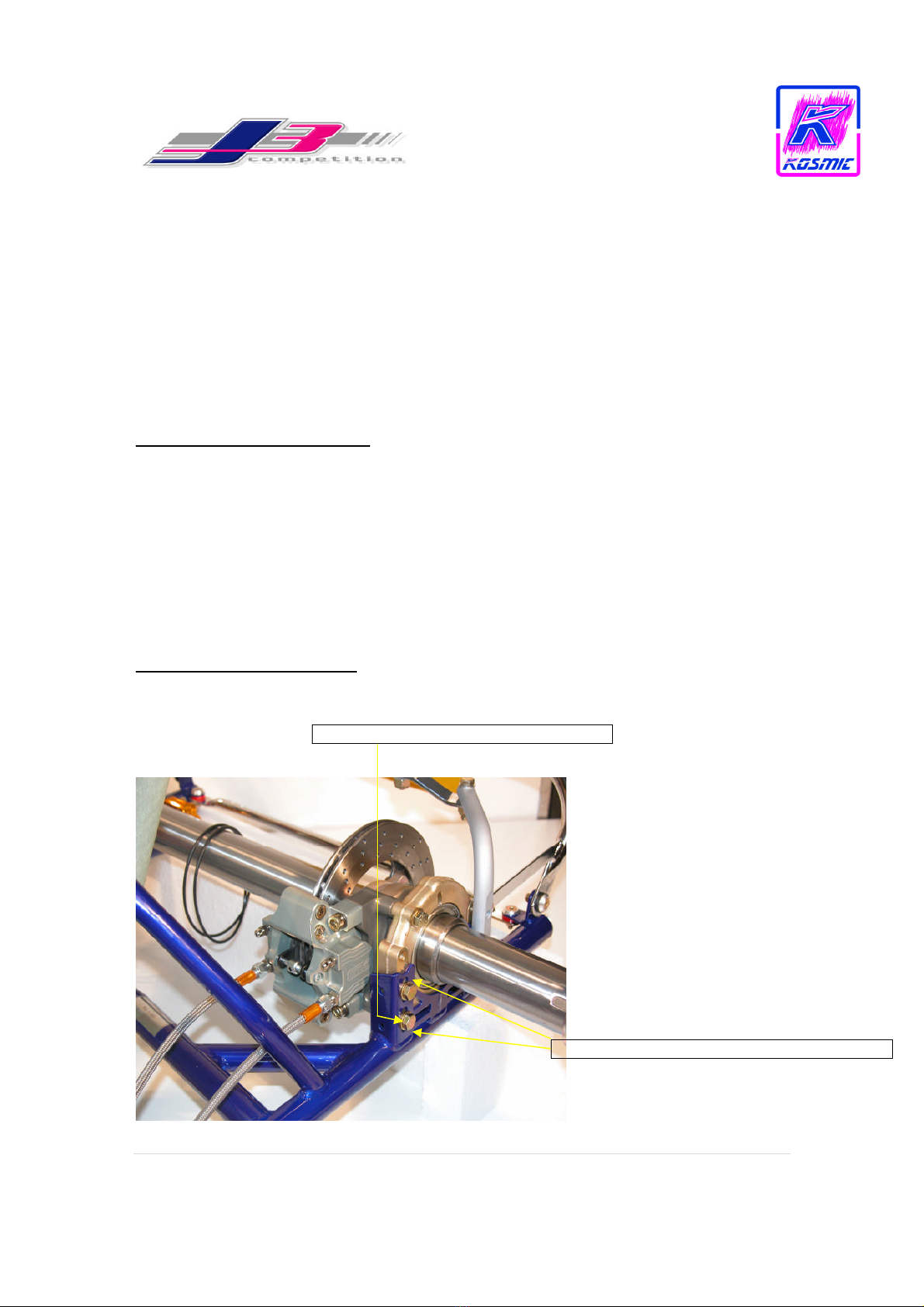

4. Caster / Camber adjustments

Caster and Camber can be adjusted at the front-end of the chassis. Depending on which

model Kosmic Racing Kart you have, there will be either 4-position ball bearing

adjustment, 4-position non-bearing eccentric either in D.8mm or D.10mm, or Post-2007

20-position ball bearing adjustment.

J3 recommends starting with full caster, which can be attained with the top eccentric

arrow facing forward and the bottom eccentric arrow facing backwards. This will give

the front-end maximum grip from a caster perspective and can possibly make the chassis

more difficult to turn as well. This is the most often setup regarding the caster position.