III

Contents

Chapter 1 Safety Specification...............................................................................................................7

1.1 Introduction .....................................................................................................................................7

1.2 Safety Warning Signs Description ..................................................................................................7

1.3 Safety Precautions ..........................................................................................................................7

1.4 Responsibility and Risk ...................................................................................................................8

1.5 Emergency ......................................................................................................................................9

1.6 Precautions for Transportation and Handling .................................................................................9

Chapter 2 Quick Start............................................................................................................................10

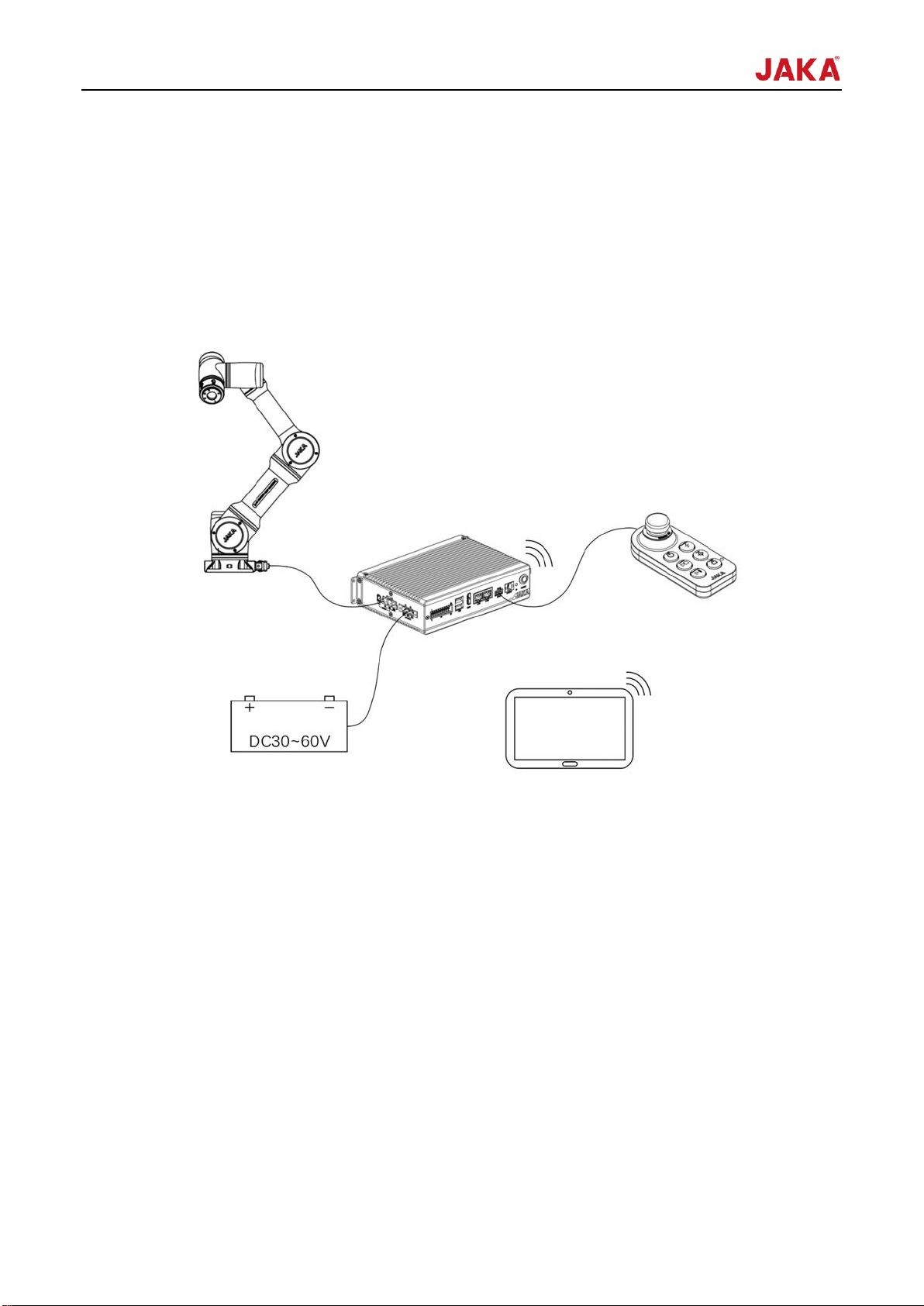

2.1 Typical Application Schematic Diagram........................................................................................10

2.2 Composite Robot Application........................................................................................................10

2.3 Operation Terminal........................................................................................................................11

2.4 Controller and Control Stick ..........................................................................................................11

Chapter 3 Mechanical Specification ....................................................................................................14

3.1 Outline Dimension.........................................................................................................................14

3.2 Specification..................................................................................................................................15

3.3 Installation .....................................................................................................................................15

3.2.1 Installation Method.................................................................................................................15

3.2.2 Installation Environment Requirements.................................................................................17

Chapter 4 Electrical Specification .......................................................................................................18

4.1 Introduction ...................................................................................................................................18

4.2 Absolute Limit Parameter..............................................................................................................18

4.3 Recommended Operating Conditions...........................................................................................18

4.4 Typical Power Consumption .........................................................................................................19

4.5 Computer Configuration................................................................................................................19

Chapter 5 Definition of Interface..........................................................................................................20

5.1 Front Panel Interface ....................................................................................................................20

5.1.1 Integrated Interface (I/O) .......................................................................................................20

5.1.2 Control stick Interface (STICK)..............................................................................................22

5.1.3 Emergency Stop Interface (E-STOP) ....................................................................................22

5.2 Side-panel Interface ......................................................................................................................23

5.2.1 Power Interface......................................................................................................................23

5.2.2 Robot Interface ......................................................................................................................24

Chapter 6 Detailed Introduction...........................................................................................................25

6.1 Overview .......................................................................................................................................25