2

This Operations Manual contains important instructions, warnings, and

safety procedures that must be understood BEFORE assembling or

using the M.I.N.E.™ Trapping System. Failure to review and understand

the ENTIRE MANUAL prior to assembly or use could result in serious

injury or death to you or someone else.

CRUSH HAZARD: This device uses a wireless transmitter to remotely

trigger a HEAVY DROP GATE, which can cause serious injury or

death. ALWAYS secure the drop gate with the Gate Safety Clip before

conducting any work on or around the gate.

ALWAYS ensure that gate area is clear BEFORE pushing the transmitter

button, connecting wires inside the control box, or replacing the

transmitter battery.

CHILD SAFETY HAZARD: This product can cause serious injury or

death. Keep children away from equipment at all times.

At least TWO PEOPLE are required to assemble and install the

M.I.N.E.™ Trapping System. Assembly and installation without the

assistance of another person may result in injury.

ALWAYS wear appropriate protective equipment when applicable,

including eye and ear protection.

ALWAYS disconnect battery from control box when trapping system is

not in use. Reciever is constantly in use and will drain the battery.

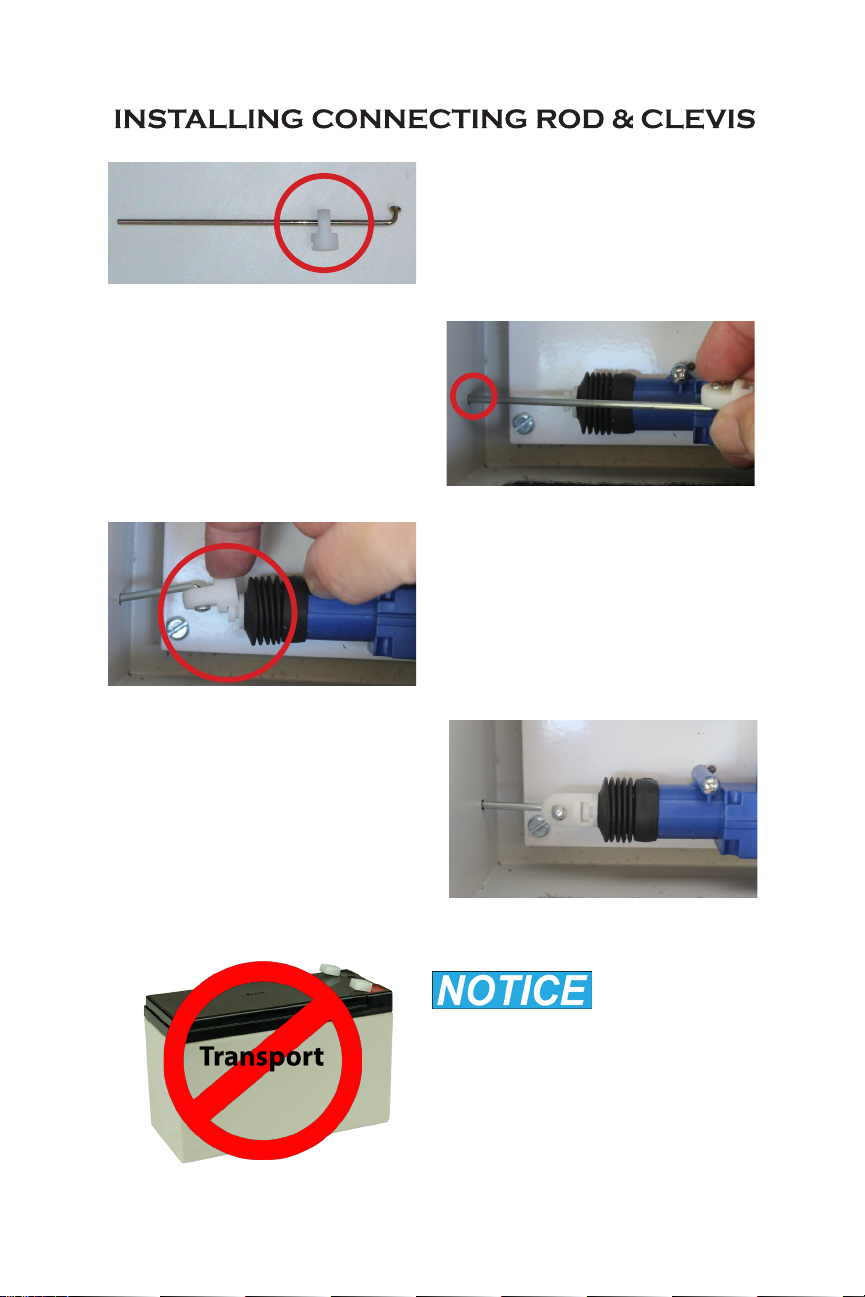

NEVER transport M.I.N.E.™ Gate with the battery inside the control

box. Transporting the gate with battery installed will cause severe and

permanent damage to both the battery and the control box electronics.

Keep control box clean and protected from moisture in order to prevent

damage and to ensure proper operation of the trapping system.