JackJaw 301 User manual

Assembly Instructions

Operating Instructions

JackJaw®301/302 Assembly and Operating Instructions

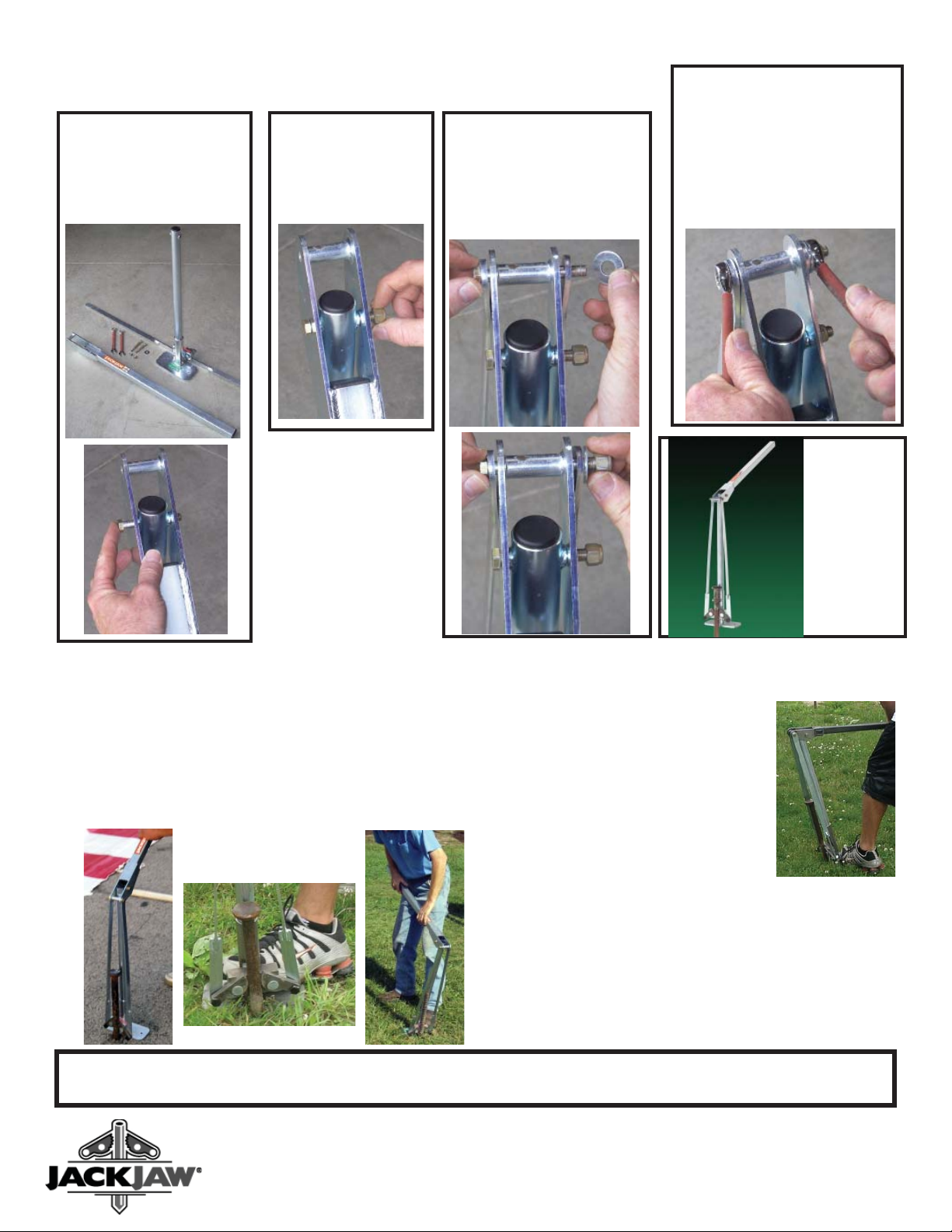

Step 1: Place contents of

box on floor or table. Place

handle over riser tube with

decal facing up and insert

short 3/8” - 24 bolt.

Step 2: Start 3/8”-24

self locking nut on to

bolt.

Step 3: Swing link arms up to

handle. Insert the long 3/8”-

24 bolt through link arms and

handle. Install flat washer on

bolt. Start 3/8”-24 locking nut

on bolt.

Step 4: Use two 9/16” wrenches

to tighten riser bolts and nuts and

link arms onto handle.

Note: Nut will stop before con-

tacting the handle.Then, back off

the nut on the link arm bolt one

half turn from the washer. Handle

should raise and lower freely.

Construction Accessories, Inc. • Phone 937-429-9089 • Fax 937-427-4653

Printed in U.S.A. • Product Made in the U.S.A.

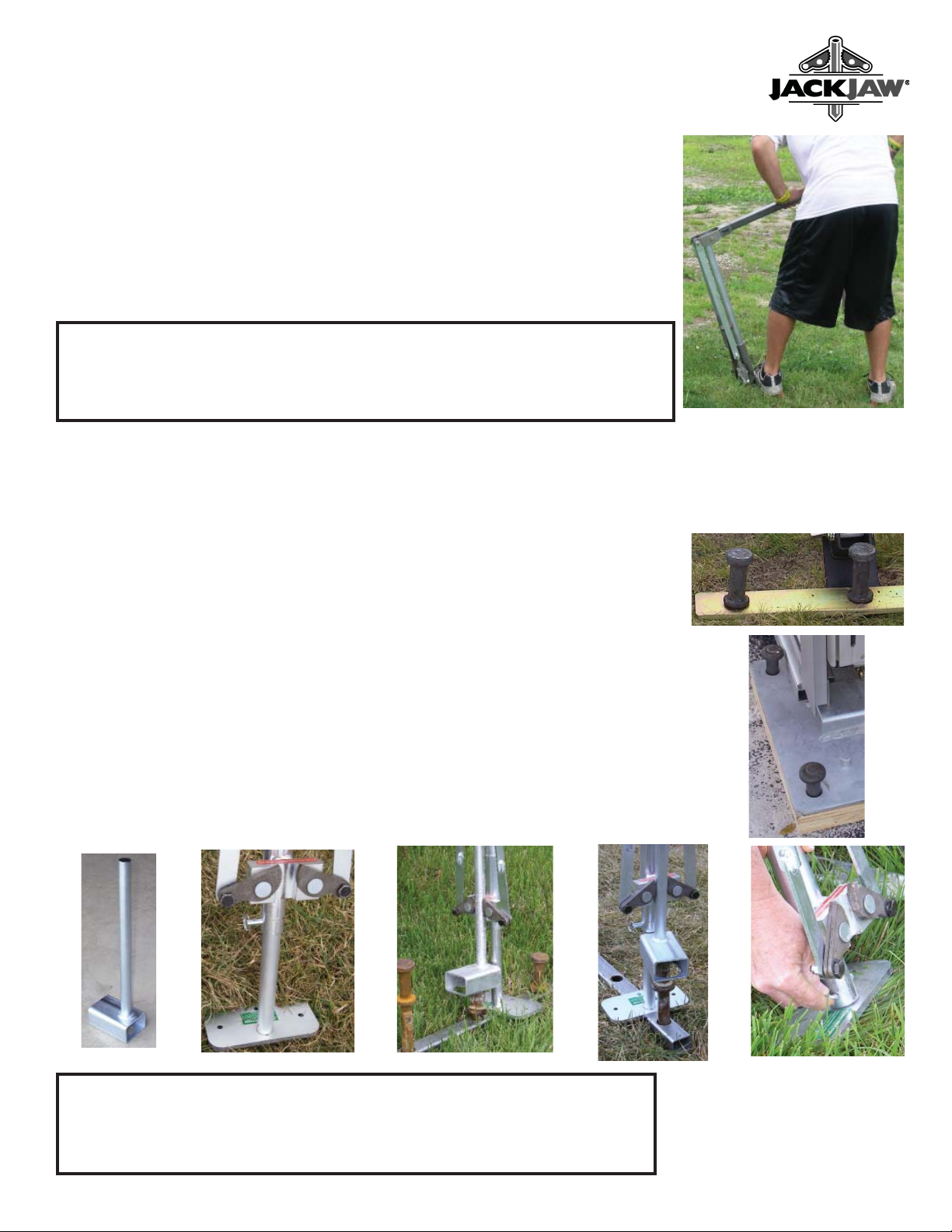

Step 1: Lift handle to up position so that jaws are fully open.

Step 2: Place unit so that jaws are on either side of the stake.

Figure 1 and 2below.

Step 3: Place foot on base. Figure 3 below. Push down

on handle, clamping on stake and lifting it out of the ground.

Step 4: Repeat motion as necessary until stake is free.

Caution: Never put your fingers or hands between the jaws, or between the jaws and the stake.

Replacement Jaw Set - 4 jaws & hardware Part # CA0003

1.

2.

March 2011

Tilted Tent Stake Removal

Step 1: When you pull a tilted or

leaning stake, simply put the unit on

the high side and lean the stake puller

over so that the shaft aligns wih the

shaft of the stake. If the ground is un-

even, use two blocks of wood to level

the base of the stake puller so that the

central shaft is parallel to the stake.

Figure 4.

Step 2-4: Same as Basic Tent Stake

4.

Pulling Stakes from Asphalt

JackJaw stake pullers excel on asphalt. When pulling from

asphalt, make sure that the stake puller is aligned with the

direction of the stake. This keeps the stake from binding with

the asphalt. The stake will usually come straight out. If you

have some difficulty, try moving the puller around the stake to

get better alignment.

Basic Tent Stake Pulling

Tip: In soft conditions or mud, place a short piece (1to 2 feet in length) of 2 x 6 lumber under the base of the unit. This will

spread the force over a larger area, allowing stake removal even in muddy conditions.

3.

Completed

Assembly

JackJaw®301/302 Operating Instructions

Construction Accessories, Inc. • 937-429-9089

www.jackjaw.com

Printed in U.S.A. • Product Made in the U.S.A.

March 2011

Pulling Flush Pounded Stakes with the JackJaw302 and AC0009 Adapter

7.

6.

8.

VERY IMPORTANT: If you are pulling a stake from a stake bar or frame plate, put

the metal base of the JackJaw unit ON TOP of the bar or plate. You must pull the stake

straight out of the bar or plate. If the unit is on the ground next to the bar or plate, a slight

misalignment can cause the stake to bind with the bar, making it difficult to pull from the bar.

If you pound your stakes so that the heads of the stakes are flush with the surface or flush to a

stake bar or frame plate (Figures 6 & 7) you will need an optional stake adapter, AC0009. The Jack-

Jaw302 was designed specifically to solve this problem.

Step 1: Slip the AC0009 stake adapter over the head of the stake. See Figure 8.

Step 2: Pull the ring pin at the bottom of the stake puller and extend the base to the high position.

Re-insert the pin in the highest hole. Figure 9.

Step 3: Place the metal base of the stake puller as close to the stake as possible. When using a

stake bar system, put the metal base of the JackJaw on top of the bar. Figure 10.

Step 4: Raise the handle of the stake puller, and put the shaft of the stake adapter between the

jaws of the stake puller. Be careful not to put your fingers in between the jaws and the adapter!

Step 5: Let the handle down to close the jaws on the shaft of the stake adapter.

Step 6: Push down on the handle, pulling up on the adapter (and the stake) until 4-5 inches of the

stake are exposed. It may take two or three pulls on the adapter. Figure 11.

Step 7: Move the stake adapter to the next stake and repeat Steps 1 - 6 for each of flush pounded

stakes that you need to pull. After all stakes have been pulled up to expose 4-5 inches of each stake

shaft, go to Step 8.

Step 8: Pull the ring pin from the high position and retract the base to the normal low position.

Re-insert the pin in the lowest hole. Figure 12.

Step 9: Pull all the stakes the rest of the way out using the steps from “Basic Stake Pulling.”

9. 10. 11. 12.

Difficult or VeryTight Stake Removal

If you encounter difficult or very tight stakes, you can optimize the pulling power of the

JackJaw by positioning the lever arm perpendicular to the vertical shaft of the stake puller.

This maximizes the leverage from the first and most important push on the handle. See

Figure 5.

To get this position, follow steps 1-2 to put the stake puller on the stake. Then, gently lift

the slide block with your hand from underneath so that the jaws slide up the stake slightly,

until the handle is perpendicular. This allows you to get your full weight, safely and comfort-

ably on top of the stake puller handle for the first push. Since the handle is perpendicular,

the leverage is maximized in this position.

5.

WARNING: Do not lengthen the handle of the JackJaw stake extractors. The JackJaw unit

must only be used for stake removal. Use extreme caution in the vicinity of moving parts such

as the fulcrum area and gripping jaws. Improper use of this tool is likely to result in serious

bodily injury or damage for which Construction Accessories shall not be responsible.

This manual suits for next models

1

Table of contents